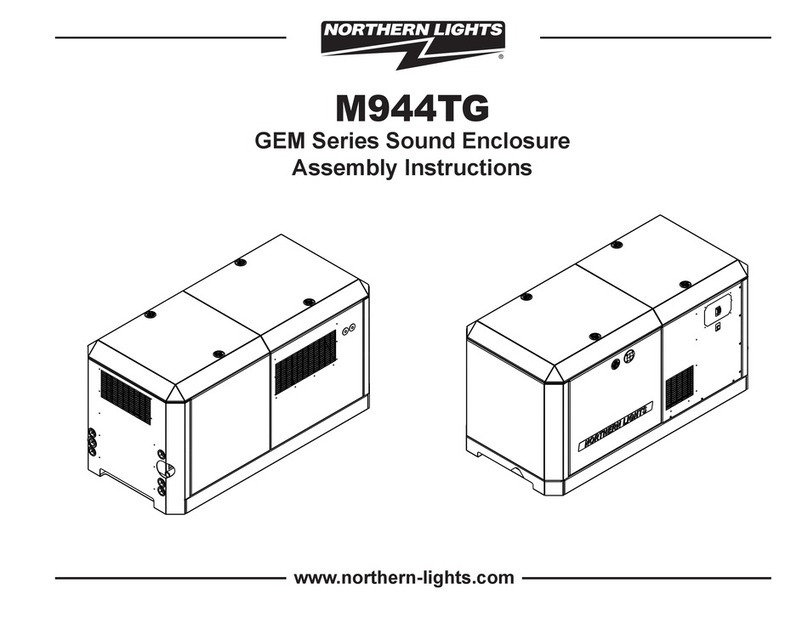

Northern Lights GEM Series User manual

www.northern-lights.com

M864W3

GEM Series Sound Enclosure

Assembly Instructions

06-78700 M864W3 GEM COVER PAGE

Corporate Headquarters

4420 14th Avenue NW

Seattle, WA 98107

Tel: (206) 789-3880

Fax: (206) 782-5455

Southeastern U.S.A.

1419 W Newport Center Dr

Deereld Beach, FL 33442

Tel: (954) 421-1717

Fax: (954) 421-1712

Alaska Branch Ofce

1200 West International

Airport Road

Anchorage, AK 99519

Tel: (907) 562-2222

Fax: (907) 563-1921

East Coast Branch

15 Aegean Dr.

Suite 4

Methuen MA 01844

Tel: (978) 475-7400

Fax: (978) 475-7745

Gulf Branch

19 Veterans Memorial Blvd.

Kenner, LA 70062

Tel: (504) 360-2180

Toll Free: (800) 843-6140

Northern Lights

4420 14th Avenue NW

Seattle, WA 98107

Tel: (206) 789-3880

Fax: (206) 782-5455

Copyright ©2020 Northern Lights, Inc.

All rights reserved. Northern Lights™, and

the Northern Lights logo are trademarks of

Northern Lights, Inc.

Printed in U.S.A.

LIT NO.: L817 7/19

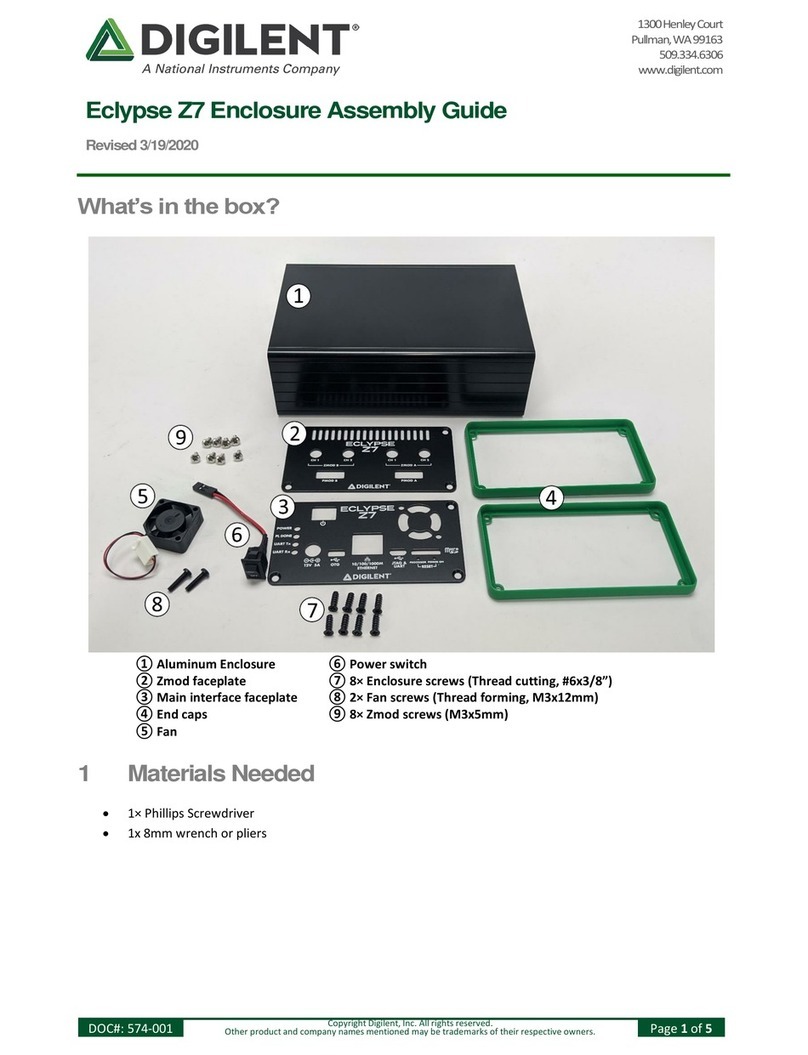

M864W3 GEM Sound Enclosure

1

SPECIFICATIONS

Enclosure (installed on generator base):

Length (OA) 48.9 in (1243 mm)

Width 25.0 in (635 mm)

Height 28.1 in (713 mm)

Assembled weight - shield only: 55.0 lbs (24.9 kg)

Assembled weight w/ genset: 952.2 lbs (432 kg)

ITEM # DESCRIPTION NLI P/N QTY NOTES

1. Rear panel assembly 06-78703 1

2. M8atwasher 15-11000 4 loose,bagged

3. M8 lock washer 15-00705 4 loose, bagged

4. M8 hex head capscrew 12-00776 4 loose, bagged

5.

Service side bottom valence assembly

06-78707 1

6.

