NORTH COAST ROCKETRY Vektra User manual

North Coast Rocketry

Copyright © 2020 North Coast Rocketry®. All rights reserved

• This kit is recommended for adults(18 and older) only. Launch systems, model rocket motors, launch supplies, tools, and

building materials are not included.

• Do not modify the design of the rocket! Changes to the design may affect the stability, and hence, the safety of the

rocket.

• North Coast Rocketry certifies that it has exercised reasonable care in the design and manufacture of its products.

However, as we cannot control the use of our products once sold, we cannot assume any responsibility or liability for

product usage.

• North Coast rocketry shall not be held responsible for personal injury or property damage resulting from the use of our

product. The buyer assumes all risks and liabilities arising from the use of our product and uses our product on these

conditions.

• North Coast Rocketry makes no warranty regarding our products, except for defects in materials or workmanship for a

period of one year after purchase.

• If any of these terms are unacceptable, please return the item to the point of purchase.

NCR 9208 (07/20)

Vektra™

Flying Model Rocket Instructions

Designed by Matt Steele

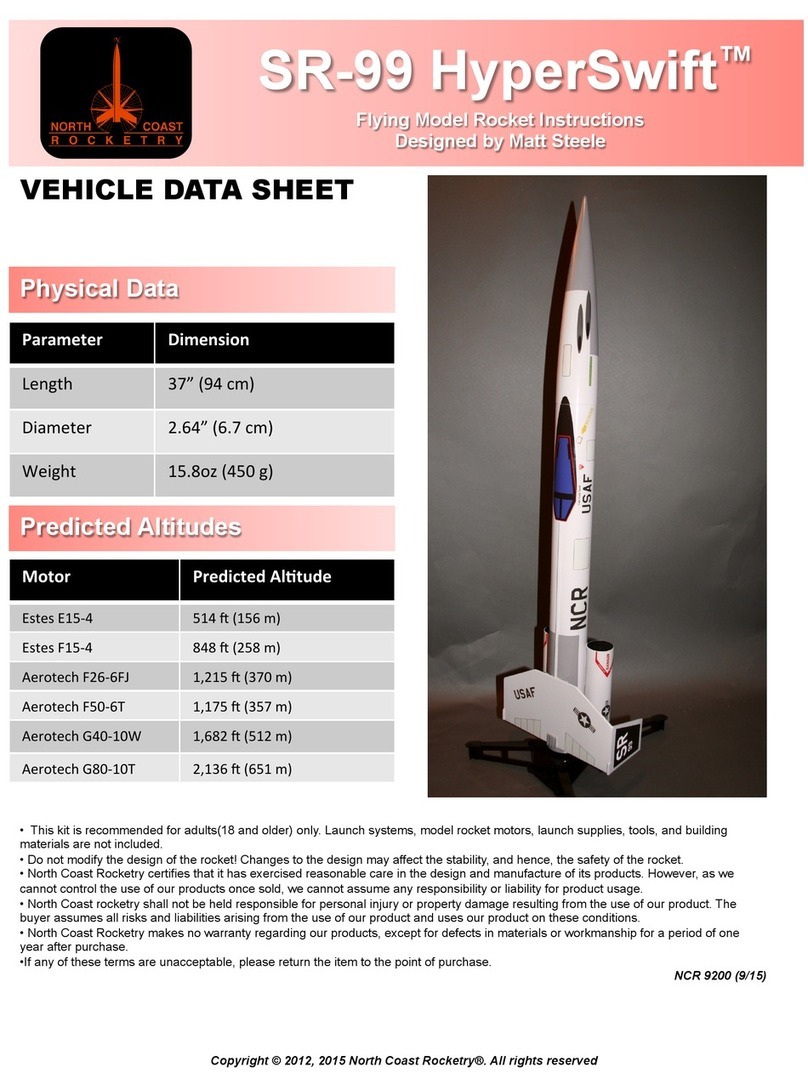

VEHICLE DATA SHEET

Physical Data

Predicted Altitudes

Parameter Dimension

Length 37” (94 cm)

Diameter 2.64” (6.7 cm)

Weight 19.5 oz (555 g)

Motor Predicted Altitude

Estes E16-4 407 ft (124 m)

Estes F15-4 686 ft (209 m)

Aerotech F25-6W 1,164 ft (355 m)

Aerotech F50-6/9T 1.245 ft (380 m)

Aerotech G40-7W 1,812 ft (552 m)

Aerotech G80-10T 2,386 ft (727 m)

• A 36” nylon parachute is not included in this kit. The NCR

36" Ripstop Nylon High Visibility Parachute (Part #822) is

recommended for this kit.

