NORDOCK TRUCK-LOCK Series User manual

i

TRUCK-LOCKTM SERIES

ATL-450

Low Profile Automatic

Vehicle Restraint

Owner’s Manual

This manual applies to ATL-450 series restraints manufactured on or

after 2013/06/01 with serial numbers 25005 and greater.

P/N: 59-0007-P

NORDOCK INC.

Website: nordockinc.com ~ Email: sales@nordockinc.com ~ Toll free: 866-885-4276

Nordock Inc. reserves the right to make changes to specifications without notice or obligation. Nordock products may be covered by

various U.S. and foreign patents or pending application.

1

Contents

Contents ............................................................................................... 1

Preface ................................................................................................. 2

Problems, Errors and Omissions.................................................................................2

Restraint Identification.................................................................................................2

Copyright.....................................................................................................................2

Warranty............................................................................................... 3

Safety Practices ..................................................................................... 4

Labels..........................................................................................................................5

Installation ............................................................................................ 6

Mounting Requirements...............................................................................................7

Tools Required ............................................................................................................7

Installation with Pit Type Levelers................................................................................8

Installation of Optional Driveway Mounting Plate.......................................................14

Operating Procedure ............................................................................ 16

To Hitch Truck: ..........................................................................................................16

To Release Truck: .....................................................................................................17

Troubleshooting................................................................................... 18

Restraint Operating Function Check..........................................................................18

Maintenance Schedule.......................................................................... 21

Acceptable Lubricants and Oils .................................................................................22

Hydraulic............................................................................................................................................. 22

Grease ................................................................................................................................................ 22

Parts Replacement............................................................................... 23

Removing Hook From Track......................................................................................23

Re-installing Hook Into Track.....................................................................................23

Wiring Diagram.................................................................................... 24

Parts List............................................................................................. 25

Nordock Inc. Owner’s Manual – ATL-450 TRUCK-LOCK 59-0007-P

- 2 -

Preface

PLEASE READ AND UNDERSTAND THIS MANUAL COMPLETELY

This manual gives detailed information and instruction on how to operate and

maintain your equipment correctly. Failure to do so could result in personal injury,

and/or equipment damage. Please consider this manual a permanent part of the unit

and keep it near the restraint for reference whenever needed.

If you have any questions about this manual, the restraint, its components, or our

products and services, please call us at 1-866-885-4276 and we will be happy to assist

you. With proper care and maintenance, this restraint is designed to work effectively

and efficiently for many years to come.

Problems, Errors and Omissions

This manual has been prepared with the utmost care and attention to detail to

provide accurate parts and service information should the need arise. Nordock

Incorporated believes this manual will provide the operators of this restraint all the

necessary information required to operate and maintain it for many years. If you believe

there is an error, if you have a problem following the guidelines, or if there is information

that you feel is missing from this manual, please contact us at the above number so that

we may resolve the issue immediately.

Restraint Identification

It is very important that in order to obtain the best possible service from Nordock Inc.,

please provide the model and serial number of the restraint whenever you contact us.

Below is the same serial number decal that will be found on the left hand hook side

plate (standing outside facing the restraint). Please record the information from the

decal on the restraint in the area below. This will greatly reduce the possibility of

improper parts being shipped to you.

Model:

Capacity:

Copyright

This manual is copyright to Nordock Incorporated. All information, text, drawings, and

technical data contained herein are for reference only. No part of this manual may be

copied, altered, or stored on electronic media, and cannot be revealed to others for the

purpose of competition.

Nordock Inc. Owner’s Manual – ATL-450 TRUCK-LOCK 59-0007-P

- 3 -

1. Replace the product or the defecteof without charge to the purchaser; or,

2. Alter or repair the product on site or elsewhere, as Nordock Inc. may deem advisable,

without charge to the purchaser.

In addition to the above, the structural components are covered by an extended Five-Year

period. In the event a structural component proves defective in years two through five, Nordock

will provide a replacement part at no l be responsible for the cost to ship and install the

replacement part during this extended period.

The warranty stated herein is that offered by Nordock Inc. and expressly disclaims all implied

warranties including those of merchantability and fitness. This warranty does not cover any

failure caused by improper installation, misapplication, overloading, abuse, negligence, or

failure to do prescribed maintenance and protect the equipment from vehicle impact. Nordock

Inc. or its representative assume no responsibility or liability for any incidental or consequential

damages of any kind including loss of use of any equipment, damage or failure resulting from

the use of unauthorized replacement parts or equipment modification, or damages resulting

from the misuse of the equipment.

