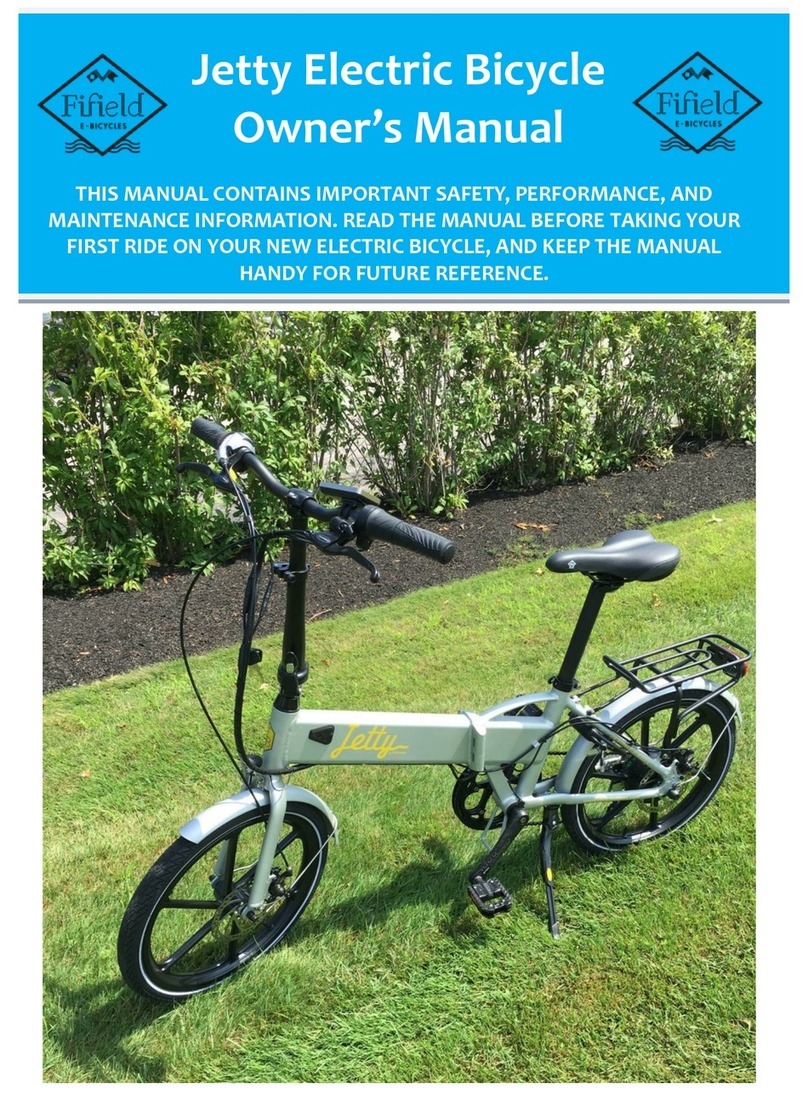

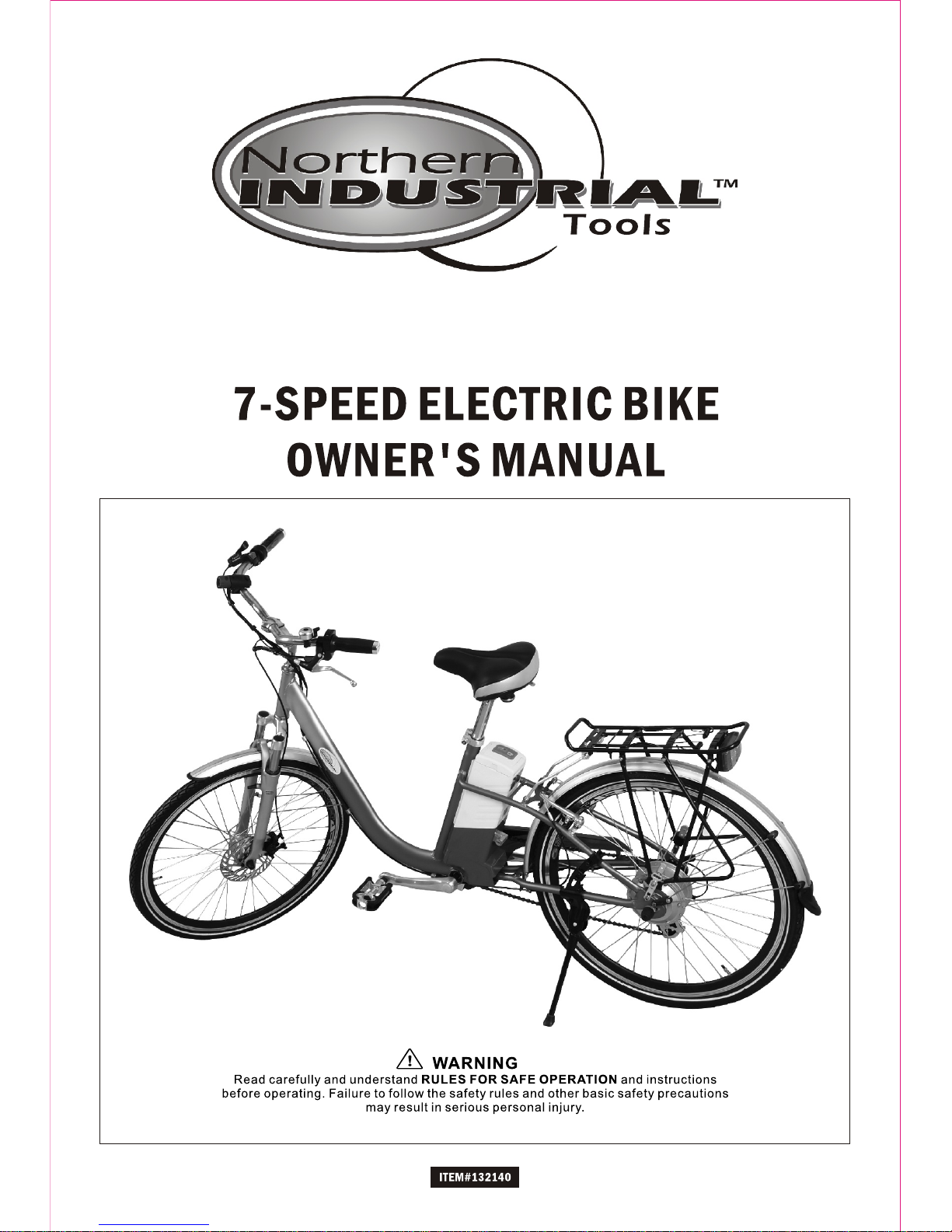

Nothern Industrial tools 132140 User manual

THANK YOUFOR CHOOSINGA NORTHERN TOOL+ EQUIPMENTCO., INC. PRODUCT!

For future reference,please complete theowner's record below:

Model: _______________ PurchaseDate: _______________

Save the receipt,warranty,and instruction manual.It is importantthat you readthe entire

manual to becomefamiliar with thisproduct before youbegin using it.

This machine isdesigned for certainapplications only. NorthernTool+ Equipment cannot

be responsible forissues arising frommodification. Westrongly recommend thismachine is

not modified and/orused for anyapplication other thanthat for whichit was designed.If you

have any questionsrelative to aparticular application, DONOT usethe machine untilyou

have first contactedNorthern Tool + Equipmentto determine ifit can orshould be performed

on the product.

For technical questionsplease call1-800-222-5381.

INTENDED USE

This electric bicycleis installed withan electric drivesystem. Althoughthis product

operates much likea standard bicycle,there are differences. Please carefullyread the

User's Manual beforeuse.

CAUTION: Do not lendthis electric bicycleto those whocannot ride abicycle.

HELMETS SAVE LIVES!Always wear aproperly fitted helmetwhen riding yourelectric

bicycle. Do notride at night.Avoidriding in wetor hazardous conditions.

TECHNICAL SPECIFICATIONS

1 OF 13

Electric Driving System

Frame Size

Frame

Wheel Size

Fork

Gear Shifter

Rear Derailleur

Chain

Rims

Brake

Spoke

Tire

Battery

Max Speed

Charging Time

Battery Life Span

Motor

Riding Distance atone charge

Recommended Load Capacity

Max ClimbingAngle

1:1.5 ASSISTPOWER

26"

Alloy

26"

Suspension

7 SPEED

M310 7TSHIMANO

HP20

26"

Front: Disc brake,Rear: V-brake

UCP

26" 1.75

Lithium-Ion (24V/8Ah)

15 1/2 MPH(25km/h)

