Northern Lights Lugger M673D User manual

M673D / M673L

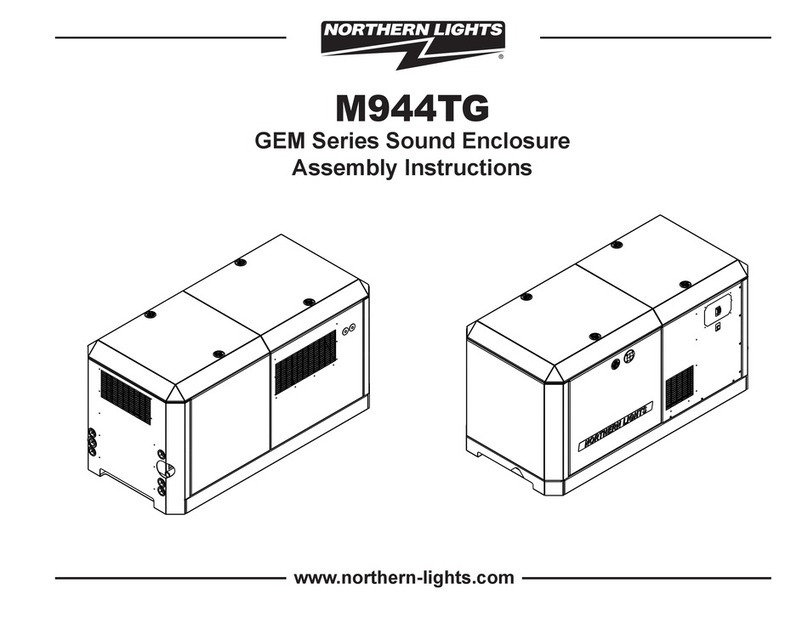

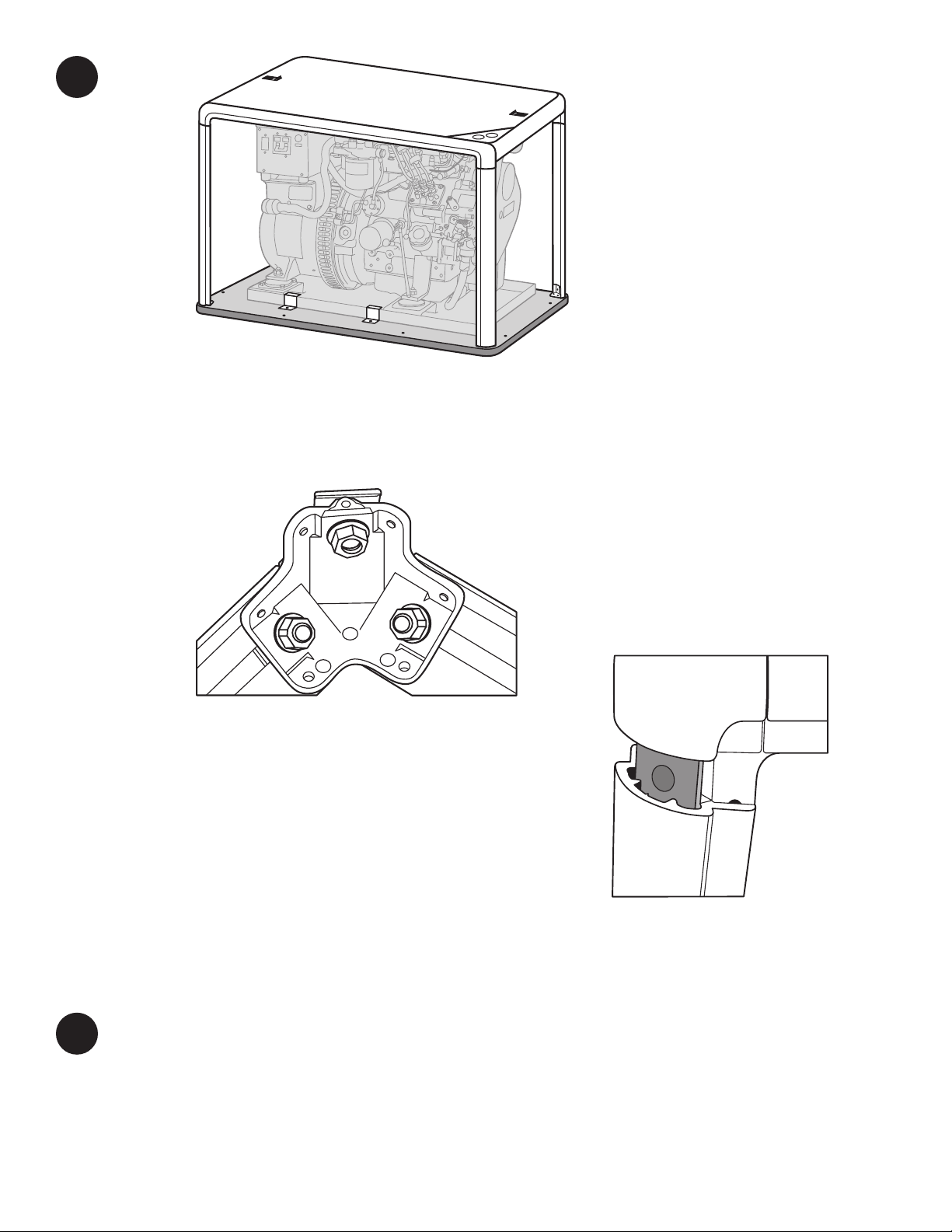

Soundshield Assembly Instructions

Corporate Headquarters

4420 14th Avenue N.W.

P.O. Box 70543

Seattle, WA 98107

Tel: (206) 789-3880

Fax: (206) 782-5455

Southeastern U.S.A.

1405 S.W. 6th Court

Suite A

Pompano Beach, FL 33069

Tel: (954) 946-7601

Fax: (954) 946-7409

East Coast Branch

Northern Lights Industrial Park

8 Connector Road

Andover, MA 01810

Tel: (978) 475-7400

Fax: (978) 475-7745

Alaska Branch Office

1200 West Int’l Airport Road

P.O. Box 190208

Anchorage, AK 99519

Tel: (907) 562-2222

Fax: (907) 563-1921

www.northern-lights.com

L612 02/05

L612 02/05

ITEM # DESCRIPTION ADE P/N QTY NOTES

1. Base board 39-78014 1

2. Extrusion, vertical 39-78016 4

3. Extrusion, horizontal, sides 39-78017 2

4. Extrusion, horizontal, ends 39-78024 2

5. Corner casting 05-70001 4

6. Bolting assembly 00-75714 20

7. Rear panel assembly 39-78006 1

8. Front panel assembly 39-78004 1

9. LH side panel assembly 39-78009 1 w/vent box

10. RH side panel assembly 39-78011 1 no vent box

11. Top panel assembly 39-78007 1

12. Penetration panel assembly 39-78008 1

13. Panel retainer bracket, 30R 23-70036 6

14. #10 screw s/s x 5/8”long 12-72002 8

15. Toe bracket, 30R 23-70038 4

16. Hex nut, nylock 1/4-20 14-00112 6

17. Intake hose 1 1/8 ID 18-28001 1

18. Air filter element 24-28002 1

19. Cover, intake 10-28001 1

Specifications

Enclosure:

Length (OA) 32.0 in (814 mm)

Width 20.63 in (524 mm)

Height 21.0 in (533 mm)

Base:

Length 32.5 in (826 mm)

Width 21.2 in (538 mm)

Height 0.75 in (19.05 mm)

Assembled Height:

21.72 in (552 mm)

Assembled Weight (est):

55 lbs (24.9 kg)

