Nordco HYDRAULIC BAAM User manual

Anchor Applicator Model BAAM HYDRAULIC

SEPT/2005 (49456900) Section H-1

CONTENTS

EMERGENCY PUMP USE

Electric Pump...................................................................................................................................H-3

Manual Pump...................................................................................................................................H-5

PRESSURE SETTINGS

General Settings and Locations of Manifolds...................................................................................H-5

Main System Pressure and Relief....................................................................................................H-6

Crossover Relief...............................................................................................................................H-7

Tool Flip Pressure Reducing Valve..................................................................................................H-8

Boxing Pressure Reducing Valve.....................................................................................................H-9

Bulk Loader Kickdown Relief Valve................................................................................................H-10

Guide Roller Pressure Reducing Valve..........................................................................................H-11

Feed Grip Pressure Reducing Valve..............................................................................................H-12

FACTORY SETTINGS

Workhead Lift.................................................................................................................................H-13

Workhead Rotate ...........................................................................................................................H-14

TROUBLESHOOTING .........................................................................................................................H-15

DRAWINGS

(In order of appearance)

FUNCTIONAL HYDRAULIC SCHEMATICS

S/N 690025 and Above............................................................................ 69A-55 (97690002 – Rev D)

HYDRAULIC Anchor Applicator Model BAAM

Section H-2 SEPT/2005 (49456900)

This Page left Intentionally Blank

Anchor Applicator Model BAAM HYDRAULIC

SEPT/2005 (49456900) Section H-3

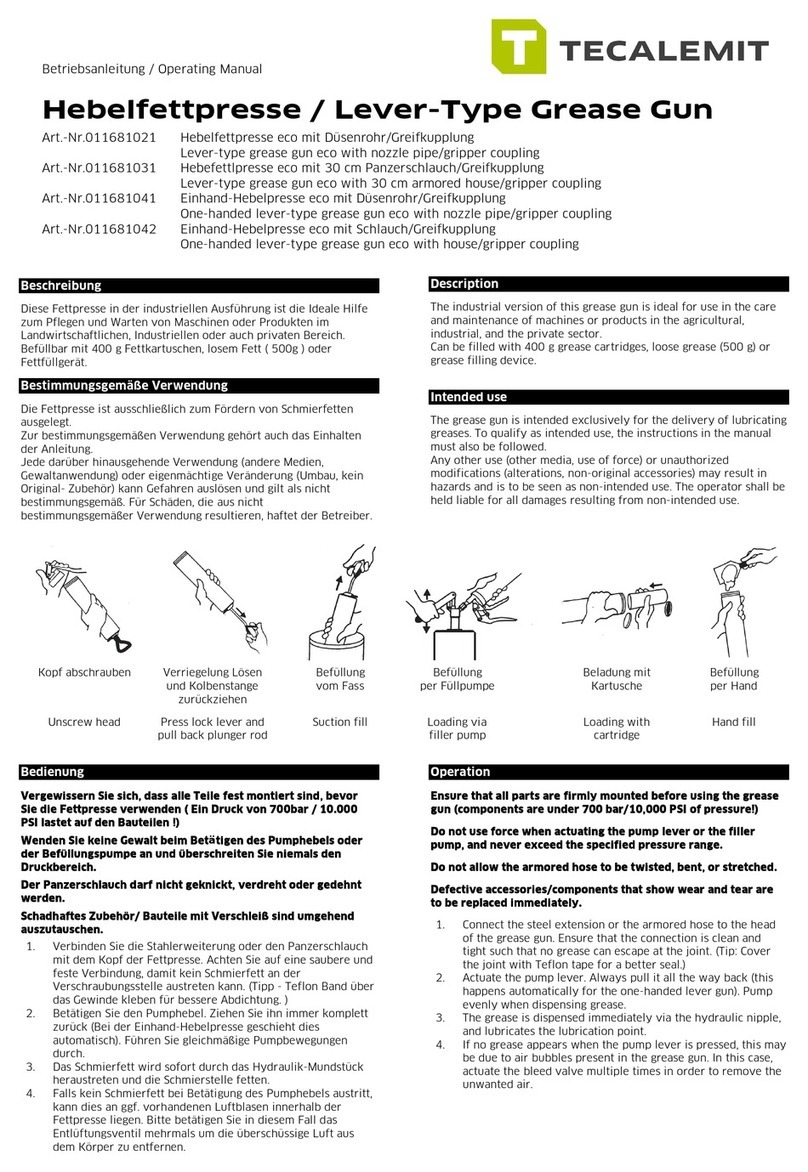

EMERGENCY PUMP USE – ELECTRIC

PUMP

For All Components Except Brakes:

1. Turn ignition switch to the OFF

position.