Non-service side bottom valence assembly

06-78709 1

7. Front bottom valence assembly 06-78719 1

8. Non-service side panel assembly 06-78715 1

9. Service side panel aft assembly 06-78713 1

10. Front panel assembly 06-78701 1

11. Seal bar assembly 06-78723 1

12. Top panel assembly 06-78705 1

13. Service side panel, fwd assembly 06-78711 1

14. Grommet 1-1/8” x 1-7/8” OD 00-70146 2 loose, bagged

15. Leak detection alarm light assembly 22-90382 1 loose, bagged

16. E-stop/leak alarm harness 22-72024 1 loose, bagged

Prior to assembly, inspect all components for damage. Report any damage to the shipping company. Check the packing list in the back of this manual

to be sure all parts are included.

Select a mounting location in accordance with the guidelines in the IM1000 Installation Manual. The generator set must typically be mounted on a

rigid,atsurfaceaboveastrongstructure,suchasthevessel’sstringers,tominimizevibrationtransferencetothehull.

Note that the generator set is designed for single side service. When viewed from the rear, the right hand side is the service side and should be

exposed for easy maintenance access.

Installthegeneratorsetinthevesselasneartoalevelattitudeaspossible.Ensurethattheenclosure’srighthandsideandrearareatthe

recommendeddistances(6inchrecommended,4inchminimum.)fromthevessel’sbulkheads.

Note: The Generator set may still possess original factory lifting points. These lifting points will need to be loosened and rotated down, below the highest

point of the engine. Be sure to tighten these bolts before installing generator set.

AVOID POSITIONING THE ENCLOSURE INTO CORNERS WITH OVERHEAD BLOCKED TO REDUCE CHANCE OF INTAKE/EXHAUST AIR

RECIRCULATION OUTSIDE THE SHIELD.

2

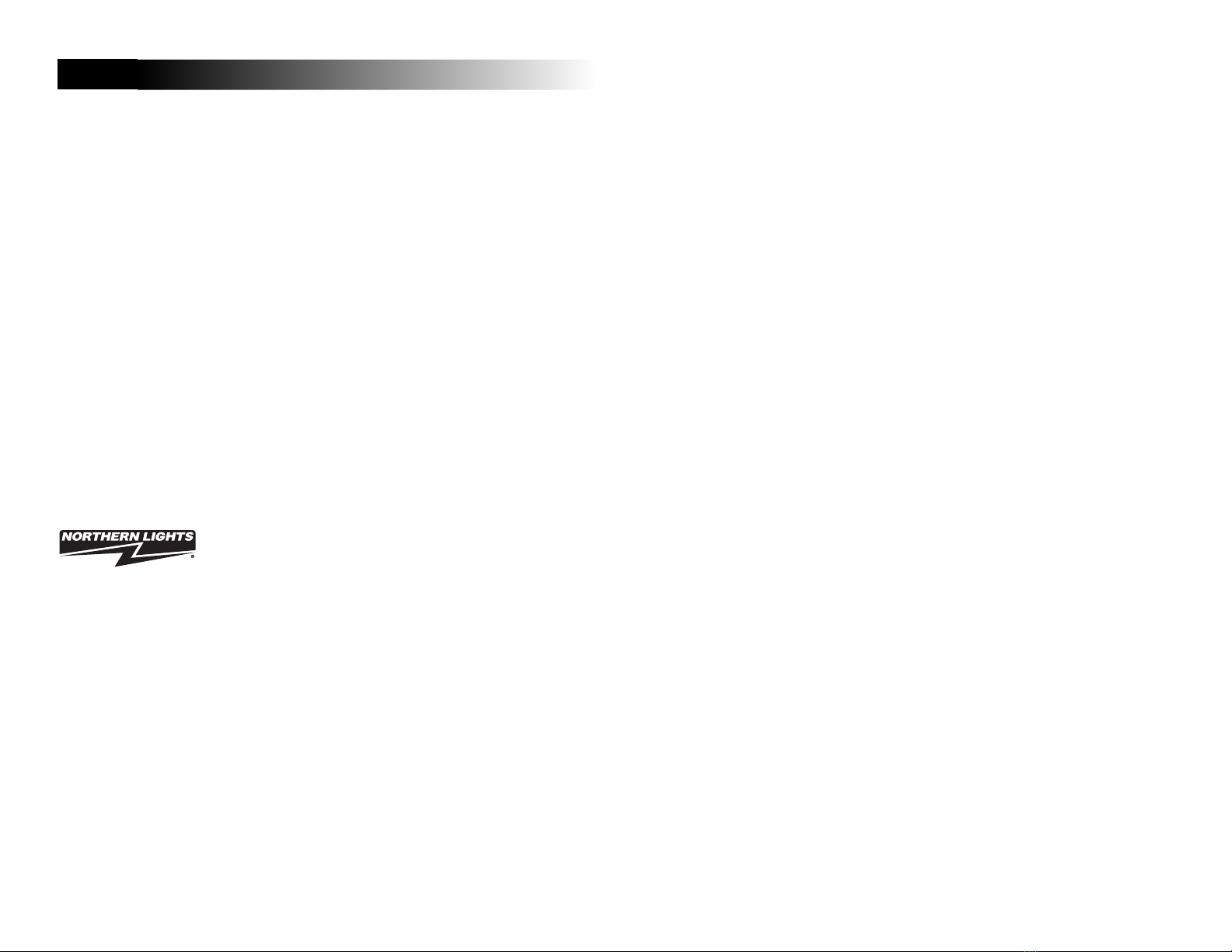

A

06-78700 M864W3 GEM Bottom of page 2.

2.