North Coast Rocketry

Copyright © 2020 North Coast Rocketry®. All rights reserved

2

Parts List

ID Part # Description

A3004 Nose Cone

B1123 Main Body Tube (18”)

C1110 Fin Can Tube (10”)

D1115 Motor Tube (17”)

E7212 Forward Fins (4 )

F7211 Aft Fins (4)

G2104 Ring Alignment Key (2)

H2102 Forward Centering Ring

J2101 Aft/Mid Centering Ring (2)

K9501 Launch Lugs (2)

L9577 Cable (15”)

M9503 Loop Sleeve Connectors (2)

N9530 Kevlar Line (2 yards)

O9531 Elastic Line (1 yard)

P1108 Coupler (Brown or White)

Q9523 Shrink Tube

R9526 Quick Link

S8222 Vektra Decal

T8200 NCR Decal

Before You Start:

Thank you for purchasing this North Coast Rocketry® model kit. We

hope you have an enjoyable time constructing and flying this model

rocket. Please read all of these instructions to become familiar with

them before starting construction. The sequence is important. Check

off each step as it is completed.

The following materials are necessary for construction:

5 minute epoxy; 15 or 30 minute epoxy; gap filling (thick) cyanoacrylate

adhesive (CA); balsa filler coat; ¾” wide masking tape, a sanding block

with #220, #320 and #400 sandpaper; spray primer; and spray paint in

the color(s) of your choice.

The following tools are required for construction:

Modeling knife or single edge razor blade; pliers or crimping tool; safety

glasses; and an 18” long ruler.

Check the kit for completeness, using the parts list and reference

photograph. If parts are missing or damaged, or if or any reason you

are dissatisfied with this product, please let us know at

www.NorthCoastRocketry.com. We will gladly replace any item found

to be defective. Our goal is for you to be satisfied with your purchase,

and to have fun!

Please be extremely careful using CA and epoxy. Avoid getting either

in your eyes or on your skin. Use safety glasses when using adhesives

and when cutting. Be sure to use adhesives and paints only in areas

with adequate ventilation, and do not breathe in fumes.

In each step, test fit parts together before bonding. It is sometimes

necessary to sand lightly or build up some parts to obtain a precision

fit.

Plywood parts, being natural wood products, have a tendency to warp.

Reverse any warps by lightly misting the part’s concave side, then

placing it between two heavy, flat objects to dry. Seal the part with

balsa fillercoat or spray primer as soon as possible afterwards..

A 36” nylon parachute is not included in this kit. The NCR 36" Ripstop

Nylon High Visibility Parachute (Part #822) is recommended for this kit.

B

A

C

D

E

F

H

T

J

S

K

M

N

Q

R

Q

P

L

G

O

North Coast Rocketry

Copyright © 2020 North Coast Rocketry®. All rights reserved 3

Assembly Instructions

□Mark the motor tube with two marks 180˚ apart,

using the marking guide below. Extend both lines

the length of the tube.

□Mark the motor tube 1” from each end. Extend

those lines around the circumference of the tube.

□Test fit each centering ring on the motor tube

and body tube to ensure they fit properly. Sand

the rings if the fit is too tight; add tape to the motor

tube if that joint is too loose.

□Locate two centering ring alignment keys.

These pieces will keep the aft and mid centering

rings aligned properly to fit the fin tabs. Using CA,

glue the key on one of the lengthwise lines, 1”

from one end. Repeat with the other key.

□Locate the one of the aft/mid centering rings

(one with the four slots in it) and slide it onto the

motor tube to mate with the key. Using epoxy,

bond the ring in place. Repeat with the other ring

in the mid location. Fillet both rings to the tube

with epoxy.

□Test fit the motor mount assembly into the slotted

airframe “fin can” tube. Check to see that the motor

mount fits snugly. Remove the motor mount. Using

15 or 30 minute epoxy, apply a band of epoxy inside

the slotted tube about 3” from one end. Insert the

motor mount assembly into the tube about 2”. Apply

additional epoxy band about ½” inside the tube.