M673D/M673L Soundshield

L612 03/03 1

L612 02/05

4

3

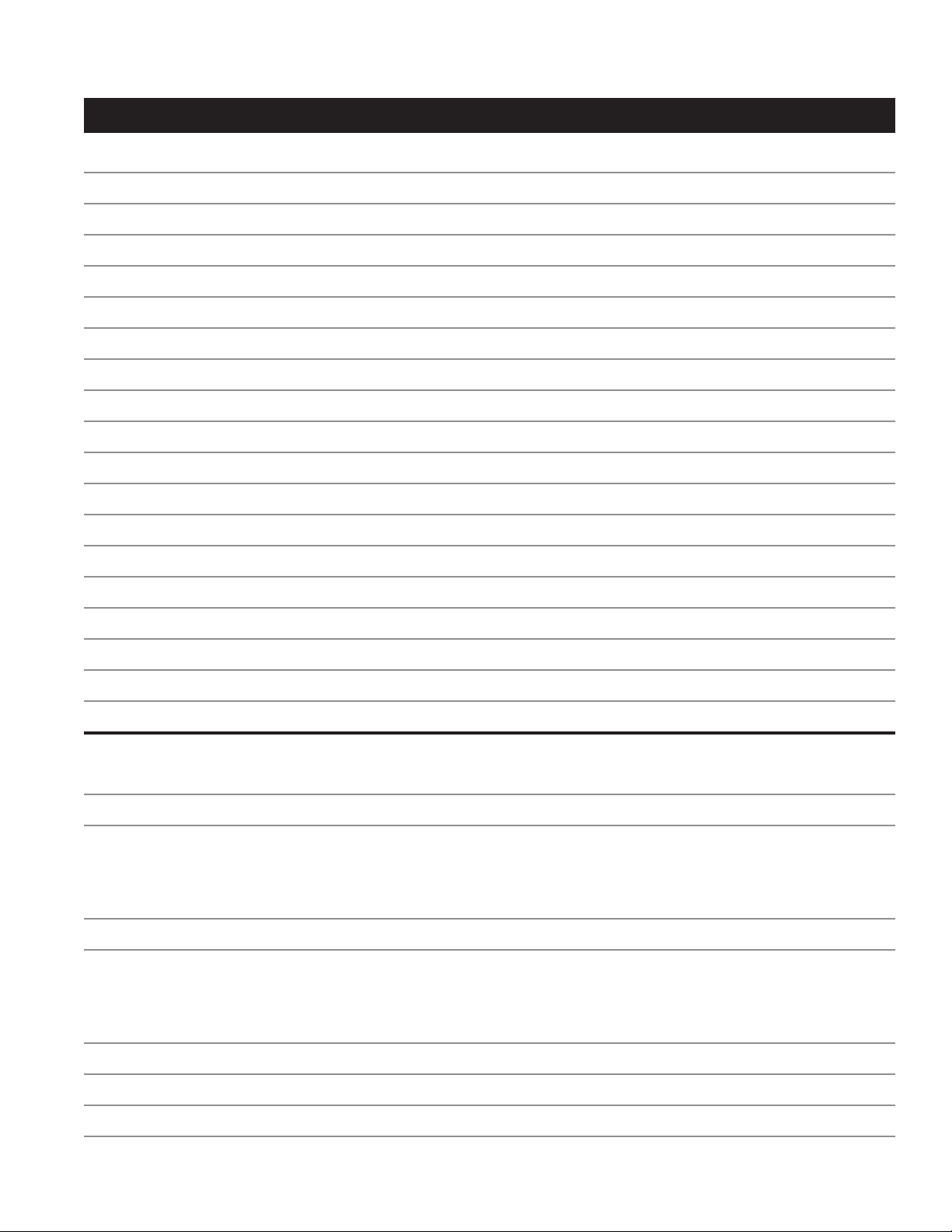

Prior to assembly, inspect all components for damage. Report any damage to the shipping company.

Check the packing list to be sure all parts are included.

Install the base board (item 1) in the vessel in as near a level attitude as possible. Observe the arrow

symbol on the board’s topside surface.This indicates the top and forward end orientation of the

genset / soundshield. Make sure arrow is correctly positioned or the unit will not mount correctly

within the shield.

