NORTHROP GRUMMAN NAVIGAT X MK 1 Manual

Northrop Grumman Sperry Marine B.V. (Representative Office)

Woltmanstr. 19 • D-20097 • Hamburg, Germany

Tel.: +49-40-299 00-0 • Fax: +49-40-299 00-146 • E-mail: service.de@sperry.ngc.com

Operation, Installation and Service Manual

NAVIGAT X MK 1

Digital Gyrocompass Systems

Type 4914-CA, Stock No. 74807 and Type 4914-CC, Stock No. 74811

056343/C, 08 May 2008

056343/C NAVIGAT X MK 1

© 2008 Northrop Grumman Sperry Marine B.V.

This document and the information herein is the intellectual property of Northrop Grumman

Sperry Marine B.V. [NGSM BV] and it’s associate companies and may not be copied or repro-

duced without the express permission of NGSM BV.

Specifications were correct at time of press but may be varied in accordance with NGSM BV’s

policy of continuous product development.

Any technical content should be verified with NGSM BV.

Sperry Marine, with worldwide headquarters in Charlottesville, VA, and major engineering and

support offices in Melville, NY, New Malden, England, and Hamburg, Germany, is part of the

Northrop Grumman Electronic Systems sector.

Revision Record

Rev. Date Remarks

C 08 May 2008 Added new options (AD10 output, alarm mute relay, speed filter).

B 17 Nov 2006 Removed gyrospere installation/service instructions. These are now

contained in separate documents delivered with the respective gyro-

sphere and container.

All information regarding the master PCB refers to the new PCB, stock

no. 20672.

A 18 Jan 2005 initial release.

NAVIGAT X MK 1 056343/C

i

Safety Instructions

Safety Notice Conventions

The following safety notice conventions are followed throughout this

manual:

DANGER

A Danger notice contains an operating or main-

tenance procedure, practice, condition, state-

ment, etc., which, if not strictly observed, will

result in injury or death of personnel.

WARNING

A Warning notice contains an operating or

maintenance procedure, practice, condition,

statement, etc., which, if not strictly observed,

could result in injury or death of personnel.

CAUTION

A Caution notice contains an operating or main-

tenance procedure, practice, condition, state-

ment, etc., which, if not strictly observed, could

result in damage to, or destruction of equip-

ment.

Note

A Note contains an essential operating or main-

tenance procedure, condition or statement,

which is considered important enough to be

highlighted.

Special safety symbols may be used in this

manual to indicate:

Risk of electrical shock.

Used in conjunction with a Danger or Warning

notice.

Electrical components sensitive to electrostatic

discharge.

Used in conjunction with a Caution notice.

056343/C NAVIGAT X MK 1

ii

General Safety Information for the Operator

WARNING

Never rely on one heading source alone to navigate a vessel.

Always confirm the plausibility of the NAVIGAT X MK 1 heading and the

speed and position input data against all available aids to navigation.

WARNING

After a power-up from cold, the NAVIGAT X MK 1 requires a settling time

of three hours before reliable heading data is available.

Power up the system at least three hours before leaving harbour.

Power down the system during long docking periods only.

Make sure that the NAVIGAT X MK 1 has settled before using its heading

as the reference for heading control systems, RADAR, ECDIS, etc.

A magnetic heading source should be made active only in case of failure

of the gyrocompass(es).

WARNING

Before using this system, operators must be appropriately trained and

familiar with the operating procedures and safety instructions contained

in this manual.

Keep system manuals in a well-known, readily available location.

CAUTION

The supporting fluid in the gyrosphere container will start freezing at

temperatures below 0 °C.

The NAVIGAT X MK 1 may no longer be operated when the ambient tem-

perature at the gyrocompass’ location falls below –10 °C while the com-

pass is in operation or when the ambient temperature falls below 0 °C

while the compass is not in operation.

CAUTION

Any service work on the gyrosphere is to be carried out by authorized

service personnel only.

CAUTION

Do not clean the compass housing with organic solvents, acetone or any

other substance which could damage or discolour plastic.

Use only soapy water or a mild detergent to clean the compass housing.

NAVIGAT X MK 1 056343/C

1-iii

General Safety Information for Service Personnel

DANGER

When the compass is energized, the gyrosphere operating voltage of

100 VAC @ 337 Hz is present on the master PCB, the gyrosphere supply

lines, and across the gyrosphere contacts.

When the AC main supply is switched on, live voltages are present at the

line filter and the power transformer’s terminals.

CAUTION

The gyrosphere is always to be transported in its carrying box in the orig-

inal transport container.

Do not throw or drop the transport container.

The transport container is to be transported in an upright position only.

Carry the carrying box containing the gyrosphere by hand only and han-

dle it with extreme care. Remove the gyroshpere from the carrying box

only if required for immediate installation.

CAUTION

After power-down of the compass system, it may take up to 45 minutes

for the gyroscopes to stop rotating.

During this time, the container must be handled with extreme care.

Should the sphere touch the wall of the container, the momentum of the

rotating gyroscopes will make it topple and damage the center pin.

CAUTION

The NAVIGAT X MK 1 contains electrostatic sensitive components.

Electrostatic discharge may permanently damage components.

