Norgren VP50 IO-Link User manual

Operation Manual

VP50 IO-Link

Before arting work read these inructions.

This manual contains proprietary information. No part of this publication

may be reproduced, transcribed or transmitted in any form without the

written consent of the publisher. Every eort has been made to ensure that

the information contained in this manual is accurate. All rights reserved.

UKLEETC002023293

02

VP50 IO-Link

02/21

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the speciications given in this document. (2019 - 9261a) © 2019 Norgren GmbH

INDEX General Information 3

Liabilities and Warranties 4

Speciications 5

Dimensions 6

Features 7

Electrical Connections 7

Pneumatic Connections 8

IO-Link General Information 9

Declaration of Confromity 11

UKLEETC002023293

03

VP50 IO-Link

02/21

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the speciications given in this document. (2019 - 9261a) © 2019 Norgren GmbH

1.0 General

1.1 Information about

these instructions

These instructions will enable you to safely install, set up and operate

the VP50 IO-Link electro-pneumatic converter. These instructions

are an integral part of the product and must be accessible to

personnel. Personnel must carefully read through and understand

these instructions before starting work of any kind on the valves.

Following all of the safety and handling instructions contained in

this manual is a fundamental requirement for safe working.

The following symbols are used to emphasise instructions, outcomes,

lists, references and other elements in these instructions.

DANGER

This symbol and the word ‚danger‘ indicates an immediately

dangerous situation that may result in death or serious injury

if not avoided.

WARNING!

This symbol and the word ‘warning’ indicates a potentially

dangerous situation that may result in death or serious injury

if not avoided.

CAUTION!

This combination of symbol and signal word indicates a

possibly hazardous situation that may result in damage to

property or environmental damage if it is not avoided.

Indicates tips and other useful information.

1.2 Explanation of

symbols safety

notice

Other symbols

Symbols Meaning

1., 2., 3., Step-by-step instructions

• Lists with no specic order

UKLEETC002023293

04

VP50 IO-Link

02/21

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the speciications given in this document. (2019 - 9261a) © 2019 Norgren GmbH

1.3 Liability and

warranty

1.4 Warranty statement

Physical modiication to the VP50 IO-Link converter may only be

carried out by the manufacturer’s personnel. If the converter requires

repairs or servicing beyond the scope of the activities described in these

instructions, this work may only be carried out by the manufacturer of

the converter or by persons who have been expressly authorised and

trained by the Manufacturer. Failure to observe the above will void the

warranty. The manufacturer accepts no liability for damages incurred.

Physical modiication to the VP50 IO-Link converter may only be

carried out by the manufacturer’s personnel. If the converter requires

repairs or servicing beyond the scope of the activities described in these

instructions, this work may only be carried out by the manufacturer of

the converter or by persons who have been expressly authorised and

trained by the Manufacturer. Failure to observe the above will void the

warranty. The manufacturer accepts no liability for damages incurred.

UKLEETC002023293

05

Subject to change without notice

UKLEETC002023293

5

VP50 IO-Link

2.0 Specifications

The factory set performance ranges for the

valve also appear on the rating plate of the

specific unit.

2.1 Technical Data

Specification

Value

Medium:

Oil free, dry media, min filtered to 5µm;

