Nordson ASYMTEK TCM-2200 User manual

Operation Manual, Troubleshooting and

Maintenance Guide for Oven Models

TCM-2200, TCM-3300 & TCM-4600

P/N 7222937

Revision: A

NOTICE

This is a Nordson ASYMTEK publication, which is protected by copyright. Original copyright date

2004. No part of this document may be photocopied, reproduced, or translated to another

language without the prior written consent of Nordson ASYMTEK. The information contained in

this publication is subject to change without notice.

Manuals on the Internet

For the convenience of Nordson ASYMTEK customers and field service representatives, copies

of Nordson ASYMTEK manuals can be downloaded from:

Contact Us

http://www.nordsonasymtek.com

Nordson ASYMTEK welcomes requests for information, comments, and inquiries about its

products. Please contact us using the information below:

Headquarters 2762 Loker Avenue West

Carlsbad, CA 92010-6603

USA

Toll Free: 1-800-ASYMTEK (1-800-279-6835)

Tel: +1-760-431-1919

Fax: +1-760-431-2678

E-mail: info@asymtek.com

Website: www.asymtek.com

Technical Support

USA: 1-800-ASYMTEK (1-800-279-6835)

Other regions: www.nordsonasymtek.com Tech Support

Trademarks

Asymtek®, Century®, Select Coat®, and Easy Coat® are registered trademarks of Nordson ASYMTEK.

Microsoft®, Windows®, and Windows®XP are registered trademarks of Microsoft Corporation.