Nordock Inc. warranties extend only to the product itself. Nordock Inc. disclaims all liability of

any kind arising out of the workmanship, methods and materials used by the installer or

premature product wear, product failure, property damage or bodily injury arising from improper

installation.

These warranties as stated herein are the exclusive remedies for all claims.

Warranty

Nordock Inc. expressly warrants that the Model ATL-450 Vehicle Restraint shall remain free

of defects in material and workmanship under normal use for One-Year from the date of

delivery to the purchaser. The purchaser must maintain & operate the product in accordance

with proper procedures. In the event the product proves defective in material or workmanship,

Nordock Inc. will at its option within the first year either:

Nordock Inc. Owner’s Manual – ATL-450 TRUCK-LOCK 59-0007-P

- 4 -

Safety Practices

The operators of this unit must read these safety practices before installing, operating or

servicing the TRUCK-LOCKTM. Failure to follow these safety practices may result in

bodily injury, property damage or death.

READ AND FOLLOW THE OPERATING INSTRUCTIONS CONTAINED IN THIS

MANUAL BEFORE OPERATING THE TRUCK-LOCKTM. If you do not understand the

instructions, contact your supervisor for explanation and instruction on the safe

operation of this unit.

Improper installation of the TRUCK-LOCKTM could result in serious injury or death to

dock workers or other users of the restraint.

The following guidelines are to be used in conjunction with all laws, governances and

codes in effect where the TRUCK-LOCKTM is installed.

1. Use by untrained people can cause property damage, serious injury and/or

death. Your supervisor should instruct you on the safe and proper way to use

the TRUCK-LOCK. Read and follow the complete OPERATIING procedure on

page 15 before use.

2. DO NOT USE THE TRUCK-LOCK IF IT IS NOT WORKING RIGHT. Tell your

supervisor it needs repair.

3. Be certain all people in the driveway stand clear when the TRUCK-LOCK is

being operated.

4. Do not stand in the driveway between the dock and a backing truck.

5. Keep all body parts clear of restraint guide tracks and moving parts at all times.

6. Do not install the TRUCK-LOCK anchor bolts into concrete of questionable

integrity.

7. Do not load or unload any truck until you make certain that the TRUCK-LOCK

has securely engaged the truck’s ICC bar and the brakes are set. If the TRUCK-

LOCK does not hitch the truck’s ICC bar for any reason, BE CERTAIN TO

CHOCK THE TRUCK WHEELS BEFORE PROCEEDING WITH LOADING OR

UNLOADING.

8. Do not use the TRUCK-LOCK as a step.

9. All electrical troubleshooting and repair must be done by a qualified technician

and must meet all applicable codes. Before doing any electrical work, make

certain the power is disconnected and properly tagged or locked out.

!

WARNING

Nordock Inc. Owner’s Manual – ATL-450 TRUCK-LOCK 59-0007-P

- 5 -

10.If the TRUCK-LOCK fails to operate using the procedures contained in this

manual, do not use the TRUCK-LOCK. Contact Nordock Inc. or an authorized

service representative for service.

11.Whenever any maintenance or repair is to be performed on the restraint,

barricade the area around the dock floor and driveway and place clear signage

on the perimeter that the dock and restraint are not to be operated.

12.If you have any questions, contact your supervisor or your local Nordock

Incorporated representative.

Labels

The labels and decals on the TRUCK-LOCK must be kept in clean, legible condition at

all times. The diagram below shows the decals and their placement on the restraint.

Please check their condition on a daily basis, and replace them immediately if they

become unreadable.

Capacity:

Model:

Nordock Inc. Owner’s Manual – ATL-450 TRUCK-LOCK 59-0007-P

- 6 -

Installation

IMPROPER INSTALLATION OF THIS TRUCK-LOCK COULD RESULT IN SERIOUS

INJURY OR DEATH TO DOCK WORKERS OR OTHER RESTRAINT USERS

A typical TRUCK-LOCK restraint installation is shown below:

The following installation materials are included with the restraint:

13 pcs. 5/8” x 5” concrete wedge anchors

1 pc horizontal shear plate

1 pc pre-wired weatherproof junction box

All other materials required are to be provided by the installer.