2. Attach one end of the hose (found in

the toolbox) to the port on the

emergency pump. Attach the other

end of the hose to the quick

disconnect at the brake valve.

3. Pressurize the hydraulic system by

turning on the emergency pump.

4. Raise all components to the point

where you can insert lockups. Insert

lockup pins.

5. Continue on to lock off brakes for

towing.

For the Hydraulic Brakes:

6. With the machine on level track,

chock ALL wheels to prevent

movement.

7. Close the ball valve at the brake

valve stack (see photo to right) and

lock in the CLOSED position.

(CLOSED is perpendicular to the

hose line, OPEN is parallel to the

hose line.)

8. Attach one end of the hose (found in

the toolbox) to the electric pump.

Attach the other end of the hose to

the quick disconnect at the brake

valve.

9. Turn on the emergency pump at the

control box until the hydraulic brake

cylinder has collapsed and has

released the brakes.

10. Install the lockpins (1) and hairpin

cotters (2) as shown in drawing to

right.

11. Turn off emergency pump, remove

hose and wheel chocks, and perform

towing as required.

12. Once you have towed to a site to

perform maintenance on the

hydraulic system, open the ball valve

(closed under step 7) and lock in the

OPEN position.

Tools And Equipment Required For These

Procedures:

¾-Inch Combination Wrench

Company Furnished Padlock

Pump Hose (Found In Toolbox)

Lockpins (Found In Toolbox)

HYDRAULIC Anchor Applicator Model BAAM

Section H-4 MAR/2005 (49454100)

EMERGENCY PUMP USE – MANUAL

PUMP

For All Components Except Brakes:

1. Turn ignition switch to the OFF

position.

2. Attach one end of the hose (found in

the toolbox) to hand pump and the

other end of the hose to the quick

disconnect at the brake lock valve.

3. Pressurize the hand pump by moving

the hand valve lever (lever with round

knob) on the pump toward the pump.

4. Continue pumping until all components

are raised to the point where you can

insert lockups. Insert lockup pins.

5. Continue on to lock off brakes for

towing.

For the Hydraulic Brakes:

8. With the machine on level track,

chock ALL wheels to prevent

movement.

9. Close the ball valve at the brake valve

stack (see photo to right) and lock in

the CLOSED position. (CLOSED is

perpendicular to the hose line, OPEN

is parallel to the hose line.)

10. Attach one end of the hose (found in

the toolbox) to the electric pump.

Attach the other end of the hose to

the quick disconnect at the brake

valve.

11. Turn on the emergency pump at the

control box.

12. Once the hydraulic brake cylinder has

collapsed and has released the

brakes, install the lockpins as shown.

13. Release hand pump pressure by

moving the hand valve lever on the

pump away from the pump, , remove

hose and wheel chocks, and perform

towing as required.

14. Once you have towed to a site to

perform maintenance on the hydraulic

system, open the ball valve (closed

under step 9) and lock in the OPEN

position.

Tools And Equipment Required For These

Procedures:

¾-Inch Combination Wrench

Company Furnished Padlock

Hand Pump Hose (Found In Toolbox)

Lockpins (Found In Toolbox)

Anchor Applicator Model BAAM HYDRAULIC

SEPT/2005 (49456900) Section H-5

HYDRAULIC PRESSURE SETTINGS

Main System Pressure: 2250 psi Main Relief Valve: 3000 psi

Crossover Relief: 2900 psi Guide Roller PRV: 600 psi

Tool Flip & Boxing PRV’s: 1000 psi Feed Grip PRV: 650 psi

Bulk Loader Kick Down Relief: 2000 psi

HYDRAULIC Anchor Applicator Model BAAM

Section H-6 MAR/2005 (49454100)

MAIN SYSTEM PRESSURE & RELIEF SETTINGS

Install the pressure gauge on the pressure tap for the main system pump

as shown in the picture at the left.

Turn relief valve adjustment screw to full clockwise (CW) position

(maximum pressure).

Turn pump compensator screw counterclockwise (CCW) (about 2-3

turns), but do not remove screw. Leave enough thread engagement to

prevent leakage. Start engine and turn on the Pump.

Turn pump compensator clockwise (CW)until 3000 psi has been

reached. Read this pressure at the main system gage on the propulsion

manifold.

Adjust relief counterclockwise (CCW) until pressure at gauge just begins

to drop. This is considered cracking pressure. Turn back 1/8 of a turn

and tighten locknut.

DO NOT ADJUST THE RELIEF VALVE FOR FULL FLOW PRESSURE!

Refer to next page to set Crossover Relief Valves.

Anchor Applicator Model BAAM HYDRAULIC

SEPT/2005 (49456900) Section H-7

CROSSOVER RELIEF SETTINGS

MAKE CERTAIN BRAKES ARE FULLY ENGAGED AND CAN HOLD

MACHINE STATIONARY BEFORE CONTINUING WITH THESE

ADJUSTMENTS. FAILURE TO DO SO MAY

CAUSE SEVERE BODILY HARM

With the pressure gauge on the pressure tap for the main system pump

still attached:

Turn both crossover relief valve adjustments screws to full clockwise

(CW) position (maximum pressure).

Back out compensator until system pressure reaches 2900 psi.

Manually override FWD relief valve.

Adjust valve counterclockwise (CCW) until pressure at gauge just begins

to drop. This is considered cracking pressure. Turn back 1/8 of a turn

and tighten locknut.

Manually override REV relief valve.

Adjust valve counterclockwise (CCW) until pressure at gauge just begins

to drop. This is considered cracking pressure. Turn back 1/8 of a turn

and tighten locknut.

Adjust pump compensator counterclockwise (CCW) to system operating

pressure (2500 psi).

HYDRAULIC Anchor Applicator Model BAAM

Section H-8 MAR/2005 (49454100)

TOOL FLIP PRESSURE REDUCING VALVE SETTINGS

Plug in gage at pressure port as shown in picture.

Turn on pump. Read pressure.

If pressure is higher than 1000 psi, loosen nut on spotting

valve adjusting screw and turn counterclockwise (CCW)

until pressure reads 1000 psi. Tighten nut at new

location.

If pressure is lower than 1000 psi, loosen nut on spotting

valve adjusting screw and turn clockwise (CW) until

pressure reads 1000 psi. Tighten nut at new location.

Anchor Applicator Model BAAM HYDRAULIC

SEPT/2005 (49456900) Section H-9

BOXING PRESSURE REDUCING VALVE SETTINGS

Plug in gage at pressure port as shown in picture.

Turn on pump. Read pressure.

If pressure is higher than 1000 psi, loosen nut on spotting

valve adjusting screw and turn counterclockwise (CCW)

until pressure reads 1000 psi. Tighten nut at new

location.

If pressure is lower than 1000 psi, loosen nut on spotting

valve adjusting screw and turn clockwise (CW) until

pressure reads 1000 psi. Tighten nut at new location.

HYDRAULIC Anchor Applicator Model BAAM

Section H-10 MAR/2005 (49454100)

BULK LOADER KICK-DOWN RELIEF VALVE SETTINGS

Plug in gage at pressure port as shown in picture.

Turn on pump. Read pressure.

If pressure is higher than 2000 psi, loosen nut on spotting

valve adjusting screw and turn counterclockwise (CCW)

until pressure reads 2000 psi. Tighten nut at new

location.

If pressure is lower than 2000 psi, loosen nut on spotting

valve adjusting screw and turn clockwise (CW) until

pressure reads 2000 psi. Tighten nut at new location.

Anchor Applicator Model BAAM HYDRAULIC

SEPT/2005 (49456900) Section H-11

GUIDE ROLLER PRESSURE REDUCING VALVE SETTING

Plug in gage as shown in picture.

Turn on pump. Read pressure.

If pressure is higher than 600 psi, loosen nut on spotting

valve adjusting screw and turn counterclockwise (CCW)

until pressure reads 600 psi. Tighten nut at new location.

If pressure is lower than 600 psi, loosen nut on spotting

valve adjusting screw and turn clockwise (CW) until

pressure reads 600 psi. Tighten nut at new location.

HYDRAULIC Anchor Applicator Model BAAM

Section H-12 MAR/2005 (49454100)

FEED GRIP PRESSURE REDUCING VALVE SETTING

Plug in gage in RH or LH port as shown in picture. (Attach

gage to valve stack being adjusted.)