A

B

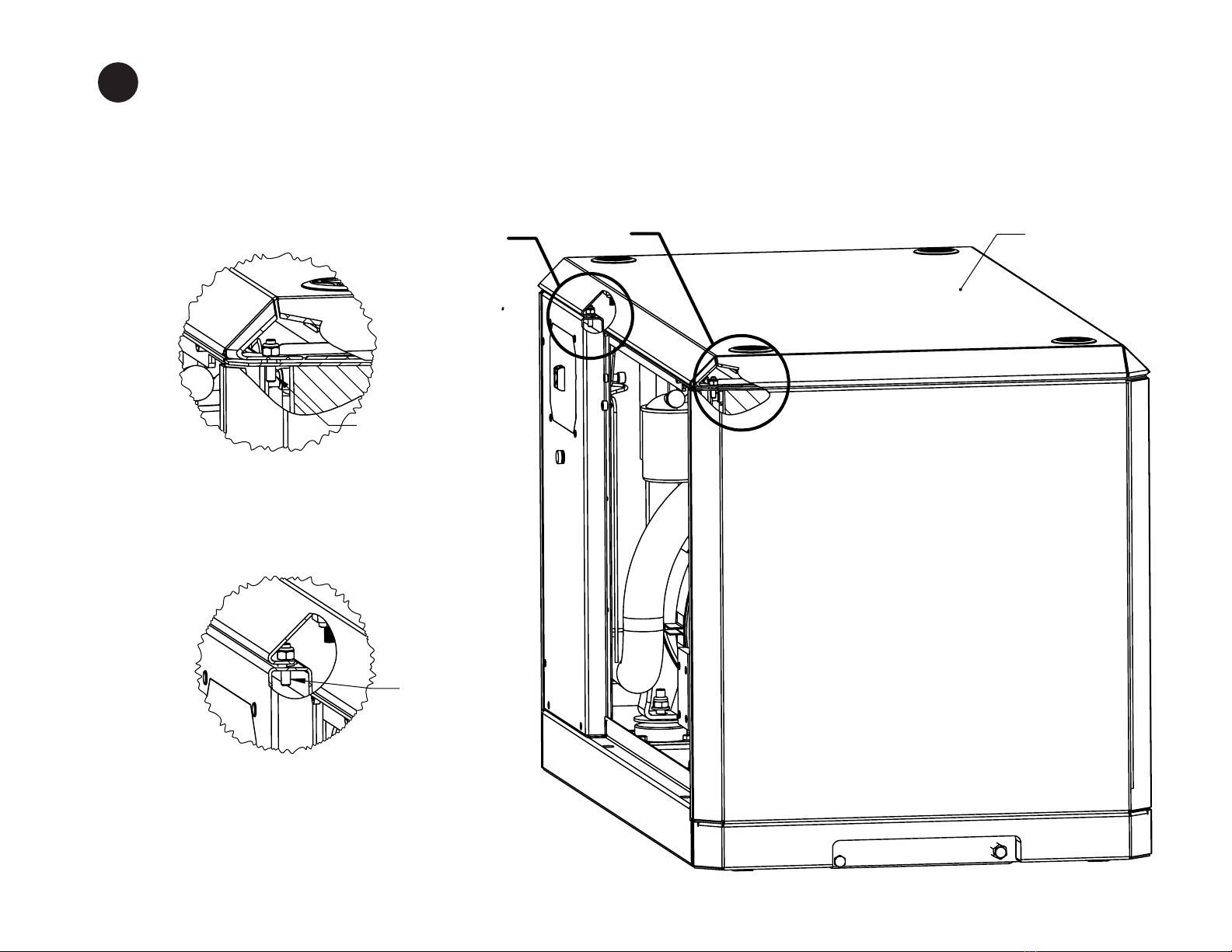

STEP 1.

INSTALL REARPANEL ASSEMBLY (ITEM #1)

TO THE BACK FACE OF THE GENSET BASE.

ALIGN SLOTS IN TAB TO BASE FRAME HOLES.

SECURE WITH HARDWARE, ITEMS 2,3, AND 4.

DETAIL B

STEP 2.

WHEN THE REAR PANEL ASSEMBLY IS SECURED, INSERT

GENSET AIR INTAKE SNORKEL HOSE INTO THE RECIEVER

AS SHOWN. PUSH INTO HOLE FIRMLY BUT DO NOT FORCE

HOSE ALL THE WAY IN. THERE IS A TAB STOP THAT LIMITS THE

HOSE INSERTION. PUSHING THE HOSE TOO FAR INSIDE THE

RECIEVER WILL CAUSE INTAKE AIR BLOCKAGE AND POOR

ENGINE PERFOMANCE.

DETAIL A

M8 HEX HEAD CAPSCREW (ITEM #4 )

M8 LOCK WASHER (ITEM #3)

M8 FLAT WASHER (ITEM #2)

3

B

C

STEP 4.

INSTALL LEFT SIDE LOWER VALENCE (ITEM#6).

NOTE THERE ARE TWO CAPTIVE NUTS FEATURED

ON THE HORIZONTAL FLANGE OF THIS PART.

STEP 3.

INSTALL RIGHT SIDE LOWER VALENCE PANEL (ITEM#5).

NOTE THIS PART HAS TWO CLIP ON NUTS IN VERTICAL

FLANGE.

DETAIL C

NOTE PRE-INSTALLED PINS.

GUIDE THESE INTO CORRESPONDING HOLES

IN REAR PANEL/FRONT LOWER VALENCE

PANEL. PUSH FIRMLY TO SNAP INTO PLACE.

DISPLACED PINS MAY BE RE-SEATED USING

A LONG TOOL SUCH AS A SCREW DRIVER OR

PRY BAR FROM THE INSIDE.

MOVE SOUND FOAM OUT OF THE WAY FOR

ACCESS TO PINS.

D

STEP 5.

INSTALL FRONT LOWER VALENCE (ITEM#7).

ALIGN CORRESPONDING HOLES TO PINS ON

BOTH LOWER SIDE VALENCE PANELS.

PUSH FIRMLY UNTIL IT SNAPS.

DISPLACED PINS MAY BE RESEATED AS

DESCRIBED IN DETAIL "C".

DETAIL D

STEP 6.

SECURE FRONT VALENCE TO BASE FRAME WITH

TWO EA: M8 FLATWASHER, LOCKWASHER, AND

HEX HEAD CAPSCREW (ITEMS 2,3,4).

06-78700 M864W3 GEM Page 3.

B

3.