Install toe bracket (item 15) to each corner of the base board with screws (item 14) into pre-drilled

holes. See figure 1.

Note that there are pre-drilled“through”holes on each side of the baseboard. Use these holes as

guides to drill into the supporting substructure for through-bolting.

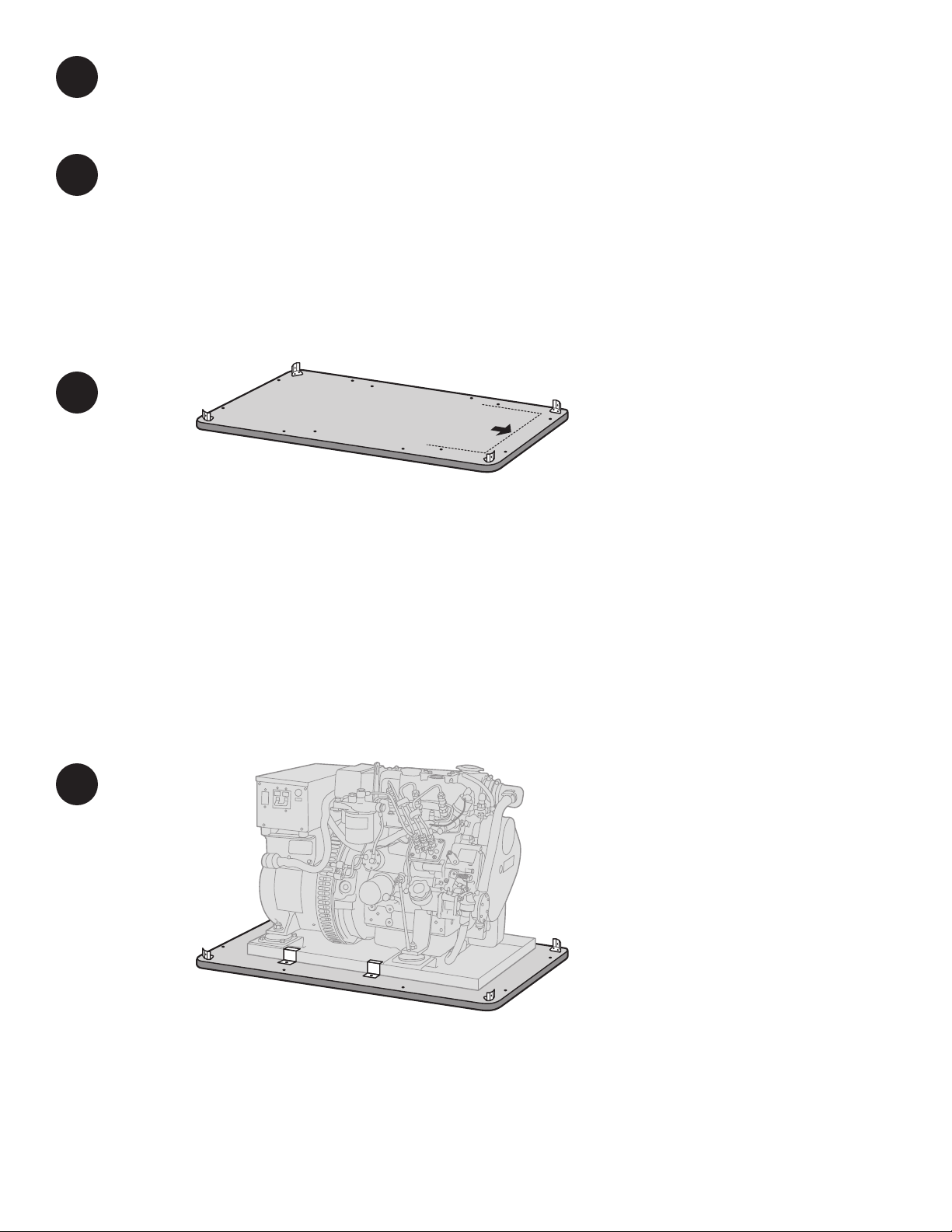

Place the generator set onto the baseboard. Note that there are lines present on the base board at

the front and the sides; position the genset base pan to conform with these alignment markings.