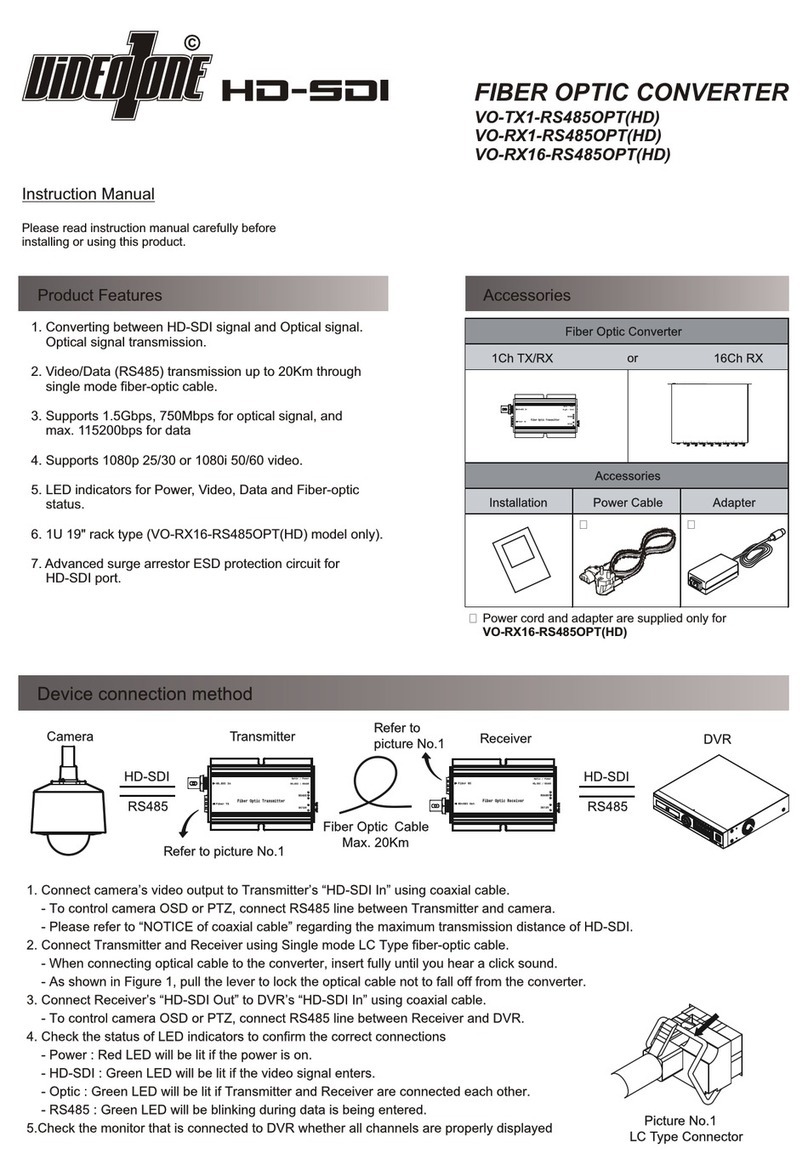

Schematic

Output Pressure:

0 ... 2 bar

0 ... 6 bar

0 ... 10 bar

Supply Pressure:

Minimum 1.5 bar (29 psi) above

maximum output required.

Standard units: 12 bar Max. (174 psi)

Flow Capacity:

Up to 1000 Nl/min

Air Consumption

< 5 Nl/min

Linearity (independant):

<±1.0% of span

Hysteresis & Deadband:

<±1.0% of span

Response Time:

< 100ms (10-90% of output pressure into

a 0,1 litre load).

Port Size:

All ports: G1/4, ¼ NPT or Manifold mount

Operating temperature:

0 ... +60oC (+32 ...140oF)

Air supply must be dry enough to avoid

ice formation at temperatures below

+2°C (+35°F).

Temperature Sensitivity:

Typically <0.1% span/oC between

0 … +60

o

C (+32 … 140

o

F)

I.P. Rating

IP65, with LED cover fitted.

Vibration Effect

<3% of span, 3g sine, 10 to 150Hz (3

axes).

VP50 IO-Link

02/21

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the speciications given in this document. (2019 - 9261a) © 2019 Norgren GmbH

2.0 Speciications

2.1 Technical Data

Schematic

The factory set performance ranges for the valve also appear

on the rating plate of the speciic unit.

Specication Value

Medium: Oil free, dry media, min ltered to 5µm;

Output Pressure: 0 ... 2 bar

0 ... 6 bar

0 ... 10 bar

Supply Pressure: Minimum 1.5 bar (29 psi) above maximum output required.