© Nordson, 2011

i

Contents

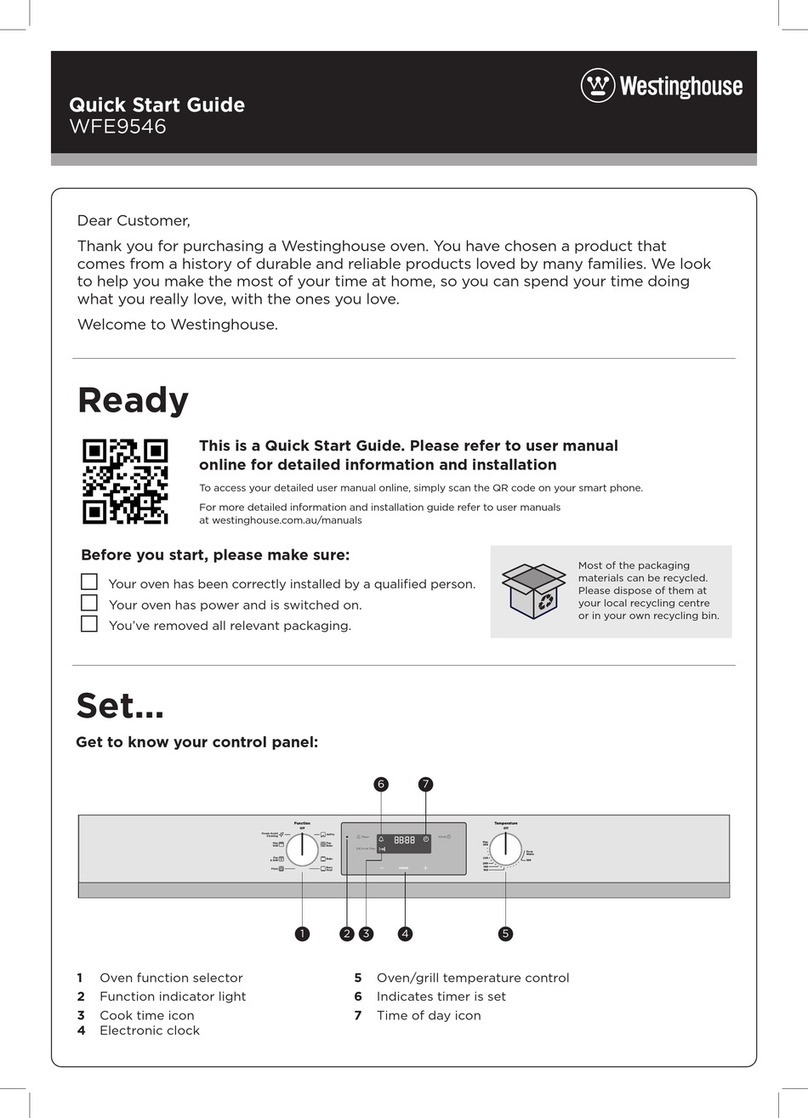

Introduction

I. How to Use this Manual--------------------------------------------------------------------------- 3

II. Safety Precautions --------------------------------------------------------------------------------- 4

Facility Installation

I. Unpacking ------------------------------------------------------------------------------------------ 17

II. General Operating Conditions --------------------------------------------------------------- 18

III. Power Requirements---------------------------------------------------------------------------- 18

IV. Lighting Requirements------------------------------------------------------------------------- 19

V. Exhaust Requirements------------------------------------------------------------------------- 19

VI. Leveling the Machine --------------------------------------------------------------------------- 19

VI. Computer Installation--------------------------------------------------------------------------- 20

VIII. Optional Battery Backup Installation------------------------------------------------------ 21

IX. Final Things to Do ------------------------------------------------------------------------------- 21

X. Sprinkler Fire Suppression System-------------------------------------------------------- 21

XI. Facility Drawings--------------------------------------------------------------------------------- 21

Operating System Software Guide

A. Starting the Program------------------------------------------------------------------------------ 25

B. Main Operating Screen --------------------------------------------------------------------------- 26

C. Selecting Screen and Function---------------------------------------------------------------- 27

D. Scheduling Calendar Events ------------------------------------------------------------------- 42

E. Setting Up User Security------------------------------------------------------------------------- 43

F. Enable Data Logging and Interval Time----------------------------------------------------- 44

G. Channel Trend Plot Screen Setup ------------------------------------------------------------ 45

H. New User Log On----------------------------------------------------------------------------------- 46

I. User Log Off ----------------------------------------------------------------------------------------- 46

J. Acknowledge Alarm-------------------------------------------------------------------------------- 46

K. Shutting Down the System---------------------------------------------------------------------- 47

L. Editing Parameters from the Channel Setup Screen------------------------------------ 47

M. Modifying A Recipe-------------------------------------------------------------------------------- 48

N. Loading A Recipe ---------------------------------------------------------------------------------- 48

O. Deleting A Recipe---------------------------------------------------------------------------------- 48

P. Software Version ----------------------------------------------------------------------------------- 48

Q. System Setup---------------------------------------------------------------------------------------- 49

Standard and Optional Equipment Operating Guide

I. Alarm and Warning Options and Operation ----------------------------------------------- 63

A. Light Tower Output ------------------------------------------------------------------------- 63

B. Audible Alarm Option ---------------------------------------------------------------------- 63

C. Independent Alarm Sensor Option (IAS)--------------------------------------------- 64

D. Power Hood Lifts ---------------------------------------------------------------------------- 64

II. Battery Backup Option --------------------------------------------------------------------------- 64

III. Edge Hold Conveyor System and Options------------------------------------------------- 64

A. Description and Standard Operation-------------------------------------------------- 64

B. Computer Controlled Edge Hold Positioning Option---------------------------- 64

C. Center Board Support Option ----------------------------------------------------------- 65

D. Board Counter/Board Drop Option ---------------------------------------------------- 66

E. Upstream and Downstream Machine Interfaces ---------------------------------- 66

ii

Troubleshooting Guide

Index------------------------------------------------------------------------------------------------------------- 69