!

WARNING

Nordock Inc. Owner’s Manual – ATL-450 TRUCK-LOCK 59-0007-P

- 7 -

Mounting Requirements

1. The dock face on which the TRUCK-LOCK is to be mounted must be flat and

vertically plumb for correct operation. If the dock face is not flat, it may be

necessary to use shims behind the backplate of the restraint or to modify the

dock face to provide a flat mounting surface. If shimming is required, it is

necessary to place shims at all of the anchor hole locations where the backplate

does not contact the wall. This will prevent distortion of the backplate when the

anchors are tightened.

2. The TRUCK-LOCK vehicle restraint requires a 4” bumper projection from the

front of the bumper to the rear of the back plate of the restraint. Less than 4” of

projection can allow trailer ICC bars to damage the restraint.

3. Some types of dock levelers that use lip saddles may interfere with the TRUCK-

LOCK vehicle restraint. Depending upon the lip length, dock height, bumper

projection, use of standoffs etc., modification to the restraint and/or dock leveler

may be required. Consult the factory for specific applications.

4. The standard concrete anchors (5/8” x 5” wedge style) provided with this restraint

may only be used on docks constructed of solid concrete. Docks constructed of

other materials require special mounting considerations. Refer to the end of this

section for optional driveway plate mounting. Contact your local Nordock

distributor for application specific information.

5. A 3/8” gap is required between the dock leveler front angle and the pit floor for

installation of the horizontal shear plate.

6. Do not install the TRUCK-LOCK anchor bolts into concrete of questionable

integrity.

7. If the driveway beneath the TRUCK-LOCK is affected by frost, additional

clearance between the TRUCK-LOCK and the driveway may be required to

prevent damage due to heaving.

Tools Required

-Welder

-Hammer drill with 5/8” diameter masonry bit

-15/16” Wrench

-General hand tools

-Touch up paint (Silver)

-Torque wrench (100 ft-lbs. min.)

-5/8” Wrench

Nordock Inc. Owner’s Manual – ATL-450 TRUCK-LOCK 59-0007-P

- 8 -

Installation with Pit Type Levelers

1. Place barricades around pit on dock floor and driveway while installing the

TRUCK-LOCK.

2. The horizontal shear plate MUST BE INSTALLED to achieve the full rated

restraining capacity of the TRUCK-LOCK.

The installation method for the horizontal shear plate will depend upon the height

of the front curb steel off grade and if there is a sufficient gap under the dock

leveler front angle.

The diagrams below illustrate acceptable shear plate mounting methods for the

most common types of restraint installations.

Please consult the factory if your particular site conditions prohibit installation of

the shear plate using the above methods.

Nordock Inc. Owner’s Manual – ATL-450 TRUCK-LOCK 59-0007-P

- 9 -

ALWAYS USE DOCK LEVELER MAINTENANCE SUPPORT WHEN WORKING

UNDER A DOCK LEVELER RAMP OR LIP

3. If there is sufficient clearance, insert the horizontal shear plate into the gap

between the dock leveler front angle and the pit floor.

Otherwise use one of the methods illustrated on the previous page.

4. Place the bottom of the TRUCK-LOCK ½” above the driveway and centre it with

the dock leveler pit.

a. If the horizontal shear plate is above the top of the backplate, weld the full

width of the shear plate to the dock leveler front angle. If there is no dock

leveler front angle (clean frame design), weld the full width of the shear

plate to the front pit curb angle.

b. If the horizontal shear plate is level

with or below the top of the backplate,

tack the shear plate to the backplate at

both ends. Pull the restraint and shear

plate away from the dock and weld the

full width of the plate on the topside

using a ¼” fillet. Refer to adjacent

diagram.

Paint welded areas to prevent rust.

5. Slide the TRUCK-LOCK and shear plate

back into position.

6. Before anchoring the TRUCK-LOCK, operate

the dock leveler through its full range of motion.

a. Check that the TRUCK-LOCK does not interfere with the below dock

operation and that the dock leveler lip does not come to rest on the

TRUCK-LOCK in such a way that it supports the weight of the dock

leveler.

b. In the full below dock position, check that the pendant dock leveler lip

does not project beyond the face of the bumpers when it is resting on the

top of the restraint.

!

