North American Tool Industries 9409 Operating instructions

8809409 02/13

PAINT SPRAY GUN

DO NOT RETURN TO STORE

Please call 800-348-5004 for

parts and service

CALIFORNIA PROPOSITION 65

WARNING: You can create dust

when you cut, sand, drill or grind

materials such as wood, paint,

metal, concrete, cement, or other

masonry. This dust often

contains chemicals known to

cause cancer, birth defects, or

other reproductive harm. Wear

protective gear.

WARNING: This product or its

power cord may contain

chemicals, including lead,

known to the State of California

to cause cancer and birth

defects or other reproductive

harm. Wash hands after

handling.

Important!

When using equipment, a few

safety precautions must be

observed to avoid injuries and

damage. Please read the complete

operating manual with due care.

Keep this manual in a safe place,

so that the information

is available at all times. If you

give the equipment to any other

person, give them these

operating instructions as well.

We accept no liability for

damage or accidents which

arise due to non-observance of

these instructions and the

safety information herein.

SPECIFICATIONS

Standard Nozzle: 2.0mm

Avg. Air Consumption: 7 CFM

Air Pressure: 50-90 PSI

Pattern Width: 9 inch

Paint Capacity: 32 oz.

CAUTION:

FOR YOUR OWN SAFETY,

READ INSTRUCTION

MANUAL COMPLETELY AND

CAREFULLY BEFORE

OPERATING THIS GENERAL

PURPOSE SPRAY GUN.

Any failures made in

following the safety

regulations and instructions

may result in an electric

shock, fire and/or serious

injury.

SAFETY

INSTRUCTIONS

Keep work area clean and

well lit. Cluttered, dim work

areas invite accidents.

Observe work area

conditions. Do not use the

tool in the presence of flames

or flammable liquids, gases,

or dust.

Keep children away.

Children must never be

allowed in the work area. Do

not let them handle

machines, tools, extension

cords, or air hoses.

Store idle equipment. When

not in use, the tool should be

stored in a safe, dry location

out of the reach of children.

Use the right tool for the

job. Do not attempt to force a

tool or attachment to do a job

that it was not intended to do.

The tool will do the job better

and safer at the rate at which

it was intended.

Dress properly. Do not wear

loose clothing or jewelry as

they can be caught in moving

Model: 9409

For Customer Service: Call 1-800-348-5004 or Email feedback@natitools.com

1

2

parts. Protective, electrically

non-conductive clothes and

non-skid footwear are

recommended when working.

Contain long hair.

Do not overreach. Keep proper

footing and balance at all times.

Do not reach over or across

running tools or air hoses.

Disconnect air hoses and

release any built-up pressure.

Never service or disassemble

the air sander with the air hose

attached. Always release any

built-up air even after

disconnecting the hose.

Disconnect the air sander when

not in use.

Avoid unintentional starting.

Be sure the trigger is in the OFF

position before connecting the

air supply. Do not carry the tool

with your finger on the trigger,

whether it is attached to the air

source or not.

Stay alert. Watch what you are

doing and use common sense

when operating this tool. Do not

use this tool while tired or under

the influence of drugs, alcohol,

or medication. A moment of

inattention while operating this

tool increases the risk of injury.

Use clean, dry, regulated,

compressed air at 90 PSI.

Never use oxygen, carbon

dioxide, combustible gases, any

other bottled gas as a power

source for this tool.

Check for damaged parts.

Before using any tool, any part

that appears damaged should be

carefully checked to determine

that it will operate properly and

perform its intended function.

Check for misalignment or

binding of moving parts,

breakage of parts, and any other

condition that may affect the

tool’s operation. If damaged,

have the tool serviced before

using. Do not use the tool if the

trigger does not operate properly.

Replacement parts and

accessories. This product is to

be serviced by a qualified

technician. When servicing, use

only identical replacement parts.

Only use accessories intended

for use with this tool. Use of any

other parts will void the warranty.

Maintenance. For your safety,

this product should be serviced

or repaired regularly by a

qualified technician.

Do not operate the spray gun

near open flames, pilot lights,

heaters, or any other heat

source. Make sure you have

adequate ventilation. Most

solvents and paints are

extremely flammable, especially

when sprayed. Never smoke

cigarettes in the same room you

are working in.

Paints and solvents may be

harmful or fatal if swallowed or

inhaled. Always use a respirator

when spraying. Avoid prolonged

skin contact with solvents or

paints as they will irritate skin.