When servicing the NAVIGAT X MK 1, take precautions to prevent elec-

trostatic discharge. Avoid touching any of the electronic circuitry.

CAUTION

It cannot be guaranteed that parameter settings in the User and Setup

menus and the entries made in the Magnetic Compass Calibration table

are left intact when the software is exchanged.

Before exchanging the system software IC, record all parameter settings

to be able to re-enter them manually, if required.

056343/C NAVIGAT X MK 1

1-iv

NAVIGAT X MK 1 056343/C

v

Contents

Safety Instructions

Safety Notice Conventions........................................................................... i

General Safety Information for the Operator ............................................ ii

General Safety Information for Service Personnel................................... iii

Chapter 1: Introduction

1.1 Design and Main Features........................................................................ 1-1

1.2 Operating Principle ................................................................................... 1-2

1.3 Example System Configurations ............................................................. 1-3

Standalone Gyrocompass/TMC System ................................................. 1-3

Dual NAVIGAT X MK 1 Gyrocompass/TMC System................................ 1-4

1.4 Technical Data............................................................................................ 1-5

Chapter 2: Operation

2.1 Operating Conditions ............................................................................... 2-1

2.2 Display and Operating Keys ..................................................................... 2-2

Control and Display Unit .......................................................................... 2-2

2.3 External control devices ........................................................................... 2-3

2.4 Power-up Sequence .................................................................................. 2-4

2.5 Selecting the active heading source ....................................................... 2-5

2.6 Adjusting the display brightness............................................................. 2-5

2.7 Optional Functions.................................................................................... 2-6

Muting Alarms Remotely.......................................................................... 2-6

Reversing the Heading Display (180° offset)........................................... 2-6

Resetting/Acknowledging a Central Watch Alarm .................................. 2-6

2.8 Operating Menu ........................................................................................ 2-7

Entering and Quitting the Main Menu..................................................... 2-7

Navigating the Menu ................................................................................ 2-7

Selecting Parameter Settings ................................................................... 2-8

Editing Parameter Values ......................................................................... 2-8

2.9 Selecting a Display Data Page ................................................................. 2-9

2.10 Manual Settings Menu ........................................................................... 2-10

Manual Settings – Overview .................................................................. 2-10

Manual Settings – Parameters ............................................................... 2-12

2.11 User Setup ............................................................................................... 2-16

User Setup – Overview ........................................................................... 2-16

User Setup – Parameters ........................................................................ 2-17

056343/C NAVIGAT X MK 1

vi

Chapter 3: Errors and Alarms

3.1 Alarm Indication ........................................................................................ 3-1

Audible Alarm Indication .......................................................................... 3-1

Visual Alarm Indication............................................................................. 3-1

3.2 Acknowledging Alarms/Muting the Audible Alarm............................... 3-2

Alarm Acknowledge ..................................................................................3-2

Alarm Mute ................................................................................................3-2

3.3 Error messages .......................................................................................... 3-3

3.4 Service Info Menu (Service Setup 2) ....................................................... 3-5

Service Setup 2 – Access Code ................................................................ 3-5

Service Setup 2 – Overview......................................................................3-6

Service Setup 2 – Parameters................................................................... 3-7

Chapter 4: Scheduled Maintenance

4.1 Maintenance by Shipboard Personnel .................................................... 4-1

4.2 Gyrosphere Maintenance Specifications ................................................ 4-1

18-Month Maintenance ............................................................................. 4-1

Five-Year Maintenance.............................................................................. 4-2

Chapter 5: Preventive Maintenance

5.1 Protecting the Gyrosphere from Low Temperatures..............................5-1

Removing the container from the compass housing ............................. 5-2

Parts, materials and tools required .......................................................... 5-2

Procedure ................................................................................................... 5-2

Re-installing the container in the compass housing .............................. 5-4

Parts, materials and tools required .......................................................... 5-4

Procedure ................................................................................................... 5-4

Power-up function test .............................................................................. 5-6

Procedure ................................................................................................... 5-6

Chapter 6: Installation

6.1 Mechanical Installation............................................................................. 6-1

Installing the Compass Housing .............................................................. 6-1

6.2 Electrical Installation................................................................................. 6-2

AC Supply Power Configuration .............................................................. 6-2

Wiring Up the System............................................................................... 6-2

6.3 Gyrosphere Installation ............................................................................ 6-3

6.4 Initial System Configuration .................................................................... 6-4

6.5 Alignment Error Correction ...................................................................... 6-6

Magnetic Compass Calibration ................................................................ 6-7

NAVIGAT X MK 1 056343/C

vii

Chapter 7: System Configuration

7.1 Configuration Menu (Service Setup 1).................................................... 7-1

Setup Access Code.................................................................................... 7-1

Service-Setup 1 – Overview ..................................................................... 7-2

Service Setup 1 – Parameters .................................................................. 7-6

7.2 Factory Settings Menu (Technical Pages) ............................................. 7-16

Setup Access Code.................................................................................. 7-16

Technical Pages – Overview ................................................................... 7-16

Technical Pages– Parameters ................................................................. 7-17

Chapter 8: Troubleshooting

8.1 Troubleshooting Instructions ................................................................... 8-1

8.2 Location of Parts on the Master PCB ...................................................... 8-2

Exchangeable Components...................................................................... 8-3

Connectors................................................................................................. 8-3

Test Resistor / Trimpots............................................................................. 8-4

Diagnostic LEDs......................................................................................... 8-4

Chapter 9: Corrective Maintenance

9.1 Exchanging the System Software ........................................................... 9-1

9.2 Replacing Socketed ICs ............................................................................ 9-2

Appendix

A Setup and Configuration Tables

B Drawings

056343/C NAVIGAT X MK 1

viii

NAVIGAT X MK 1 056343/C

Design and Main Features 1-1

Chapter 1: Introduction

1.1 Design and Main Features

The NAVIGAT X MK 1 is a microprocessor controlled marine gyrocom-

pass system with integrated automatic North speed error correction.

As a gyrocompass, the system complies with IMO resolutions A.424(IX)

and A.694(17) and with EN ISO 8728.

The HSC-version (stock no. 74811) with a specially selected gyrosphere

also complies with IMO resolution A.821(19).

The rate of turn output of the NAVIGAT X MK 1 complies with IMO reso-

lution A.526(13).

The NAVIGAT X MK 1 has been type approved by the German Federal

Maritime and Hydrographic Agency (BSH), in accordance with the

Marine Equipment Directive (MED) 96/98/EC, as modified by Directive

2002/75/EC.

The single unit design with a polyurethane hard foam housing allows

the gyrocompass to be installed on any bridge. If required, the operating

unit may be installed at a location remote from the compass or an addi-

tional remote operating unit may be used.

The unique method of supporting the gyrosphere by means of mere

buoyancy ensures North stabilisation during short power failures. E.g.,

after a three minute loss of power, no more than two degrees of devia-

tion may be expected. Once power has been restored, the gyrocompass

will return quickly to the correct heading. The combined effects of the

twin rotors and the liquid damping system virtually eliminate latitude

error.

Heading is measured as a 13-bit absolute value with a digital shaft

encoder. The high-speed follow-up system (follow-up speed up to

100°/s) ensures that accurate heading and rate of turn data is provided

under all operating conditions.

Integrated monitoring of the supply powers, gyroscope current and the

follow-up system ensure secure and trouble-free operation.

056343/C NAVIGAT X MK 1

1-2 Operating Principle

1.2 Operating Principle

The north-seeking element used in the NAVIGAT X MK 1 system is the

gyrosphere, a hermetically sealed unit with a funnel-shaped recess,

reaching from the outer skin down to its center.

Inside the gyrosphere, two mechanically linked gyroscopes are mounted

with their spin axes horizontal in a carrying frame. The gyroscopes are

allowed to turn around the vertical, but torsion bands effect a defined

rest position, while a mechanical linkage ensures that the resultant spin

vector of the gyros remains stationary relative to the gyrosphere. This

twin gyro arrangement eliminates intercardinal roll error. Once the

gyros have run up to speed, their resultant spin vector, and with it the

sphere, settles in the direction of true North.

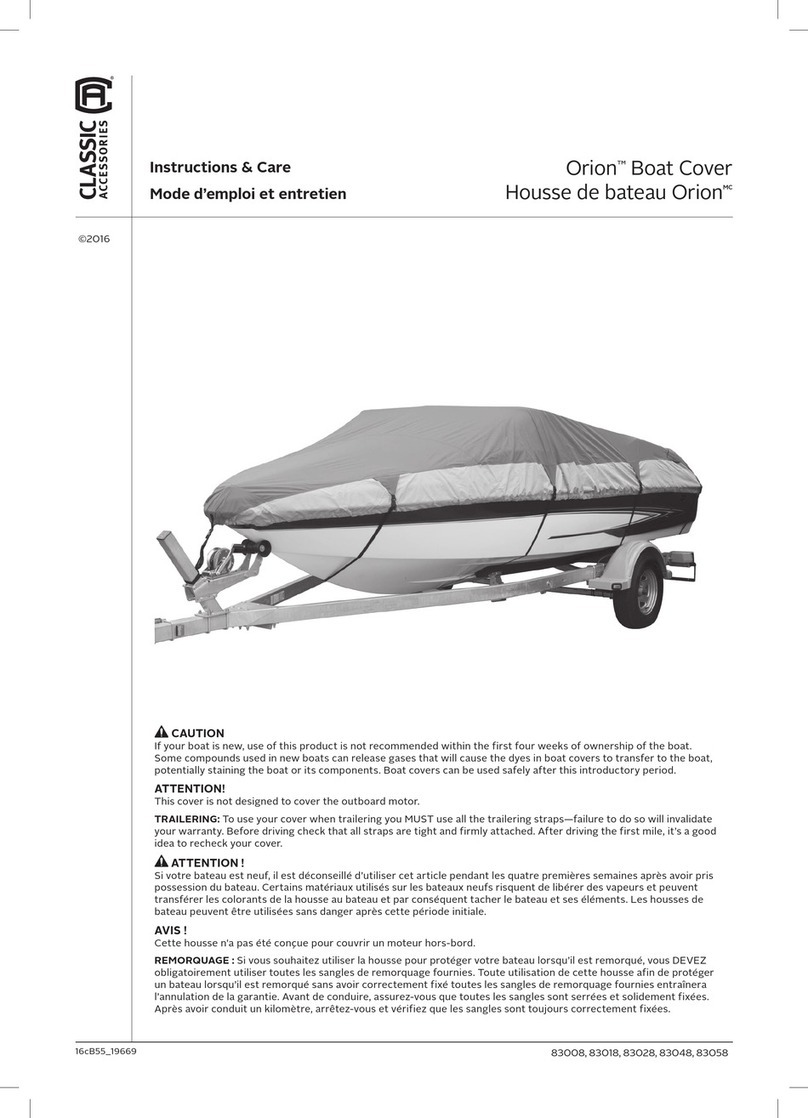

Figure 1-1:

The gyrosphere

The top of the gyrosphere contains an annular damping trough, half

filled with a viscous fluid. The fluid damps azimuthal oscillations of the

gyroscope system. The oscillation period is tuned to the Schuler period

of 84.4 minutes, so that heading errors during horizontal acceleration

due to changes in speed and/or direction are prevented.

The gyrosphere floats in a supporting fluid inside the gyrosphere con-

tainer. Because the buoyancy of the sphere is a little greater than its

weight, a bearing cup at the bottom of the recess is pressed against the

centering pin and keeps the sphere exactly centered in the container.

In order to make the gyroscope system pendulous, that is, to provide the

gravity controlling moment, the gyrosphere is designed so that its cen-

tre of gravity lies slightly below the centre of bouyancy.

The gyroscopes are in fact squirrel-cage induction motors, which attain

a speed of nearly 20000 rpm at a voltage of 100 VAC @ 337 Hz.

In the Mod. 10/3 container, their supply power is applied through the

electrolytically conducting supporting fluid, via the top and bottom con-

tacts. In the Mod. 10/2 and Mod. 7/2 containers, the power is applied via

the centering pin and the bottom contacts.

A follow-up control circuit keeps the container aligned with the sphere at

all times, thus heading can be derived from the container’s orientation.

While systems with the Mod. 10/3 container employ an optical pickoff to

provide the follow-up control signal, systems with the Mod. 10/2 and

Mod. 7/2 containers use a resistance bridge circuit, formed by the con-

ducting paths from the contact pins in the container, through the sup-

porting fluid and to the equator contact of the gyrosphere.

centering pin

N gyro

gyro linkage

damping trough

S gyro

gyrosphere shell

NAVIGAT X MK 1 056343/C

Example System Configurations 1-3

1.3 Example System Configurations

Standalone Gyrocompass/TMC System

As a standalone system, the NAVIGAT X MK 1 provides North-speed

error corrected true heading as well as rate of turn data.

If a fluxgate sensor, type 4863, or an electronic magnetic compass is

installed, the NAVIGAT X MK 1 applies magnetic variation and distrib-

utes magnetic heading data to external equipment (TMC function).

The heading diff. alarm function permits to monitor the difference

between the gyro and magnetic heading sources.

In case of failure of the gyrocompass, the magnetic heading source may

be activated to provide an emergency heading reference for repeaters

and other peripheral equipment.