Standard units: 12 bar Max. (174 psi)

Flow Capacity: Up to 1000 Nl/min

Air Consumption < 5 Nl/min

Linearity

(independant):

<±1.0% of span

Hysteresis &

Deadband:

<±1.0% of span

Response Time: < 100ms (10-90% of output pressure into a 0,1 litre load).

Port Size: All ports: G1/4, ¼ NPT or Manifold mount

Operating

temperature:

0 ... +60ºC (+32 ...140ºF)

Air supply must be dry enough to avoid ice formation at

temperatures below +2°C (+35°F).

Temperature

Sensitivity:

Typically <0.1% span/oC between 0 … +60ºC (+32 … 140ºF)

I.P. Rating IP65, with LED cover tted.

Vibration Effect <3% of span, 3g sine, 10 to 150Hz (3 axes).

Materials: Body: Aluminium, Gafon and Zinc Diecasting

Diaphragms: NBR

Coatings: PTFE, So Anodising, Black polyester powder coating

UKLEETC002023293

06

Subject to change without notice

UKLEETC002023293

6

VP50 IO-Link

Specification

Value

Materials:

Body: Aluminium, Gafon and Zinc

Diecasting

Diaphragms: NBR

Coatings: PTFE, Soft Anodising, Black

polyester powder coating

Electrical Parameters

Control Signal:

IO-Link

Power Supply:

24V d.c. ±25%

Power Consumption:

Typically <0.5W

Insulation Resistance:

10MΩd.c.

Connection:

M12x1, 5 pin connector

Max. Cable Length

20 metres

Failure Mode:

Pressure falls to below 15mbar within

1s when power supply is lost

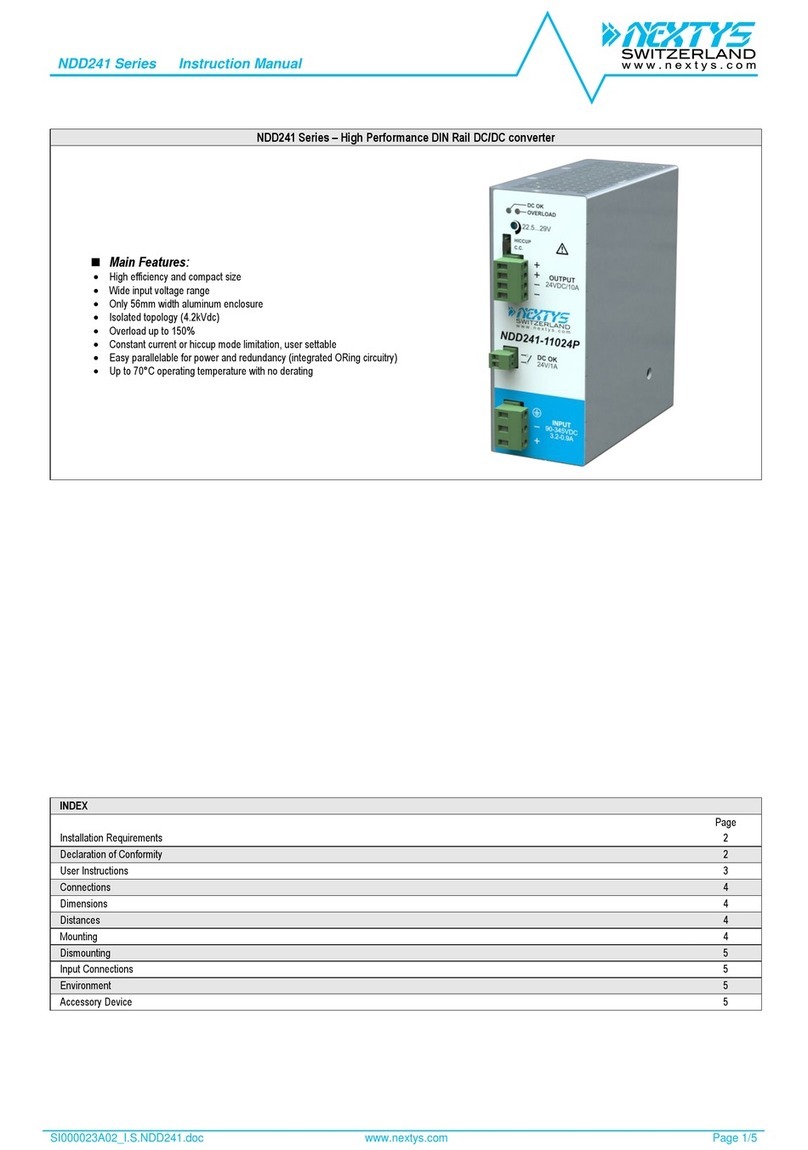

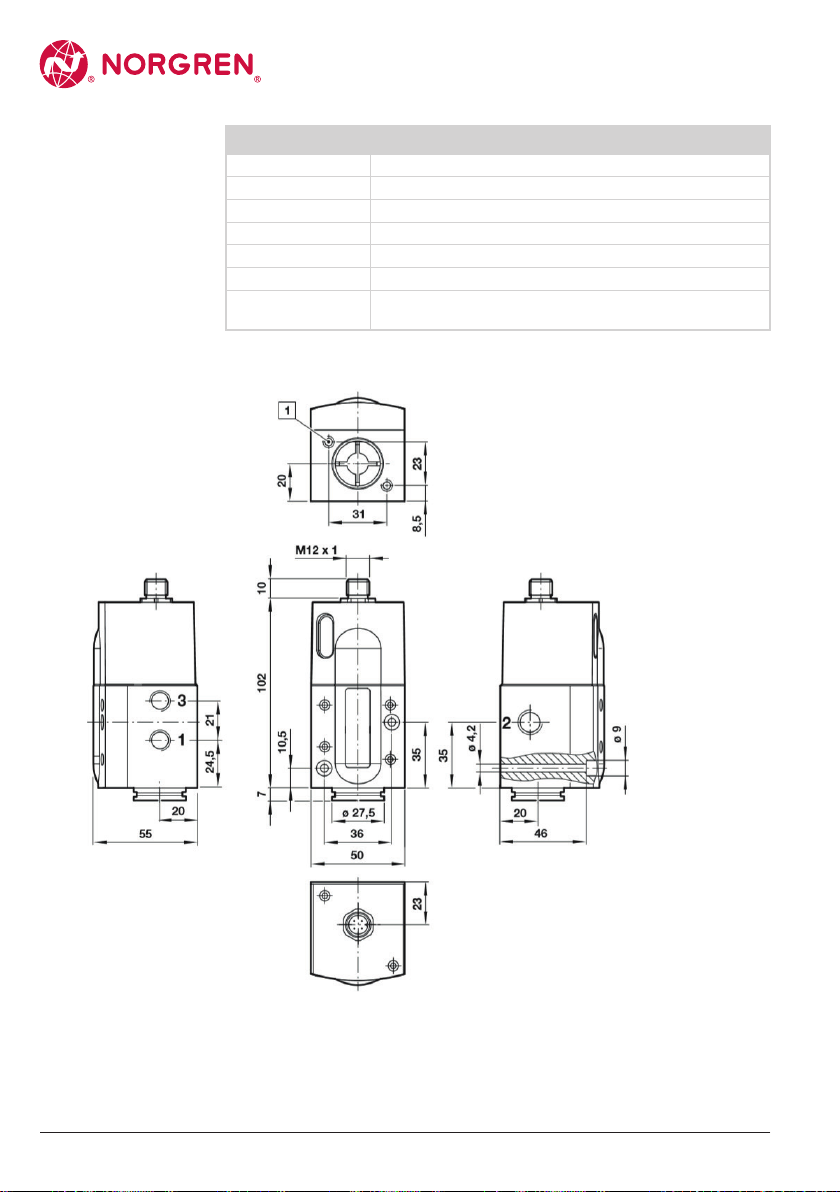

Dimensions

VP50 IO-Link

02/21

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the speciications given in this document. (2019 - 9261a) © 2019 Norgren GmbH

Electrical Parameters

Dimensions

Specication Value

Control Signal: IO-Link

Power Supply: 24V d.c. ±25%

Power Consumption: Typically <0.5W

Insulation Resistance: 10MΩ d.c.

