Northern Industrial Tools 998800 User manual

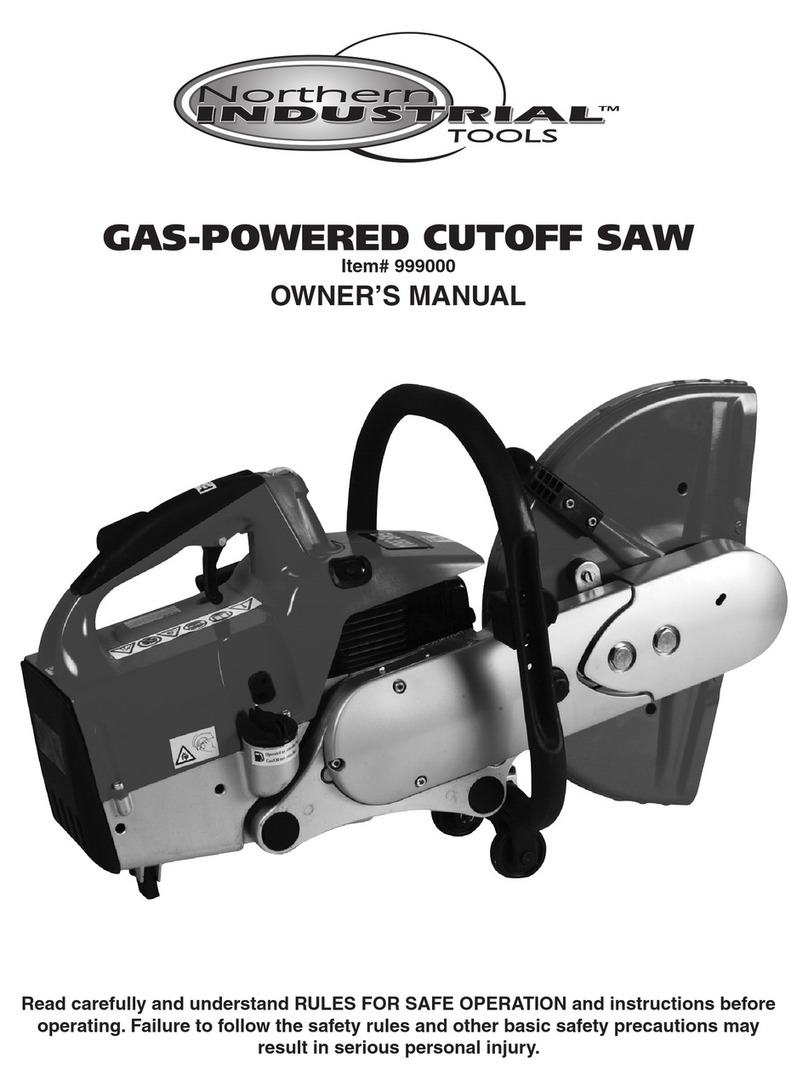

GAS-POWERED CUTOFF SAW

OWNER’S MANUAL

WARNING: Read carefully and understand all

INSTRUCTIONS before operating. Failure to follow the safety

rules and other basic safety precautions may result in serious

personal injury.

Item# 998800

1

Thank you very much for choosing a NORTHERN TOOL + EQUIPMENT CO., INC. Product!

For future reference, please complete the owner’s record below:

Model: _______________ Purchase Date: _______________

Save the receipt, warranty and these instructions. It is important that you read the entire

manual to become familiar with this product before you begin using it.

This machine is designed for certain applications only. Northern Tool + Equipment

cannot be responsible for issues arising from modification. We strongly recommend this

machine is not modified and/or used for any application other than that for which it was

designed. If you have any questions relative to a particular application, DO NOT use the

machine until you have first contacted Northern Tool + Equipment to determine if it can or

should be performed on the product.

For technical questions please call 1-800-222-5381.

INTENDED USE

This Heavy-Duty Cutoff Saw cuts steel, stone, asphalt, concrete, rebar and more.