Turn on pump. Read pressure.

If pressure is higher than 650 psi, loosen nut on spotting

valve adjusting screw and turn counterclockwise (CCW)

until pressure reads 650 psi. Tighten nut at new location.

If pressure is lower than 650 psi, loosen nut on spotting

valve adjusting screw and turn clockwise (CW) until

pressure reads 650 psi. Tighten nut at new location.

Repeat for other side.

Anchor Applicator Model BAAM HYDRAULIC

SEPT/2005 (49456900) Section H-13

RETURNING HYDRAULICS TO FACTORY SETTINGS

(To be used in the event that valves were incorrectly set)

VALVE HOW TO ADJUST

Workhead Lift

Counterbalance Valve With the WORKHEAD LIFT lock-up rocker switch unlocked, set the

counter-balance valve on WORKHEAD LIFT (bottom valve in

stack) by turning the adjusting screw CCW and stopping just before

the workhead starts to drift down (approximately 2-1/2 turns CCW

from closed). The Workhead is not to drift down when the machine

is shut down.

Workhead Lift

Flow Control Valve Remove the slow speed valve DIN connector and set WORKHEAD

LIFT flow control (2nd valve from bottom) such that the travel time to

fully retract the lift cylinder from its extended length is approximately

1 second (approximately 7 turns CCW from closed).

Workhead Lift

Slow Speed Valve Re-install the slow speed valve DIN connector and set the

WORKHEAD LIFT slow speed valve (3rd valve from the bottom)

such that the travel time to extend the lift cylinder 1” is

approximately 1 second (approximately ¾ turn from closed).

HYDRAULIC Anchor Applicator Model BAAM

Section H-14 MAR/2005 (49454100)

RETURNING HYDRAULICS TO FACTORY SETTINGS

(To be used in the event that valves were incorrectly set)

VALVE HOW TO ADJUST

Workhead Rotate

Counterbalance Valve With the WORKHEAD ROTATE lock-up rocker switch unlocked,

set the counter-balance valve on WORKHEAD ROTATE (bottom

valve in stack) by turning the adjusting screw CCW and stopping

just before the workhead starts to drift down (approximately 1-1/2

turns CCW from closed). The workhead is not to drift down when

the machine is shut down.

Workhead Rotate

Flow Control Valve Set WORKHEAD ROTATE flow control (2nd valve from bottom)

such that the travel time to fully retract the rotate cylinders is

approximately ½ second (approximately 7 turns CCW from closed).

Anchor Applicator Model BAAM HYDRAULIC

SEPT/2005 (49456900) Section H-15

TROUBLESHOOTING - GENERAL

Troubleshooting is a matter of quickly and logically isolating the cause of a problem and taking

corrective action. Operating experience, a thorough understanding of the information in this manual,

and accurate maintenance and operation records are the best troubleshooting tools an operator can

have.

This is intended to give you basic troubleshooting guidelines for the hydraulic systems on this machine.

Local conditions and operating methods may result in problems, causes and remedies not covered in

this guide. To use the guide most efficiently, locate a problem that matches the one being experience

and, in a step-by-step method, check the causes listed until the correct remedy is found and the

problem solved.

Always turn off machine when performing maintenance, making adjustments, or whenever

unintended movement of machine could occur; unless directed otherwise. Failure to comply

could result in personal injury and/or damage to the machine.

To avoid possible personal injury and/or engine damage from accidental engine startup, always

disconnect the battery before servicing this machine.

INSPECTION

Inspect the hydraulic system for clues to the malfunction. Check to see if the unit can be operated

without further damage. If not, shut down machine immediately. Always check these items before

starting the machine:

1. Check hydraulic oil level.

2. Look for loose or disconnected hoses. An oil spot below the machine is a good indication of a

loose hose or hydraulic component.

3. Make certain shut-off valve on suction strainer is OPEN. Opening valve can often correct what

appears to be a malfunction.

4. Inspect all vital hose connections, especially at main pump and the main pump hose

connection at the manifold.

Loosen fittings only when system is not pressurized. High pressure leaks can cause personal

injury.

5. Look for cover damage and/or indications of twisted, worn, crimped, brittle, cracked, or leaking

hoses. Hoses with their outer cover worn through or otherwise damages should be considered

unfit for further service.

