- Always observe the safety data sheets for the media to be handled.

The system operator must ensure that these safety data sheets are

available and that kept up-to-date.

- The safety data sheets for the fluid being handled are always deci-

sive for initiating countermeasures and/or first aid in the event of

leakage of the fluid.

- Observe the general restrictions in relation to viscosity limits, che-

mical resistance and density.

- Always switch the pump off before exchanging the pump hose

Incorrect and improper use

Possible consequence: fatal or very serious injuries.

- The unit is not intended to convey or regulate gases or solid media

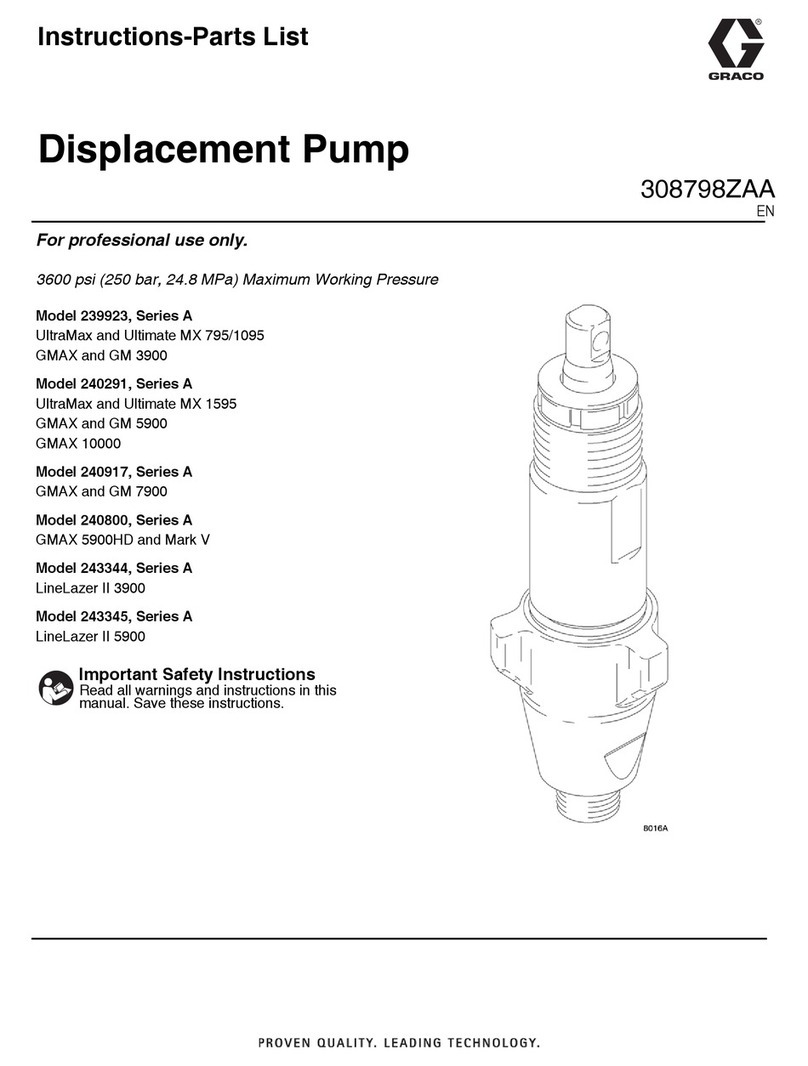

- Do not exceed the rated pressure, speed or temperature for the

pump

- Maximum pressure on suction/inlet side is 3 bar (45 psi approx.)

and maximum pressure on suction/inlet side is 0,5 bar (7,25 psi

approx.) only in pumps with Norprene, Silicone and Tygon tube).

- The unit may only be used in accordance with the technical data

and specifications provided in these operating instructions and in

the operating instructions for the individual components

- Only switch the pump on if it has been properly fastened to the

floor

- Only switch the pump on if the front cover has been attached.

- Do not carry out any maintenance operations or dismantle the

pump without first making sure that the pipes are not under pres-

sure and are empty or isolated.

- In the case of the hose becoming stuck during extraction or fitting it

is necessary to reverse the direction of the pump, re-lubricate, and

then repeat the operation.

- As the peristaltic pump is volumetric and its functioning is positive

displacement, it is necessary to prevent a possible overload of pres-

sure, due to, for example, the accidental closure of a valve. For this

reason, it is advisable to fit a safety device such as: a safety valve,

pressure limiter, etc.

Operational lifetime of the pump hoses

Possible consequence: fatal or very serious injuries.

The hose has an indeterminate life and due to the possibility of its

Operating instru

ct

ions Peristaltic Pumps AMP Series

North Ridge Pumps Registered in England and Wales 03652700.

Registered Office: 12 Bridgford Road, West Bridgford, Nottingham, NG2 6AB . VAT No. GB324963488

NORTH RIDGE HOUSE, 3 CHRYSALIS WAY, EASTWOOD, NOTTINGHAM, NG16 3RY

-This pump is NOT supplied for use in areas of risk from explosion.

ATEX versions of North Ridge pumps are available and they are

supplied with a special ATEX version of the Instruction Manual.