8

• The core of the power line cable should be connected between the two gasket, ensure there is

no bur. Check and ensure there is no damage on the cable when put through the cable entry of the

terminal box, the cable should be xed by a blanking plate and bow washer to prevent moving.

• To t different voltage different connection mode (by changing its connection straps) should be

adopted (see the connection diagram on terminal box cover).

• Motor will rotate clockwise viewed from driving shaft end if the terminal U,V,W is connected

to power line phase sequence A, B, C. Otherwise the motor will rotate anti-clockwise. Provided the

reverse rotation is need, any two of the three U, V, W can be interchanged.

•Ensure the internal & external grounding bolts have been safely grounded.

•After checking all the connections, turn on power for no-load operation test for 30-40min, and

then put into with-load operation.

3. Maintenance

Warning!

1. Non-full phase operation is prohibited.

2. Repeated starting will cause overheat of motor, or even damage motor.(In

particular, start with the load directly).

3. Avoid overload. Overload will cause overheat, and overheating will shorten the

insulation life. As a result, it will reduce motor reliability.

3.1 Check and clean the motor periodically, make sure no dust cover on the motor. Do not inject

water to clean the motor.

3.2 Bearing temperature should not exceed 95 ℃(Thermometer method) during operation. The

bearing should be inspected every 2500h (about half a year) operation. The bearing grease should be

replaced immediately if the grease is found to be spoiled. It’s proper to ll 1/3~1/2 capacity of the

bearing chamber with lubrication grease. No.3 Lithium-base lubricating grease is recommended.

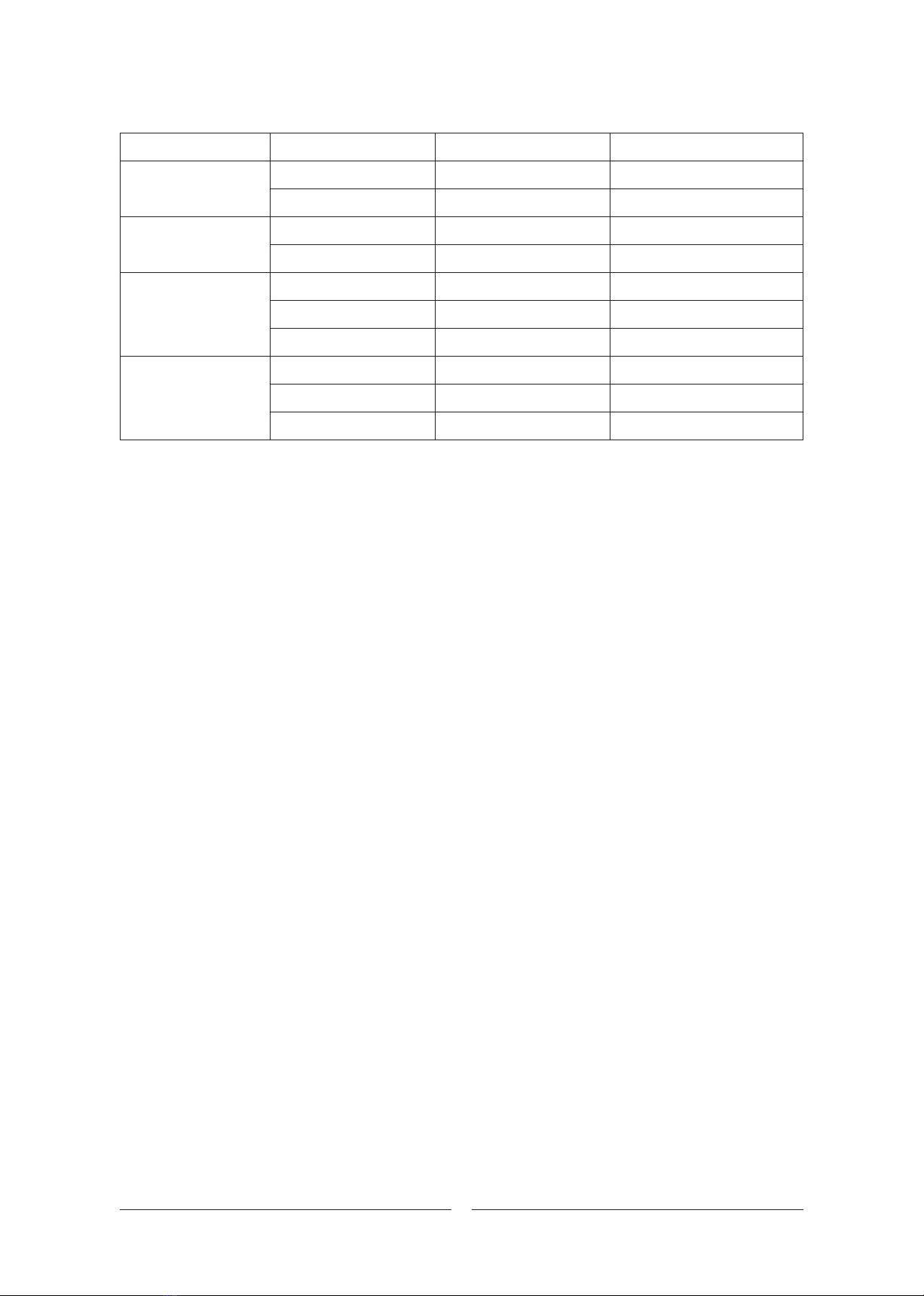

Bearing size is listed in the table below:

Frame size Pole Drive end Non-drive end

80 2~8P 6204-2RZ 6204-2RZ

90 2~8P 6205-2RZ 6205-2RZ

100 2~8P 6206-2RZ 6206-2RZ

112 2~8P 6206-2RZ 6206-2RZ

132 2~8P 6208-2RZ 6208-2RZ

160 2~8P 6309-2RZ 6309-2RZ

180 2~8P 6311-2RZ 6311-2RZ

200 2~8P 6312-2RZ 6312-2RZ

225 2~8P 6313-2RZ 6312-2RZ