After contact, immediately wash

off exposed

area with hot, soapy water.

Check all spray gun seals and

connections. Before use, make

sure the lid is fully tightened on

the cup, ensure that the screws

and nuts are correctly tightened,

and make sure the air hose is

securely fastened and does not

leak.

WARNING

Never point the paint gun at

yourself or any other person or

animal. Solvents and diluting

agents can cause burns.

WARNING

The warnings, cautions, and

instructions discussed in this

instruction manual cannot

possibly cover all conditions and

situations that may occur. It must

be understood by the operator

that common sense and caution

are factors that cannot be built

into this product, but must be

supplied by the operator.

OPERATION

1. Fluid cup, container, and air

hose should be connected

tightly to the spray gun.

2. Adjust the air pressure

according to the viscosity and

type of paint. An air pressure

between 50 and 90 PSI is

recommended.

3. A spraying distance of 10

inches is recommended.

ADJUSTMENTS

The desired pattern, volume of

fluid output, and fine

feedback@natitools.com

3

atomization can easily be

obtained by regulating the

pattern adjusting knob and fluid

adjusting knob.

1. Adjusting pattern:

•Turn the pattern adjusting

knob to the left will make the

spray pattern wider.

2. Adjusting the volume of

fluid output:

•Turning the fluid adjusting

knob clockwise will reduce

the volume of fluid output,

and turning it

counterclockwise will

increase fluid output.

CLEANING AND

MAINTENANCE

•Be extremely careful not to

damage the air cap, fluid

nozzle, or fluid needle.

•Use the brush with thinner to

clean the air cap, fluid nozzle,

and other parts. Never immerse

the spray gun completely in

thinner or solvent.

•Spray thinner to clean out the

paint passageway.

• When reassembling, always

clean the tool in order to

prevent dust from sticking.

•The packing seat should not

be tight enough that it interferes

with the free movement of the

needle, but secure enough to

prevent leakage.

feedback@natitools.com

4

Adjust paint viscosityPaint viscosity is excessively high

Increase air pressure

Air pressure from the square bore of

the air cap gets excessively low

Adjust paint viscosityPaint viscosity is too thin

Adhesion of solid dirt at the top of the

fluid nozzle

Tighten the coupling nut

Air mixing caused by a loosening of

the coupling nut of the paint cup

Tighten air cap

Loose air cap

Replace the part with a new one

Clearance between nozzle outside

diameter and the center bore of the air

cap gets worn wider

Thick Pattern

Reduce the air pressure

Air pressure from the square bore of

air cap is critically high

Narrow Pattern

Dirt inside the square bore must

be cleaned

A portion of the square bore of the air

cap is clogged

Crescent Pattern

Dirt inside the square bore must

be cleaned. (Needle or wire must

not be used)

A portion of square bore of air cap is

clogged

One-sided Pattern

Replace O-Ring with a new one

or tighten the packing screw

Air gets mixed with paint in the paint

passage caused by the needle packing

being worn out

Paint Breaking

Corrective ActionPossible Cause(s)Symptom

feedback@natitools.com

5

North American Tool Industries (NATI) makes every effort to ensure that this product meets high

quality and durability standards. NATI warrants to the original retail consumer a 1-year limited

warranty from the date the product was purchased at retail and each product is free from defects in

materials. Warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence,

or accidents, repairs or alterations, or a lack of maintenance. NAT shall in no event be liable for death,

injuries to persons or property, or for incidental, special, or consequential damages arising from the

use of our products. To receive service under warranty, the original manufacturer part must be

returned for examination by an authorized service center. Shipping and handling charges may apply. If

a defect is found, NATI will either repair or replace the product at its discretion.

DO NOT RETURN TO STORE

For Customer Service:

Email: feedback@natitools.com or Call 1-800-348-5004

feedback@natitools.com

8809409 02/13

GENERAL PURPOSE SPRAY GUN

6

For Customer Service: Call 1-800-348-5004 or Email feedback@natitools.com

Model: 9409

7

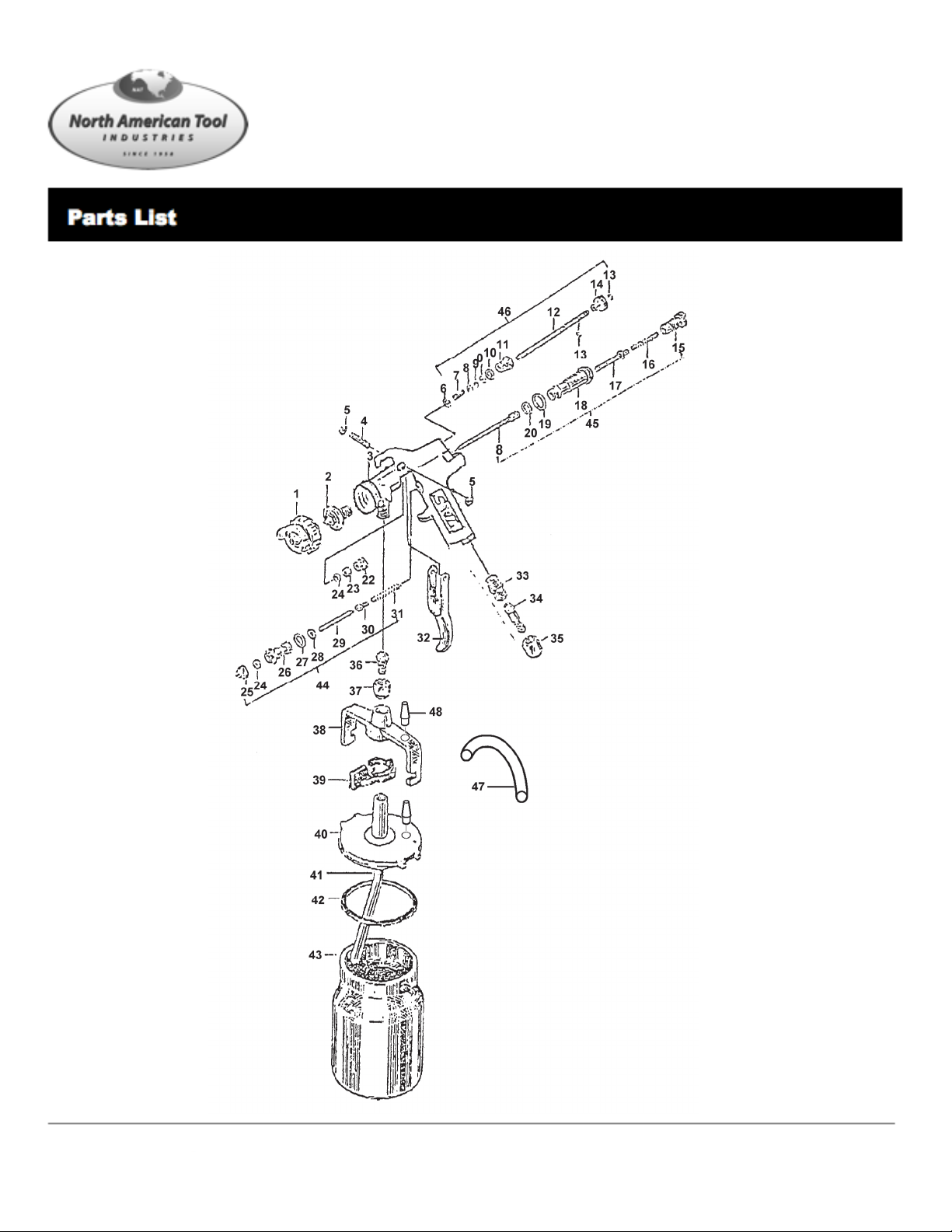

Fluid Control Knob15

Needle Spring16

Needle Packing Screw22

Needle Packing Ring23

Air Inlet34

Air inlet Screw33

Trigger32

Air Valve Packing Ring24

Pattern Control Knob14

Stop Ring5

Trigger Stud4

Gun Body3

Fluid Nozzle2

Air Cap Set1

DescriptionNo.

Vent Port48

Vinyl Vent Tube47

Pattern Control Assembly46

Fluid Control Assembly45

Trigger Valve Assembly44

Cup43

Cup Cover Gasket42

Liquid Tube41

Cup Cover40

Cup Locking Lever39

Fastener38

Screw Cap37

Fluid Joint36

Nipple35

DescriptionNo.

feedback@natitools.com

Table of contents

Popular Paint Sprayer manuals by other brands

DETE

DETE BM 250 operating manual

SATA

SATA SATAJET 3000 K RP/HVLP operating instructions

EINHELL

EINHELL 11077 operating instructions

Ribimex

Ribimex RIBILAND Pila50 User and maintenance manual

Lafferty

Lafferty A-40 SS Installation & operation instructions

Ribimex

Ribimex Rubiland Pila50 PRP500PER User and maintenance manual