I. No Power to the Machine----------------------------------------------------------------------- 71

II. Communication with the Oven Was Lost-------------------------------------------------75

III. Low Deviation of A Heat Zone or A Zone Not Reaching Temperature ---------- 80

IV. High Deviation of A Heat Zone or A Zone Overheating ------------------------------ 83

V. High Process Alarm------------------------------------------------------------------------------ 86

VI. Zone Temperature Is Not Stable ------------------------------------------------------------- 89

VII. Heat Rise Rate Alarm---------------------------------------------------------------------------- 92

VIII. Software Lock-Up or Odd Behavior--------------------------------------------------------- 93

IX. Conveyor Not Moving --------------------------------------------------------------------------- 93

X. Conveyor Speed Controller Adjustment -------------------------------------------------- 96

XI. Conveyor Speed Not Stable------------------------------------------------------------------- 99

XII. Machine In A Warning Condition ------------------------------------------------------------ 101

XIII. Tripped Breakers---------------------------------------------------------------------------------- 101

Maintenance Procedures

Index------------------------------------------------------------------------------------------------------------- 105

I. Replacing A Top IR Panel---------------------------------------------------------------------- 107

II. Replacing A Bottom IR Panel (Removing the Edge Hold Conveyor) ------------ 108

III. Adjusting the Slip Clutch (Edge Hold Conveyor w/o mesh belt)------------------ 109

IV. Replacing an SSR (Solid State Relay)------------------------------------------------------ 110

V. Replacing A Thermocouple ------------------------------------------------------------------- 111

VI. Replacing Carbon brush of DC motor ----------------------------------------------------- 112

VII. Lubrication------------------------------------------------------------------------------------------ 113

VIII. Verifying Accuracy of the System----------------------------------------------------------- 114

IX. Profiling---------------------------------------------------------------------------------------------- 116

X. PM Schedule --------------------------------------------------------------------------------------- 119

Parts Ordering Information------------------------------------------------------------------------------- 120

EC Declaration Conformity------------------------------------------------------------------------------- 121

1

Introduction

2

3

I. How to Use this Manual

Congratulations on the purchase of your Asymtek oven. This equipment is designed to satisfy a

wide range of solder Cure and PCB curing applications. When properly used and maintained

within operating limits described throughout this manual the machine will provide years of trouble

free service.

This manual is applicable to all Asymtek oven models TCM-2200, TCM-3300 and TCM-4600

running WINDOWS-XP based software. It contains installation, operation, troubleshooting and

maintenance procedures for electrical and mechanical systems on all models, including most of

the common optional equipment available for the ovens. Electrical schematics, nitrogen plumbing

diagrams and additional information may be found at the back of this manual and/or OEM

instruction manuals.

CAUTION: Although most installation and service

routines can be performed easily, extreme caution

should be exercised when working with live electrical

circuits. ONLY a trained electrical technician or

engineer following all required codes and

lockout/tagout procedures should perform this work.

The first section of the manual describes for the technician the requirements and necessary steps

to uncrate and install the oven.

For a detailed explanation of software operation, please refer to the section entitled “Operating

System Software Guide”.

The section entitled “Standard and Optional Equipment Operating Guide” explains each of the

features and available standard options. It includes operating instructions as well as schematics

and diagrams.

To use the troubleshooting guide, please refer to the contents to select the troubleshooting

section most applicable to the symptoms exhibited by the machine. It is recommended that the

technician read the entire applicable section first before starting the troubleshooting procedure.

Once he is familiar with all the required tests, he may then decide upon the most logical

troubleshooting steps to take. The troubleshooting section contains a page useful for determining

computer channel assignments for the various heating zones as well as a guide for determining

which SSR (Solid State Relay) is controlling a particular zone. It also includes a section that will

instruct the technician as to which covers will need to be removed to access internal components.

The technician should refer to the final section of the manual for any maintenance procedures

that need to be performed.