Connection: M12x1, 5 pin connector

Max. Cable Length 20 metres

Failure Mode: Pressure falls to below 15mbar within 1s when power supply is lost

M5 x 8 mm deep

UKLEETC002023293

07

VP50 IO-Link

02/21

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the speciications given in this document. (2019 - 9261a) © 2019 Norgren GmbH

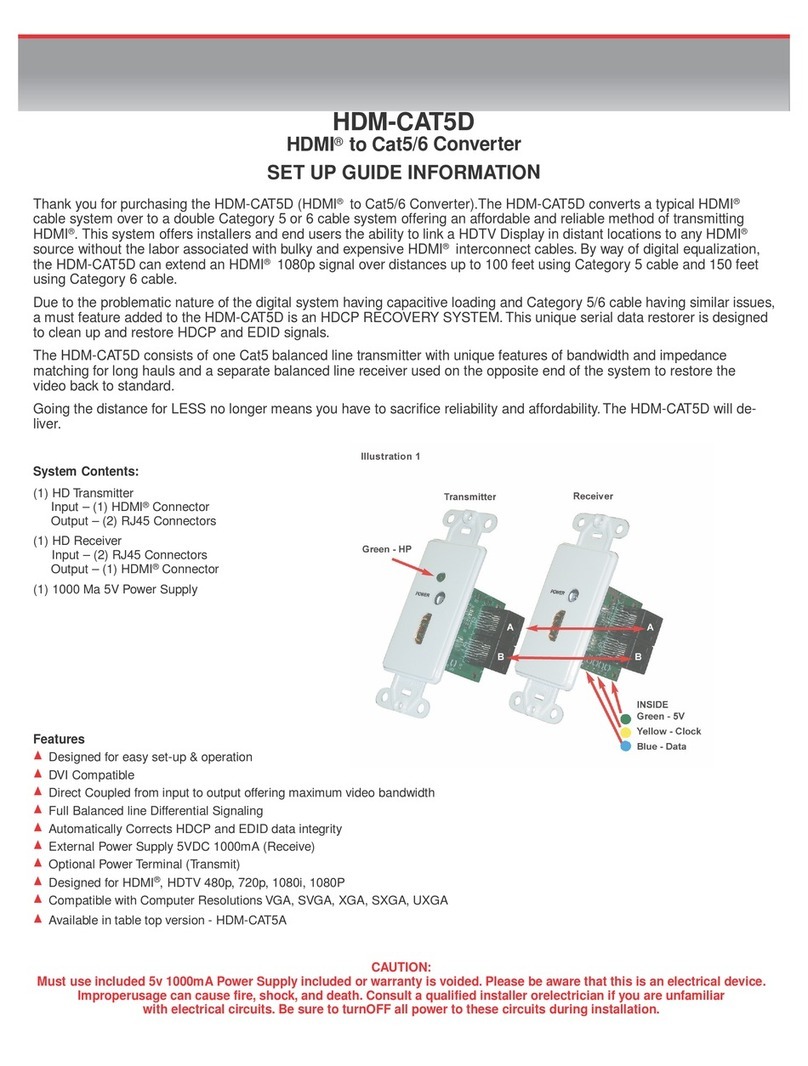

3.0 Features

Pin Colour (typ.) Connection

1 Brown Power input (24 VDC ±25%)

2n/a -

3 Blue Power ground (-V)

4 Black Signal (C/Q)

5n/a -

• Closed-loop air piloted proportional control valve

• IO-Link communications

• Fast Response time

• Low Power consumption

• Output Pressure Feedback

• High visibility LED status light

• Manifold mountable

• RoHS compliant

• CE marked

The unit must be connected by a qualiied individual. The

national and international regulations for the installation

of electrical equipment must be adhered to.