Install the hold down clips to the pre-drilled through holes along both sides of the genset base pan.

Use 3/8”or 9 mm bolts of appropriate length to secure the genset and baseboard to the underlying

structure. Loosen lifting eye mounting bolt and tip lifting eye down until lower than highest point on

engine.Tighten lifting eye mounting bolt.

1

2

Select a mounting location in accordance with the guidelines in the IM1000 Installation Manual

(supplied with the generator set). The generator set must typically be mounted on a rigid, flat sur-

face above a strong structure, such as the vessel’s stringers, to minimize vibration transference to the

hull. CAUTION: THE BASEBOARD IS A NONSTRUCTURAL MATERIAL AND MUST BE FULLY

SUPPORTED TO MINIMIZE FLEX.

Note that the generator set is designed for single side service.When viewed from the rear, the right

hand side is the service side and should be exposed for easy maintenance access.

2

L612 02/05

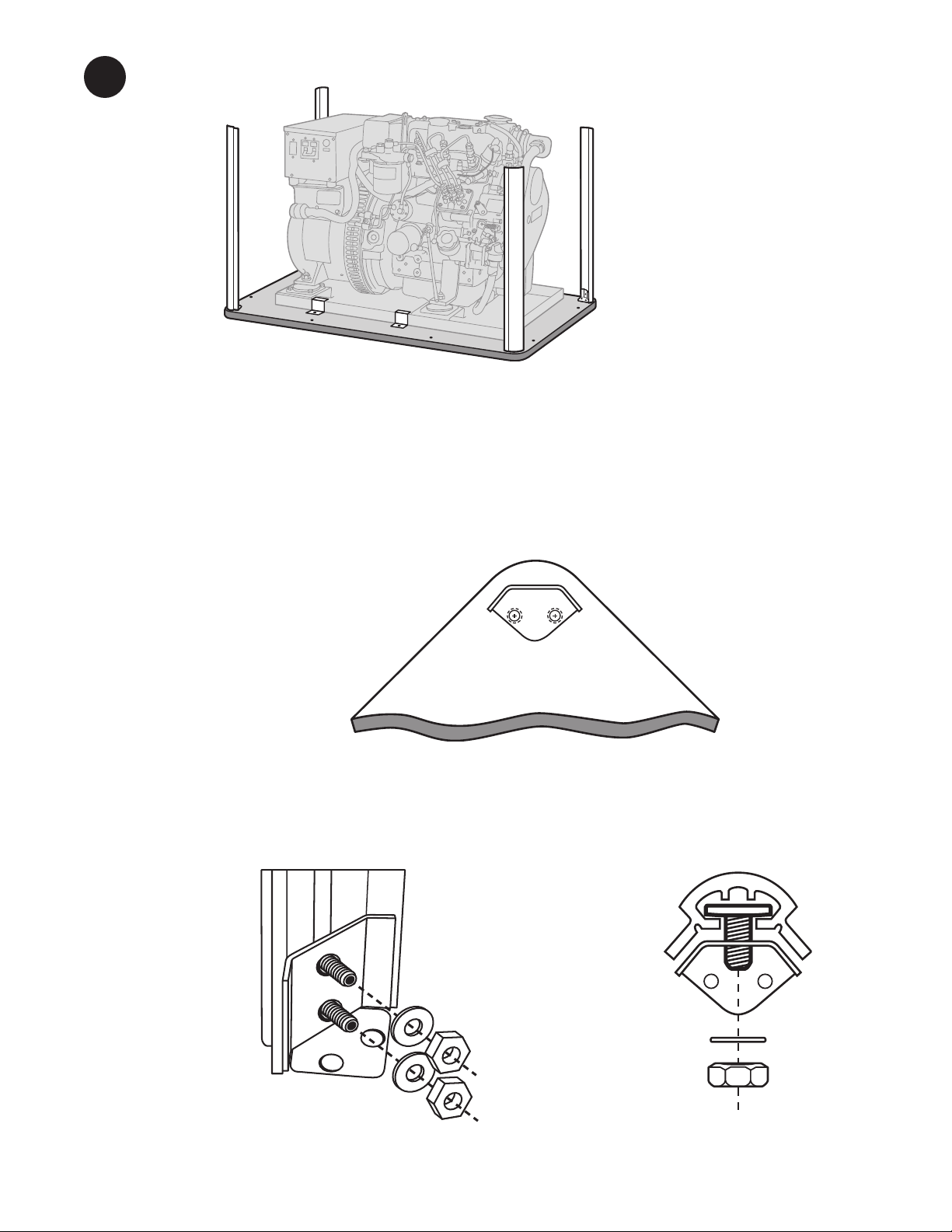

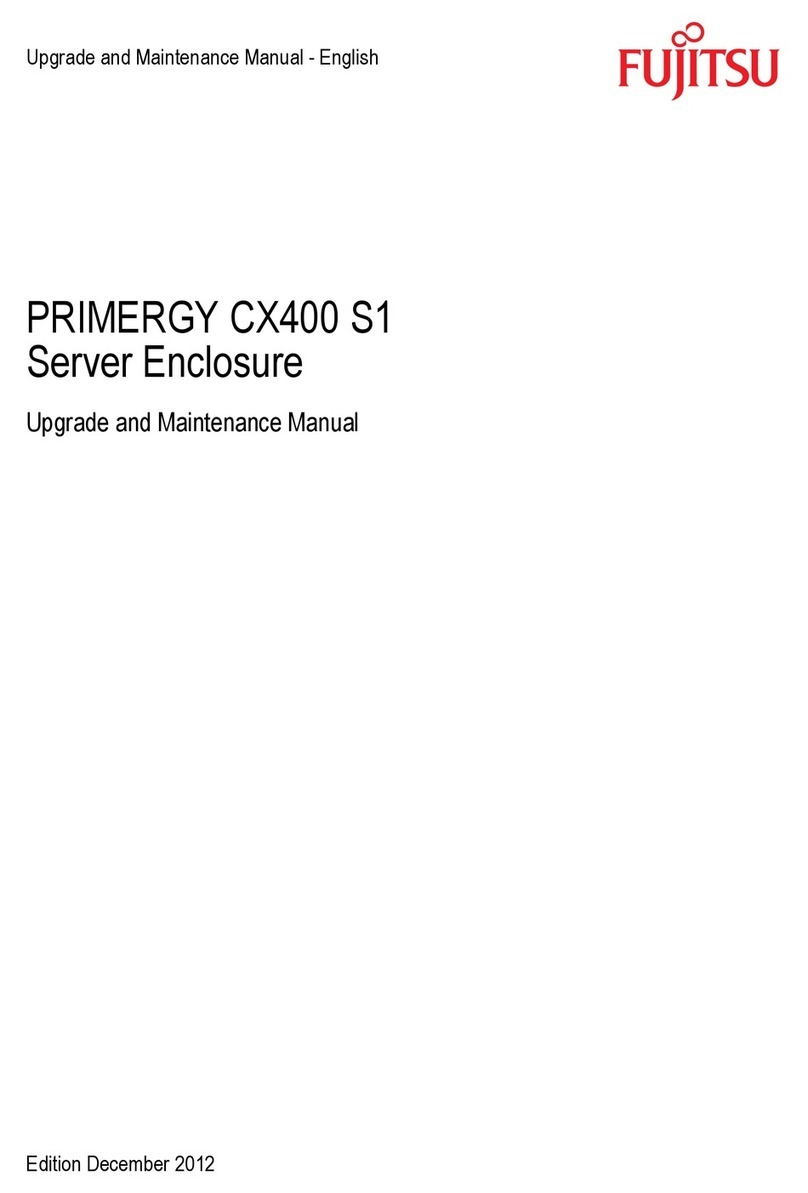

Install the four vertical corner extrusions (item 2) with eight bolting assemblies (item 6) per figures

1A and 1B. Leave hexnuts finger tight.