5-6 hours

500 times

24V 180W

15 1/2 miles(25Km)

165 lbs. (75kg)

7

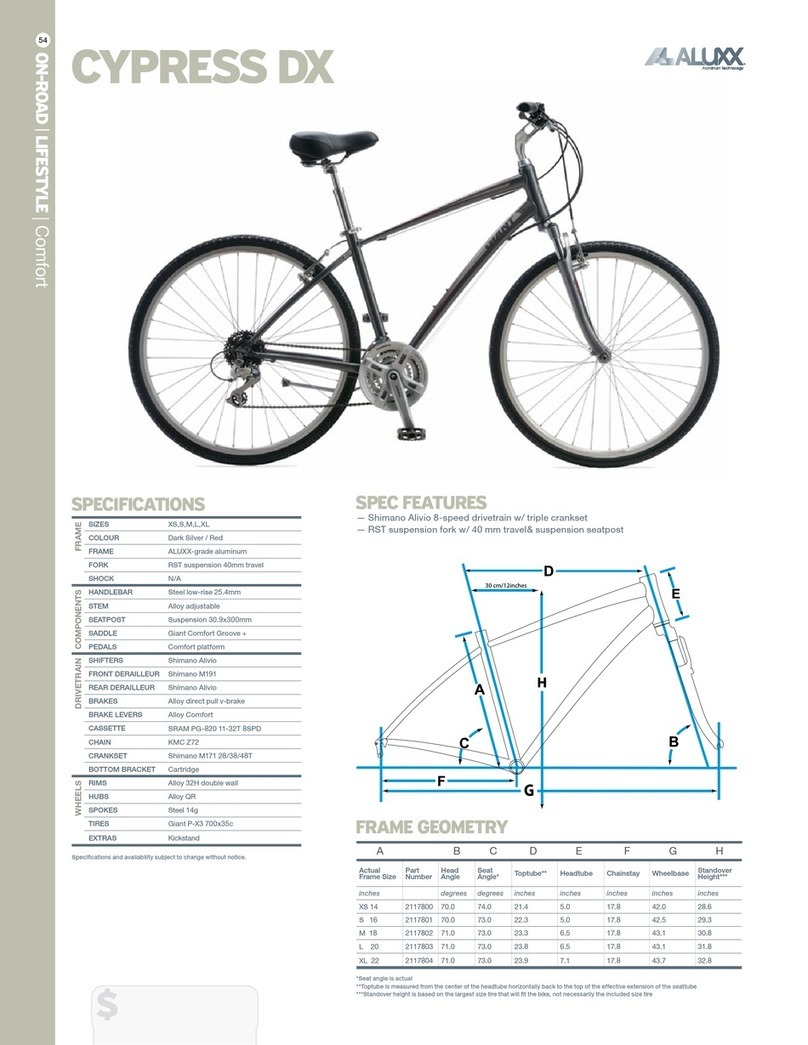

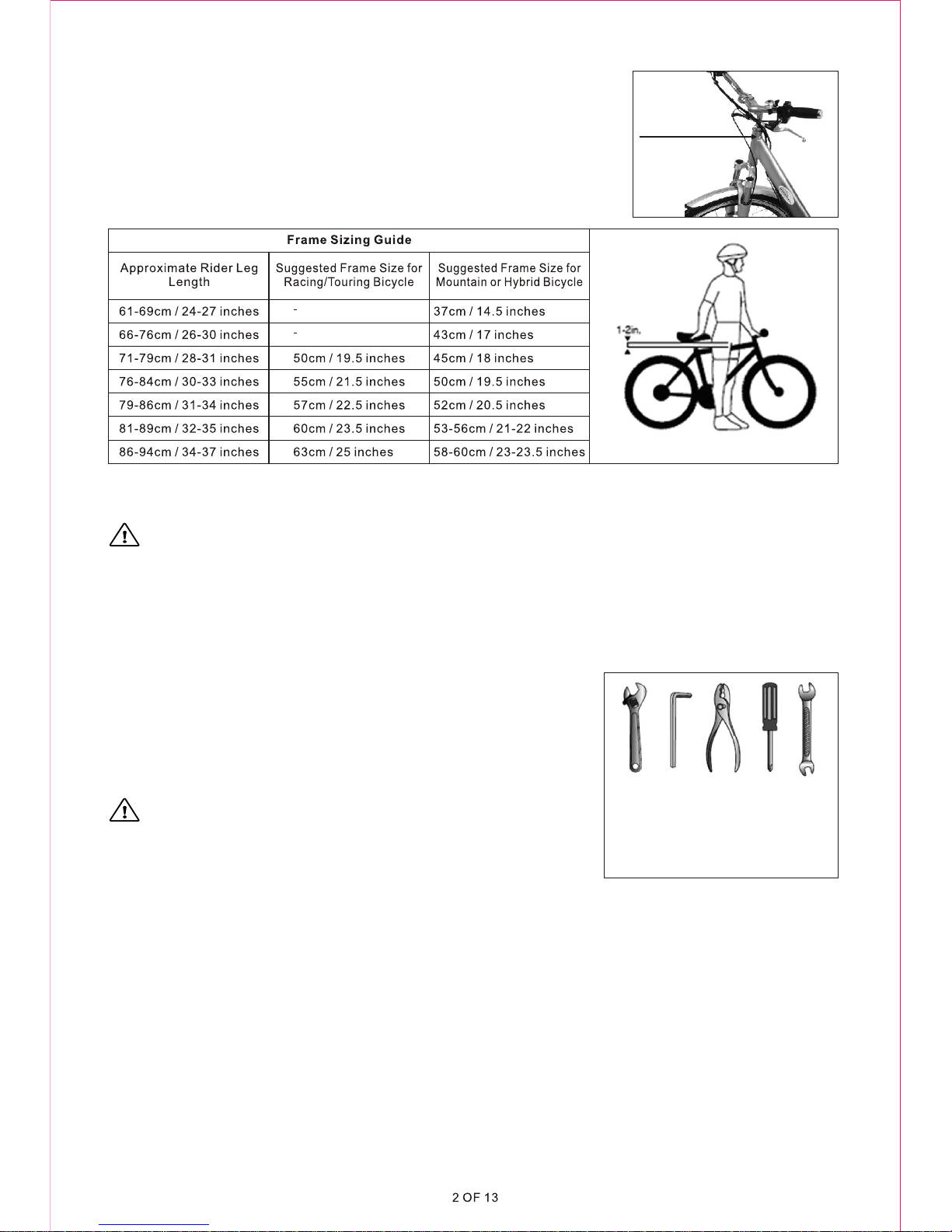

CORRECT FRAME SIZE

When selecting anew bicycle, framesize is veryimportant.

Most full-sized bicyclescome in arange of framesizes. These

sizes usually referto the distancebetween the centerof the

bottom bracket andthe top ofthe frame seattube.

The above chartand diagram willhelp you findthe correct

frame size. Riderleg length shouldbe measured fromthe inseam.

WARNING:For riding safetyand comfort, thereshould be noless than 1"to 2" of

clearance between theintended rider andthe top tubeof the bicycleframe.

The ideal clearancewill vary basedon rider preference.These basicrules are inplace to

make straddling theframe when off the saddleeasier and safer.

When measuring thefit of thebicycle, make sureyou have bothfeet flat onthe ground. Itis

okay for womento use amen's bike todetermine proper fit.

ASSEMBLYINSTRUCTIONS

Yournew bicycle wasassembled and tunedin the factory

and then partiallydisassembled for shipping.Youmay have

purchased the bicyclealready fully assembledand ready to

ride or inthe shipping cartonin the partiallydisassembled

form. Thefollowing instructions willenable you toprepare

your bicycle foryears of ridingenjoyment.

WARNING:We recommendthat you consulta bicycle

technician if youhave doubts orconcerns about yourability

to properly assembly, repair,or maintain yourbicycle.

GETTING STARTED

Open the cartonfrom the topand remove thebicycle. Remove thestraps and protective

wrapping. Inspect thebicycle and allaccessories and partsfor damaged ormissing parts. It

is recommended thatthe threads belubricated prior toinstallation. Do notdiscard packing

materials until assemblyis complete toinsure that norequired parts areaccidentally

discarded. Assembleyour bicycle followingthe steps thatpertain to yourmodel.

