NORSE PROFESSIONAL SK125 User manual

SK125

Electric Pressure Washer

OPERATION MANUAL

Read this manual carefully before use and keep it for future reference. Failure to do so

may result in injury, property damage and may void the warranty.

Products covered by this manual may vary in appearance, assembly, inclusions,

specications, description or packaging.

V 3.2

English Français Deutsch Italiano Español

SK125

© NØRSE

2© NØRSE

English

2 Contents

3 Quick Start Guide

5 Parts guide

7 General cleaning

8 Detergent

9 Drawing from a barrel

10 Patio brush and triangle brush

10 Post operation / storage

12 Safety Symbols

12 Safety and Warning Information

14 Troubleshooting

14 Technical Data

15 Disposal Regulations

15 Wiring diagram

16 CE Certication

16 - Français

31 - Deutsch

46 - Italiano

61 - Español

Contents Languages

Attach the wheels by slotting them into

the underside of the rear of the washer.

They will click into place and lock.

Quick Start Guide

Open the front of the washer by

releasing the catch.

SK125

© NØRSE 3

© NØRSE

English

2 Contents

3 Quick Start Guide

5 Parts guide

7 General cleaning

8 Detergent

9 Drawing from a barrel

10 Patio brush and triangle brush

10 Post operation / storage

12 Safety Symbols

12 Safety and Warning Information

14 Troubleshooting

14 Technical Data

15 Disposal Regulations

15 Wiring diagram

16 CE Certication

16 - Français

31 - Deutsch

46 - Italiano

61 - Español

Contents Languages

Attach the wheels by slotting them into

the underside of the rear of the washer.

They will click into place and lock.

Fit the hose reel to the brackets on the top side of the washer

using the supplied screws. The handle attaches to the reel

and is secured using the supplied screws. Slot the reel crank

handle into place.

Quick Start Guide

Open the front of the washer by

releasing the catch.

Install the quick connector lter by screwing it onto the water

inlet of the power washer.

These steps describe the quickest method to get your pressure washer up and running.

However, it is essential you fully read this manual to ensure you are familiar with the general

safety features, precautions and functions necessary to operate the product. Failure to do so

may result in injury and damage to your washer or personal items.

SK125

© NØRSE

4© NØRSE

English

Attach the hose from the reel to the spray gun.

Next, connect the spray gun lance attachment and

variable nozzle to the spray gun. A small amount of

lubrication can be applied to help tting.

1. Screw the quick hose connector on to

your garden hose and slide onto the quick

connector filter, it will “click” into place.

2. Plug in the washer to the mains power

supply.

Start Up:

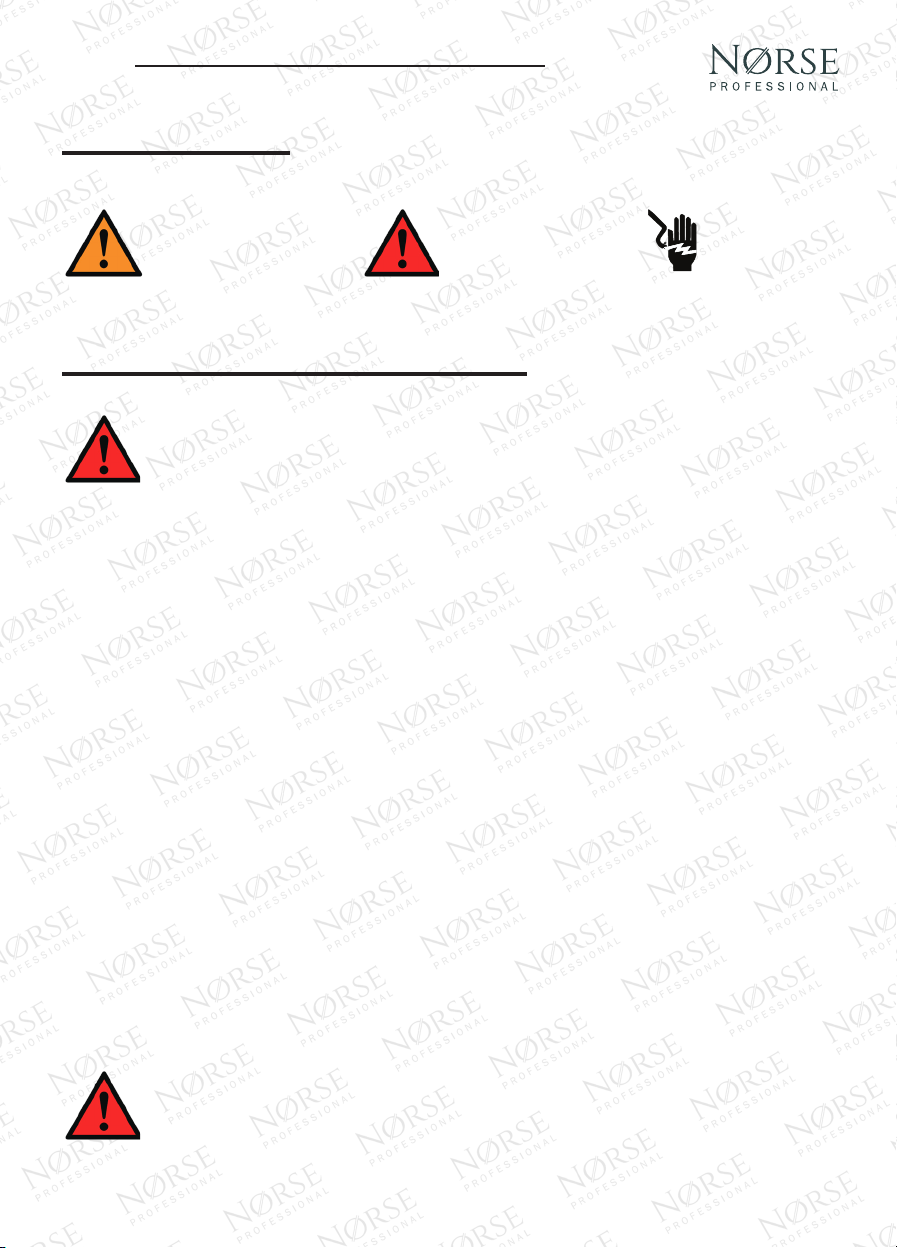

Stand clear of the unit taking care not to aim the

gun towards the pressure washer.

1. Release the safety button

2. Depress the trigger

3. Turn on the washer

Ø13

The variable nozzle has a wide range of uses and will deliver varying intensities of pressure depending

on your requirements. Twist the nozzle to change from a low pressure fan spray, ideal for large surfaces,

to a narrow jet of high pressure which will blast small areas for intense cleaning.

For detergent use, ll the tank ‘13’ before twisting the nozzle to the detergent position.

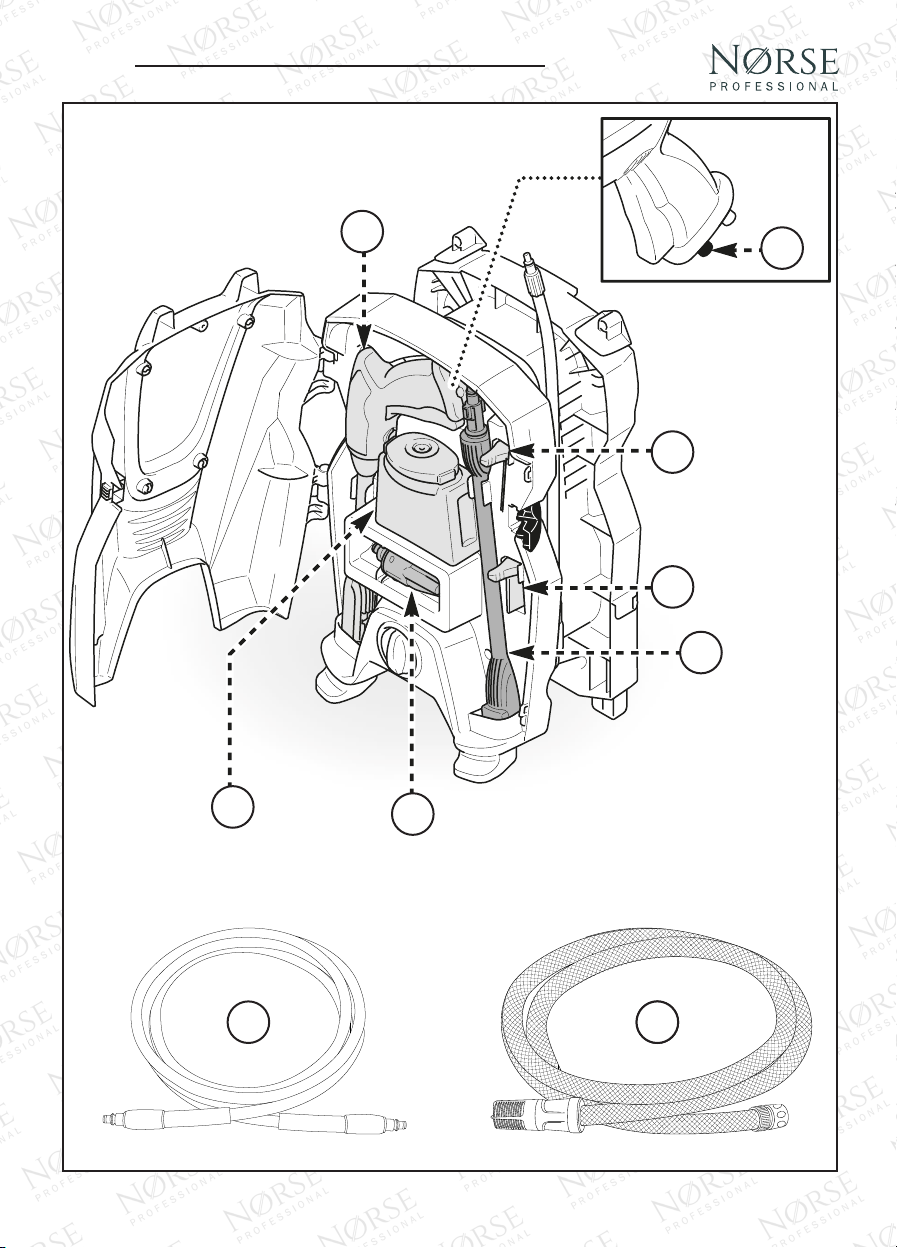

1. Hose reel

2. Handle

3. Reel crank handle

4. Quick connector filter

5. Quick hose connector

6. Wheels

7. Spray gun

8. Spray gun water inlet

9. Nozzle cleaning tool

10. Lubricant (certain models)

SK125

© NØRSE 5

© NØRSE

English

Before starting up the appliance check that the water supply hose is connected properly;

use of the appliance without water will damage it; do not cover the ventilation grilles when

the appliance is in use.

