10

Reference Tools & Sample Calculations

The tables and samples below are for reference only. The professional sizing and installing the gas

line should always run the appropriate calculations before all installations.

CAUTION

Which Table to Use

• For NG installations with the initial supply pressure at point of delivery (at the meter, for example) is

less than 8” WC, use the 0.5” WC pressure drop table (Table 1).

• For NG installations with the initial supply pressure at point of delivery is greater than or equal to 8”

WC, use the 3.0” pressure drop table (Table 2).

• For all LP installation use (Table 3)

The inlet pressure must be at least 5” WC for NG or 8” WC for LP for all appliances in the gas system.

If the inlet gas pressure drops below 5” WC for NG or 8” WC for LP, the heater may continue to operate,

but the other appliances in the house may experience ame loss or ignition failure, which can result in gas

leakage into the home. Refer to the NFPA 54 for details.

Please contact Noritz for details. For corrugated stainless steel tubing (CSST) capacity tables, please

consult with the manufacturer.

Pipe

Size

Length (including ttings)

10' 20' 30' 40' 50' 60' 70' 80' 90' 100' 125'

(3m) (6m) (9m) (12m) (15m) (18m) (21m) (24m) (27m) (30m) (38m)

3/4" 360 247 199 170 151 137 126 117 110 104 92

1" 678 466 374 320 284 257 237 220 207 195 173

1 1/4" 1,390 957 768 657 583 528 486 452 424 400 355

1 1/2" 2,090 1,430 1,150 985 873 791 728 677 635 600 532

2" 4,020 2,760 2,220 1,900 1,680 1,520 1,400 1,300 1,220 1,160 1,020

2 1/2" 6,400 4,400 3,530 3,020 2,680 2,430 2,230 2,080 1,950 1,840 1,630

3" 11,300 7,780 6,250 5,350 4,740 4,290 3,950 3,670 3,450 3,260 2,890

4" 23,100 15,900 12,700 10,900 9,660 8,760 8,050 7,490 7,030 6,640 5,890

Table 1. For Less than 8” WC initial supply pressure

Maximum Natural Gas Delivery Capacity (0.5” Pressure Drop) [Schedule 40 Metallic Pipe]

Values in Table are in Cubic Feet of Gas per Hour (0.60 Specic Gravity, 0.5” Pressure Drop, inlet pressure less than 2psi). Contact your gas

supplier for BTU/Cubic Foot ratings. For simplication of your calculations, 1 Cubic Foot of Gas is approximately equivalent to 1000 BTU.

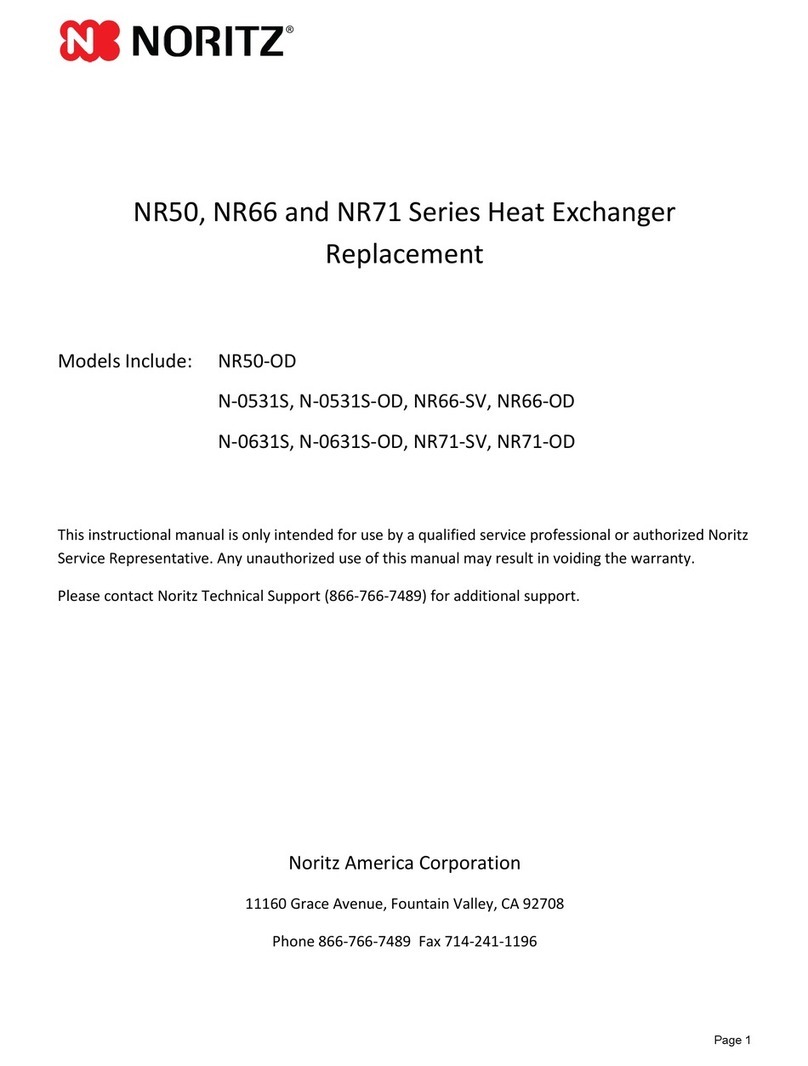

1. Size each outlet branch starting from the furthest

using the Btuh required and the length from the meter.

2. Size each section of the main line using the length to

the furthest outlet and the Btuh required by everything

after that section.

Sample Calculation - (Using 0.5” WC Pressure Drop Table)

Outlet A: 45' (13.5m) (Use 50' (15m)), 50,000 Btuh requires 1/2"

Outlet B: 40' (12m), 65,000 Btuh requires 1/2"

Section 1: 45' (13.5m) (Use 50' (15m)), 115,000 Btuh requires 3/4"

Outlet C: 30' (9m), 35,000 Btuh requires 1/2"

Section 2: 45' (13.5m) (Use 50' (15m)), 150,000 Btuh requires 3/4"

Outlet D: 25' (7.5m) (Use 30' (9m)), 25,000 Btuh requires 1/2"

Section 3: 45' (13.5m) (Use 50' (15m)), 175,000 Btuh requires 1"

Outlet E: 25' (7.5m) (Use 30' (9m)), 180,000 Btuh requires 3/4"

Section 4: 45' (13.5m) (Use 50' (15m)), 355,000 Btuh requires 1 1/4"

Meter

Noritz Tankless Gas Water Heater

(180,000 Btuh)

Clothes Dryer

(35,000 Btuh)

Barbecue

(50,000 Btuh)

Gas Range Stove

(65,000 Btuh)

10' (3m) 10' (3m)

10' (3m)

10' (3m)

5' (1.5m)

5' (1.5m)

5' (1.5m)

5' (1.5m)5' (1.5m) 5' (1.5m)

Gas Fireplace

(25,000 Btuh)

Section 3 Section 2 Section 1

Outlet A

Outlet B

Outlet C

Outlet D

Outlet E

Section 4