PSM04-20 Rev -, Effective Date: 08/27/20

Viton®, Krytox®are registered trademarks of Dupont Corp.

Norman Filter Company

9850 S. Industrial Drive • Bridgeview, Illinois 60455

Phone: 708-233-5521 • Fax: 708-430-55961

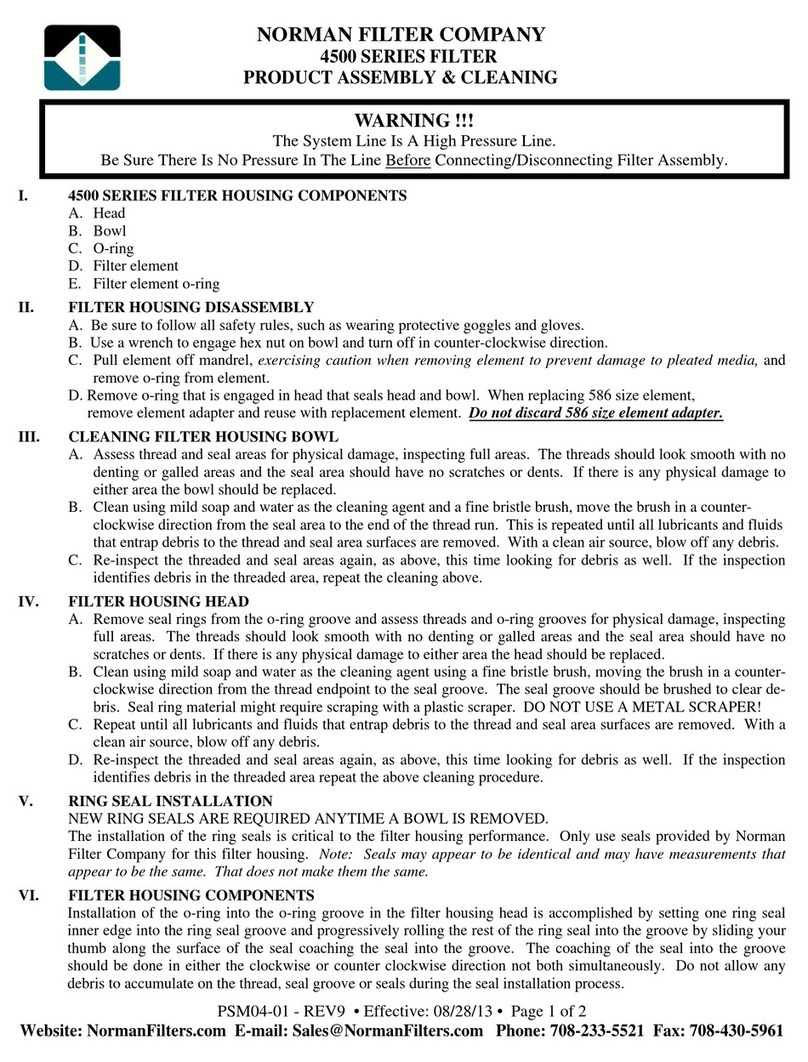

2.0c 4700 FILTER SERIES WITH PORT 11, 11J, 22, 23 DISASSEMBLY

2.1c Be sure to follow all safety rules, such as wearing protective eyewear and gloves.

2.2c Disconnect the filter assembly from the system supply line AFTER depressurization.

2.3c Secure filter assembly (case portion) in vise using flat area at the end of the cylinder.

NOTE: Exercise caution when removing element to prevent damage to pleated media. Scratches,

punctures, tears or otherwise damaging the filter element media will require replacement of the

element.

2.4c Use a suitable wrench to unscrew the Filter Housing Plug from the Filter Housing Case,

using the flat area at the other end of the cylinder as the connection point for the wrench.

Filter Housing Plug will have the Filter Element attached to it. Remove with it with caution

and set the Filter Housing Plug and Filter Element assembly aside. Be careful not to

damage the pleated filter media. Scratches, punctures, tears or otherwise damaging the

element will require replacement.

2.5c Remove the Filter Housing Case from the vise and set it aside. Secure the Filter Housing

Plug & Filter Element assembly to the vise. Use a suitable wrench to unscrew the Filter

Element from the Filter Housing Plug.

2.6c Remove Filter Element O-ring and discard.

2.7c Remove Filter Housing O-ring and then discard.

2.8c Glass Fiber and paper elements are not reusable and must be replaced.

3.0c 4700 FILTER SERIES WITH PORT 11, 11J, 22, 23 CLEANING

3.1c Stainless steel Filter Elements may be cleaned as follows:

3.2c Remove rough external dirt in a separate container with cleaning fluid. Acceptable

cleaning fluids can be but are not limited to acetone or mineral spirits.

3.3c Soak the filter for thirty minutes in unsoiled, high-quality cleaning fluid.

3.4c Following the soak, blow through the element (150 psi max.) from inside to outside with

clean compressed air or similar clean gas.

3.5c Remove any remaining water particles by dipping the filter in isopropyl alcohol.

3.6c Inspect element for uniform pleats. If there is any visible damage, the Filter Element is a

non-conforming product and requires replacement.

4.0c 4700 FILTER SERIES WITH PORT 11, 11J, 22, 23 PLUG CLEANING

4.1c Assess thread and seal areas for physical damage, inspecting areas in full. The threads

should look shiny and smooth with no denting or galled areas and the seal area should

have no scratches or dents. If there is any physical damage to either area the Filter

Housing Plug should be replaced.

4.2c Clean using an acceptable cleaning fluid and a fine bristle brush. Acceptable cleaning

fluids can be but are not limited to acetone or mineral spirits. Move the brush in a

counterclockwise direction from the seal area to the end of the thread run. This is

repeated until all lubricants and fluids that entrap debris to the thread and seal area

surfaces are removed. With a clean air source, blow off any debris.

4.3c Re-inspect the threaded and seal areas again, as above, this time looking for debris as

well. If the inspection identifies debris in the threaded area, repeat the cleaning above.

4.4c Visually inspect for the presence of a flow arrow marking and heat numbers on the Filter

Housing Plug. If either is missing the part is a non-conforming product.