The variable nozzle has a wide range of uses and will deliver varying intensities of pressure depending

on your requirements. Twist the nozzle to change from a low pressure fan spray, ideal for large surfaces,

to a narrow jet of high pressure which will blast small areas for intense cleaning.

For detergent use, ll the tank ‘13’ before twisting the nozzle to the detergent position.

Parts guide

01

04

03

02

05

06

1. Hose reel

2. Handle

3. Reel crank handle

4. Quick connector filter

5. Quick hose connector

6. Wheels

7. Spray gun

8. Spray gun water inlet

9. Nozzle cleaning tool

10. Lubricant (certain models)

11. Spray gun lance

12. Variable nozzle

13. Detergent tank (certain models)

14. Filtered hose

15. Fiber extension hose

16. Rotary brush

17. Triangle brush

18. Patio brush

18a. Angle connector

19. 90 turbo nozzle

20. Wall mount brackets

17

18

18a 19

16

20

SK125

© NØRSE

6© NØRSE

English

07 08

09

10

11

12

13

Distance from Cleaning Surface

Another factor that determines the impact force of the water is the distance from the variable nozzle to

the cleaning surface

Angle to the Cleaning Surface

When spraying water against a surface, maximum impact is generated when the water strikes the

surface head on. However, this type of impact tends to cause dirt particles to embed in the surface,

thereby preventing the desired cleaning action. The optimum angle for spraying water against a surface

is 45 degrees.

Avoid Damaging Surfaces

Damage to surfaces occurs because the impact force of the water exceeds the durability of the surface.

Never use a narrow high impact stream or a turbo / rotary nozzle on a surface that is susceptible to

damage.

The surest way to avoid damaging surfaces:

1. Adjust the nozzle to a wide spray pattern.

2. Place the variable nozzle approximately 4-5 feet from and 45 degrees to the cleaning surface.

3. Vary the spray pattern, spray angle and the distance to the cleaning surface until optimum

cleaning efficiency is achieved without damaging the surface.

Looking After your Product

1. This pressure washer is not meant to pump hot water. Never connect to a hot water supply.

2. Never operate the unit for more than one minute without spraying water. This will cause a heat

build-up that can damage the pump.

3. Only use the nozzles supplied with the machine.

General cleaning

01

14

15

SK125

© NØRSE 7

© NØRSE

English

Distance from Cleaning Surface

Another factor that determines the impact force of the water is the distance from the variable nozzle to

the cleaning surface

Angle to the Cleaning Surface

When spraying water against a surface, maximum impact is generated when the water strikes the

surface head on. However, this type of impact tends to cause dirt particles to embed in the surface,

thereby preventing the desired cleaning action. The optimum angle for spraying water against a surface

is 45 degrees.

Avoid Damaging Surfaces

Damage to surfaces occurs because the impact force of the water exceeds the durability of the surface.

Never use a narrow high impact stream or a turbo / rotary nozzle on a surface that is susceptible to

damage.

The surest way to avoid damaging surfaces:

1. Adjust the nozzle to a wide spray pattern.

2. Place the variable nozzle approximately 4-5 feet from and 45 degrees to the cleaning surface.

3. Vary the spray pattern, spray angle and the distance to the cleaning surface until optimum

cleaning efficiency is achieved without damaging the surface.

Looking After your Product

1. This pressure washer is not meant to pump hot water. Never connect to a hot water supply.

2. Never operate the unit for more than one minute without spraying water. This will cause a heat

build-up that can damage the pump.

3. Only use the nozzles supplied with the machine.

A cleaning tool is supplied to remove any debris from the nozzle before and after use.

General cleaning

SK125

© NØRSE

8© NØRSE

English

The following cleaning procedure will ensure that you achieve the most benecial results in the shortest

amount of time.

Surface preparation

Clear the working area and make sure that all windows and doors are closed tightly. Make sure that all

plants and trees adjacent to the cleaning area are protected by a drop cloth.

Initial high pressure rinse

The next step is to spray the cleaning surface with water to clear off any dirt or grime that may have

collected on the surface. If you use detergent, this will allow your detergent to attack the dirt that has

worked its way into the cleaning surface. Before triggering the gun, adjust the nozzle to a wide spray

pattern and slowly adjust to the desired spray pattern. This will help you avoid applying too much

pressure to the surface that could cause damage.

Detergent application

Only use detergents formulated for pressure washers. Test the detergent in an inconspicuous area before

use. Follow the manufacturer’s label directions for mixing the correct concentrations of detergent to

water.

Detergent

4. Never store the pressure washer outdoors or where it could freeze. The pump will be seriously

damaged. Any components with water left inside will also be damaged, e.g. the pressure gun.