WARNING

Nordock Inc. Owner’s Manual – ATL-450 TRUCK-LOCK 59-0007-P

- 10 -

Improper installation that allows the pendant dock leveler lip to support the weight of

the dock leveler could result in serious injury or death. It is sometimes necessary to

install lip deflector plates to prevent the possibility of the pendant lip storing on top of

or behind the restraint backplate.

An optional bolt-on lip deflector plate is available for use with this restraint. It is

shown in the diagram below. If the optional deflector is insufficient to prevent the

dock leveler lip from resting on top of or in behind the restraint, the installer must

provide additional steel.

If the optional deflector plate interferes with the storing of the dock leveler lip, it may

be removed.

7. Anchor the TRUCK-LOCK backplate to the dock face using the wedge anchors

provided. The anchor bolts must be torqued to 90 ft-lbf to achieve maximum

holding strength.

Anchors must be installed in a minimum of six (6) back plate-mounting holes.

The anchors should be installed as the holes are drilled to prevent the TRUCK-

LOCK from shifting.

8. Anchor the shear plate to the pit floor using the concrete anchors provided. The

anchor bolts must be torqued to 90 ft-lbf to achieve maximum holding strength.

NOTE

!

WARNING

Nordock Inc. Owner’s Manual – ATL-450 TRUCK-LOCK 59-0007-P

- 11 -

Before doing any electrical and hydraulic work, the power must be disconnected and

properly locked/tagged off. Failure to do so could result in death or serious injury.

All electrical and hydraulic work must meet all applicable codes and be carried out

by a qualified technician.

The control voltage for this restraint is 24 VDC. All motor power wires or other high

voltage wires should be run in a separate conduit.

9. Mount the control box inside the building, to the left of the doorway, 4 ft. above

the floor. Refer to diagram below.

10.The outside signal light is to be placed approximately 9 ft above the driveway on

the driver’s side of the door opening as shown in the diagram on the next page.

Drill a hole through the wall at the centre of the signal light mounting position.

11.Run a length of 16/3 electrical cable (not supplied) from the control box location

through the wall. Make connections in panel and signal light assembly as

indicated in the wiring diagram located at the back of this manual.

!

WARNING

NOTE

Nordock Inc. Owner’s Manual – ATL-450 TRUCK-LOCK 59-0007-P

- 12 -

12.Fasten the signal light housing to the wall.

13.Mount the “Move On Green Only” sign provided to the exterior wall under the

signal light as shown in the diagram above.

14.Mount the supplied electrical junction box to the exterior wall adjacent to the

restraint in the location shown in the diagram above.

15.Run a length of 18/2 electrical cable (not supplied) from the control box to the

exterior junction box. Make connections inside the control box and junction box

as indicated in the wiring diagram located at the back of this manual.

16.If this installation includes an optional dock leveller “stored” limit switch, wire in

the normally closed contact. This will prevent the restraint from being released

until the dock leveler is stored.

17. Bring 110/1/60 power to panel and wire according to the diagram located in the

control panel. DO NOT APPLY POWER AT THIS TIME. Running the pump

without oil can cause permanent damage.

18. Cap both ends of the 16’ length of ¼” hydraulic hose (supplied) with the restraint.

CAUTION

MOVE ON

GREEN

ONLY

Nordock Inc. Owner’s Manual – ATL-450 TRUCK-LOCK 59-0007-P

- 13 -

19.Route the hose through conduit from the control box to the bulkhead hose

connection on the restraint back plate.

20.Clip the hose to the wall as necessary to prevent any tension on the hose ends.

21.Connect one end of the hose to the control box port.

22.Connect the other end of the hose to the bulkhead fitting on the backplate hose-

mounting bracket.

23.Tighten all connections.

24.Remove the filler cap from the hydraulic pump reservoir.

25.Using the supplied hydraulic oil, fill the reservoir to the top. Leave the filler cap

off, as oil will need to be added while the pump is running.

26.Apply power to the control panel.

27.The outside light should be flashing green and the inside light solid red. If the

lights are not on or not as described, verify power and all field wiring connections.

28.Press and release the “LOCK” button. The pump will turn on and the outside

light will change to flashing red. If the pump does not turn on, verify that the

restraint sensor bar is not deflected. If the sensor bar is not deflected, then the

field wiring between the restraint sensor and the control box needs to be verified.