TECHNICAL SPECIFICATIONS & PACKING LIST

Item Specification

Engine Displacement (cc.) 71

Bore Diameter (in.) 2"

Stroke (in.) 1–13/32"

Idle Speed (RPM) 2700

Recommended Max. Speed, Unloaded (RPM) 9500

Power (watts) 3,400

Ignition Type BPMR-7A

Spark Plug (mm.)

0.5

Fuel Capacity (qt.) 0.73

Weight (without fuel and cutting blade) (lbs.) 22

Dimension (length ×width ×height) (in.) 26" x 11" x 20"

Cutting Blade Diamond Blade, Maximum 14"

Max. Operating Speed 5,400

Required Fuel Unleaded 90 Octane

Required Oil Two-Stroke Engine Oil

Engagement Speed (RPM) ≥3800

Rated Spindle Speed (RPM) ≤5400

Equivalent Sound Pressure Level at the Operator’s Position 102 dB(A)

Equivalent Sound Power Level from the Machine 114dB( A)

Vibration Level (hand/arm) Max. 12m/s2

2

GENERAL SAFETY RULES

WARNING: The use of any cutoff machine can be dangerous. Because a cutoff

machine is a high-speed, fast-cutting power tool, special safety precautions must be

observed to reduce the risk of personal injury.

WARNING: Read and understand all instructions. Failure to follow all

instructions listed below may result in electric shock, fire and/or serious injury. Do not lend or

rent your cutoff saw without this manual.

WARNING: The warnings, cautions, and instructions discussed in this

instruction manual cannot cover all possible conditions or situations that could occur.

It must be understood by the operator that common sense and caution are factors which

cannot be built into this product, but must be supplied by the operator.

SAVE THESE INSTRUCTIONS.

WORK AREA

•Keep the work area clean, free of clutter and well lit. Cluttered and dark work areas

can cause accidents.

•Do not use your tool where there is a risk of causing a fire or an explosion; e.g.

in the presence of flammable liquids, gasses or dust. Power tools create sparks,

which may ignite the dust or fumes.

•Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control, so visitors should remain at a safe distance from the work

area.

•Be aware of all power lines, electrical circuits, water pipes and other mechanical

hazards in your work area, particularly those hazards below the work surface hidden

from the operator’s view that may be contacted unintentionally and may cause

personal harm or property damage.

•Be alert to your surroundings. Using power tools in confined work areas may put

you dangerously close to cutting tools and rotating parts.

INTERNAL COMBUSTION ENGINE SAFETY

WARNING: Only operate the engine in a well-ventilated area. Carbon Monoxide

produced by the engine during use can kill. Do not use indoors, near windows or in other

sheltered areas.

WARNING: Internal combustion engines present special hazards during

operation and fueling. Read and follow the warning instructions in the engine Owner’s

Manual and the safety guidelines below. Failure to follow the warnings and safety standards

could result in severe injury or death.

•DO NOT run the machine indoors or in an enclosed area such as a deep trench

3

unless adequate ventilation, through such items as exhaust fans or hoses, is

provided. Exhaust gas from the engine contains poisonous carbon monoxide gas;

exposure to carbon monoxide can cause loss of consciousness and may lead to

death.

•DO NOT smoke while operating the machine.

•DO NOT smoke when refueling the engine.

•DO NOT refuel a hot or running engine.

•DO NOT refuel the engine near an open flame.

•DO NOT spill fuel when refueling the engine.

•DO NOT run the engine near open flames.

•DO NOT modify or disengage safety devices.

•DO NOT operate the machine if any safety devices or guards are missing or

inoperative.

•DO NOT touch the engine or muffler while the engine is on or immediately after it

has been turned off. These areas get hot and may cause burns.

•ALWAYS refill the fuel tank in a well-ventilated area.

•ALWAYS replace the fuel tank cap after refueling.