5. Release the trigger when changing the spray pattern. Failure to do so could result in damage.

6. Do not operate the pressure washer with the inlet water screen removed. Be sure to keep the

screen clear of debris and sediment.

7. Make sure you clean the machine every three months and inspect the filter and the nozzle prior

to every use, ensuring there is no debris that may impair use.

Drawing from a barrel

First ensure the machine is switched off before connecting / disconnecting any hoses or attachments.

Instead of attaching the hose from pump to tap, use the supplied hose and lter set placing the lter end

in the water supply.

It is advised that the water supply is on the same level as the washer. If you struggle to get initial suction,

remove the outlet hose from the pump and try drawing again - this reduces the pressure on the pump

making it easier to draw. Once owing, turn engine off and reconnect outlet hose before re-starting.

1. Unscrew the top of detergent tank and fill with detergent.

2. Put the top of detergent applicator back on.

3. Set variable nozzle to detergent feature.

4. Apply the detergent so it thoroughly covers the cleaning surface. Apply from bottom to top to

prevent the detergent from sliding down and streaking.

5. Allow the detergent to remain on the surface for a few minutes. This is a good time to use a

brush to lightly scrub heavily soiled areas. Never allow detergent to dry on the cleaning surface.

6. Rotate the variable nozzle from the detergent setting to the wide angle fan spray.

7. Rinse detergent from surface.

8. Rinse the detergent tank with clean water following each use.

9. Final rinse. Make sure you thoroughly rinse the surface and that all detergent has been removed.

Shut down

1. Make sure all detergent is flushed from the system.

2. Turn off the motor.

3. Turn off the water supply.

4. Trigger the spray gun to de-pressurise the system.

5. After each use, wipe all surfaces of the pressure washer with a clean, damp cloth.

SK125

© NØRSE 9

© NØRSE

English

The following cleaning procedure will ensure that you achieve the most benecial results in the shortest

amount of time.

Surface preparation

Clear the working area and make sure that all windows and doors are closed tightly. Make sure that all

plants and trees adjacent to the cleaning area are protected by a drop cloth.

Initial high pressure rinse

The next step is to spray the cleaning surface with water to clear off any dirt or grime that may have

collected on the surface. If you use detergent, this will allow your detergent to attack the dirt that has

worked its way into the cleaning surface. Before triggering the gun, adjust the nozzle to a wide spray

pattern and slowly adjust to the desired spray pattern. This will help you avoid applying too much

pressure to the surface that could cause damage.

Detergent application

Only use detergents formulated for pressure washers. Test the detergent in an inconspicuous area before

use. Follow the manufacturer’s label directions for mixing the correct concentrations of detergent to

water.

4. Never store the pressure washer outdoors or where it could freeze. The pump will be seriously

damaged. Any components with water left inside will also be damaged, e.g. the pressure gun.

5. Release the trigger when changing the spray pattern. Failure to do so could result in damage.

6. Do not operate the pressure washer with the inlet water screen removed. Be sure to keep the

screen clear of debris and sediment.

7. Make sure you clean the machine every three months and inspect the filter and the nozzle prior

to every use, ensuring there is no debris that may impair use.

Drawing from a barrel

First ensure the machine is switched off before connecting / disconnecting any hoses or attachments.

Instead of attaching the hose from pump to tap, use the supplied hose and lter set placing the lter end

in the water supply.

It is advised that the water supply is on the same level as the washer. If you struggle to get initial suction,

remove the outlet hose from the pump and try drawing again - this reduces the pressure on the pump

making it easier to draw. Once owing, turn engine off and reconnect outlet hose before re-starting.

1. Unscrew the top of detergent tank and fill with detergent.

2. Put the top of detergent applicator back on.

3. Set variable nozzle to detergent feature.

4. Apply the detergent so it thoroughly covers the cleaning surface. Apply from bottom to top to

prevent the detergent from sliding down and streaking.

5. Allow the detergent to remain on the surface for a few minutes. This is a good time to use a

brush to lightly scrub heavily soiled areas. Never allow detergent to dry on the cleaning surface.

6. Rotate the variable nozzle from the detergent setting to the wide angle fan spray.

7. Rinse detergent from surface.

8. Rinse the detergent tank with clean water following each use.

9. Final rinse. Make sure you thoroughly rinse the surface and that all detergent has been removed.

Shut down

1. Make sure all detergent is flushed from the system.

2. Turn off the motor.

3. Turn off the water supply.

4. Trigger the spray gun to de-pressurise the system.

5. After each use, wipe all surfaces of the pressure washer with a clean, damp cloth.

Ø13

SK125

© NØRSE

10 © NØRSE

English

Post operation / storage

• Do not store the pressure washer outdoors or in a location where it may freeze. Any water left

in the machine, gun or any other components will expand if allowed to freeze, causing damage.

• Always turn the motor off before turning the water supply off.

• Never disconnect the hose from machine while the system is pressurized. To de-pressurise,

turn the motor off, then turn the water supply off and squeeze spray gun trigger 2-3 times.