Then, insert the assembly all the way in until the aft

centering ring is at least even with the aft slot. Make

sure that the fin slots and the notches in the

centering rings are aligned with the fin can tube

by test fitting each fin into each slot. Remove the

fins, and set aside to cure.

□Locate the tube coupler; mark it at half it’s length.

Test fit it in the slotted tube assembly. Using epoxy,

bond the coupler in place.

□Slide the forward centering ring (the one with the

two holes in it) onto the exposed end of motor tube at

the 1” mark. Using epoxy, bond the ring in place.

North Coast Rocketry

Copyright © 2020 North Coast Rocketry®. All rights reserved 4

□Locate the steel cable and one of the

loop/sleeve connectors. Thread one of the

loop/sleeve connectors on to the cable. Then,

thread the cable down through the top of one hole

in the centering ring. Pull it back through the other

hole and thread the end of the cable back through

the loop/sleeve connector, making a 1-2” loop.

Crimp the loop/sleeve connector with a crimping

tool or a pair of pliers. Apply a drop of CA to the

connector.

□Slide both of the heat shrink sections onto the

cable. Place the other loop/sleeve connector on

the free end of the cable. Make a 1-2” diameter

loop and thread the free end back through the

loop/sleeve connector. Measure to make sure the

cable assembly is no longer than 11” long from

the forward centering ring to the top of the loop.

Make the top loop bigger to keep the overall

length correct. Crimp the loop/sleeve connector

with a crimping tool or a pair of pliers. Apply a

drop of CA to the connector.

□Slide the heat shrink tubing over each loop

sleeve connector, and, using a heat gun or hair

dryer, shrink the tubing over the connector to

prevent the parachute from snagging on it.

□Tie one end of the Kevlar shock line onto the

top cable loop and triple knot it. Secure the knot

with a drop of CA. Trim the excess off.

□Tie one end of the elastic shock line onto the

top cable loop and triple knot it. Trim the excess

off.

□Coil up both the Kevlar and elastic shock lines and

stuff them into the forward end of the motor tube.

This will keep them out of the way when the motor

mount is bonded in place.

□Locate the fins. Round the leading and trailing

edges of the fins with coarse #100 grit sandpaper.

Leave the root edge of the fins flat. Fine sand the

parts with #180, #220, #320, and #400 sandpaper.

Plywood is a natural wood product; as such, we can

not control factors such as warping after it leaves our

facility. If your plywood parts are warped, place them

under a stack of books for 24-48 hours to flatten

them.

□It is a good idea to sand and seal the fins prior to

bonding them on the airframe. Cover the fin tab area

with a strip of ½” wide masking tape. The fins can

best be sealed with finishing epoxy, balsa filler coat,

or primer paint. Apply a coat of filler, sand smooth,

and repeat the process until the wood grain is filled

and the surfaces are smooth.

□Insert the main body tube onto the coupler, and

line up the slots in both of the tubes. Mark a line that

extends from the outside edge of the aft slot on the

short tube to the aft slot tube on the long tube. This

will ensure the fins are aligned.

North Coast Rocketry

Copyright © 2020 North Coast Rocketry®. All rights reserved 5

□Using epoxy, apply a band of epoxy inside the

main airframe tube about 1-3” from the aft end.

Insert the tube into the lower tube assembly all the

way in until two tubes meet. Make sure the

alignment lines match.

□Using epoxy, glue the lower fins in place on the

lower body tube. Fillet each fin/body joint.

□Using epoxy, glue the upper fins in place on

the upper body tube. Fillet each fin/body joint.

□Using a pencil and a straight edge, mark a line

in between two of the fins the length of the tube.

Epoxy one lunch lug even with the aft end of the

tube. Make a mark 2” from the forward end of the

tube on the same line. Epoxy the other launch lug

aft of the 2” mark. Fillet the lugs for added

strength.

□Coil up both the Kevlar and elastic shock lines and

stuff them into the forward end of the motor tube.

This will keep them out of the way when then motor

mount is bonded in place.

□Locate the nose cone. Because of the recovery

system approach NCR uses, the molded attachment

point is not used. Using a ¼” drill, drill a hole in the aft

end of the nose cone.

□Insert one end of the kelvar line into the center

hole, and then route it back out the drilled hole. Tie

the line to itself. Secure the knot with CA. Locate and

tie the free end of the elastic to the Quick Link, then

attach the Quick Link. See the next page for a photo.

Table of contents

Other NORTH COAST ROCKETRY Toy manuals

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions