Northern Lights GEM Series User manual

www.northern-lights.com

M944TG

GEM Series Sound Enclosure

Assembly Instructions

Corporate Headquarters

4420 14th Avenue NW

Seattle, WA 98107

Tel: (206) 789-3880

Fax: (206) 782-5455

Southeastern U.S.A.

1419 W Newport Center Dr

Deereld Beach, FL 33442

Tel: (954) 421-1717

Fax: (954) 421-1712

Alaska Branch Ofce

1200 West International

Airport Road

Anchorage, AK 99519

Tel: (907) 562-2222

Fax: (907) 563-1921

East Coast Branch

15 Aegean Dr.

Suite 4

Methuen MA 01844

Tel: (978) 475-7400

Fax: (978) 475-7745

Gulf Branch

19 Veterans Memorial Blvd.

Kenner, LA 70062

Tel: (504) 360-2180

Toll Free: (800) 843-6140

Northern Lights

4420 14th Avenue NW

Seattle, WA 98107

Tel: (206) 789-3880

Fax: (206) 782-5455

Copyright ©2019 Northern Lights, Inc.

All rights reserved. Northern Lights™, and

the Northern Lights logo are trademarks of

Northern Lights, Inc.

Printed in U.S.A.

LIT NO.: L831 7/20

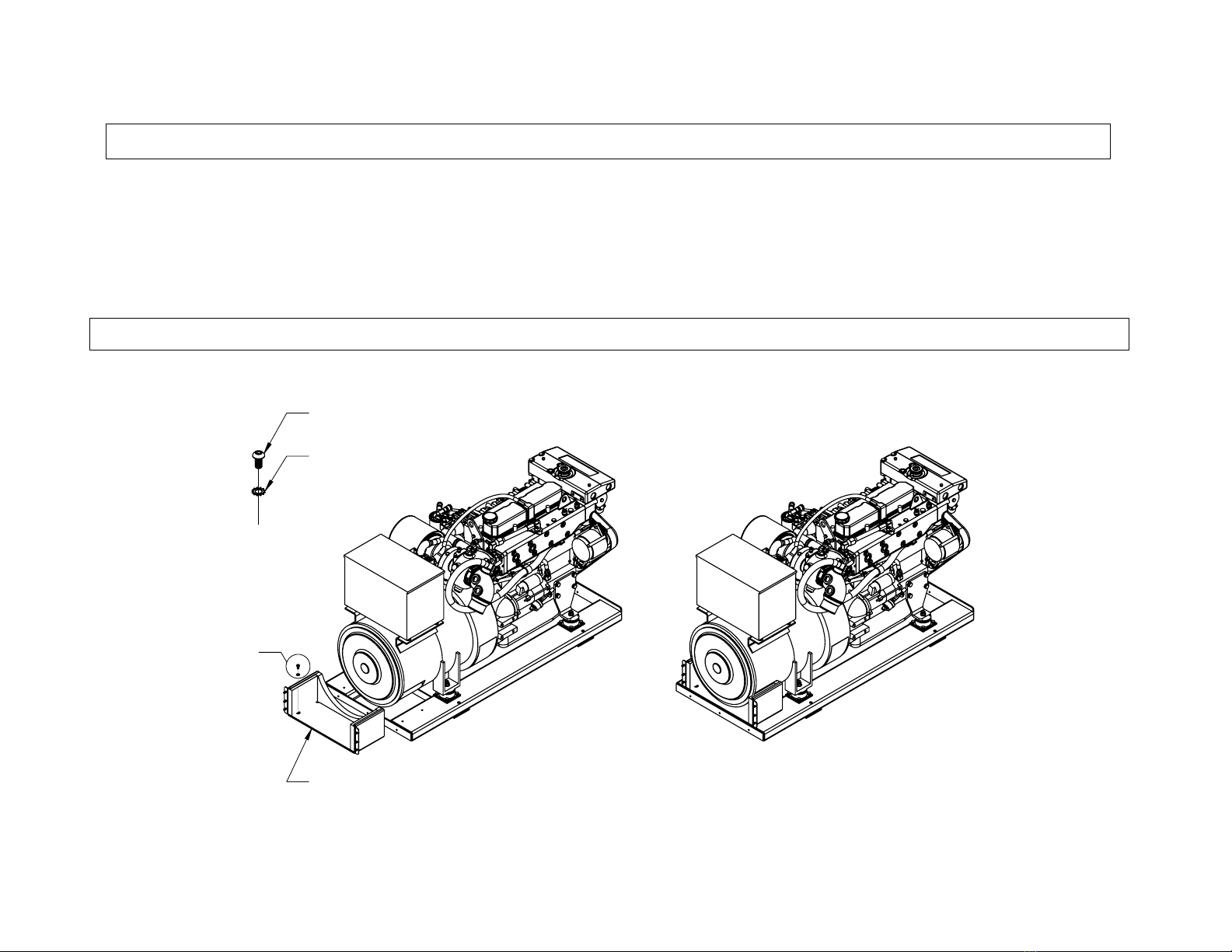

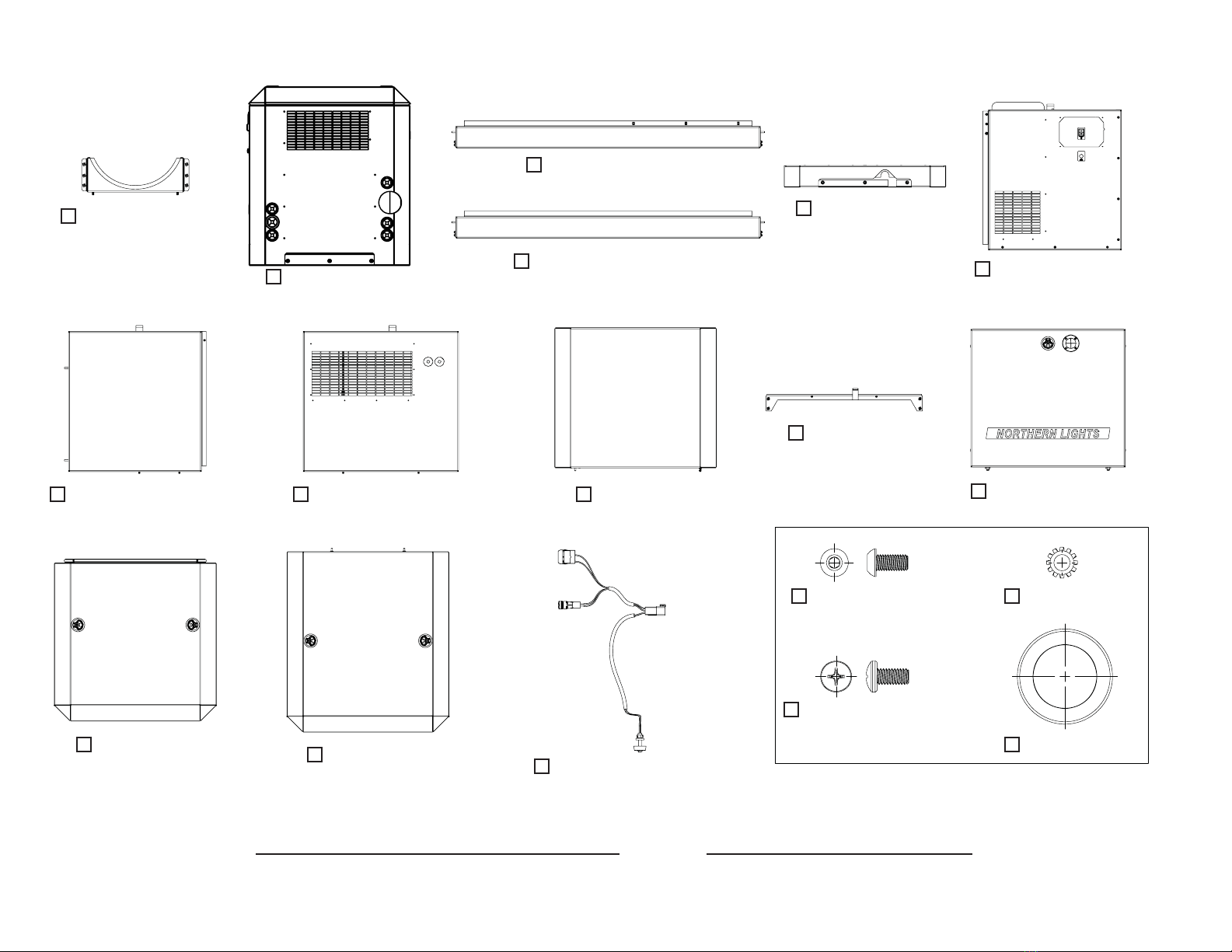

ITEM # DESCRIPTION NLI P/N QTY NOTES

1. Lower intake duct assembly 06-71272 1

2. Rear panel assembly 06-71202 1

3. Service side valence assembly 06-71206 1

4. Non-service side valence assembly 06-71207 1

5. Front valence assembly 06-71213 1

6. Service side aft panel assembly 06-71217 1

7. Non-service side aft panel assembly 06-71212 1

8. Non-service side fwd panel assembly 06-71211 1

9. Front panel assembly 06-71201 1

10. Seal bar assembly 06-71271 1

11. Service side fwd panel assembly 06-71208 1

12. Top aft panel assembly 06-71204 1

13. Top fwd panel assembly 06-71203 1

14. Sound shield wire harness 22-71227 1

15. M8 button head screw 12-00118 10

16. 5/16-18 Phillips head screw 12-00119 6

17. 5/16 lock washer 15-09204 16

18. 1-1/4” ID grommet 00-70146 2

SPECIFICATIONS

Enclosure:

Length (OA) 60.1 in (1527 mm)

Width 28.7 in (729 mm)

Height 32.0 in (813 mm)

Assembled height on base frame: 32.0 in (813 mm)

Assembled weight w/o sub-base (est): 164 lbs (74 kg)

M944TG GEM Sound Enclosure

1

STEP 1.

INSTALL LOWER INTAKE DUCT ASSY (ITEM #1).

MOUNT LOWER INTAKE ON TO THE BASE FRAME WITH M8

BUTTON HEAD SCREW AND 5/16 LOCK WASHER. USE 5mm

HEX WRENCH AND TIGHTEN WITH HAND TOOLS ONLY.

A

LOWER INTAKE DUCT ASSY

ITEM #1

DETAIL A

M8 BUTTON HEAD SCREW

ITEM #15, QTY: 4

5/16" LOCK WASHER

ITEM #17, QTY: 4

2

3

A

REAR PANEL ASSY

ITEM #2

DETAIL A

M8 BUTTON HEAD SCREWS

ITEM #15, QTY: 3

5/16" LOCK WASHER

ITEM #17, QTY:3

B

DETAIL B

5/16 LOCK WASHER

ITEM #17, QTY: 6

5/16 -18 PAN HEAD

SCREW, ITEM #16, QTY: 6

STEP 2.

INSTALL REAR PANEL ASSY (ITEM #2).

1. MOUNT REAR PANEL TO BASE FRAME WITH M8 BUTTON HEAD

SCREW AND 5/16 LOCK WASHER. USE 5mm HEX WRENCH,

TIGHTEN WITH HAND TOOLS ONLY.

2. SECURE LOWER INTAKE DUCT TO REAR PANEL WITH 5/16-18 PAN

HEAD SCREW AND 5/16 LOCK WASHER. USE PHILLIPS HEAD

SCREW DRIVER AND DO NOT OVER-TIGHTEN.

NOTES:

FOR GENERATOR CONNECTION TO THE VESSEL. SEE PAGE 10.

GENERATOR CONNECTION SHOWN ON PAGE 4

4

B

A

G

E

F

D

C

ABOUT

C:

FUTURE:

AS

LISTED,

BUT

CURRENTLY

USES

5/16-37T

JIC.

INLET

OUTLET.

IN

LIEU

OF

AN

UNCERTAIN IMPLEMENTATION TIME, CAN WE PUT: EARLY PRODUCTION: 5/16-37T JIC INLET/OUTLET.

LATE PRODUCTION: 1/4 NPT INLET OUTLET?

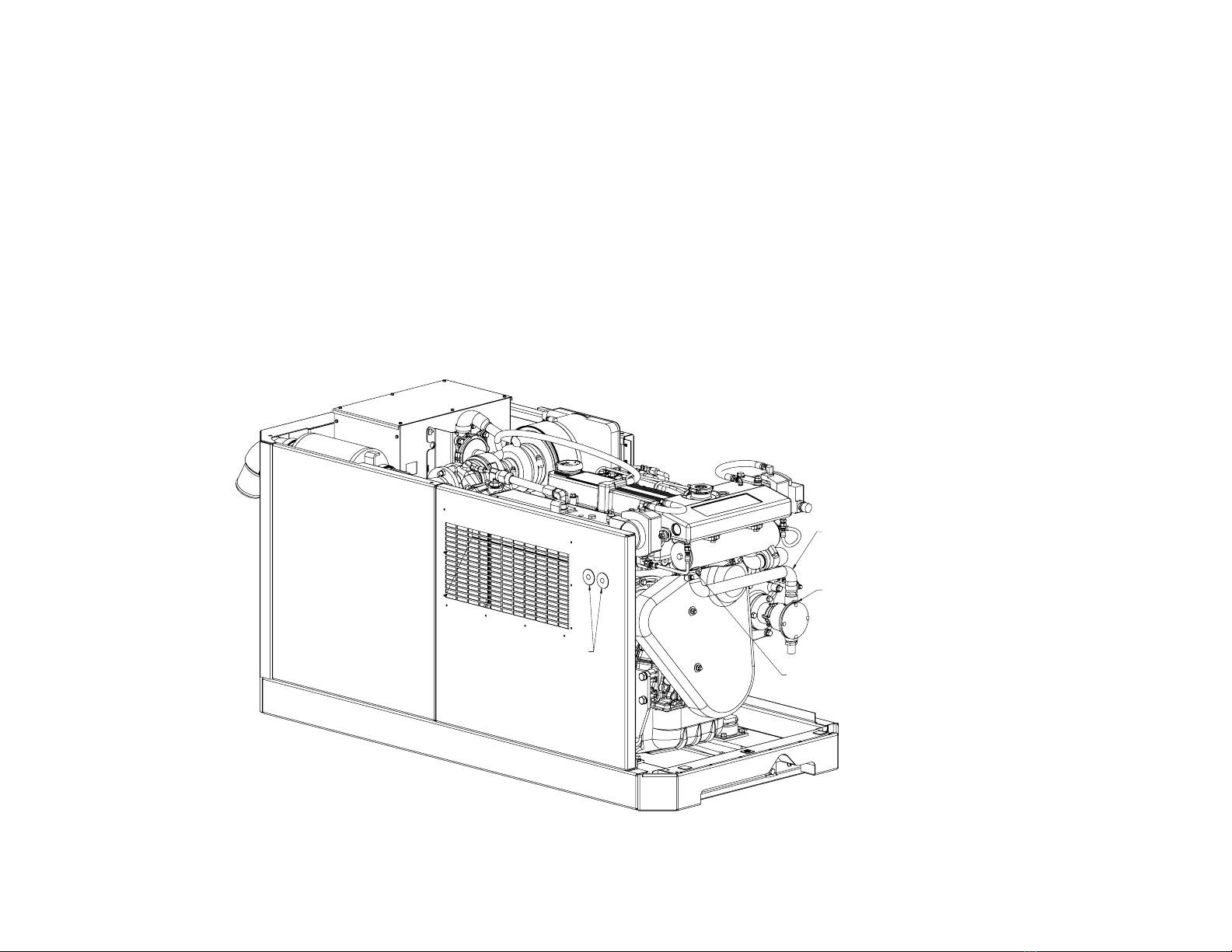

A- Connect the exhaust elbow of the diesel engine to the exhaust system of the vessel.

B- Connect the sea water pump to the vessel’s water inlet. Pass a 3/4” ID hose from the vessel’s sea water strainer through

hole B to the sea water pump inlet tting.

C- Connect the vessel’s fuel supply and fuel return to the generator set through hole C. Fuel connections are located at the

fuel manifold on the base frame of the generator’s left hand side. Size will be 1/4” NPT or 5/16” JIC-37T depending on year

of manufacture. Use Coast Guard-approved rubber hose only.

D- Connect the DC control panel harness to the genset engine harness plug through hole D.

E- Connect the 12 volt battery leads to the generator set through hole E.

F- Connect the AC output leads from the generator junction box to the vessel’s power distribution panel through hole F.

G- “OPTIONAL” This port is used for water outlet in KEEL COOLED applications.

5

A

B

C

SERVICE SIDE LOWER VALENCE ITEM #3

NON-SERVICE SIDE LOWER VALENCE

ITEM #4

FRONT LOWER VALENCE ASSY ITEM #5

STEP 3.

INSTALL SIDE VALENCE ASSEMBLIES (ITEM #3 AND 4).

ALIGN GUIDE PIN TO CORRESPONDING HOLES IN THE REAR

PANEL. USE CAPTIVE THUMBSCREWS TO SECURE TO REAR PANEL.

MAY USE LONG PHILLIPS TYPE SCREW DRIVER FOR REACH ASSIST.

STEP 4.

INSTALL THE FRONT VALENCE PANEL ASSY (ITEM #5).

ALIGN GUIDE PINS OF BOTH SIDE VALENCES TO GUIDE PIN

1.

HOLES IN THE FRONT VALENCE ASSY.

CONNECT THE FRONT AND SIDE VALENCES WITH THE CAPTIVE

THUMBSCREWS.

2. SECURE THE FRONT VALENCE ASSY TO THE BASE FRAME WITH

M8 BUTTON HEAD SCREWS AND 5/16 LOCK WASHERS. USE A

5mm HEX KEY AND TIGHTEN WITH HAND TOOLS ONLY.

DETAIL A

3X CAGE NUT (SERVICE SIDE ONLY)

GUIDE PIN

CAPTIVE THUMBSCREW

DETAIL B

GUIDE PIN HOLE

DETAIL C

5/16 LOCK WASHER ITEM #17 QTY: 3

M8 BUTTON HEAD SCREW, ITEM #15 QTY: 3

6

A

DETAIL A

CAPTIVE SCREW FASTENERS

STEP 5.

INSTALL SERVICE SIDE AFT PANEL ASSY (ITEM #6).

POSITION PANEL IN PLACE AS SHOWN AND FINGER START THE

CAPTIVE SCREWS. USING A PHILIPS TYPE SCREWDRIVER PROGRESSIVELY

TIGHTEN ALL SCREWS IN ALTERNATING ORDER (ONE VERTICAL,

ONE HORIZONTAL, ETC) UNTIL FULLY ENGAGED. TIGHTEN ONLY WITH

FIRM HAND PRESSURE, DO NOT OVERTIGHTEN.

NOTES:

SEE NEXT PAGE FOR E-STOP AND LEAK ALARM LIGHT INSTALLATION

AND CONNECTIONS.

7

STEP i.

STEP ii.

STEP iii.

A

B

NON-SERVICE SIDE AFT PANEL

ITEM #7

DETAIL A

SCREW ROD WHEEL

DETAIL B

GUIDE PIN

STEP 6.

INSTALL NON-SERVICE SIDE AFT PANEL ASSY (ITEM #7).

GUIDE THE PINS (DETAIL B) TO CORRESPONDING HOLES

IN THE REAR PANEL.

USE THE SCREW ROD WHEELS (DETAIL A) TO ATTACH THE

PANEL ASSY TO THE LOWER SIDE VALENCE.

APPLY DOWNWARD PRESSURE AS YOU TURN THE SCREW

ROD WHEELS TO ENGAGE THE CAPTIVE NUTS INSIDE THE

LOWER VALENCE.

8

9

A

B

C

DETAIL A

DETAIL B

DETAIL C

STEP 7.

INSTALL NON-SERVICE SIDE FWD PANEL ASSY (ITEM #8).

USE THUMBSCREW (DETAIL B) TO SECURE THE NON-SERVICE

1.

SIDE FWD PANEL ASSY (DETAIL A) TO THE NON-SERVICE SIDE

AFT PANEL.

2. USE THE SCREW ROD WHEELS (DETAIL C) TO SECURE THE

NON-SERVICE SIDE FWD PANEL TO THE LOWER SIDE VALENCE.

APPLY DOWNWARD PRESSURE AS YOU TURN THE SCREW ROD

WHEEL TO ENGAGE THE CAPTIVE NUTS INSIDE THE LOWER

VALENCE.

10

A

B

C

FRONT PANEL ASSY

ITEM #9

DETAIL A

CAPTIVE THUMB SCREW

DETAIL B

COMPRESSION THUMB SCREW LATCH

DETAIL C

GUIDE PINS

STEP 8.

INSTALL FRONT PANEL ASSY (ITEM #9).

BEFORE PLACING FRONT PANEL ASSY IN POSITION,

1.

TWIST COMPRESSION THUMB SCREW LATCH

(DETAIL B) IN COUNTER-CLOCKWISE DIRECTION

SO THAT THE PAWL POINTS FORWARD, IN FULLY

LOWERED POSITION.

GUIDE PINS (DETAIL C) TO CORRESPONDING HOLES

IN THE FRONT LOWER VALENCE.

2. WHEN POSITIONED, TURN COMPRESSION THUMB

SCREW LATCHES IN CLOCK-WISE DIRECTION TO

ENGAGE, UNTIL TIGHT WITH FIRM FINGER PRESSURE.

3. NOW ENGAGE CAPTIVE THUMB SCREW (DETAIL A)

TO CORRESPONDING HOLE IN NON-SERVICE SIDE

FWD PANEL TO SECURE. FIRM BUT NOT OVER TIGHT.

11

12

A

SEAL BAR ASSY

ITEM #10

DETAIL A

CAPTIVE THUMB SCREWS

B

SERVICE SIDE FWD PANEL ASSY

ITEM#11

DETAIL B

NYLON LOCATOR PIN

STEP 9.

INSTALL SEAL BAR ASSY (ITEM #10.)

LOCATE SEAL BAR ASSEY TO THEIR

CORRESPONDING CAPTIVE NUT HOLES

ON THE FRONT PANEL ASSY FLANGE

AND THE SERVICE SIDE AFT PANEL ASSY

FLANGES.

SECURE WITH CAPTIVE THUMB SCREWS

UNTIL FIRM BUT NOT OVER TIGHT.

STEP 10.

INSTALL SERVICE SIDE FWD PANEL ASSY (ITEM #11).

GUIDE NYLON LOCATING PINS (DETAIL B) TO SLOTS

IN LOWER SIDE VALENCE PANEL.

ENGAGE THE RING LATCH BY LIFTING RING LEVER OUT

AND TWIST A HALF-TURN SO IT FOLDS DOWN FLUSH AGAIN.

YOU WILL FEEL A CERTAIN AMOUNT OF RESISTANCE AS YOU

DO, WHICH MEANS THE LATCH IS ENGAGING.

NORMAL LATCH OPERATION AFTERWARDS ONLY REQUIRES

A QUARTER TURN TO RELEASE AND RE-ENGAGE THE PANEL.

NOTE:

LATCHES ARE FACTORY PRE-SET BUT OCCASIONALLY

REQUIRE SOME ADJUSTMENT. REFER TO LATCH ADJUSTMENT

PAGE FOR DETAIL.

LATCHES ARE INSTALLED IN FULLY OPEN POSITION FROM

FACTORY, SO LATCH RING IS BACKWARDS WHEN PACKED,

AND LATCH PAWL IS POINTING TO THE CENTER OF THE PANEL.

13

TOP PANEL AFT

ITEM #12

STEP 11.

INSTALL TOP AFT AND FWD PANEL ASSY (ITEM# 12 AND 13).

GUIDE PINS ON TOP AFT PANEL ASSY TO THE CORRESPONDING

1.

HOLES ON TOP OF THE REAR AND SIDE PANEL ASSYS.

LIFT RING LATCH LEVER AND TWIST A HALF TURN AND FOLD

DOWN FLUSH AGAIN. YOU WILL FEEL A CERTAIN AMOUNT OF

RESISTANCE AS YOU DO, WHICH MEANS THE LATCH IS ENGAGING.

NORMAL LATCH OPERATION AFTERWARDS ONLY REQUIRES A

QUARTER TURN TO RELEASE AND RE-ENGAGE THE PANEL.

2. TO INSTALL THETOP FWD PANEL ASSY, NOTE THE PINS AT THE REAR

OF THE TOP FWD PANEL, GUIDE THESE PINS INTO CORRESPONDING

HOLES IN THE FRONT OF THE TOP AFT PANEL.

LATCH OPERATION IS THE SAME AS THE TOP FWD PANEL.

NOTE:

THE RING LATCHES ARE FACTORY PRE-SET BUT OCCASIONALLY

REQUIRE SOME ADJUSTMENT. REFER TO THE LATCH ADJUSTMENT

PAGE FOR DETAIL.

LATCHES ARE INSTALLED IN FULLY OPEN POSITION FROM FACTORY

SO LATCH RING IS BACKWARDS WHEN PACKED, AND LATCH PAWL

IS POINTING TO THE CENTER OF THE PANEL.

GUIDE PINS

GUIDE PIN HOLES

TOP PANEL FWD

ITEM #13

GUIDE PINS

GUIDE PIN HOLES

14

16

Packed By : Date :

LIT NO.: L831 7/20

06-71202 06-71217

Other manuals for GEM Series

3

This manual suits for next models

1

Table of contents

Other Northern Lights Enclosure manuals