29.After the pump runs for several seconds, the hook will slowly start to rise. The

motion will be “jerky” at first due to the air in the line. This is normal.

30.As the hook raises and the accumulator charges, the oil level in the reservoir will

drop significantly. Add oil as the motor is running to keep the reservoir

approximately 1/2 full.

31.The pump will shut off automatically when the pressure reaches a preset value.

32.Turn the “RESTRAINT BYPASS” switch to OFF. The inside light will change to

solid red and the exterior light will flash green. If equipped with the optional

alarm, turn the switch to OFF when the alarm sounds.

33.Check for oil leaks at all hose connections.

34.Press the “RELEASE” button to store the hook.

35.Add hydraulic oil as necessary to bring the fluid level up to the “MAX” line on the

side of the reservoir.

36. Replace filler cap on hydraulic oil reservoir.

37. Operate the TRUCK-LOCK control box “LOCK” and “RELEASE” pushbuttons

several times to release any remaining air that is trapped in the system.

Nordock Inc. Owner’s Manual – ATL-450 TRUCK-LOCK 59-0007-P

- 14 -

38.Verify that the hook raises and lowers smoothly.

39.Verify correct operation as follows:

a. One light must be on, both interior and exterior at all times.

b. With the restraint in the stored position, the exterior light will flash GREEN

and the interior light will turn RED.

40.If the lights do not operate as described, there is a field-wiring problem. Turn off

the power and check the wiring per the Wiring Diagram at the back of this

manual. Rewire as required.

41.Instruct the dock workers how to correctly use the TRUCK-LOCK. The Operating

Procedure can be found in the next section.

Installation of Optional Driveway Mounting Plate

When the optional driveway mounting plate is used, the driveway material must be

concrete. For driveway materials other than concrete, a stepped concrete pad must be

poured as shown next page. Allow concrete to properly cure before installing restraint.

Place plate on driveway or concrete pad.

Place bottom of TRUCK-LOCK on the driveway plate. Keep both the TRUCK-LOCK

and driveway plate centered with the dockleveler pit.

Make sure the horizontal shear plate is welded to the restraint back plate as previously

noted in Installation Instruction 4a and b.

Weld the bottom of the TRUCK-LOCK back plate to the driveway plate, as shown on

next page. Paint welded areas to prevent rust.

Nordock Inc. Owner’s Manual – ATL-450 TRUCK-LOCK 59-0007-P

- 15 -

Nordock Inc. Owner’s Manual – ATL-450 TRUCK-LOCK 59-0007-P

- 16 -

Operating Procedure

Before operating or maintaining this truck restraint, read and follow the safety practices

contained in this manual. Failure to follow the guidelines in this manual and those in

effect in the workplace can result in serious bodily harm and equipment damage.

Do not load or unload any truck unless you make certain the TRUCK-LOCK has

securely engaged the truck’s ICC bar and that the truck brakes are set. If the TRUCK-

LOCK does not engage the truck’s ICC bar for whatever reason, THE TRUCK’S

WHEELS MUST BE CHOCKED BEFORE LOADING OR UNLOADING CAN BEGIN.

Failure to store the TRUCK-LOCK when not in use could result in damage to the

TRUCK-LOCK and incoming trucks.

To Hitch Truck:

(Initial conditions: –hook stored –outside light

flashing green –inside light red)

1. Press and release the “LOCK” button. The

hook will raise to engage the truck’s ICC

bar.

2. The outside traffic light will change to

flashing red. If the sensor bar is deflected

by the truck’s ICC bar as the hook rises, the

inside light will change to GREEN.

VISUALLY CHECK ICC bar engagement.

3. If the sensor bar is not deflected, the inside

light will remain RED. If equipped, the

alarm will sound.

4. Secure the trailer by chocking the wheels on BOTH sides.

5. Silence the alarm and change the inside light to GREEN by turning the

RESTRAINT BYPASS” selector to the “ON” position

6. The dock leveller can now be used to load/unload the truck.

!

WARNING

Nordock Inc. Owner’s Manual – ATL-450 TRUCK-LOCK 59-0007-P

- 17 -

To Release Truck:

1. Ensure the dock leveler is stored.

2. The “RESTRAINT BYPASS” selector must be turned to the “OFF” position before

the hook can be released.

3. Press the “RELEASE” button. The hook

will disengage and begin to lower to its

stored position.

