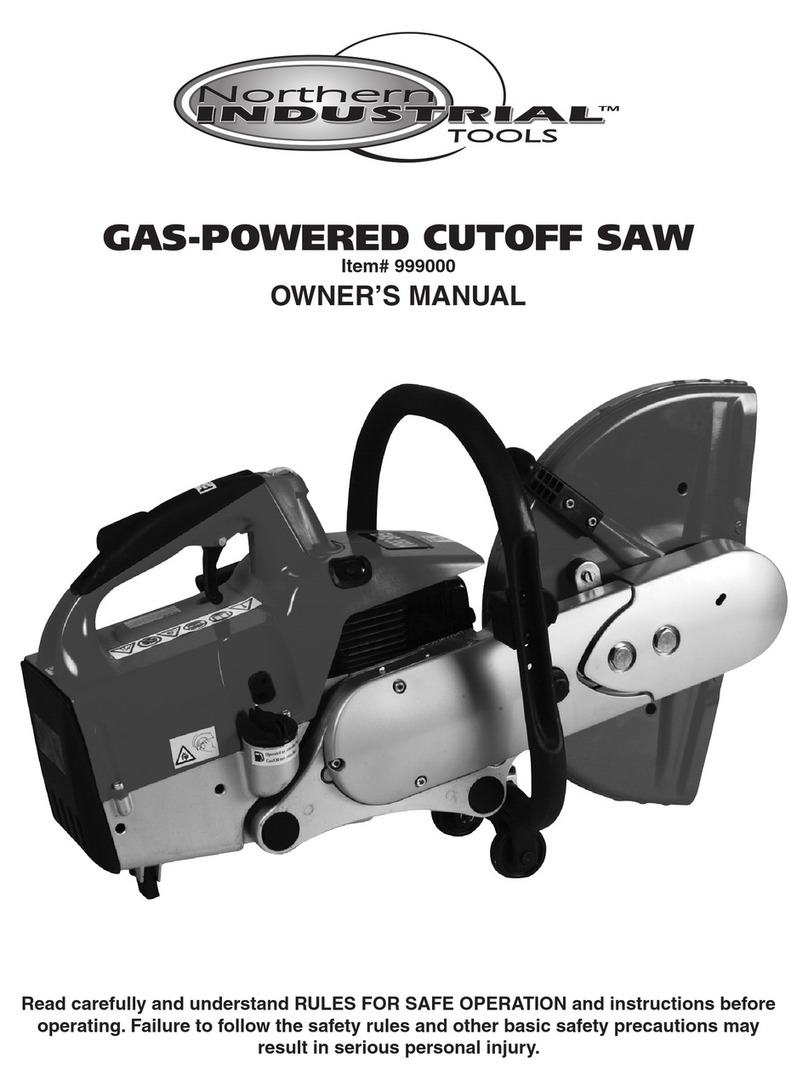

Northern Industrial Tools 338070 User manual

6IN. CUTOFF SAW

OWNER’S MANUAL

WARNING:

Read carefully and understand all ASSEMBLY AND OPERATION

INSTRUCTIONS before operating. Failure to follow the safety rules and other

basic safety precautions may result in serious personal injury.

Item# 338070

Page of 9

2

Thank you very much for choosing a NORTHERN Industrial product! For future reference, please

complete the owner's record below:

Model: _______________ Purchase Date: _______________

Save the receipt, warranty and these instructions. It is important that you read the entire manual to

become familiar with this product before you begin using it.

This machine is designed for certain applications only. The distributor cannot be responsible for

issues arising from modification. We strongly recommend this machine is not modified and/or used

for any application other than that for which it was designed. If you have any questions relative to a

particular application, DO NOT use the machine until you have first contacted the distributor to

determine if it can or should be performed on the product.

For technical questions please call 1-800-222-5381.

INTENDED USE:

This 6in. CUTOFF SAW is designed for cutting metal.

TECHNICAL SPECIFICATIONS:

Motor:

120V ~ 60Hz 780W 6.5AMPS

No Load Speed:

7400 RPM

Blade Type:

6in. Diameter reinforced Cutting Disc

Packed Weight:

11.5 lbs.

CSA Listed:

GENERAL SAFETY RULES

WARNING: Read and understand all instructions. Failure to follow all instructions listed

below may result in electric shock, fire and/or serious injury.

CAUTION: Do not allow anyone to operate or assemble this Cutoff Saw until they

have read this manual and have developed a thorough understanding of how the Cutoff Saw

works.

WARNING: The warnings, cautions, and instructions discussed in this instruction

manual cannot cover all possible conditions or situations that could occur. It must be

understood by the operator that common sense and caution are factors which cannot be built into

this product, but must be supplied by the operator.

SAVE THESE INSTRUCTIONS

Page of 9

3

IMPORTANT SAFETY CONSIDERATIONS

Make sure the cutoff wheel is securely mounted as described in the assembly instructions,

BEFORE connecting the tool to a power supply. Do not tighten wheel excessively, since this

can cause cracks.

Check wheel for fissures and cracks, and test for normal operation prior to use.

Use only 6in. cutoff wheel rated for 10,000 RPM or greater and manufactured in compliance

with ANSI B7.1. Always store wheels in a dry place with little temperature variation.

Always ease the abrasive wheel against the workpiece when starting to cut. A harsh impact can

break the wheel.

Always press the trigger switch and allow the cutoff wheel to reach full speed before cutting.

Because of the downward cutting motion, stay alert to keep hands and fingers away from the

path that the blade travels.

Never replace the abrasive wheel with a toothed blade.

CUTOFF SAW USE AND CARE

Do not modify the Cutoff Saw in any way. Unauthorized modification may impair the function

and/or safety and could affect the life of the equipment. There are specific applications for which

the Cutoff Saw was designed.

Always check of damaged or worn out parts before using the Cutoff Saw. Broken parts will

affect the Cutoff Saw operation. Replace or repair damaged or worn parts immediately.

Store idle Cutoff Saw. When Cutoff Saw is not in use, store it in a secure place out of the

reach of children. Inspect it for good working condition prior to storage and before re-use.

ASSEMBLY

WARNING! Do not connect saw to power source until assembly is complete. Failure to

comply could result in accidental starting and possible serious injury.

CUTOFF WHEEL REMOVAL

1. Make sure saw is unplugged and in the "OFF" position.

2. Pull out the locking pin (16) and raise the saw to its full open position.

3. Using a Phillips head screwdriver, remove the inner blade guard cover screw (88).

4. Swivel the outer blade guard (91) up to reveal the hex

head bolt (66) as shown in Figure 1.

5. Place the pins of the supplied flange wrench into the

holes in the outer flange (64) and hold the outer flange

steady.

6. Using the supplied blade arbor wrench, remove the hex

head bolt by turning it counterclockwise.

7. Remove outer flange washer (65) and outer flange.

8. Remove cutoff wheel (81).

Page of 9

4

CUTOFF WHEEL INSTALLATION

WARNING! Use only reinforced, 6in. cutoff wheels, rated for 10,000 RPM or higher.

1. Disconnect saw from the power source.

2. Inspect the replacement wheel for defects such as cracks, chipping, and correct speed rating.

If defects are found or the speed rating is not 10,000 RPM or higher, discard the wheel and

choose another wheel that fits the proper specifications.

3. Remove any debris from the inner flange (63).

4. Position the new cutoff wheel against the inner flange.

5. Align the outer flange with the wheel arbor, then slide it onto the arbor until it rests flush against

the cutoff wheel.

6. Place the outer flange washer against the cutoff wheel.

7. Insert the hex head bolt into the threaded end of the wheel arbor and hand tighten.

8. Insert the pins of the flange wrench into the holes of the outer flange and hold the outer flange

steady.

9. Using the blade arbor wrench, firmly tighten the hex head bolt in place.

WARNING! Do not overtighten the hex head bolt. Overtightening can cause the new wheel

to crack, resulting in premature failure and serious personal injury.

10. Swivel the outer blade guard back to its original position, making sure that the guard cover pivot

(74) slides back into the guide arm (79). (See Figure 2)

11. Align the hole in the inner blade guard cover with the

hole in the inner blade guard.

12. Insert the inner blade guard cover screw through the

inner blade guard cover, into the inner blade guard.

13. Using a Phillips head screwdriver, firmly tighten the

inner blade guard cover screw.

ADJUSTMENTS

WARNING! Always make sure the tool is switched off and unplug the saw from power

source before making adjustments or performing routine maintenance. Failure to heed this warning

can result in serious personal injury.

ADJUSTABLE STATIONARY VISE

The adjustable stationary vise is located on the base of your cutoff saw. This vise can be adjusted

for cutting angles from 0 to 45 degrees.

CUTTING ANGLE ADJUSTMENT

To adjust the angle of cut:

Page of 9

5

1. Using the supplied allen wrench, loosen screws (26) behind the vise fence (23).

2. Rotate the vise fence until the desired angle of cut is aligned with the indicator arrow in th saw

base (14).

3. Check the angle of the vise fence to the cutoff wheel using a protractor, bevel square, or similar

device.

4. Using the supplied allen wrench, securely tighten the bolts holding the vise to the saw base.

QUICK LOCK/RELEASE VISE

The cutoff saw is equipped with a quick lock/release vise system as standard equipment.

With this feature you are able to open and close the vise quickly without excessive turning of the

vise adjustment handle.

USING THE QUICK LOCK/RELEASE VISE

To loosen:

1. Slightly release tension on the Vise (06) by rotating the vise adjustment handle (01)

counterclockwise 1/2 to 1 turn.

2. Lift up the quick Lock/release lever (13) and pull back on vise adjustment handle to slide open

the vise.

To tighten:

1. Push the vise adjustment handle forward to slide the vise against the workpiece.

2. Push down on the quick Lock/release lever to engage its threads with the vise adjusting screw

(03).

3. Rotate the vise adjustment handle clockwise to tighten the vise against the workpiece.

OPERATION:

To start the saw

1. Press the safety on/off button located on the left side of the saw housing (38).

2. While holding the safety on/off button, pull the trigger (49).

To stop the saw

1. Release the trigger completely.

CUTTING

WARNING! Do not attempt to cut wood or masonry with this saw. Never cut magnesium or

magnesium alloy with this tool. Failure to comply with this warning could result in serious personal

injury.

WARNING! If wheel stops during operation, makes an odd noise or begins to vibrate,

switch off the tool immediately.

WARNING! Large, circular, or irregularly shaped material may require additional means of

clamping to be secured in place adequately for cutting. Use C-clamps and blocks to hold material

securely. Failure to comply could result in serious personal injury.

Page of 9

6

1. Firmly secure the material to be cut using the saw’s vise.

2. Start the saw by pressing safety on/off button and pulling the trigger.

Note: Allow the cutoff wheel to come up to full speed before contacting wheel to material.

3. Slowly push down on the saw arm handle until the cutoff wheel contacts the material being cut.

Use a steady and even pressure to obtain a uniform cut. Never force the wheel into the material.

4. When the cut is complete, release the trigger switch and allow the wheel to stop completely

before raising it to the full open position.

DANGER! Do not touch the cut material until it cools or you will be burned. Failure to heed

this warning will result in serious personal injury.

MAINTENANCE

•Maintain your Cutoff Saw. It is recommended that the general condition of any Cutoff Saw be

examined before it is used. Keep your Cutoff Saw in good repair by adopting a program of

conscientious repair and maintenance. Have necessary repairs made by qualified service

personnel.

WARNING! Make sure this saw is turned off and disconnected from its power source

before attempting any maintenance, cleaning, or inspection.

•Maintain your tools. It is recommended that the general condition of any tool be examined

before it is used. Keep your tools in good repair by adopting a program of conscientious repair

and maintenance in accordance with the recommended procedures found in this manual. If any

abnormal vibrations or noise occurs, turn the tool off immediately and have the problem

corrected before further use. Have necessary repairs made by qualified service personnel.

•Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control. Keep handles dry, clean, and free from oil

and grease.

Your cutoff saw is designed to perform with little or no maintenance required from you. To help

prolong the life of your tool, follow the simple maintenance routine below:

1. Keep your tool clean. Periodically wipe your tool down with a damp rag and blow out air

vents with compressed air.

Note: Do not allow moisture inside the saw when cleaning.

2. Regularly check screws and bolts to make sure they are properly tightened.

3. Apply dry lubricant monthly to the points listed below to extend saw service life.

Lubrication points:

• Vise Adjusting Screw

• Vise Swivel Pin

4. Remove the brush caps at regular intervals to check the carbon brushes. When the

brushes are worn, replace them. (see below two images)

Page of 9

7

This cutoff saw has a quick brush change system.

1. Use slotted screwdriver to remove the the brush caps.

2. Take out the worn brush and insert the new one.

DIAGRAM & PARTS LIST

Page of 9

8

For replacement parts and technical questions, please call 1-800-222-5381.

Page of 9

9

WARNING

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains

chemicals known to the State of California to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment,

such as those dust masks that are specially designed to filter out microscopic particles.

Distributed by

Northern Tool + Equipment Company, Inc.

Burnsville, Minnesota 55306

Made in China

Other manuals for 338070

1

Table of contents

Other Northern Industrial Tools Saw manuals

Northern Industrial Tools

Northern Industrial Tools 999000 User manual

Northern Industrial Tools

Northern Industrial Tools 155793 User manual

Northern Industrial Tools

Northern Industrial Tools 998800 User manual

Northern Industrial Tools

Northern Industrial Tools 338070 User manual

Northern Industrial Tools

Northern Industrial Tools Item# 145765 User manual