B

4

C

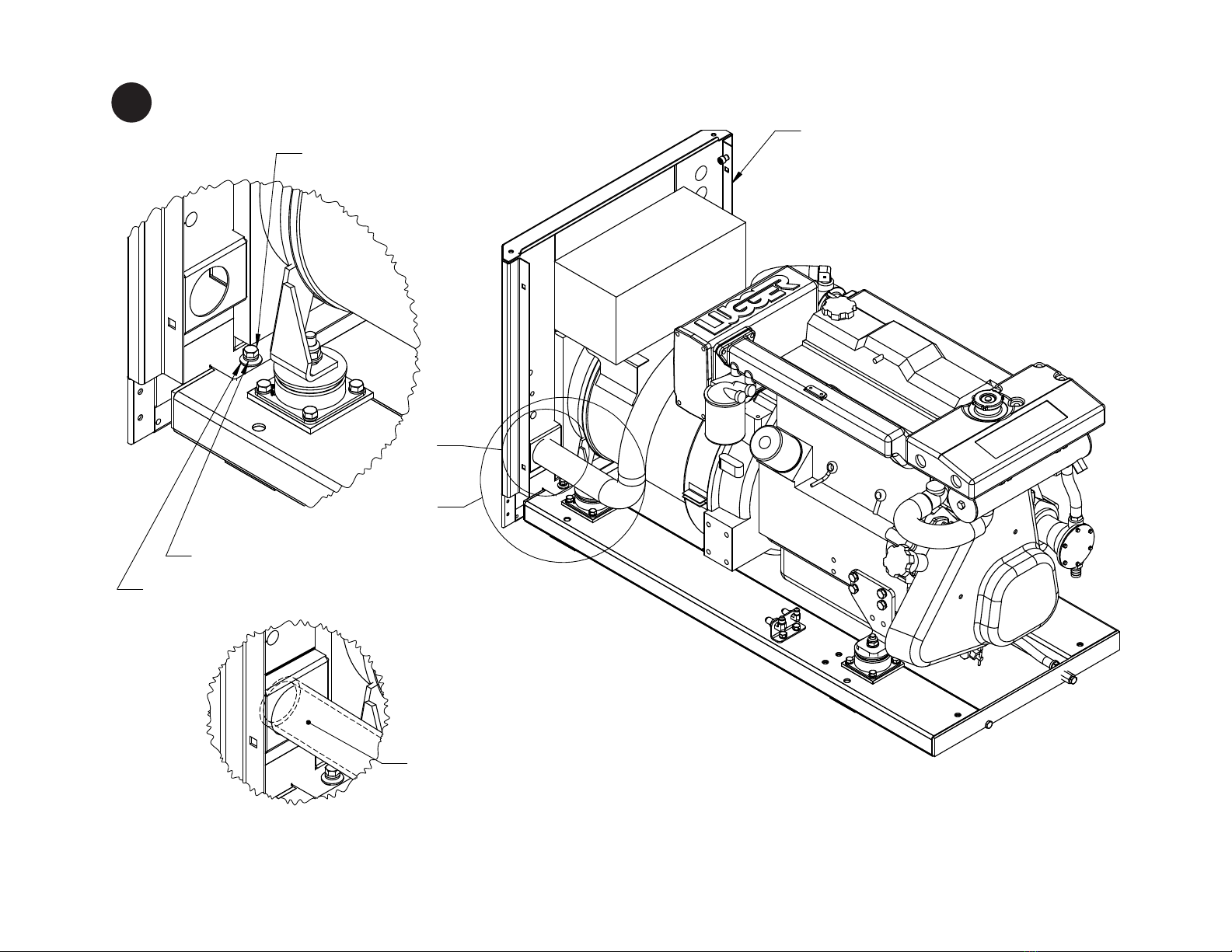

5

A

E

B

D

F

C

G

REAR PANEL

06-78700 M864W3 GEM Page 4 upper.

4.

STEP 7.

CONNECT YOUR GENERATOR TO THE VESSEL.

C

a. Connect the exhaust elbow of the diesel engine to the exhaust system of the vessel. Pass the three inch exhaust hose through the opening provided in the

left side of the rear panel.

b.Connecttheseawaterpumptothevessel’swaterinlet.Passa3/4”IDhosefromthevessel’sseawaterstrainer,throughthebottomholeontheleftside

oftherearpaneltotheseawaterpumpinlettting.

c.Connectthevessel’sfuelsupplyandfuelreturntothegeneratorsetusingCoastGuardapprovedrubberfuelhose.Fuelconnectionsare5/16-37TJICinlet

and1/4-37TJICoutletlocatedatthefuelmanifoldonthebaseframeofthegeneratorset’srighthandside,throughthebottomholeintherightsideofthe

rear panel.

d.ConnecttheDCcontrolpanelharnesstothegensetengineharnessplugthroughthemiddleholeontherearpanel’srightmidside.

e. Connect the 12 volt battery leads to the generator set using the top hole on the left side of the rear panel.

f.ConnecttheACoutputleadsfromthegeneratorjunctionboxtothevessel’spowerdistributionpanel.Passthetwoleadsthroughthelowerholeontheright

side of the panel.

g. *OPTIONAL* These ports are used for siphon break applications.

Install connections for exhaust, AC power

leads, DC control panel leads, battery and

water inlet through holes in the rear panel

as shown in the drawing and as described

below:

STEP 7.

CONNECT YOUR GENERATOR TO

THE VESSEL

E

06-78700 M864W3 GEM Page 5.

D

STEP 8.

INSTALL NON-SERVICE SIDE PANEL (ITEM#8).

DETAIL E

SHOWING HOW THUMB SCREW

"B" ENGAGES LOWER CAPTIVE NUT.

F

G

THUMB SCREW A

THUMB SCREW B

THUMB SCREW B

DETAIL F

THUMB SCREW "B"

DETAIL G

THUMB SCREW A

5.

PANEL ATTACHES TO REAR PANEL AND LOWER VALENCE

WITH THUMB SCREWS "A" AND "B".

WITH PANEL IN PLACE USE THUMB SCREW "A" TO RETAIN

SIDE PANEL, MOVING ON TO THUMB SCREWS "B".

APPLY DOWNWARD PRESSURE AS YOU TURN THUMB SCREW "B"

TO ENGAGE THE CAPTIVE NUTS INSIDE THE LOWER VALENCE.

DO THE OPPOSITE TO REMOVE.

D

6

7

H

ITEM#10

DETAIL H

THUMB SCREW A

I

DETAIL I

THUMB SCREW A

LOCATOR PINS

06-78700 M864W3 GEM Page 6.

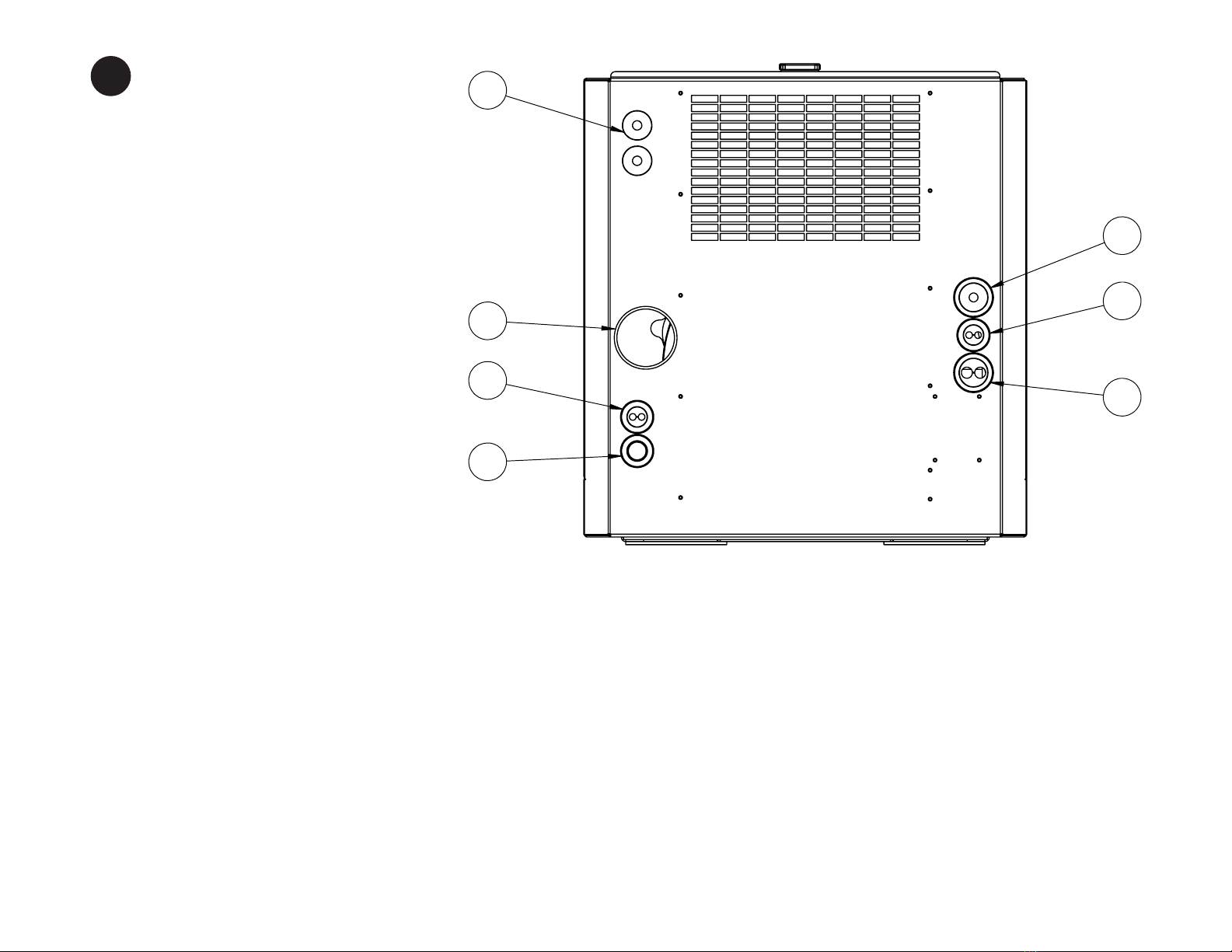

E

6.

STEP 9.

INSTALL FRONT PANEL ASSEMBLY (ITEM#10)

POSITION FRONT PANEL ON TOP OF THE FRONT LOWER VALENCE.

NOTE THE PINS IN THE BOTTOM OF THE FRONT PANEL ALIGN

TO HOLES IN THE LOWER VALENCE. ENGAGE, AND SECURE

TO THE SIDE PANEL WITH THUMB SCREW 'A' (DETAIL H) AND

THUMB SCREW 'A' IN BOTTOM FLANGE INSIDE THE FRONT

PANEL (DETAIL I) .

E

F

PRE-INSTALLED EMERGENCY STOP SWITCH

ITEM #9.

LEAK ALARM LIGHT MOUNTING HOLE

LEAK ALARM LIGHT ASSEMBLY (ITEM#15)

J

EMERGENCY STOP TERMINALS

HARNESS MOUNTING POINT

HARNESS MOUNTING POINT

LEAK ALARM LIGHT TERMINALS

DETAIL J

SCREW COLLAR

ITEM#15.

SOUND FOAM OMITTED

FOR VIEW CLARITY.

NOTE POSITIVE TERMINAL

POLARITY, POSITION AT

TOP.

06-78700 M864W3 GEM Page 7

F

STEP 10

PRIOR TO INSTALLING THE SERVICE SIDE AFT PANEL (ITEM#9) THE LEAK ALARM LIGHT AND CONNECTING

HARNESS (ITEM#16) MUST BE INSTALLED. START WITH THE ALARM LIGHT, THEN FOLLOW WITH THE HARNESS

AS SHOWN IN THE FOLLOWING ILLUSTRATIONS.

7.

UNSCREW COLLAR RING FROM LIGHT

ASSEMBLY TO INSTALL THROUGH PANEL.

RE-INSTALL COLLAR TO SECURE.

8

9

C

A

B

SHIPPED LOOSE

SOUND SHIELD WIRE HARNESS

STEP 12

INSTALL FLOAT SWITCH TO THE CORRESPONDING

BRACKET ON THE BASE FRAME. BE SURE TO CHECK THE

LEAK ALARM LIGHT BY LIFTING UP THE FLOAT AFTER

GENERATOR SET IS CONNECTED TO STARTER BATTERY.

FLOAT

DETAIL C

BASE FRAME

FLOAT SWITCH BRACKET

RED LEAD

RED LEAD

DETAIL A

RED LEAD (+)

BLACK LEAD (-)

DETAIL B

SHIPPED LOOSE

LEAK ALARM LIGHT

STANDARD ENGINE HARNESS CONNECTOR

WITH PRE-INSTALLED END PLUG

A

ENGINE HARNESS CONNECTOR

WITH THE END PLUG REMOVED

B

ENGINE WIRE HARNESS

CONNECTOR

END PLUG

SHIPPED LOOSE

SOUND SHIELD WIRE HARNESS

E-STOP SWITCH

LEAK ALARM LIGHT

FLOAT SWITCH

TO BE CONNECTED TO

ENGINE WIRE HARNESS

C

STEP 13

A. LOCATE AND IDENTIFY THE ENGINE WIRE HARNESS.

B. REMOVE THE ENGINE WIRE HARNESS END PLUG.

C. CONNECT SOUND SHIELD WIRE HARNESS TO THE ENGINE WIRE HARNESS.

PRE-INSTALLED

EMERGENCY STOP SWITCH

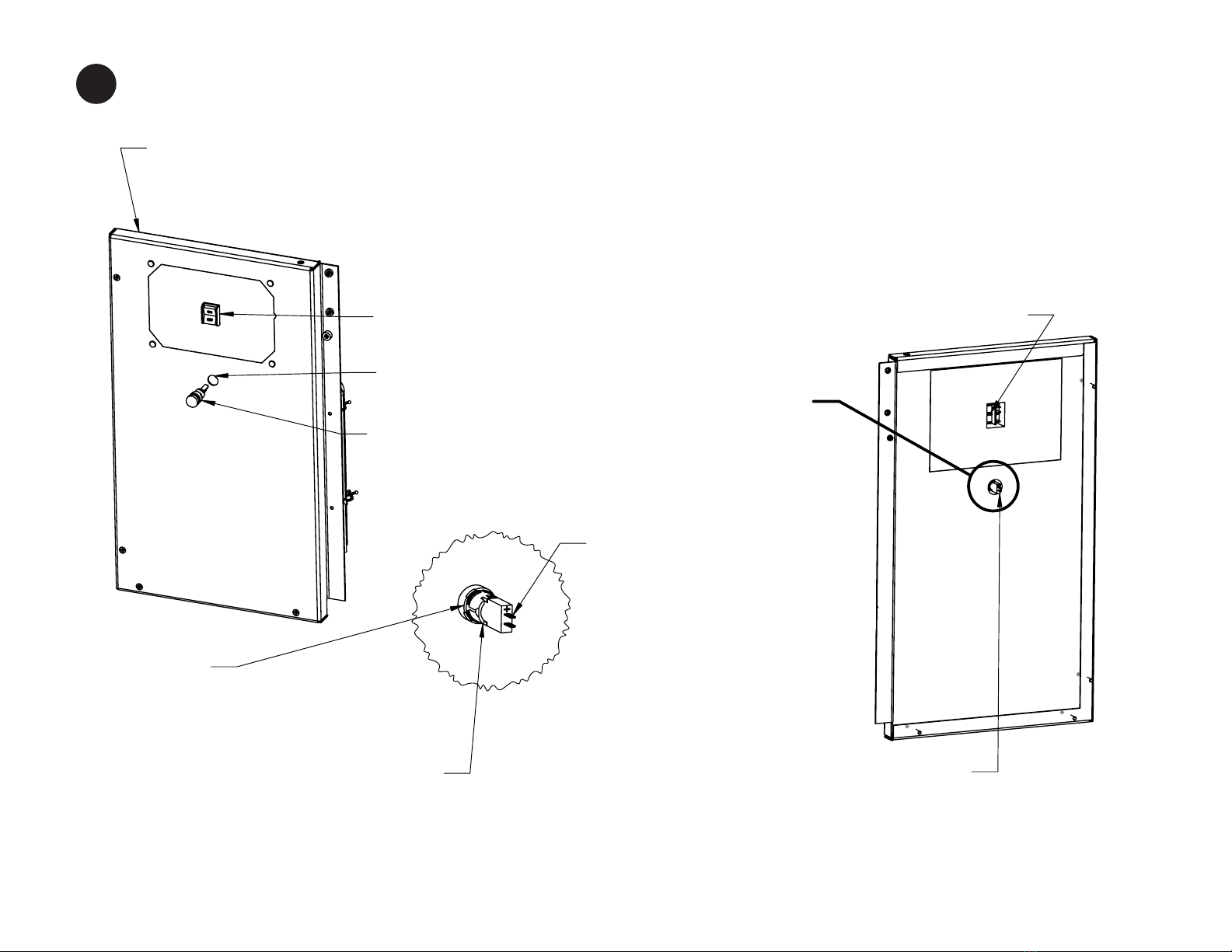

STEP 11

CONNECT SOUND SHIELD WIRE HARNESS TO

EMERGENCY STOP SWITCH AND LEAK ALARM

LIGHT AS SHOWN IN DETAIL A AND DETAIL B.

NOTES:

LEAK ALARM LIGHT WILL NOT

OPERATE IF POLARITY IS SWITCHED.

C

A

B

SHIPPED LOOSE

SOUND SHIELD WIRE HARNESS

STEP 12

INSTALL FLOAT SWITCH TO THE CORRESPONDING

BRACKET ON THE BASE FRAME. BE SURE TO CHECK THE

LEAK ALARM LIGHT BY LIFTING UP THE FLOAT AFTER

GENERATOR SET IS CONNECTED TO STARTER BATTERY.

FLOAT

DETAIL C

BASE FRAME

FLOAT SWITCH BRACKET

RED LEAD

RED LEAD

DETAIL A

RED LEAD (+)

BLACK LEAD (-)

DETAIL B

SHIPPED LOOSE

LEAK ALARM LIGHT

STANDARD ENGINE HARNESS CONNECTOR

WITH PRE-INSTALLED END PLUG

A

ENGINE HARNESS CONNECTOR

WITH THE END PLUG REMOVED

B

ENGINE WIRE HARNESS

CONNECTOR

END PLUG

SHIPPED LOOSE

SOUND SHIELD WIRE HARNESS

E-STOP SWITCH

LEAK ALARM LIGHT

FLOAT SWITCH

TO BE CONNECTED TO

ENGINE WIRE HARNESS

C

STEP 13

A. LOCATE AND IDENTIFY THE ENGINE WIRE HARNESS.

B. REMOVE THE ENGINE WIRE HARNESS END PLUG.

C. CONNECT SOUND SHIELD WIRE HARNESS TO THE ENGINE WIRE HARNESS.

PRE-INSTALLED

EMERGENCY STOP SWITCH

STEP 11

CONNECT SOUND SHIELD WIRE HARNESS TO

EMERGENCY STOP SWITCH AND LEAK ALARM

LIGHT AS SHOWN IN DETAIL A AND DETAIL B.

NOTES:

LEAK ALARM LIGHT WILL NOT

OPERATE IF POLARITY IS SWITCHED.

C

A

B

SHIPPED LOOSE

SOUND SHIELD WIRE HARNESS

STEP 12

INSTALL FLOAT SWITCH TO THE CORRESPONDING

BRACKET ON THE BASE FRAME. BE SURE TO CHECK THE

LEAK ALARM LIGHT BY LIFTING UP THE FLOAT AFTER

GENERATOR SET IS CONNECTED TO STARTER BATTERY.

FLOAT

DETAIL C

BASE FRAME

FLOAT SWITCH BRACKET

RED LEAD

RED LEAD

DETAIL A

RED LEAD (+)

BLACK LEAD (-)

DETAIL B

SHIPPED LOOSE

LEAK ALARM LIGHT

STANDARD ENGINE HARNESS CONNECTOR

WITH PRE-INSTALLED END PLUG

A

ENGINE HARNESS CONNECTOR

WITH THE END PLUG REMOVED

B

ENGINE WIRE HARNESS

CONNECTOR

END PLUG

SHIPPED LOOSE

SOUND SHIELD WIRE HARNESS

E-STOP SWITCH

LEAK ALARM LIGHT

FLOAT SWITCH

TO BE CONNECTED TO

ENGINE WIRE HARNESS

C

STEP 13

A. LOCATE AND IDENTIFY THE ENGINE WIRE HARNESS.

B. REMOVE THE ENGINE WIRE HARNESS END PLUG.

C. CONNECT SOUND SHIELD WIRE HARNESS TO THE ENGINE WIRE HARNESS.

PRE-INSTALLED

EMERGENCY STOP SWITCH

STEP 11

CONNECT SOUND SHIELD WIRE HARNESS TO

EMERGENCY STOP SWITCH AND LEAK ALARM

LIGHT AS SHOWN IN DETAIL A AND DETAIL B.

NOTES:

LEAK ALARM LIGHT WILL NOT

OPERATE IF POLARITY IS SWITCHED.

G

M

ITEM #11

DETAIL M

THUMB SCREW A

06-78700 M864W3 GEM Page 9

G

STEP 11

INSTALL SEAL BAR ASSEMBLY (ITEM#11).

LOCATE BAR TO CORRESPONDING HOLES AND

SECURE WITH THUMB SCREW 'A', FOUR PLACES.

HAND TIGHTEN FIRM, DO NOT USE TOOLS.

9.

STEP 14

10

11

H

N

O

10.

ITEM#12

DETAIL N

LOCATOR PIN

DETAIL O

LOCATOR PIN

06-78700 M864W3 GEM Page 10.

H

STEP 12

INSTALL THE TOP PANEL ASSEMBLY (ITEM#12). NOTE THAT THE PANEL HAS LOCATING PINS

UNDER THE MATING FLANGE ( 6 TOTAL). ALIGN THESE WITH THE CORRESPONDING HOLES

ON THE TOP OF THE FRONT AND REAR PANELS ASSEMBLIES. REFER TO DETAILS 'N' AND 'O'.

THE RING LATCHES ARE FACTORY PRESET BUT OCCASIONALLY REQUIRE SOME ADJUSTMENT.

SEE THE LATCH ADJUSTMENT SECTION (PAGE 12) OF THESE INSTRUCTIONS.

STEP 15

I

06-78700 M864W3 GEM Page 10.

I

11

STEP 13

INSTALL THE SERVICE SIDE PANEL ASSEMBLY (ITEM#13).

NYLON LOCATOR PINS

NYLON LOCATOR PINS

ITEM #13

GUIDE THE BLACK NYLON LOCATOR PINS ON PANEL (ITEM#13) INTO THE

CORRESPONDING SLOTS ON THE LOWER VALENCE. TWIST RING LATCH

TO CLOSE AND LOCK. THE RING LATCH IS PRESET FROM THE FACTORY

BUT MAY OCCASIONALLY REQUIRE SOME ADJUSTMENT. REFER TO

THE LATCH ADJUSTMENT SECTION (PAGE 12) OF THE INSTRUCTIONS.

STEP 16

12

13

A

A

A

SECTION A-A

PAWL SLOT

TOP NUT

BOTTOM NUT

STAR WASHER

LATCH SHAFT

LATCH PAWL

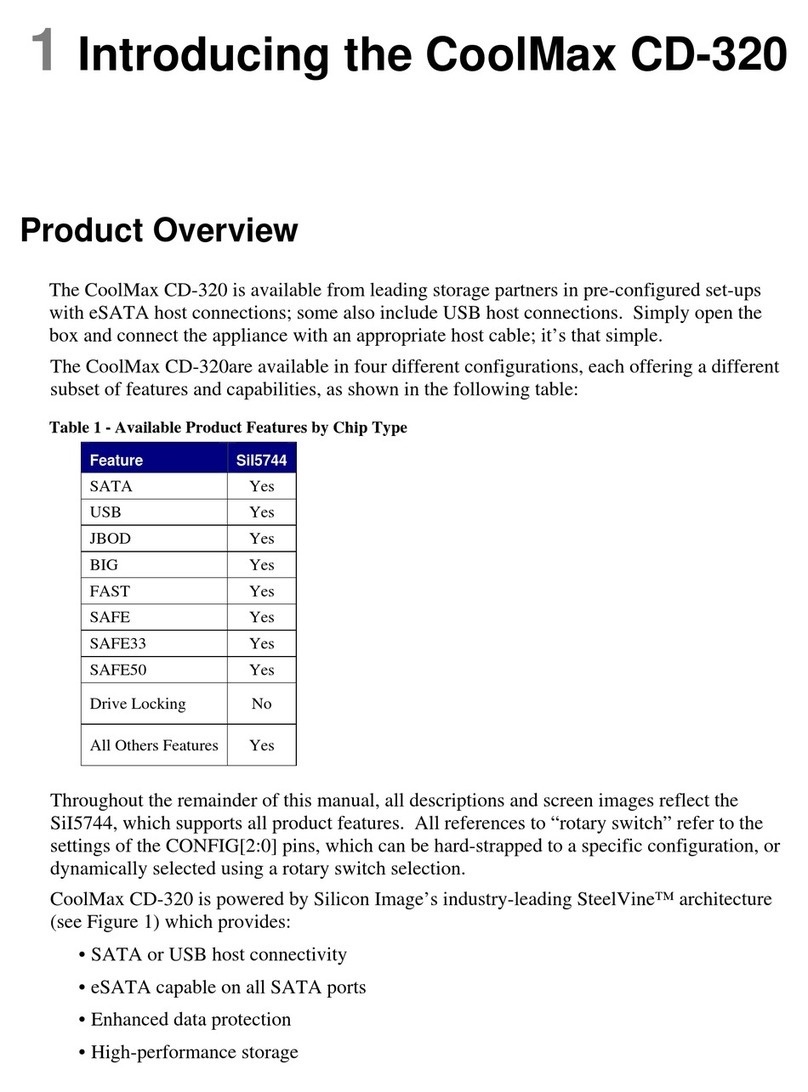

ALL LATCHES ARE PRE-ADJUSTED FROM FACTORY. IN THE EVENT A LATCH REQUIRES ADJUSTMENT, FOLLOW THESE STEPS:

NOTE THE INTERFERENCE, OR REASON WHY THE LATCH PAWL WILL NOT ENGAGE THE PAWL SLOT. IF PAWL HITS SLOT BRACKET

1.