If any further assistance should be required, contact Asymtek Technical Support Group;

Asymtek Technical Support Group;

In the U.S.: 1-800-ASYMTEK (1-800-279-6835)

From outside the U.S.: +1-760-431-1919

or

Email: [email protected]

4

To perform the procedures presented in this manual you may need the following equipment:

•Medium and large Phillips head screwdrivers

•Large, medium and small flat blade screwdrivers

•Set of Allen (hex) keys: Metric (1.5mm to 10mm)

•Set of open end wrenches or socket set: Metric (9mm to 20mm)

•Channel-lock pliers or pipe wrench with 3”(75mm) capacity

•Wire cutters (diagonal cutters)

•Needle-nose pliers

•Wire strippers

•Terminal crimpers with assorted terminals

•Multimeter (voltmeter/ohmmeter)

II. Safety Precautions

II.1. Overview

This chapter provides safety guidelines that should be followed when operating the Cure Oven

System. These guidelines ensure personal safety and protect equipment during installation,

operation, maintenance, troubleshooting, and other potentially dangerous procedures. Safety

training is available upon request.

Facility

Installation The oven should be uncrated and installed using an appropriate forklift and

following the procedures as outlined. Failure to use appropriate equipment

may result in personal injury and/or property damage.

The oven should be connected to power by a qualified electrician and must

comply with all appropriate electrical and safety codes. See instruction

manual Section III in Facility Installation for power supply requirements.

Failure to follow electrical codes or the use of under-rated supply

conductors may cause property damage and may subject the operator to

hazardous voltages.

The exhaust ducting for the oven should be designed and installed by a

qualified HVAC technician capable of calculating air flow from suction

blowers and flow losses in upstream and downstream ducting. Improper

exhausting may allow flux fumes to be inhaled by the operator.

Special Precautions should be taken if the unit is installed in a sprinklered

room or building. Refer Sprinkler System in Facility Installation, Section XI.

Ensure packing material is removed.

Read instruction manual.

Refer Leveling of the oven in Facility Installation, Section VII.

Operating the

Equipment When oven is in use, the edge hold conveyor system and other machine

components will become hot. Please observe all hot surface warning

placards applied to the machine. Please also observe all other warning

placards and instructions. Do not open the oven while it is in operation.

This will expose the operator to high temperature air.

Power Hood Lifts When closing the top shell of the oven, be aware that long hair or loose

5

fitting clothing may become entangled in the system. The shell may also

pose a crushing threat to bodily extremities.

Software

Operation Do not alter settings in the system software beyond that which is described

in this manual without first contacting the factory. Doing so may affect safe

operation of the machine.

Nitrogen

Operation Even though nitrogen is an inert substance, a few simple precautions

should be made. Proper ventilation in the area where the system is being

used must be maintained to keep the oxygen level in the air at safe levels.

Otherwise the continuous flow of nitrogen can displace the air and deplete

the normal oxygen level. Create sufficient ventilation in the area of the

Cure oven to exhaust the excessive nitrogen laden air and replace it with

normal atmosphere. Installation of a room oxygen monitoring system is

recommended especially if the oven is installed in a small-enclosed area.

Edge Hold/Mesh

Belt Operation

Caution must be exercised when working near the belt or conveyor

systems. Do not operate the system with guards removed and be aware of

all pinch point warning decals. Also, be aware that long hair or loose fitting

clothing may become entangled in the system. Should this occur, an

EMERGENCY STOP button is located at each end of the oven. Pressing

this button will immediately stop the conveyor system.

Troubleshooting

and Maintenance Please be aware that although many service routines can be performed

easily, extreme caution should be exercised when working with live

electrical circuits. ONLY a trained electrical technician or engineer should

perform this work. Before removing any panels, all power to the oven

should be switched off and the temperature should be at room ambient.

While system components are fully tested and rated for long life, it is the responsibility of

the customer to properly maintain the equipment after the warranty period to ensure the safety

and functionality of the machine. Improper maintenance and checking can result in system or

subsystem failures that are not the responsibility of the manufacturer. This includes the cleaning

of the various areas, the tightening of screws, the confirmation of proper voltage and current

draws, appropriate lubrication, proper exhaust, proper handling during movement of the machine,

and periodic checks of each of the subsystems for functionality.