HYDRAULIC Anchor Applicator Model BAAM

Section H-16 MAR/2005 (49454100)

While machine is running, and before working, inspect for leaks. If the machine has not been run for

some time, oil may thicken causing a variety of malfunctions. If this is true, make certain that the oil

tank has been properly drained, cleaned and refilled.

If your visual inspection does not indicate the possible malfunction, refer to the troubleshooting guide

that follows.

FLUID CONTAMINATION

Contamination comes in many forms. It may be air, water and cutting oils, rust, chips and grit. It is

usually easier to keep contaminants out of a system rather than remove them after they are in the

system.

Bulk handling and the re-use of oil containers almost guarantees you that "new" oil will be dirty. Make it

a practice to filter all "new" oil before adding it to your system. Make it another practice to change

filters on a regular basis before they become clogged.

LOCATING LEAK SOURCES

Petroleum oils are used in most hydraulic application to lubricate parts as well as transmit power. As

oil temperature increases, however, the lubricating film thins out. The result is rubbing parts supported

by the oil film move closer together; friction and wear increase; seal materials age more quickly,

become stiff and hard, and may readily permit leakage.

The first step in locating leaks is to eliminate the possibility that an over-filled reservoir or spill created

the "suspected" leak. The next step would be to clean the suspected area and watch. Leaks usually

occur in fittings, hoses, O-rings, and other seals.

Most leaks occur at fittings, but too often, finding the fitting that is leaking is difficult because the fluid

runs along the hose and drips off at some other point. Leaks in high pressure lines sometimes are

difficult to pin-point because the fluid comes out as a mist.

Once you find the location of a leak, the specific cause has to tbe determined before it can be

corrected. A scratch in a fitting seat or a cut in a seal lip that is big enough to leak excessively can still

be too small to find with the naked eye. The use of a magnifying glass would assist you.

HOSE LIFE

Hose leakage or failure many times occurs where the end fitting grips the hose. Check the system for

pressure spikes or surge. If bulges or bubbles occur on a flexible hose, a leak is taking place within the

layers. The hose should be replaced.

High oil temperatures (over 200 degrees Fahrenheit, 93 degrees Celcius) quickly harden or stiffen a

rubber hose. When pressure pulses flex a hardened hose, it fails by cracking. Every increase of 25°F

(14°C) cuts hose life in half. Use a replacement hose rated for actual fluid temperatures. Keep a log of

hose use so replacement can be made before failure occurs.

If a hose is installed with a twist in it, high operating pressures tend to force it straight. This can loosen

the fitting or even burst the hose at the point of the strain.

Anchor Applicator Model BAAM HYDRAULIC

SEPT/2005 (49456900) Section H-17

HYDRAULIC SYSTEM

TROUBLESHOOTING GUIDE

PROBLEM

POSSIBLE CAUSE

SOLUTION

Hydraulic pump does

not develop pressure

No hydraulic oil in tank (NOTE: if pump is

run without oil in tank, pump damage will

occur.)

Shut-off valve closed. (NOTE: if pump is

run with valve closed, pump damage will

occur.)

Main relief valve bypassing. (NOTE: oil

blowing past any relief valve can cause

oil to overheat.)

Main pump compensator setting is too

low.

Pump is defective.

Destroke valve stuck.

Pump switch turned off.

Check oil level. Refill tank.

Open valve completely.

Increase pressure setting on

relief valve. (See Pressure

checks)

Adjust compensator setting.

(See Pressure Checks)

Refer to pump manual or

replace pump.

Repair or replace.

Turn on.

Hydraulic pump

excessively noisy

Cold oil.

Low oil level.

Oil viscosity too high (oil too thick)

System relief valve set too low.

Intake hose to pump restricted.

Defective pump.

Allow unit to warm up.

Check and add oil.

Drain and add correct oil as

specified under

"RECOMMENDED

LUBRICANTS".

Increase pressure setting on

relief valve (see Pressure

Checks)

Inspect and repair.

See pump manual, repair or

replace pump.

Machine will not propel

Main pump not developing pressure.

Propulsion relief setting too low.

Nippers not retracted or nipper work up

switch not actuated.

See above.

Increase relief setting. (See

Pressure checks)

Check nipper up switch, repair

or replace.

Hydraulic Oil

Overheats

Oil viscosity too high (oil too thick)

System relief valve set too low.

Drain and add correct oil as

specified under

"RECOMMENDED

LUBRICANTS".