•ALWAYS check the fuel lines and the fuel tank for leaks and cracks before starting

the engine. Do not run the machine if fuel leaks are present or the fuel lines are

loose.

•ALWAYS avoid contact with hot fuel, oil, exhaust fumes and solid surfaces.

•ALWAYS be sure that the operator is familiar with proper safety precautions and

operation techniques before using the machine.

•ALWAYS close the fuel valve when the machine is not being operated.

•ALWAYS operate the machine with all safety devices and guards in place and in

working order.

•ALWAYS avoid conditions that can create “kick-back”.

NOTE: All Federal and State laws and any regulation having jurisdiction covering the safety

requirements for use of the machine take precedence over the statements in this manual.

Users of this machine must adhere to such regulations.

PERSONAL SAFETY

•Stay alert. Watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattentiveness while operating power

tools may result in serious personal injury.

•Dress properly. Do not wear loose clothing, dangling objects, or jewelry. Keep

your hair, clothing and gloves away from moving parts. Loose clothes, jewelry

and/or long hair can be caught in moving parts. Air vents often cover moving parts

and should be avoided.

•Use the proper safety apparel and equipment. Use safety goggles or safety

glasses with side shields which comply with current national standards, or when

needed, a face shield. Use as dust mask in dusty work conditions. This applies to

all persons in the work area. Also use non-skid safety shoes, a hardhat, gloves, a

dust collection system and hearing protection when appropriate.

•Avoid accidental starting. Do not carry the power tool with your finger on the

switch. Ensure the switch is in the off position before starting.

•Do not overreach. Keep your footing and balance at all times.

4

•Remove adjusting keys or wrenches before connecting the tool to the power

supply or turning it on. A wrench or key that is left attached to a rotating part of the

tool may result in personal injury.

TOOL USE AND CARE

•Do not force the tool. Tools do a better and safer job when used in the manner for

which they are designed. Plan your work, and use the correct tool for the job.

•Never use a tool with a malfunctioning on/off switch. Any power tool that cannot

be controlled with the switch is dangerous and must be repaired by an authorized

service professional before using.

•Disconnect spark plug from the tool and place the switch in the locked or off

position before servicing, adjusting, installing accessories or attachments or storing.

Such preventative safety measures reduce the risk of starting the power tool

accidentally.

•Secure your work with clamps or a vise instead of your hands when practical.

This safety precaution allows for proper tool operation using both hands.

•Use both hands to operate the saw.

•Always stop the engine and let the wheel come to a complete stop before putting

down or carrying the saw.

•This saw vibrates during use. Repeated or long-term exposure to vibration may

cause temporary or permanent physical injury, particularly to the hands, arms and

shoulders. Vary your time of operation.

•Make sure the Cutting Wheel's maximum operating speed is greater than the

maximum motor speed of 9500 RPM.

•Inspect the abrasive wheel frequently and replace immediately if cracked,

warped or showing other signs of wear.

•Never use circular saw blades,carbide-tipped blades, rescue blades, wood cutting

blades or toothed blades with this saw.

•Store idle tools. When tools are not is use, store them in a dry, secure place out

of the reach of children. Inspect the tools for good working condition prior to

storage and before re-use.

•Use only manufacturer-recommended accessories for your model. Accessories

that may be suitable for one tool may cause injury when used on another tool.

•Do not store the Cut-off Saw with the Blade installed.

•Keep all guards in place and in working order.

•Never leave the tool unattended when running.

DIAGRAM AND PARTS LIST

5

Table of contents

Other Northern Industrial Tools Saw manuals

Northern Industrial Tools

Northern Industrial Tools Item# 145765 User manual

Northern Industrial Tools

Northern Industrial Tools 155793 User manual

Northern Industrial Tools

Northern Industrial Tools 338070 User manual

Northern Industrial Tools

Northern Industrial Tools 338070 User manual

Northern Industrial Tools

Northern Industrial Tools 999000 User manual