4. The interior light will switch to a solid red.

5. Once the hook has lowered sufficiently

that the sensor bar is no longer

depressed, the outside light will change to

a flashing GREEN.

6. VISUALLY CHECK that the hook is in the

fully lowered position.

7. The truck may now pull out.

Nordock Inc. Owner’s Manual – ATL-450 TRUCK-LOCK 59-0007-P

- 18 -

Troubleshooting

Restraint Operating Function Check

Initial Conditions:

-“RESTRAINT BYPASS” in the OFF position.

-Hook stored –Inside solid red light –Outside light flashing green.

Press the LOCK pushbutton:

-The inside red light will remain on and the hook will raise.

-The outside light will change to flashing red.

-The cylinder will extend fully and the pump will shut off at 1000 psi.

-If the sensor bar is deflected before the pump shuts off, the inside light will

change to a solid green.

-If the sensor bar is not deflected, the inside light will remain red. If

equipped with the optional alarm, alarm will sound.

Turn the “RESTRAINT BYPASS” selector switch to the “ON” position:

-The hook will remain in the raised position with the inside light showing

solid green.

-If equipped with the optional alarm, the alarm will silence.

Press the RELEASE pushbutton:

NOTE: The “RESTRAINT BYPASS” selector must be in the “OFF” position

before the hook can be released.

-The inside light will turn red.

-The hook will lower to the stored position.

-The outside light will change to green, once the hook clears the ICC bar.

NOTE:

-Visually check to make sure the hook has fully lowered before instructing

truck driver to leave.

Nordock Inc. Owner’s Manual – ATL-450 TRUCK-LOCK 59-0007-P

- 19 -

Troubleshooting

PROBLEM

CAUSE

CORRECTIVE ACTION

No interior or exterior signal

lights.

1.No power to panel.

Check that power is coming

into control panel.

2 Control panel fuse blown.

Check fuse and replace as

necessary.

Interior light stays solid red

even when hook sensor bar

is deflected.

Control panel not “seeing”

change of state in sensor

bar switch.

1. Manually deflect sensor bar

and verify that trigger plate

passes within 1/4” of round

sensing zone.

2. Check for missing or

damaged sensor bar made

switch.

3. Check continuity of sensor

bar made switch wiring to

control panel.

4. If wiring checks out OK,

place a piece of steel

against switch sensing

face. If lights do not

change, replace switch.