Figure 1A: Toe bracket shown with vertical extrusion

installed.

3

Figure 1B: Note how the square head of the T-bolt goes

inside the extrusion recess.

5

Figure 1: Typical corner, top view.

L612 02/05

Orient top with triangular shaped penetration plate (item 12) toward front of genset and unattached

corner legs facing down. Install each leg into the top of vertical extrusion. See Figure 3.You may wish

to temporarily remove the top panel (item 11) and set it aside to improve access to the bolting

assemblies and for step 8. Check frame for squareness and tighten all connections.

Figure 3: Note how bolting assembly fits inside vertical

extrusion. Finger tighten only until all four corners have

been fully installed.

6

Note the available leg on each cast corner (item 5) of the pre-assembled enclosure top (items 3, 4, 5,

6, 11, 12, 13 & 16). Loosely install a bolting assembly (item 6) to each of these legs. See Figure 2.

Figure 2: Internal view of corner casting, part of

the pre-assembled top enclosure frame assembly.

Note arrangement of bolting assembly.

4

7

L612 02/05

8

Mount the rear panel assembly (item 7) to the rear of the enclosure frame. Ensure that the panel is

properly fitted into the back of the frame, with the panel surface to extrusion being flush. Rotate

panel retainer brackets (item 13) until they are directly on top of the extrusion flange.Tighten nylock

nuts so the retainer effectively clamps the panel against the extrusion flange. Caution: do not

overtighten retainer clip nuts, as seal damage could occur.

If engine contains pre-installed pre-formed rubber intake hose, proceed to step 10. Check to see if air

filter element protrudes below air box. If it does, it is an older style element and should be replaced

with new filter (item 18) included with kit. Your unit may already be equipped with the new style

filter and if so, replacing it is not required.Take cover (item 19) and insert end (indicated with star)

first into intake manifold opening. Now close the intake cover by pushing the remaining clip into

manifold recess. Remove and discard pre-installed grommet in side of intake box. Take the other end

of the intake hose (item 17) and firmly push it into the hole on the side of the intake box

(see figure 4). Proceed to step 11

5

Figure 4: Air snorkel kit for use in sound shield.

Discard items 17, 18 & 19. Install free end of formed rubber intake hose through grommet on side of

intake box as shown in figure 4.

9

10

L612 02/05

Install connections for exhaust, fuel, AC power leads, DC control panel leads, battery, and water

through holes in the rear panel as shown in drawing (Figure 5) and as described below:

a. Connect the exhaust elbow of the diesel engine to the exhaust system of the vessel.

Pass the two inch exhaust hose through the opening provided in the left mid-section

of the rear panel.

b. Connect the sea water pump to the vessel’s water inlet. Pass a 3/4”hose from the vessel’s

sea water strainer through the lower hole at the bottom left of the rear panel to the sea

water pump inlet fitting.

c. Connect the vessel’s fuel supply and fuel return to the generator set using Coast Guard

approved rubber fuel hoses. Pass these lines through the slot provided at the bottom

right of the rear panel and attach them to the generator set’s 5/16”hose barb fittings.

d. Connect the DC control harness to the engine harness plug. Pass the harness and plug

through the hole at the mid-section of the right side of the rear panel.

e. Connect the 12 volt battery leads to the generator set passing the two leads through the

second hole above the bottom left side on the rear panel.

f. Connect the AC output leads from the generator to the vessel’s power distribution panel.

Pass the two leads through the third hole above the bottom left side of the rear panel.

11

6

Figure 5: Facing the rear panel.