Shut down:

1. Turn off the washer

2. Release the gun trigger

3. Lock the safety button

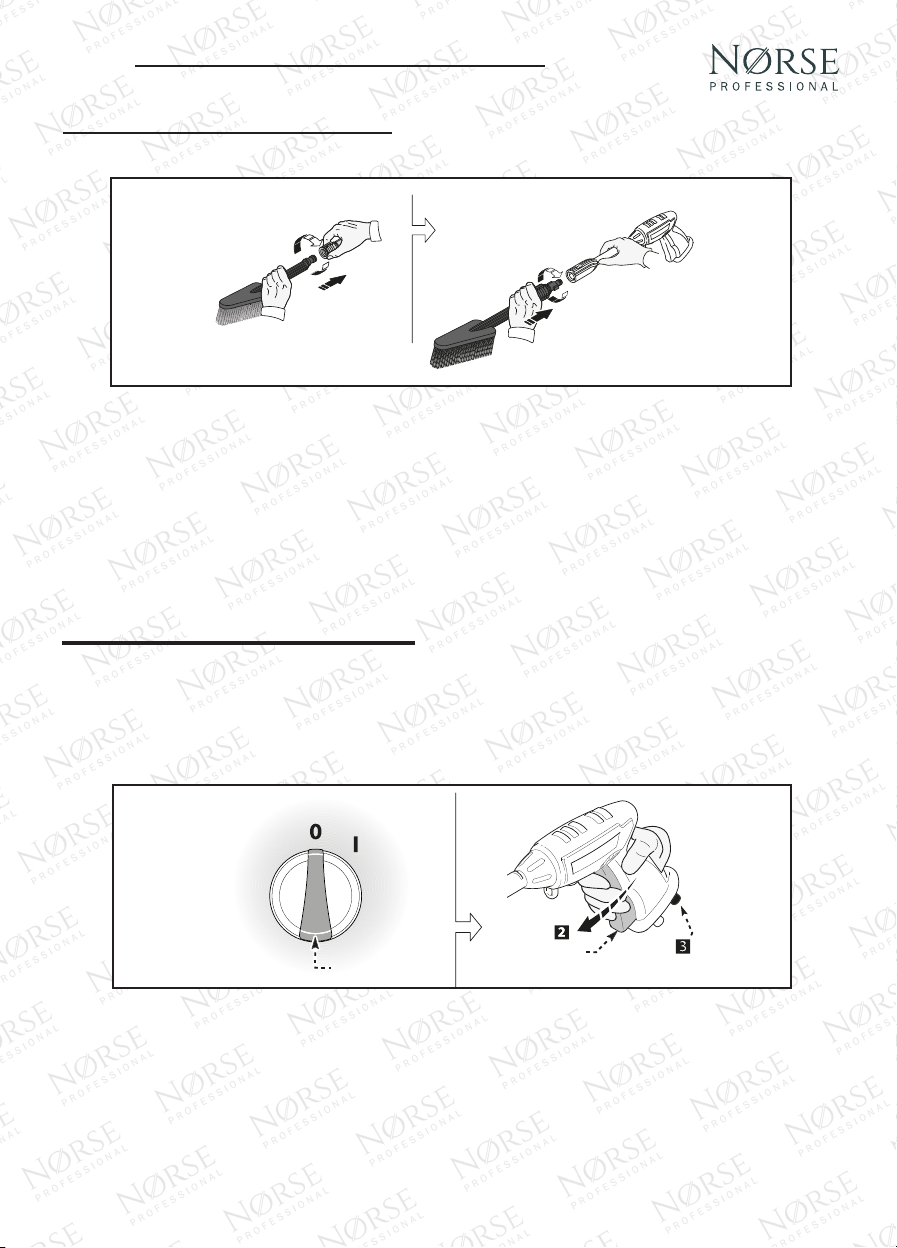

Patio brush and triangle brush

The triangle brush is specially designed to clean

rims and the wheel of vehicles.

Screw the adaptor on the triangle brush. Then

align the tongues of the adaptor with the grooves

of the spray gun and insert it.

Securely t the accessory by turning it clockwise

and let it lock into place.

Wall Mounting

SK125

© NØRSE 11

© NØRSE

English

Patio brush and triangle brush Wall Mounting

R L

RL

The SK125 includes two brackets which can be used to hang your

pressure washer on the wall.

Drill the holes for the brackets as shown. Ensure you mount to a solid

wall.

Remove the wheels from your pressure washer.

Hang your pressure washer on the brackets via the designated cut

outs on the back of the washer. The brackets also have integrated

clips on the sides which can be used to hang your hose and lance.

40mm 40mm

200mm

08mm

08mm

SK125

© NØRSE

12 © NØRSE

English

Safety Symbols

Safety and Warning Information

CAUTION: Indicates a

potentially hazardous

situation which, if not

avoided, may result in

minor or moderate injury.

WARNING: Indicates a

potentially hazardous

situation which, if not

avoided, could result in

death or serious injury.

WARNING: The electrical supply connection must be made by a qualied person and comply

with IEC 60364-1. The electric supply to this machine should include either a residual-

current device / circuit breaker that will interrupt the supply if the current to earth exceeds

30 mA for 30 ms.

Risk of

electrocution

WARNING: When the machine is used, the following precautions should always be

considered:

• To reduce the risk of injury, close supervision is necessary when the machine is used near

children.

• Follow all safety codes as well as the Occupational Safety and Health Act (OSHA).

• Ensure safety devices are operating properly before using the machine. Do not remove or

modify any part of the gun or main unit of the machine.

• Stay alert at all times when using the machine and always hold the gun firmly when operating

the machine.

• Do not operate the machine when fatigued, suffering from reduced physical, sensory or mental

capabilities or whilst under the influence of alcohol or drugs.

• Keep the operation area clear of all electrical equipment, persons, animals and pets. Do not

leave the machine unattended when setup for use. Always engage the trigger safety latch after

use.

• Do not point the pressure gun at anyone whilst the unit is connected to a water supply.

• Do not overreach or stand on an unstable support. Keep good footing and balance at all times.

• Use a cleaning agent supplied or recommend by the manufacturer. Always protect your eyes,

skin, and respiratory system from detergent use.

• If your eyes (or any other sensitive part of your body) comes into contact with detergent, rinse

with plenty of clean water.

• In the event of an accident, switch off the machine, pull the plug from the socket outlet and

disconnect the water supply.

• Always wear safety goggles, ear protection and protective clothing even when performing

maintenance.

• Never put hands or fingers over the spray tip while operating the unit.

• Never try to stop or deflect leaks with any body part.

SK125

© NØRSE 13

© NØRSE

English

WARNING: The electrical supply connection must be made by a qualied person and comply

with IEC 60364-1. The electric supply to this machine should include either a residual-

current device / circuit breaker that will interrupt the supply if the current to earth exceeds

30 mA for 30 ms.

Risk of

electrocution

• To reduce the risk of injury, close supervision is necessary when the machine is used near

children.

• Follow all safety codes as well as the Occupational Safety and Health Act (OSHA).

• Ensure safety devices are operating properly before using the machine. Do not remove or

modify any part of the gun or main unit of the machine.

• Stay alert at all times when using the machine and always hold the gun firmly when operating

the machine.

• Do not operate the machine when fatigued, suffering from reduced physical, sensory or mental

capabilities or whilst under the influence of alcohol or drugs.

• Keep the operation area clear of all electrical equipment, persons, animals and pets. Do not

leave the machine unattended when setup for use. Always engage the trigger safety latch after

use.

• Do not point the pressure gun at anyone whilst the unit is connected to a water supply.

• Do not overreach or stand on an unstable support. Keep good footing and balance at all times.

• Use a cleaning agent supplied or recommend by the manufacturer. Always protect your eyes,

skin, and respiratory system from detergent use.

• If your eyes (or any other sensitive part of your body) comes into contact with detergent, rinse

with plenty of clean water.

• In the event of an accident, switch off the machine, pull the plug from the socket outlet and

disconnect the water supply.

• Always wear safety goggles, ear protection and protective clothing even when performing

maintenance.

• Never put hands or fingers over the spray tip while operating the unit.

• Never try to stop or deflect leaks with any body part.

WARNING: This is a double-insulated machine so two systems of insulation are provided

instead of grounding. No grounding means are provided for a double-insulated machine, nor

should grounding means be added to the machine. Servicing a double-insulated machine

requires extreme care and knowledge of the system. It should be done only by qualied

service personnel. Replacement parts for a double-insulated machine must be identical to

the original parts.

WARNING: To reduce the risk of electrocution, keep all connections dry and off the

ground. Do not touch the plug with wet hands.

WARNING: Do not use the machine if the supply cord or any important parts of the

machine are damaged (e.g. safety devices, high pressure hoses, etc).

WARNING: Do not use an inlet pressure that exceeds the operating pressure of any of the parts (hoses,

ttings, etc). Ensure all equipment and accessories are rated to withstand the maximum working

pressure of the unit.

WARNING: Never spray ammable liquids or use the pressure washer in areas containing combustible

dust, liquids or vapours.

WARNING: Do not spray electrical apparatus and wiring.

WARNING: To ensure machine safety, please only use original spare parts (including nozzles) from the

manufacturer or approved by the manufacturer.

WARNING: Make sure the inlet water is maintained between 0.01MPa and 0.4MPa.

WARNING: If the mains cable is damaged it must be replaced by the manufacturer, or its service agent

or similarly qualied person to avoid a hazard or injury.

WARNING: Use only extension cords intended for outdoor use and that have an electrical rating equal to

or more than the rating of the machine. Examine the cord before using and replace it if damaged. Keep

the cord away from heat and sharp edges. It is recommended that you use a cord reel that keeps the

socket at least 60mm above the ground.

CAUTION: Keep the hose away from sharp objects. Bursting hoses may cause injury. Examine the hose

regularly and replace it if damaged. Do not attempt to repair a damaged hose.

• Never disconnect the high pressure outlet hose from the machine while the system is pressurised. To

de-pressurise machine, turn power and water supply off, then press gun trigger 2-3 times.

• Never operate the machine without all of the components properly connected to the machine (handle,

gun / lance assembly, nozzle, etc).

• Never operate the pressure washer with broken or missing parts. Check equipment regularly and

repair or replace worn or damaged parts immediately.