OR SHELF IT MUST BE MOVED TO ALLOW PAWL TO ROTATE INSIDE SLOT.

2. LATCH PAWL SHOULD OPERATE WITHIN SLOT FREELY WHEN LATCH HANDLE ROTATES ON REMOVAL.

3. WITH LATCH IN CLOSED POSITION, (LATCH PAWL POINTING TOWARDS SLOT, LOOSEN THE BOTTOM NUT. TURN TOP NUT

TO CHANGE POSITION OF PAWL AND THEN RE-TIGHTEN THE BOTTOM NUT. ENSURE THE NUT IS FULLY TIGHT BEFORE

OPERATING THE LATCH.

4. AN IDEAL LATCH CONDITION IS WHEN THE PAWL SWINGS INTO POSITION ON CLOSING, PULLS UP AND ENGAGES THE TOP OF

THE SLOT WITH INCREASING RESISTANCE. WHEN THE LATCH RING IS FULLY DEPRESSED THERE SHOULD BE FIRM COMPRESSION OF

PANEL PERIMETER SEAL.

5. IF YOU CAN LIFT UP A CORNER OF THE TOP PANEL AND SEE A SPACE, THE LATCH IS NOT TIGHT ENOUGH.

RING LATCH GRIP ADJUSTMENT INSTRUCTIONS

SOME MODELS USE

THIS SURFACE TO LATCH

SOUND FOAM OMITTED FOR VIEW CLARITY

06-78700 M864W3 GEM Page 12.

12.

J

K

REAR PANEL VIEW

FROM SEA WATER PUMP OUTLET TO SIPHON BREAK

FROM SIPHON BREAK TO HEAT EXCHANGER INLET

06-78700 M864W3 GEM Page 13

13.

IF YOU HAVE CHOSEN TO INSTALL A SIPHON BREAK:

Note the two plugged penetrations in the top left corner

of the rear panel. These are the ports through which the

siphon break lines will be routed.

At this time you should refer to the plumbing diagram in the

mounting and exhaust sections of the IM1000 Installation manual.

Remove the white plastic hole plugs by pushing them out

from the inside and replace with the two rubber grommets

(ITEM#14) provided.

CAUTION. GENERATOR SETS WITH WET EXHAUST THAT ARE

INSTALLED NEAR OR BELOW THE VESSEL'S HULL WATER LINE

MUST USE A SIPHON BREAK TO PREVENT BACK FLOW OF

WATER INTO THE ENGINE. THIS BACKFLOW CAN RUIN AN

ENGINE AN POSSIBLY SINK THE VESSEL.

Disconnect the hose from the sea water pump output and

a.

the inlet to the heat exchanger. Replace this single hose

with two 3/4" ID lines, one from the sea water output and

the other to the heat exchanger inlet. These hoses must

be of adequate length to mount a siphon break a min

of 12 inches above the vessel's loaded water line.

b. Pass these lines through the two holes in the rear panel,

as indicated per the diagram.

c. For more information, see the "Exhaust" section of the

IM 1000 Installation Manual.

OUT TO VENTED LOOP

IN FROM VENTED LOOP

FOR APPLICATIONS USING A SIPHON BREAK:

Remove the white plastic hole plugs by pushing them out from the inside and

replace with the two rubber grommets (item 15) provided.

a. Disconnect the hose from the seawater pump output and from the rubber

elbow on the expansion tank. Install two lengths of 3/4” hose. The hoses

must be of adequate length to allow mounting of a siphon break, a minimum

of12inchesabovethevessel’sloadedwaterline.

b. Pass the seawater pump output hose through the top hole in the panel. The

hose from the expansion tank must go through the bottom hole in the panel.

c. For more information, see the “Exhaust” section of IM1000 Installation

Manual.

CAUTION: GENERATOR SETS WITH WET EXHAUST THAT ARE

INSTALLEDNEARORBELOWTHEVESSEL’SWATERLINEMUSTUSE

A SIPHON BREAK TO PREVENT BACKFLOW OR WATER INTO THE

ENGINE. THIS BACKFLOW CAN RUIN AN ENGINE AND POSSIBLY

SINK THE VESSEL.

14

REAR PANEL ASSEMBLY

06-78703 QTY 1.

SERVICE SIDE LOWER VALENCE 06-78707

QTY: 1.

ITEM#5

NON-SERVICE SIDE LOWER VALENCE 06-78709

QTY: 1.

ITEM#6

FRONT LOWER VALENCE

ASSEMBLY 06-78719 QTY 1.

NON-SERVICE SIDE PANEL ASSEMBLY 06-78715

QTY 1.

ITEM#8

SERVICE SIDE AFT

PANEL ASSEMBLY

06-78713 QTY 1.

FRONT PANEL ASSEMBLY

06-78701 QTY 1.

ITEM#10

SEAL BAR ASSEMBLY 06-78723

QTY: 1.

ITEM#11

TOP PANEL ASSEMBLY 06-78705

QTY 1.

ITEM#12

SERVICE SIDE FWD PANEL

ASSEMBLY 06-78711 QTY 1.

ITEM#13

06-78700 M864W3 GEM Page14.

PACKING LIST

CABLE ROUTING CLIP 00-40052 QTY 2.

E-STOP/LEAK ALARM HARNESS

22-72024 QTY 1.

LEAK DETECTION ALARM

LIGHT 22-90382 QTY 1.

VENTED LOOP GROMMETS

00-70083 QTY 2

ITEM#1

ITEM#7

ITEM#9

ITEM#17

ITEM#15

ITEM#16

ITEM#14

ITEM#2

ITEM#3

ITEM#4

ITEMS IN THIS BOX ARE ENLARGED FOR DETAIL

M8 FLATWASHER

15-11000 QTY4

M8 LOCK WASHER

15-00705 QTY4

M8 HEX CAPSCREW

12-00776 QTY 4

Packed By : Date :

00-70146

LIT NO.: L817 4/20

Other manuals for GEM Series

3

This manual suits for next models

1

Table of contents

Other Northern Lights Enclosure manuals