Increase pressure setting on

relief valve

(

see Pressure

HYDRAULIC Anchor Applicator Model BAAM

Section H-18 MAR/2005 (49454100)

PROBLEM

POSSIBLE CAUSE

SOLUTION

Oil lines damaged causing excessive

internal restriction

Travel relief set too low

Checks)

Inspect and repair.

Check and reset

Hydraulic Oil Foams

Water in oil

Using wrong oil

Low hydraulic level

Damaged hydraulic oil lines

Air leak in suction line to hydraulic pump

or pump shaft seal leaking

Inspect oil for water. Drain and

add correct oil as specified

under "RECOMMENDED

LUBRICANTS".

Drain and add correct oil as

specified under

"RECOMMENDED

LUBRICANTS".

Fill

Inspect, repair or replace.

Inspect, repair or replace.

Hydraulic Oil Filter

Restriction Indicator

Light stays on all the

time (optional

equipment)

Restricted hydraulic oil filter.

Hydraulic oil filter restriction switch

Replace filter.

Replace switch.

Table of contents

Other Nordco Tools manuals

Popular Tools manuals by other brands

SKF

SKF TMBS 100E Instructions for use

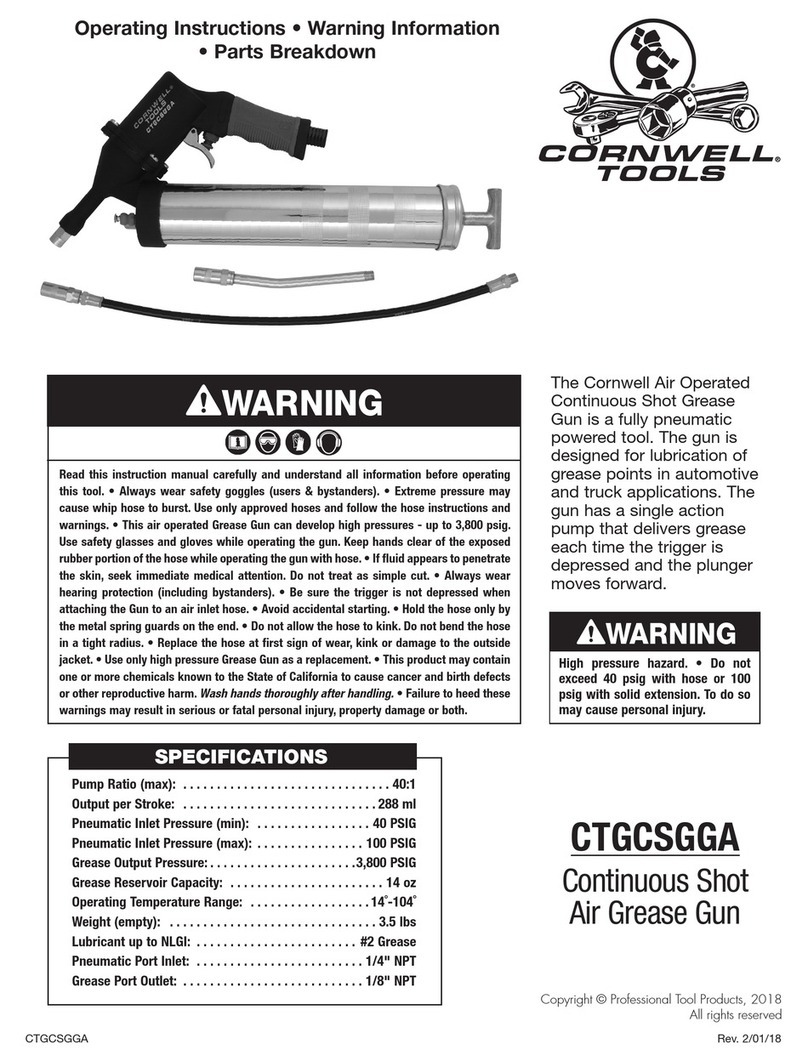

Cornwell Tools

Cornwell Tools CTGCSGGA Operating instructions, warning information, parts breakdown

Rosenberger

Rosenberger 60W107-CX5 Instruction

NovoPress

NovoPress ACO203 operating manual

HAUL MASTER

HAUL MASTER 30131 Owner's manual & safety instructions

Simpson

Simpson PTP-27ASMAGR Operator's manual