II.2. Cautions and Warnings

Three basic types of alert boxes are used in this manual to warn personnel during operation,

maintenance, and troubleshooting of the Cure Oven System:

DANGER! means the action will cause serious injury or death to

personnel if proper procedures are not followed.

WARNING! means the action may result in serious injury or death if

proper procedures are not followed.

CAUTION! means the action may cause damage to equipment and/or

minor to moderate injury to personnel if proper procedures are not

followed.

6

II.3. Cure Oven System Safety Labels

Safety labels affixed to system hardware are used to make personnel aware of potential hazards

and remind them to take necessary safety precautions. Table II-1 describes them in detail.

Table II-1 Safety Hazard Labels

Label Part Number Description

2545 Hazardous Voltage Warning - Warns

personnel of areas where high voltage is

present which may cause severe injury

or death.

3628 Hot Surface Warning - Warns personnel of

hot surfaces that may cause burns if touched.

3627 Moving Parts Warning - Warns personnel to

keep hands and fingers away from

mechanisms that could cause injury.

7

II.4. Basic Safety Precautions

When used properly, the Asymtek Cure Oven System provides safe and reliable service. The

purpose of this advisory is to point out possible hazards that may be encountered during

operation, maintenance, and servicing of your system. This equipment is designed with IP32

code.

WARNING! Only qualified and authorized personnel should perform

equipment, installation, setup, maintenance, troubleshooting, and repair.

II.5. Electrical Hazards

WARNING! Always disconnect the equipment from the power source and

attach a lockout device to the electrical disconnect before performing any

maintenance or repair.

II.6. Fire Hazard

WARNING! Always use class-c fire extinguisher in case of any fire in Asymtek

Cure oven.

In case of any leakage of flux gases or any smoke form the oven, turn on utility room exhaust to

clear area.

8

II.7. Environmental Hazards

Hazardous Material

CAUTION! Cleaners are used during maintenance and servicing should be

considered hazardous material. Consult with your facility safety officer and the

manufacturer’s Material Safety Data Sheet for instructions concerning proper

disposal of hazardous materials. Contact Asymtek if you have any questions.

See Maintenance Procedure section for anticipated change-out frequency,

quantity and potential for contamination from the process.

CAUTION! Do not use flammable solvents to clean.

Component Disposition

Cleaners: ALPHA

saponifier/Vigon RC101 Discard in accordance with local safety/environmental regulations.

Hazardous Waste

CAUTION! Solid wastes generated during system maintenance and servicing

should be considered hazardous waste. Consult with your facility safety officer

and the manufacturer’s Material Safety Data Sheet for instructions concerning

proper disposal of hazardous materials. Contact Asymtek if you have any

questions.

CAUTION! Customer should be aware that the flux they add to the oven will be

exhausted.

Component Disposition

Interior deposits and

Dirty rags Discard in accordance with local safety/environmental regulations.

Cleaned Used Flux Discard in accordance with local safety/environmental regulations.

Process Exhaust

CAUTION! Exhaust discharge hazards are dependent upon the process gas

(es) used and the material(s) being treated.

The chemistry of exhaust discharges should be evaluated for potential hazards

by trained safety/environmental engineers prior to system start-up. Contact

Asymtek if you have any questions.

9

Smoke from Electrical Fault

CAUTION! Smoke generated by electrical faults inside the Cure Oven System

may be exhausted into the surrounding area. Personnel should avoid inhaling

the smoke because it might contain hazardous substances.

The chemistry of the smoke should be evaluated for potential hazards by

trained safety/environmental engineers prior to system start-up. Contact

Asymtek if you have any questions.

Hazardous Energy

CAUTION! Thermal Energy: Oven may be HOT, wait until oven cools down or

proper insulated gloves should be used. See Operating System Software Guide,

Section-K.

CAUTION! BBU Energy: Oven BBU will be turned OFF remotely by rotary

switch OFF position with one bip sound. If BBU bip sounds more than once,

turn BBU OFF manually by pressing ON/OFF button (top first). To access BBU

unit, open right rear base bottom panel where BBU is mounted in the base.

10

II.8. Decommissioning Procedures

The Asymtek Cure Oven System should provide you with years of safe and reliable service.

When it becomes necessary to decommission the system, the components should be disposed of

as specified in Table II-2.

Table II-2 Recommended Decommission Procedures

Component Disposition

Chamber Residue Discard in accordance with local safety/environmental regulations.

Aluminum Parts Recycle aluminum Chamber, panels, shelves, doors, and

hardware.

Steel Parts Recycle all steel parts.

Copper Wiring Recycle any copper wiring.

Electronic

Components Discard in accordance with local safety/environmental regulations.

Plastics Recycle or discard in accordance with local safety/environmental

regulations.

11

II.9. Cure Oven System Safety Features

The Asymtek Cure Oven System is designed with several integrated safety features to protect

against personal injury and equipment damage. These features include the emergency shut off

button and the safety interlocks.

II.9.1. Emergency Stop

The Asymtek Cure Oven System is equipped with a large, clearly marked, front console-mounted

emergency stop (E-Stop) push button. When activated, the power to the system heaters is

disconnected, the system conveyor is stopped, & the oven goes into “Cooldown” mode. This is

accomplished via relay contacts that set the heater power contactor to the OFF state and stop

system conveyor operation. To reset E-Stop function, twist emergency stop button and press “E-

Stop Reset”, oven stays in “Cooldown” mode. To restore full power to the system heaters and

system conveyor, reset system software and load a wakeup or hot job recipe from the system

software.

.

CAUTION! When the Emergency stop button is activated, the Main Circuit

Breaker, Rotary Switch, the line side of the Main Power contactor and

Transformer are still energized. Before accessing the system’s Lower

Enclosure, perform the lockout/tag out procedure in Error! Reference source

not found. to prevent serious injury to personnel.

12

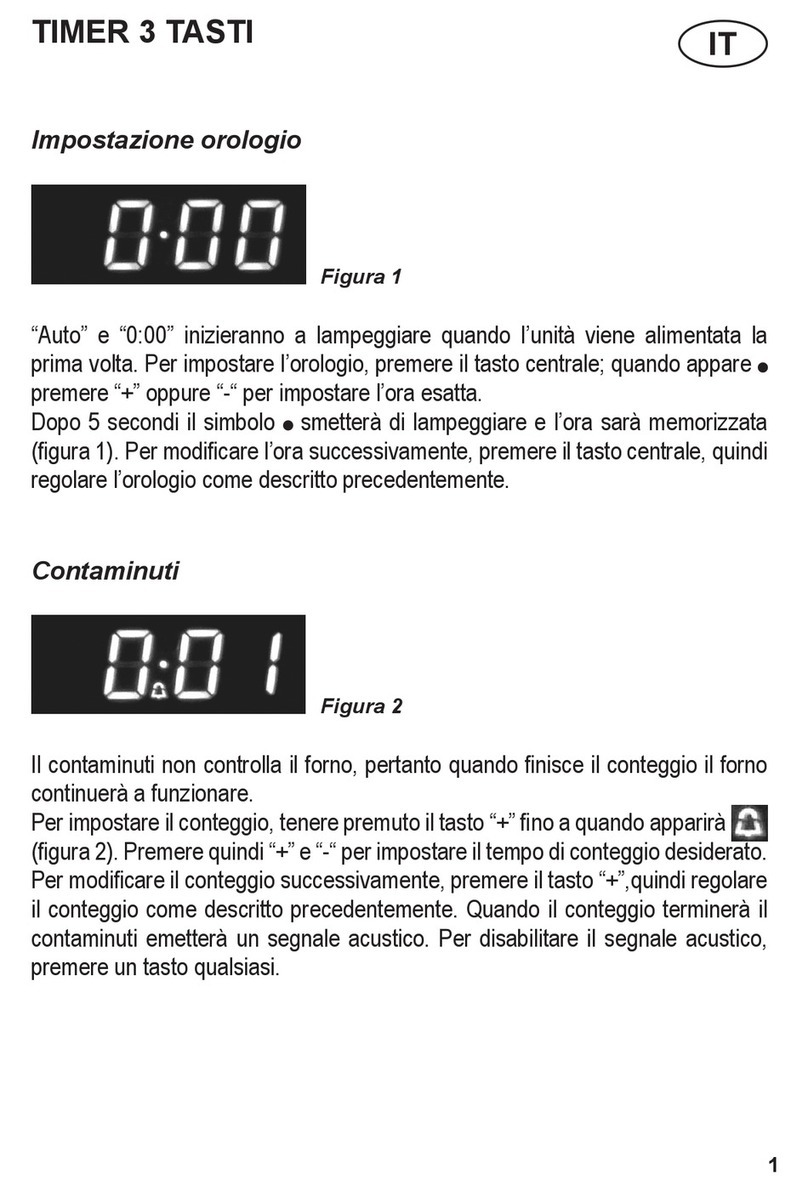

II.10. Light Tower Status Lights

The Asymtek Cure Oven System includes a Light Tower (Figure II-1) that constantly shows the

status of the current operation. Table II-3 describes the meaning of Light Tower status lights.

Figure II-1 Cure Oven Light Tower Status Lights

Table II-3 Light Tower Status Lights

Light Color System Status Reasons

FLASHING

RED ALARM A system alarm is present. Refer to Section

Troubleshooting for recovery information.

GREEN OK The system is ready to process material.

FLASHING

YELLOW WARNING OR

NEW JOB The System warning, Board drop, Board backup

or Job start up.

II.10.1. Audible Alarm

This option consists of an audible signal that sounds when the system goes into an alarm mode

or board drop occurs. The signal is activated whenever the red light on the light tower is

illuminated. In the event of an alarm, the light tower turns red, the audible alarm sounds and the

machine load the Cooldown job.

The operator can silence the audible alarm by acknowledging it. See the “Operating System

Software Guide” section.

RED

YELLOW

GREEN

13

II.11 System Lockout

During maintenance and servicing tasks, prevent injury to personnel by locking out and tagging

out system power supply. Follow equipment shut down procedure as described below:

1. Notify affected personnel before beginning any maintenance, servicing, and

troubleshooting.

2. Load the Cooldown program.

a. From the main toolbar click the Cooldown icon or from the menu bar select Mode

then select Cooldown from the dropdown menu.

b. After all heat zones have cooled below a pre-determined temperature (factory

default is 95° C) the blowers and conveyor drive motor will turn off. (Opening the

oven hood will allow the oven to cool faster but be aware that the oven will be

blowing hot air.)

3. Continue the shutdown process by clicking on the Exit icon on the main toolbar or

selecting Mode then Shutdown+Exit from the drop down menu. This will close the Oven

Operating Software and return the user to the desktop.

4. From the desktop the user can shut down the PC before turning off power to the oven.

5. Turn oven power OFF by rotating the main rotary power switch to the OFF (0) position.

a. This will also remotely shut off BBU unit if equipped. BBU unit will beep once

during shutdown.

6. Turn off supply power to the oven at facility three phase circuit breaker feeders.

7. Obtain locks and tags from facility lock-out/tag-out station.

8. Lock-out and tag-out the following energy source disconnects:

a. Facility three-phase power supply circuit breaker.

b. Main oven power rotary switch.

9. Check AC power at X1 (primary) terminal block. Measure AC voltage between phases

L1- L2, L1- L3, L2-L3 using a voltmeter. Meter should read zero volts.

10. Perform maintenance, servicing and troubleshooting as necessary.

II.12 Restoring system to service

Following maintenance and tasks restore the system to service as follows:

1. Make sure all doors, panels, and guards are in place.

2. When equipment is safe to run, remove all locks and tags from all locked out devices.

3. Turn main power supply facility circuit breaker “ON”.

4. Turn rotary switch on oven to ON (I) position.

5. Reset E-stop circuit by pressing blue push button.

6. Follow recommended start-up procedures described in Operating System Software

Guide, Section-A

14

15

Facility Installation

16

This manual suits for next models

2

Table of contents

Other Nordson ASYMTEK Oven manuals

Popular Oven manuals by other brands

NEFF

NEFF B4ACM5HH0B User manual and installation instructiions

Valencia Euro

Valencia Euro EV6004WH user manual

Frigidaire

Frigidaire FGET2745KB - Gallery 27" Double Electric Wall... Wiring diagram

Frigidaire

Frigidaire PLEB30S8A Specifications

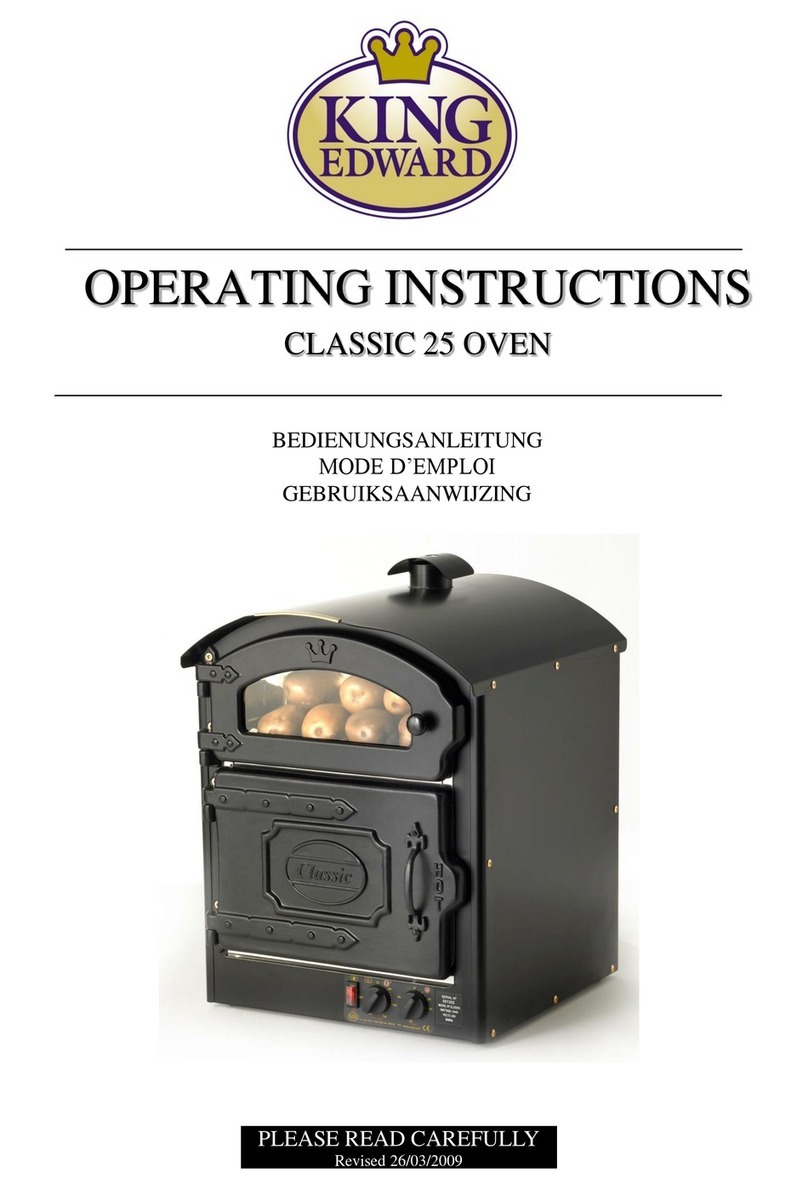

King Edward

King Edward CLASSIC 25 operating instructions

HearthStone

HearthStone Patio Oven 4.5 user manual