SK125

© NØRSE

14 © NØRSE

English

Troubleshooting

Technical Data

Symptom Possible Cause(s) Corrective Actions

No detergent

suction 1. Detergent tank is clogged 1. Clean detergent tank with warm water

Pressure washer

does not start up

1. Unit is pressurised

2. Plug is not connected correctly or

electrical supply is damaged / faulty

3. Thermal safety switch has tripped

1. Clean water inlet

2. Check that connections are properly

tightened

3. Switch off unit and allow to cool down

Pump does not

reach necessary

pressure

1. Water inlet is clogged

2. Pump sucking air from hose

connections

3. Variable spray nozzle is worn or not

correct size

4. Unloader / valves are clogged/ worn

1. Clean quick connector filter

2. Check that connections are properly

tightened

3. Call the dealer

4. Call the dealer

Fluctuating

pressure

1. Pump is sucking air

2. Clogged nozzle

3. Valves dirty, worn or clogged

4. Water seals worn

1. Check that hoses and connections are

tight

2. Clean with tip cleaner

3. Call the dealer

4. Call the dealer

Motor stops

suddenly 1. Thermal safety switch has tripped

due to overheating 1. Check mains supply voltage

corresponds to specifications

Item SK125

Working pressure 11.8 MPa / 118 BAR / 1750 PSI

Allowable pressure 16 MPa / 160 BAR / 2350 PSI

Maximum ow rate 460 Litres / hour

Motor capacity 2200 Watt

Power supply voltage 240V ~ 50HZ

Intake water pressure Min 0.1MPa / Max 1MPa

Max input temperature 50 °

Motor insulation rating Class F

Dimensions 355 x 255 x 950mm

Weight 11.5Kg

SK125

© NØRSE 15

© NØRSE

English

Symptom Possible Cause(s) Corrective Actions

No detergent

suction 1. Detergent tank is clogged 1. Clean detergent tank with warm water

Pressure washer

does not start up

1. Unit is pressurised

2. Plug is not connected correctly or

electrical supply is damaged / faulty

3. Thermal safety switch has tripped

1. Clean water inlet

2. Check that connections are properly

tightened

3. Switch off unit and allow to cool down

Pump does not

reach necessary

pressure

1. Water inlet is clogged

2. Pump sucking air from hose

connections

3. Variable spray nozzle is worn or not

correct size

4. Unloader / valves are clogged/ worn

1. Clean quick connector filter

2. Check that connections are properly

tightened

3. Call the dealer

4. Call the dealer

Fluctuating

pressure

1. Pump is sucking air

2. Clogged nozzle

3. Valves dirty, worn or clogged

4. Water seals worn

1. Check that hoses and connections are

tight

2. Clean with tip cleaner

3. Call the dealer

4. Call the dealer

Motor stops

suddenly 1. Thermal safety switch has tripped

due to overheating 1. Check mains supply voltage

corresponds to specifications

Disposal Regulations

Do not dispose of electrical machines as unsorted municipal waste, use separate collection facilities.

Contact your local government for information regarding the collection systems available. If electrical

machines are disposed of in landlls or dumps, hazardous substances can leak into the groundwater and

get into the food chain, damaging your health and well-being.

For transportation safety, the machine should comply with ISTA.

Wiring diagram

© NØRSE

SK125

© NØRSE

16

English

We hereby declare that the machine described below complies with the relevant basic safety and health

requirements of the EU Directives, both in its basic design and construction as well as in the version put

into circulation by us. This declaration shall cease to be valid if the machine is modied without our prior

approval.

The undersigned: Michael S McQuaide

as authorised by: Union Mart Ltd

Declares that

Description: Electric Pressure Washer

Identication code: NØRSE SK125

Conforms to the following European Directives:

2006/42/EG, 2006/95/EG, 2011/65/EG, 2002/96/EG, 2004/108/EG, 2000/14/EG

--

And are manufactured in accordance to the following standards or standardised documents:

EN 60335-1; EN 60335-2-79; EN 55014-1; EN55014-2; EN 61000-3-2; EN 61000-3-3; EN 61000-3-11;

EN 60704-1

Sound power level: Measured: 93 dB (A) – Guaranteed: 94 dB (A)

CE marking was afxed

Notied body: TÜV SÜD Product Service GmbH

The technical documentation is kept by: Union Mart Ltd

Date: 02/12/19

Signed:

Michael S McQuaide

Chief Executive Ofcer

Name and address of the manufacturer:

Union Mart Ltd, Company No. 8384155.

Registered address: Unit 15, Brickeld Industrial Estate Brickeld Lane, Chandler’s Ford, Eastleigh,

SO53 4DR

CE Certication

SK125

Nettoyeur à Pression Electrique

MANUEL D’UTILISATION

Lisez attentivement ce manuel avant de l’utiliser et conservez-le pour vous y référer

ultérieurement. Le non-respect de ces consignes peut entraîner des blessures, des

dommages matériels et peut entraîner l’annulation de la garantie. Les produits couverts

par ce manuel peuvent varier en termes d’apparence, d’assemblage, d’inclusions, de

spécications, de description ou d’emballage.

© NØRSE© NØRSE

We hereby declare that the machine described below complies with the relevant basic safety and health

requirements of the EU Directives, both in its basic design and construction as well as in the version put

into circulation by us. This declaration shall cease to be valid if the machine is modied without our prior

approval.