Ensure power is isolated.

Connect the unit as follows:

3.1 General Description

3.2 Electrical

Connections

The VP50 IO-Link is a digital proportional control valve using

the IO-Link communications protocol to both control the valve

output pressure but also provide feedback to the user system.

The pneumatic section is a diaphragm actuated glandless spool valve.

Pilot pressure applied to the diaphragm moves the spool and regulates

the output pressure of the unit. The pilot pressure is developed by a voice-

coil pilot (I/P) which is controlled electronically by the onboard PCB.

The IO-Link communication protocol allows the user to not

only control the output of the device but also adjust operating

parameters and monitor various performance feedbacks,

such as current output pressure and cycle count.

Chassis Earth connection should always be connected to

deliver optimum continuous EMC performance.

Subject to change without notice

UKLEETC002023293

7

VP50 IO-Link

3.0 Features

Closed-loop air piloted proportional control valve

IO-Link communications

Fast Response time

Low Power consumption

Output Pressure Feedback

High visibility LED status light

Manifold mountable

RoHS compliant

CE marked

3.1 General Description

The VP50 IO-Link is a digital proportional control valve using the IO-Link communications protocol

to both control the valve output pressure but also provide feedback to the user system.

The pneumatic section is a diaphragm actuated glandless spool valve. Pilot pressure applied to the

diaphragm moves the spool and regulates the output pressure of the unit. The pilot pressure is

developed by a voice-coil pilot (I/P) which is controlled electronically by the onboard PCB.

The IO-Link communication protocol allows the user to not only control the output of the device but

also adjust operating parameters and monitor various performance feedbacks, such as current

output pressure and cycle count.

3.2 Electrical Connections

The unit must be connected by a qualified individual. The national and international regulations for the

installation of electrical equipment must be adhered to.

►Ensure power is isolated.

►Connect the unit as follows:

Chassis Earth connection should always be connected to deliver optimum continuous EMC

performance.

Pin Colour

(typ.)

Connection

1

Brown

Power input (24 VDC ±25%)

2

n/a

-

3

Blue

Power ground (-V)

4

Black

Signal (C/Q)

5

n/a

-

UKLEETC002023293

08

VP50 IO-Link

02/21

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the speciications given in this document. (2019 - 9261a) © 2019 Norgren GmbH

3.3 Pneumatic

Connections

These instruments are recommended for use with clean, dry,

oil free instrument grade air to BS 6739 or ISA-7.0.01-1996

Dew Point: At least 10°C (18°F) below anticipated ambient temperature.

Dust: Filtered to below 5 microns

Oil Content: Not to exceed 1ppm mass.

The inlet and outlet ports are threaded G1/4 or 1/4”NPT female

and suitable itting should be used. For most installations

1/4” (6mm) pipe will be adequate. Always ensure that the

downstream volume between the output of the VP50 and

the actuator/device is between 100cc and 2000cc.

If the air supply is not of adequate quality this can normally

be achieved by the use of an air ilter regulator. In all cases,

purge the supply pipework before connection to the valve.

The use of a soft setting anaerobic seal is recommended,

(e.g. Loctite Hydraulic Seal 542). Always follow the sealent

manufacturer’s recommendations during use.

Under no circumstances should PTFE tape be used for sealing

the ittings as this tends to shred small particles which may

contaminate the instrument and cause malfunctions.

UKLEETC002023293

09

VP50 IO-Link

02/21

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the speciications given in this document. (2019 - 9261a) © 2019 Norgren GmbH

4.0 IO-Link General

Information

4.1 User Settings

This unit has an IO-Link communication interface which requires

an IO-Link-capable module (IO-Link master) for operation. The IO-

Link interface enables direct access to the process and diagnostic

data and provides the possibility to set the parameters of the

unit during operation. In addition communication is possible via

a point-to-point connection with a USB adapter cable.