This manual suits for next models

1

Table of contents

Popular Automobile Accessories manuals by other brands

TrailFX

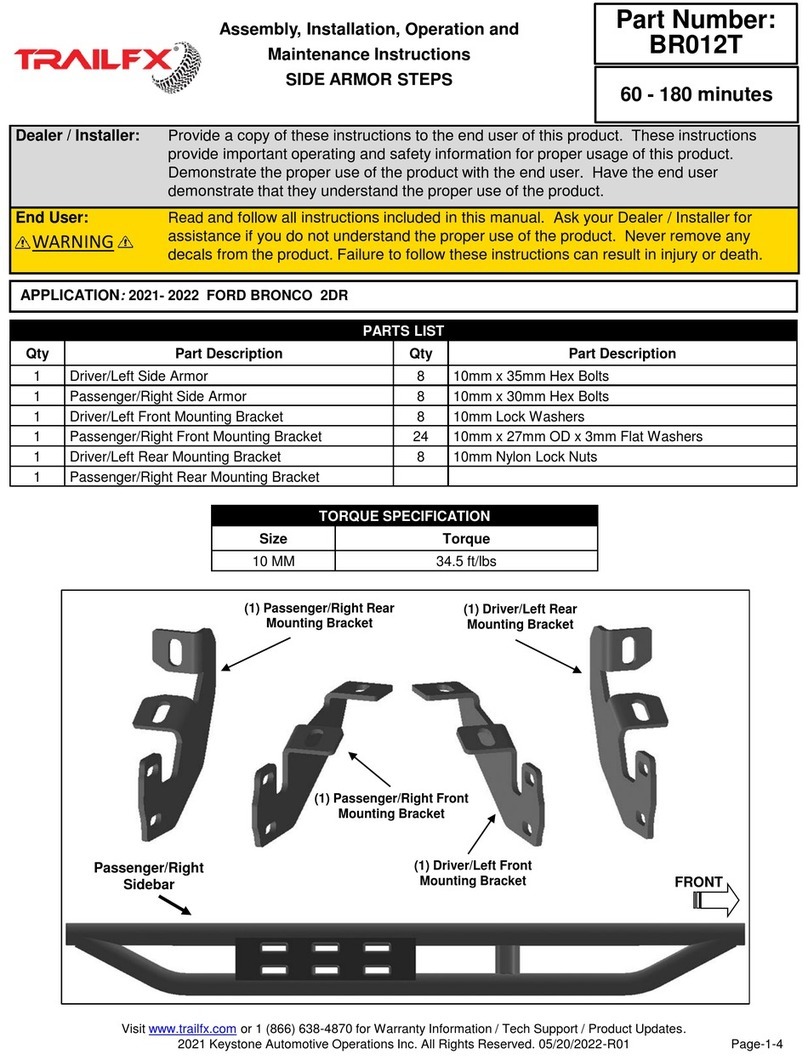

TrailFX BR012T Assembly, Installation, Operation and Maintenance Instructions

Osram

Osram LEDHL102 - CM manual

Fab Fours

Fab Fours A4160 installation instructions

Westin

Westin 46-24025 installation instructions

Whispbar

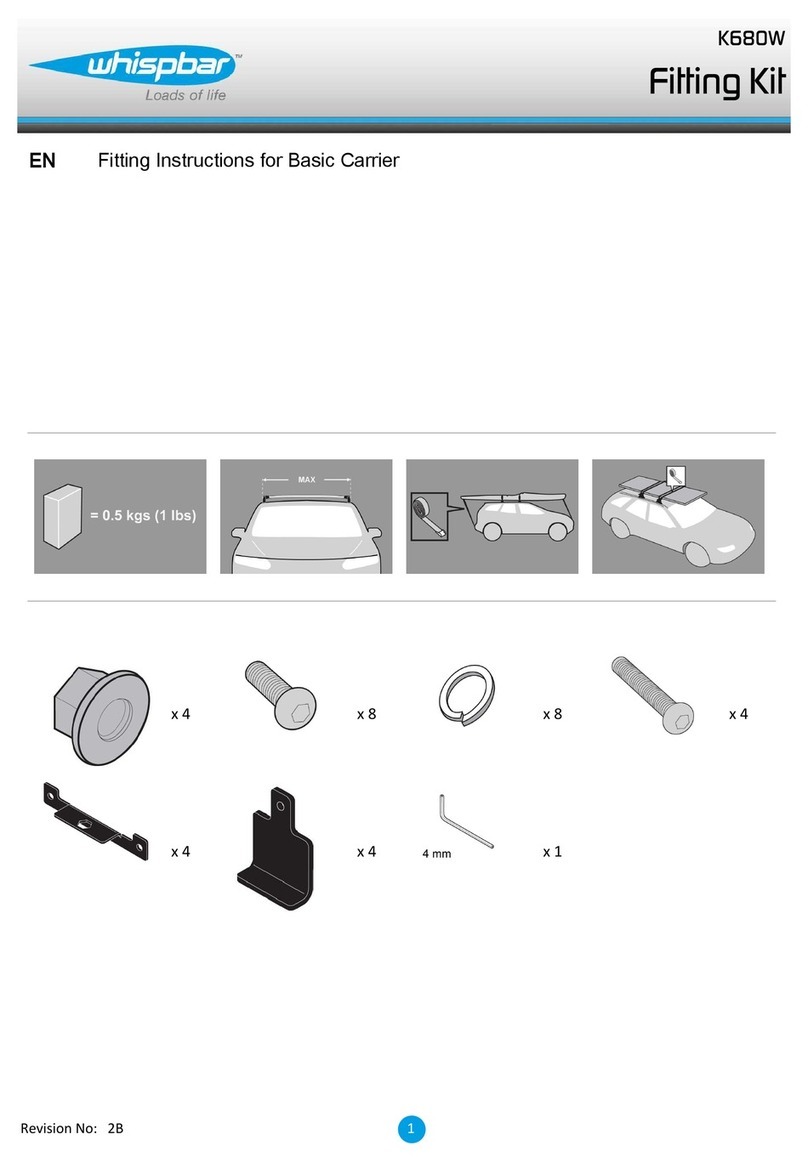

Whispbar K680W Fitting instructions

SportRack

SportRack SR2902LR installation instructions