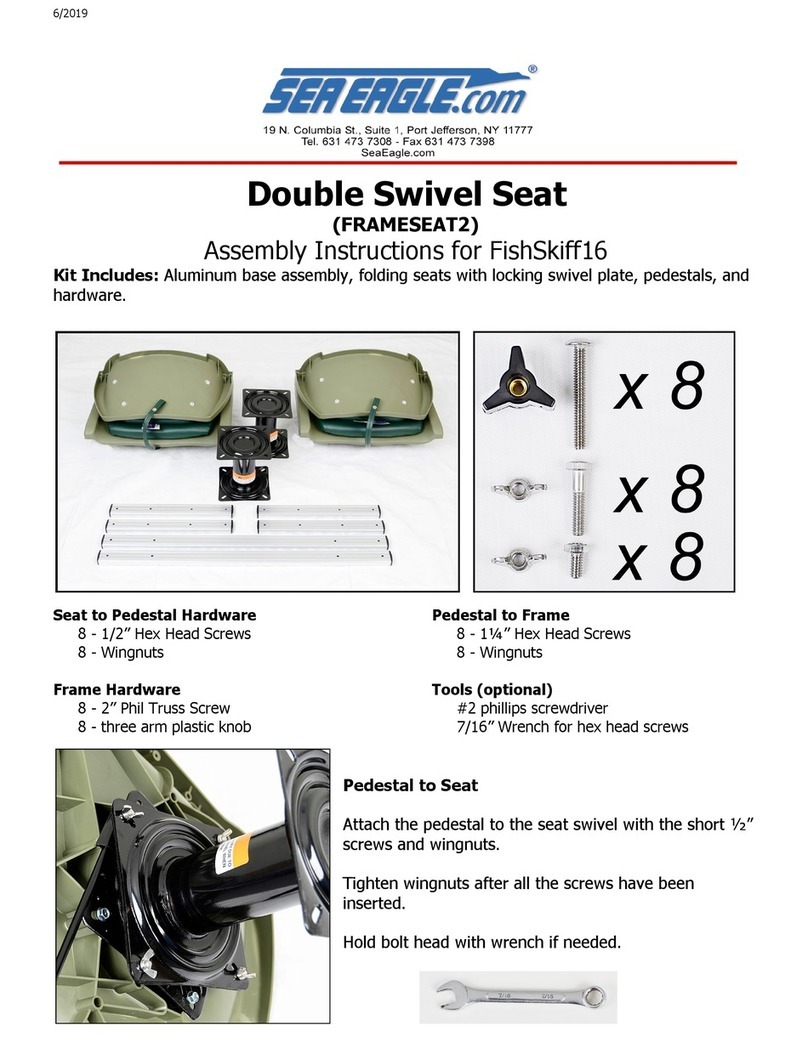

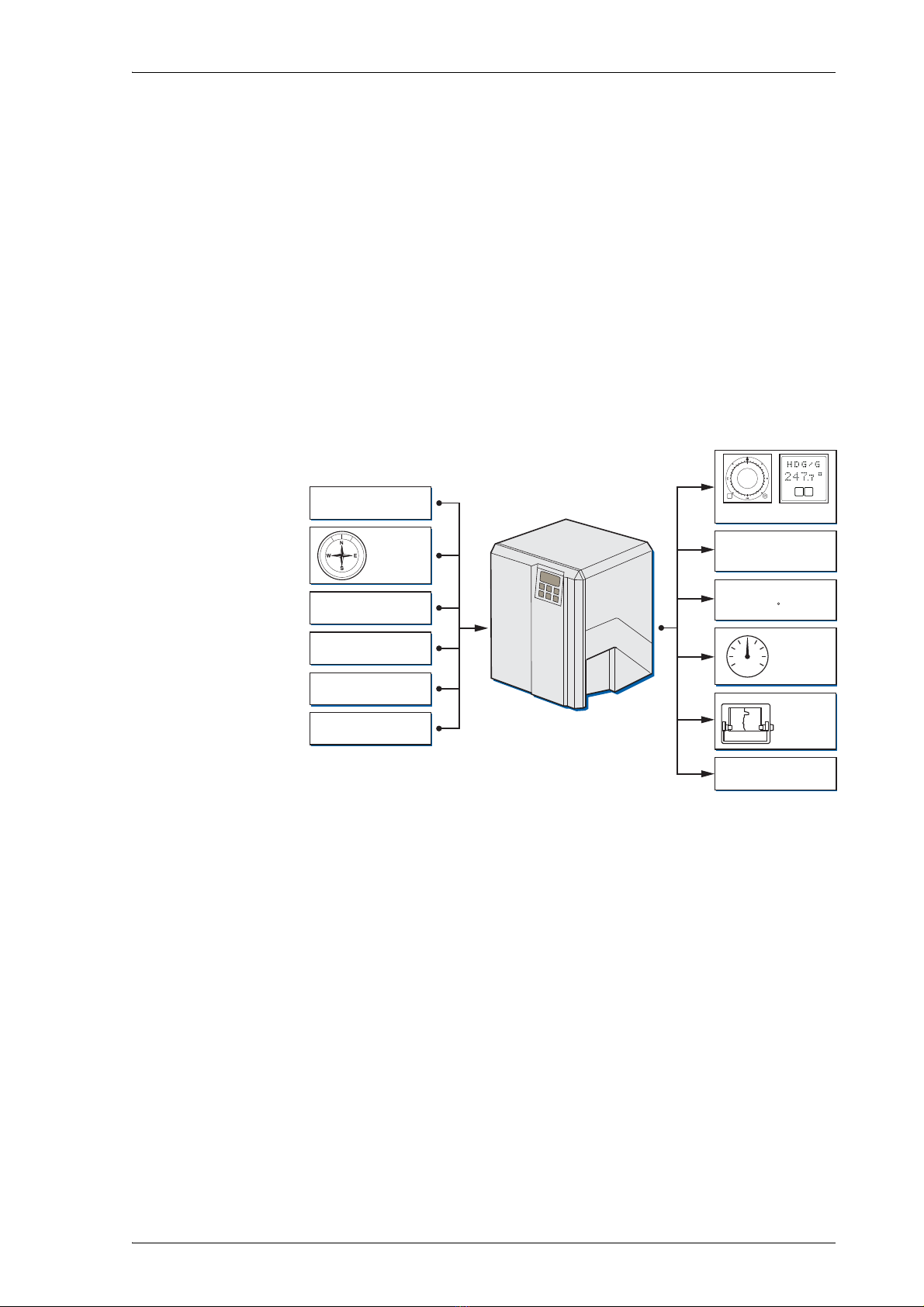

Figure 1-2:

Standalone

Gyrocompass/TMC

system

Magnetic

Compass

Position Receiver

Speed Log

Rudder Angle

Feedback Unit(s)

Status Signals In

Ext. Gyrocompass

ROT

Serial Repeaters

Equipment using

serial input

Equipment using

6 step/ input

Analogue

R.o.T.