L612 02/05

Note the pre-installed penetration plate (item 12) in the forward right corner of the enclosure

frame top. Reference the plumbing diagram in the mounting and exhaust sections of the IM1000

installation manual.

a. Disconnect the hose from the seawater pump output and from the rubber elbow on the

expansion tank. Install two lengths of 3/4”hose.The hoses must be of adequate length

to allow mounting of a siphon break a minimum of 12 inches above the vessel’s loaded

water line.

b. Pass the seawater pump output hose through the hole in the penetration plate closest

to the front of the shield.The hose from the expansion tank must go through the hole in

the penetration plate closest to the side of the shield.

c. For more information, see the“Exhaust”section of the IM-1000 Installation Manual

included with the generator set.

Start the generator set and run under load to check for leaks of fuel, water, or exhaust gas.

12

13

7

CAUTION: GENERATOR SETS WITH WET EXHAUST THAT ARE INSTALLED NEAR OR BELOW

THE VESSEL’S WATER LINE MUST USE A SIPHON BREAK TO PREVENT BACKFLOW OF WATER

INTO THE ENGINE. THIS BACKFLOW CAN RUIN AN ENGINE AND, POSSIBLY, SINK THE

VESSEL. The penetration plate (item 12) facilitates the siphon break installation as follows:

L612 02/05

14

Install cover panels as shown above.

As you install the panels, observe that there should be a minimum clearance of approximately 1/32”

around the panel perimeter (except at the bottom of the side panels).You may adjust for this by

loosening any number of corner bolting assemblies or toe brackets until fit is satisfactory. Tighten all

connections when done.

Although preset at the factory, one or more panel latches may occasionally need adjustment. Using

a 1/4”box-end wrench, rotate latch striking bolt one-half turn; counter clockwise to tighten panel,

clockwise to loosen panel.

8

L612 02/05

L612 02/05

ITEM # DESCRIPTION ADE P/N QTY NOTES PACKED

1 Base board 39-78014 1 assembled

q

2 Extrusion, vertical 39-78016 4 loose

q

7 Rear panel assembly 39-78006 1 assembled

q

13 Panel retainer bracket, 30R 23-70036 4 installed

q

16 Hex nut, nylock 1/4-20 14-00112 4 installed

q

Enclosure top, assembled. 1

q

Consists of the following parts:

3 Extrusion, horizontal, sides 39-78017 2 assembled –

4 Extrusion, horizontal, ends 39-78024 2 assembled –

5 Corner casting 05-70001 4 assembled –

6 Bolting assembly 00-75714 8 installed –

12 Penetration panel assembly 39-78008 1 installed –

13 Panel retainer bracket, 30R 23-70036 2 installed –

16 Hex nut, nylock 1/4-20 14-00112 2 installed –

11 Top panel assembly 39-78007 1 assembled –

8 Front panel assembly 39-78004 1 assembled

q

9 LH side panel assembly 39-78009 1 assembled

q

10 RH side panel assembly 39-78011 1 assembled

q

6 Bolting assembly 00-75714 12 loose (bagged)

q

14 #10 screw s/s x 5/8”long 12-72002 8 loose (bagged)

q

15 Toe bracket, 30R 23-70038 4 loose (bagged)

q

17. Intake hose 1 1/8 ID 18-28001 1 loose (bagged)

q

18. Air filter element 24-28002 1 loose (bagged)

q

19. Cover intake 10-28001 1 loose (bagged)

q

Packed By : Date :

M673D/M673L Soundshield Packing List

This manual suits for next models

1

Other Northern Lights Enclosure manuals

Popular Enclosure manuals by other brands

Thermaltake

Thermaltake ARMOR REVO GENE VO800M1W2N user manual

Fujitsu

Fujitsu PRIMERGY CX400 S1 Upgrade and maintenance manual

MonsterLabo

MonsterLabo Only The First user manual

LEGRAND

LEGRAND 0 880 62 quick start guide

L-Acoustics

L-Acoustics 12XTi user manual

Thermaltake

Thermaltake Element T VK9000 Series user manual