Device-speciic Information You can ind the IODDs necessary

for the coniguration of the IO-Link unit and detailed information

about process data structure, Diagnostic information

and parameter addresses at www.norgren.com

User Adjustable Setting Description

Set Zero calibration

adjustment

+/- 5% of Span

Set Span calibration

adjustment

+/- 5% of Span

Reset to Factory Setting Resets all user settings to Factory supplied.

Communications Failure

Mode

Conguration of fail to zero (default) or fail freeze in the event

of IO-Link communications failure

PID Adjustment of the Gain settings within the control algorithm.

These settings should only be altered by experienced personnel

Set Pressure units Select demand/feedback pressure unit.

PSI,Bar,kPa,Kgcm2,Atms

Pressure Ramp prole Preset unit response time adjustment

Displayed pressure

damping

Applies moving average to displayed pressure output

Read Only Parameters Description

Demand Cycle Count Number of pressure operations totalling 10% of Span

Total Hours Total hours unit has been powered since manufacture

Current Power On Hours Total hours since last power cycle

Internal Temperature feedback ºC reading of internal temperature. For indication only.

Total Error Count Total number of error events

UKLEETC002023293

010

VP50 IO-Link

02/21

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the speciications given in this document. (2019 - 9261a) © 2019 Norgren GmbH

4.2 Diagnostic

Indicators LED Status Description

Green Off No power

Green Solid Power OK

Green Flashing IO-Link Communications established

Red On * Refer to error table below

Error Event Code Detailed Device Status Fault Description Recommendation

0x5000 Device hardware fault Internal hardware fault Cycle power to unit. If error remains

contact Technical Support

0x183A IOLink PHY chip fault IO-Link hardware fault Check power supply voltage is within

specication

0x6320 Parameter error Demanded pressure outside of

unit specication

Check demanded pressure is

achievable.

UKLEETC002023293

011

VP50 IO-Link

02/21

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the speciications given in this document. (2019 - 9261a) © 2019 Norgren GmbH

5.0 Declaration of

Conformity

The current EMC Declaration of Conformity can now be found on the

Norgren Ltd website, along with all other product documentation.

Please visit: https://www.imi-precision.com/uk/en/technical-support

Norgren Ltd.

Cross Chancellor Street, Leeds West Yorkshire, LS6 2RT,

UK Registered in England No. 564656

Tel.: +44 (0) 1132 45 7587

Email: UK[email protected]

The data speciied above only serve to describe the product. No statements

concerning a certain condition or suitability for a certain application can be derived

from our information. The information given does not release the user from the

obligation of exercising judgement and veriication. It must be remembered

that our products are subject to a natural process of wear and ageing.

© This document, as well as the data, speciications andother

information presented in it are the sole property of Norgren. It may not

be reproduced or given to third parties without their consent.

Printed in England.

These instructions were originally written in English.

Part No. YM50006

For further information, scan this

QR code or visit

www.norgren.com

Norgren operates four global

centres of technical excellence

and a sales and service network

in 50 countries, as well as

manufacturing capability in Brazil,

China, Czech Republic, Germany,

India, Mexico UK and the USA.

For information on all Norgren

companies visit

www.norgren.com

Supported by distributors

worldwide.

Norgren, Buschjost, FAS, Herion,

Kloehn, Maxseal and Thompson

Valves are registered trademarks

of Norgren companies.

Due to our policy of continuous

development, Norgren reserve

the right to change speciications

without prior notice.

OM_VP50 IO-Link en/02/21

Selected Images used under

license from Shutterstock.com

Incorporating

Table of contents

Popular Media Converter manuals by other brands

TRENDnet

TRENDnet TFC-1000MGB - Intelligent 1000Mbps TX user guide

StarTech.com

StarTech.com ET90110WDM2 instruction manual

DeLOCK

DeLOCK 64221 user manual

Conair

Conair Travel Smart TS702CRC Instruction guide

Ross

Ross ADC-8032B user manual

Digital Barriers

Digital Barriers EDGEVIS HD-R700 Hardware installation guide