Indicators

Nav. Data

Printer

Status Signals Out

056343/C NAVIGAT X MK 1

1-4 Example System Configurations

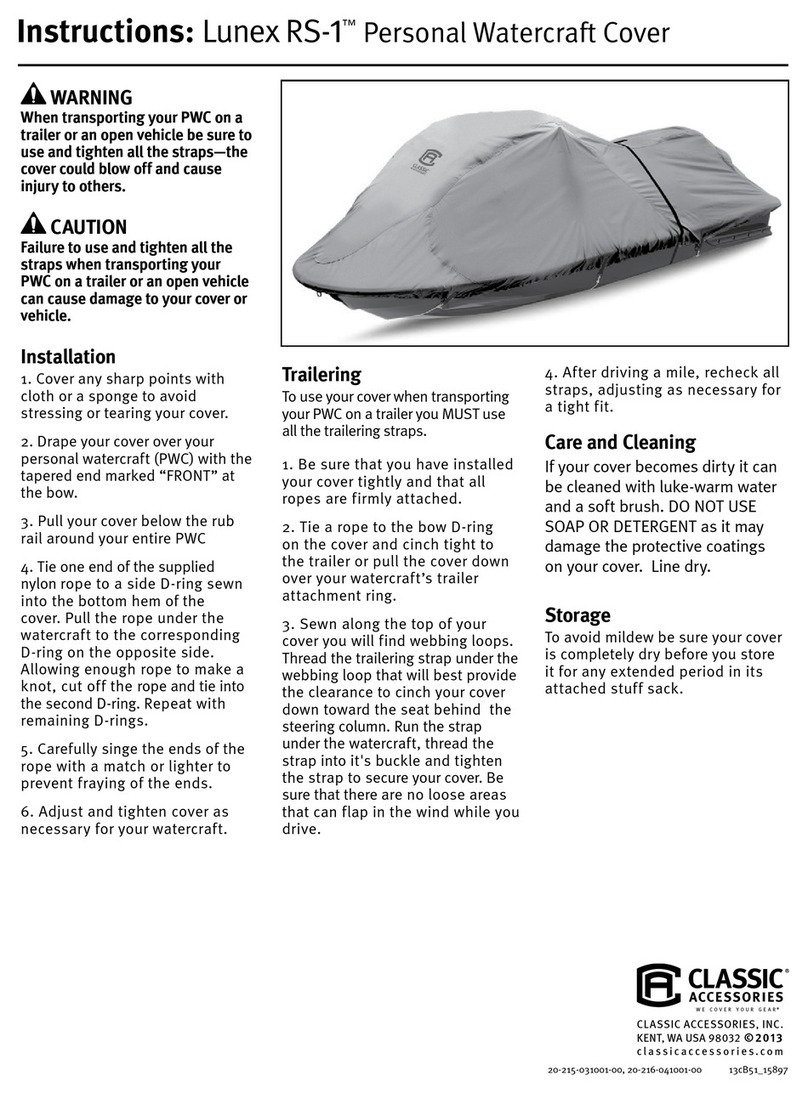

Dual NAVIGAT X MK 1 Gyrocompass/TMC System

The system shown in Figure 1-3 below is the standard configuration for

a dual NAVIGAT X MK 1 gyrocompass system.

In addition to the two NAVIGAT X MK 1 compasses, this system com-

prises the NAVITWIN IV heading management system and the Switch-

Over Unit Type 4932.

By selecting the active heading source at the NAVITWIN IV, the operator

determines which compasses’ data is distributed via the Switch-Over

Unit to external equipment, such as heading control systems, RADAR,

compass repeaters etc.

The NAVITWIN’s heading diff. alarm function permits to monitor the dif-

ference between any two of the available heading sources.

The off heading alarm function permits to monitor the difference

between the actual heading from the active source and the set heading

order, as received from a heading control system or entered manually.

Alarms generated locally by a NAVIGAT gyrocompass are indicated and

may be acknowledged at the NAVITWIN IV.

In turn, the NAVITWIN IV transmits system-wide operational settings

and setup parameters to the NAVIGAT gyrocompasses.

The available heading sources, the current source selection and the hdg.

diff. threshold are also indicated at both gyrocompasses.

If a magnetic heading source is installed, the NAVITWIN applies mag-

netic variation and distributes the data to external equipment (TMC

function). In case of failure of the gyrocompasses, the magnetic heading

source may be activated to provide an emergency heading reference for

repeaters and other peripheral equipment.

Figure 1-3:

NAVIGAT Dual

Gyrocompass System

GYRO

1

GYRO

2

MAGN

COMP

246.8

246.7

247.0

G1 Hdg.

G2 Hdg.

M Hdg.

Source Sel.

Status

Alarm Status

(Hdg. Diff, Off Hdg)

G/ M Headings,

RoT, and all other

data/signals

distributed via

Switch-Over Unit

Switch-Over Unit

NAVITWIN IV

G2

M

G1

Note

A system with one NAVIGAT X MK 1 and one NAVIGAT 2100 fiber-optic

gyrocompass is also possible in an otherwise identical configuration.

NAVIGAT X MK 1 056343/C

Technical Data 1-5

1.4 Technical Data

Accuracies

heading:

lin. mean settle point error

static error

dynamic error

deviation after 3 min. power interruption

≤0.1° secant latitude

≤0.1° secant latitude

≤0.4° secant latitude

< 2°

rate of turn ≤0.5°/minute

Operational Characteristics

mean setting time < 3h

max. follow-up speed 100°/s

freedom of roll and pitch

- with container Mod. 10

- with container Mod. 7

±40°

±90°

MTBF 40 000 h

Environmental Requirements

ambient temperature, operation –10 to +55 °C

ambient temperature, storage

(without supporting fluid)

–25 to +70 °C

environmental conditions / EMC in accordance w. IEC 60945

Protection Grade

according to IEC 60529/DIN 40050 IP 23

Magnetic Clearance

to standard magnetic compass 0.6 m

to steering magnetic compass 0.4 m

reduced, to standard magnetic compass 0.3 m

reduced, to steering magnetic compass 0.3 m

Power Supply

supply voltage main: 115/230 VAC, 50/60 Hz;

backup: 24 VDC (18-36 V), includ-

ing automatic switchover to

backup supply in case of main

supply failure

max. ripple content DC supply ±4 Vpp; extreme values may not

exceed 36 V or fall below 18 V

power consumption:

start-up

operation

each repeater compass

AC: 125 VA; DC: 80 W

AC: 75 VA; DC: 45 W

7 W

056343/C NAVIGAT X MK 1

1-6 Techni cal D ata

Dimensions and Weight

width 404 mm

height 520 mm

depth 420 mm

weight 25 kg approx.

Data Inputs

ext. gyro heading NMEA 0183 / IEC 61162-1

or PLATH protocol

or Lehmkuhl (1200, 2400, 4800 or

9600 Bd.)

magnetic heading NMEA 0183 / IEC 61162-1

or PLATH protocol

or NAVIPILOT

position NMEA 0183 / IEC 61162-1

speed NMEA 0183 / IEC 61162-1

compass monitor NAVITWIN NMEA 0183 / IEC 61162-1

Signal and Status Inputs

magnetic heading,

fluxgate sensor

sin., cos. and ref. voltages from

Sperry Marine fluxgate sensor

type 4863

speed, 200 pulse/nm connection to P.Gnd via ext. con-

tact, momentary

rudder angle feedback unit

(2x; reads rudder angle for output

to NAVIPRINT)

0 – 5 VDC return voltage from

feedback potentiometer(s)

steering mode status (auto/man) connection to P.Gnd via ext. con-

tact, latching

ext. heading reference sel.

(gyro1/gyro2)

connection to P.Gnd via ext. con-

tact, latching

ext. heading reference sel.

(gyro/mag)

connection to P.Gnd via ext. con-

tact, latching

ext. alarm acknowledge (mute) connection to P.Gnd via ext. con-

tact, momentary

status input port (log status or

hdg. +180° function)

connection to P.Gnd via ext. con-

tact, latching

404

520

420420

NAVIGAT X MK 1 056343/C

Technical Data 1-7

Data Outputs

serial repeater outputs

(12x TTL)

NMEA 0183

sensor data outputs

(4x RS-422; 3 available if AD10

output active)

NMEA 0183 / IEC 61162-1

FAST output

(1x RS-422)

NMEA 0183 / IEC 61162-1

or PLATH protocol

SuperFAST output

(2x RS-422; 1 available if AD10

output active)

NMEA 0183 / IEC 61162-1

or NMEA 0183 / IEC 61162-2

or PLATH protocol

AD10 heading data output AD10 serial data and clock

NAVITWIN output NMEA 0183 / IEC 61162-1

to ext. gyro / compass monitor

NAVITWIN

NAVIPRINT output serial data to nav. data printer

Signal and Status Outputs

6 step/° output (2 x) 3 phases, switched to 0V potential

if active („minus switching“),

common positive;

internal supply 24 VDC

max. 18 W

(12–70 VDC phase voltage when

ext. power supply is used)

rate of turn, analogue ±0.1–999.9 mV/°/min;

max. 10 V, 10 mA

power failure/general alarm

heading difference alarm

max. ROT exceeded alarm,

heading source sel. status

status out to switch-over unit

watch alarm acknowledge

AC power status

DC power status

potential-free contact closures,

each rated

30 VDC/1.0 A,

100 VDC/0.3 A,

125 VAC/0.5 A

056343/C NAVIGAT X MK 1

1-8 Techni cal D ata

NAVIGAT X MK 1 056343/C

Operating Conditions 2-1

Chapter 2: Operation

2.1 Operating Conditions

The permitted ambient temperature for the operation of the gyrocom-

pass system is -10 – +55 °C.

When the ambient temperature at the gyrocompass’ location falls below

-10 °C while the compass is in operation or when the ambient tempera-

ture falls below 0 °C while the compass is not in operation, the gyro-

sphere container must be removed from the compass housing and

stored in a place where the ambient temperature will not fall below 0 °C.

If no storage place is available where the ambient temperature will not

fall below 0 °C, the gyrosphere must be removed from the gyrosphere

container to prevent possible damage by frozen supporting fluid.

CAUTION

The supporting fluid in the gyrosphere container will start freezing at

temperatures below 0 °C.

The NAVIGAT X MK 1 may no longer be operated when the ambient tem-

perature at the gyrocompass’ location falls below –10 °C while the com-

pass is in operation or when the ambient temperature falls below 0 °C

while the compass is not in operation.

CAUTION

The gyrosphere may be removed from the gyrosphere container by

authorized service personnel only.

056343/C NAVIGAT X MK 1

2-2 Display and Operating Keys

2.2 Display and Operating Keys

Control and Display Unit

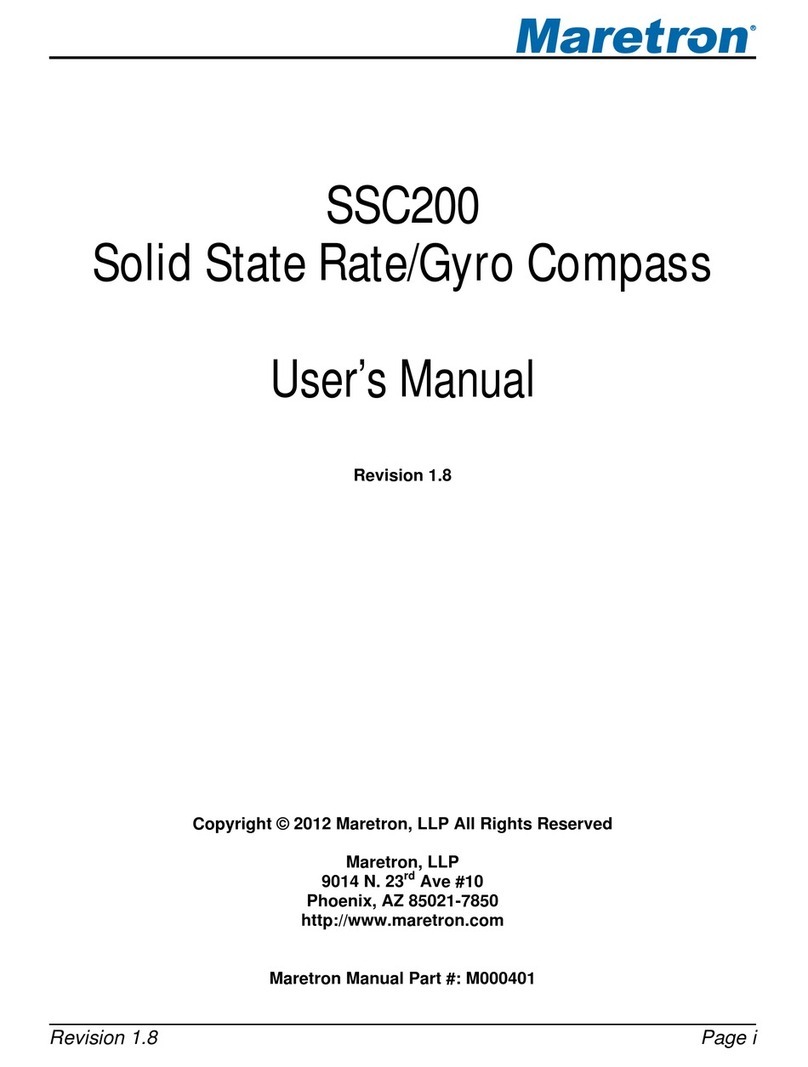

Figure 2-1:

NAVIGAT X MK 1

control and display unit

Display

Operating Keys

➀LCD Display: 4x20 character text display

In normal operational mode, shows the available heading sources

and the heading diff. alarm threshold.

In menu mode: displays the currently active op. menu screen

➁MENU /F1 key: Calls up the main menu from normal operational

mode. When pressed in menu mode, returns to next higher menu

level.

When pressed simultaneously with the SHIFT key, the F1 function is

executed.

➂Up () / F2 key: In menu mode, returns from the main menu to nor-

mal operational mode. Within a sub-menu, scrolls up through avail-

able pages on same menu level.

When pressed simultaneously with the SHIFT key, the F2 function is

executed.

➃Down () / F3 key: Calls up the Main Menu from normal operational

mode. Within a sub-menu, scrolls down through available pages on

same menu level.

When pressed simultaneously with the SHIFT key, the F3 function is

executed.

➄SHIFT key: Pressed with other key to call up key’s SHIFT function.

➅DIM+ / RESET key: Adjust the display brightness.

When pressed simultaneously with the SHIFT key, the RESET function

is executed.

➆DIM- / ENTER key: Adjust the display brightness.

When pressed simultaneously with the SHIFT key, the ENTER func-

tion is executed.

5

1

2

3

6

4

7

Table of contents

Popular Boating Equipment manuals by other brands

Seamax

Seamax Sunlitec manual

JRC

JRC Fleet F77 Operation manual

Lippert

Lippert Taylor Made EasyGuide 2022106874 Installation and owner's manual

Raymarine

Raymarine Dragonfly-4 DV Installation and operation instructions

SLEIPNER MOTOR AS

SLEIPNER MOTOR AS Side-Power Series installation manual

DockCraft

DockCraft DockSider DS200 Assembly, Installation, Setup, and Operating Instruction