The undersigned: Michael S McQuaide

as authorised by: Union Mart Ltd

Declares that

Description: Electric Pressure Washer

Identication code: NØRSE SK125

Conforms to the following European Directives:

2006/42/EG, 2006/95/EG, 2011/65/EG, 2002/96/EG, 2004/108/EG, 2000/14/EG

--

And are manufactured in accordance to the following standards or standardised documents:

EN 60335-1; EN 60335-2-79; EN 55014-1; EN55014-2; EN 61000-3-2; EN 61000-3-3; EN 61000-3-11;

EN 60704-1

Sound power level: Measured: 93 dB (A) – Guaranteed: 94 dB (A)

CE marking was afxed

Notied body: TÜV SÜD Product Service GmbH

The technical documentation is kept by: Union Mart Ltd

Date: 02/12/19

Signed:

Michael S McQuaide

Chief Executive Ofcer

Name and address of the manufacturer:

Union Mart Ltd, Company No. 8384155.

Registered address: Unit 15, Brickeld Industrial Estate Brickeld Lane, Chandler’s Ford, Eastleigh,

SO53 4DR

SK125

Nettoyeur à Pression Electrique

MANUEL D’UTILISATION

Lisez attentivement ce manuel avant de l’utiliser et conservez-le pour vous y référer

ultérieurement. Le non-respect de ces consignes peut entraîner des blessures, des

dommages matériels et peut entraîner l’annulation de la garantie. Les produits couverts

par ce manuel peuvent varier en termes d’apparence, d’assemblage, d’inclusions, de

spécications, de description ou d’emballage.

Français

SK125

© NØRSE

18 © NØRSE

Français

18 Contenus

19 Guide de démarrage rapide

21 Guide des pièces détachées

23 Nettoyage général

24 Détergent

25 Extraire du cylindre

26 Brosse de patio et brosse triangulaire

26 Après utilisation / rangement

28 Symboles de sécurité

28 Informations sur la sécurité et les avertissements

30 Dépannage

30 Données techniques

31 Règlements sur l’élimination des déchets

31 Schéma de câblage

32 Certication CE

Contenus

SK125

© NØRSE 19

© NØRSE

Français

18 Contenus

19 Guide de démarrage rapide

21 Guide des pièces détachées

23 Nettoyage général

24 Détergent

25 Extraire du cylindre

26 Brosse de patio et brosse triangulaire

26 Après utilisation / rangement

28 Symboles de sécurité

28 Informations sur la sécurité et les avertissements

30 Dépannage

30 Données techniques

31 Règlements sur l’élimination des déchets

31 Schéma de câblage

32 Certication CE

Fixez les roues en les emboîtant dans la

partie inférieure de l’arrière de la machine.

Elles s’enclenchent et se verrouillent.

Fixez l’enrouleur de tuyau sur les supports situés sur la face

supérieure de la pièce en utilisant les vis fournies. La poignée se

xe sur l’enrouleur et est xée à l’aide des vis fournies. Mettez la

manivelle du dévidoir en place.

Guide de démarrage rapide

Ouvrez l’avant du nettoyeur en libérant le

loquet.

Installez le ltre à raccord rapide en le vissant sur l’entrée d’eau de

la pièce mécanique.

Il est essentiel que vous lisiez entièrement ce manuel pour vous familiariser avec les

caractéristiques générales de sécurité, les précautions et les fonctions nécessaires au

fonctionnement du produit. Le non-respect de ces consignes peut entraîner des blessures

et des dommages sur votre nettoyeur ou vos articles personnels.

SK125

© NØRSE

20 © NØRSE

Français

Fixez le tuyau du dévidoir au pistolet de pulvérisation.

Ensuite, connectez la xation de la lance du pistolet

pulvérisateur et la buse variable au pistolet pulvérisateur.

Une petite quantité de lubriant peut être appliquée pour

faciliter le montage.

1. Vissez le raccord rapide sur votre tuyau

d’arrosage et faites-le glisser sur le filtre du

raccord rapide, il s’enclenchera pour se mettre

en place.

2. Branchez la pièce sur l’alimentation électrique

Pour commencer :

Éloignez-vous de l’unité en prenant soin de ne pas

pointer le pistolet vers le nettoyeur à pression.

1. Relâchez le bouton de sécurité

2. Appuyer sur la gâchette

3. Allumer la machine

Ø13

La buse variable a de nombreuses utilisations et délivrera des intensités de pression variables en fonction de vos

besoins. Tournez la buse pour passer d’un jet en éventail à basse pression, idéal pour les grandes surfaces, à un jet

étroit à haute pression qui soufera de petites zones pour un nettoyage intense.

Pour l’utilisation de détergent, remplissez le réservoir ‘13’ avant de tourner la buse en position détergent.

Table of contents

Languages:

Other NORSE PROFESSIONAL Pressure Washer manuals

Popular Pressure Washer manuals by other brands

Briggs & Stratton

Briggs & Stratton Electric Pressure Washer Operator's manual

Nilfisk-Advance

Nilfisk-Advance P 160.2-15 SUPER PRO X-TRA operating instructions

GÜDE

GÜDE GHD 100 Translation of original operating instructions

STERWINS

STERWINS 135C EPW.4 Assembly, Use, Maintenance Manual

Kärcher

Kärcher K 2.250 instructions

Craftsman

Craftsman 580.751651 owner's manual