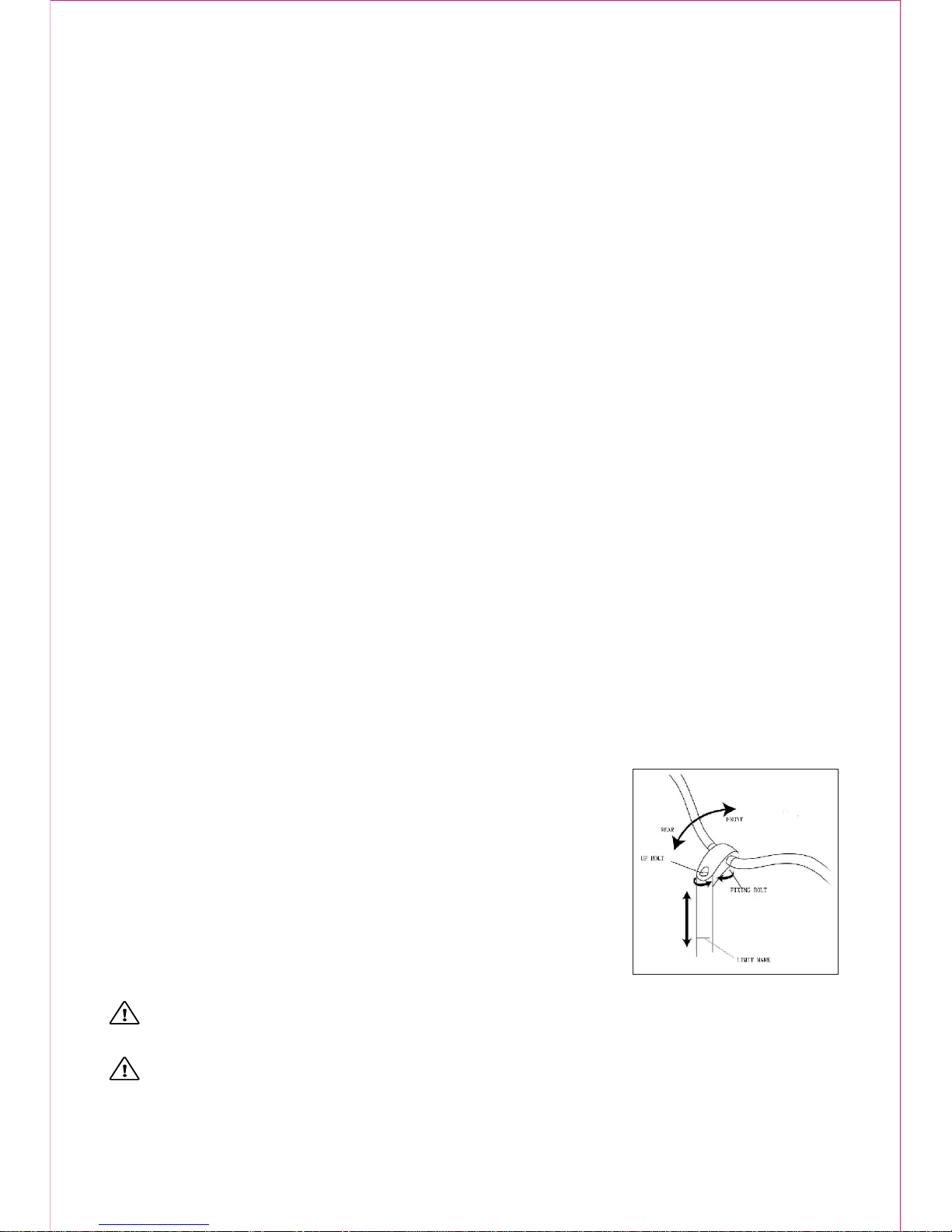

Handlebars

Remove the bubblebag from thehandlebar. Placethe handlebar steminto the topof the

handle tube, ensuringthat all cablesare free oftangles. Tightenthe stem boltobserving the

minimum insertion markand checking thatthe forks andthe handlebars arefacing

forward.

ToolsRequired: Inner HexWrench (notincluded)

Serial Number

ToolsRequired:

- Philips headscrewdriver

- 4mm5mm6mm& 8mmAllenkeys

-Adjustable wrenchora9mm,10mm,

14mm& 15mm open andbox end

wrenches

-Apair of pliers withcablecuttingability

WARNING: Over tighteningthe stem boltor headset assemblymay cause damageto

the bicycle and/orinjury to therider.

If the stemis not insertedto at leastthe "Minimum Insertion" mark, it ispossible to over-

tighten the stembolt and damagethe fork steeringtube. Thiscould result inunsafe

conditions and aninjury risk tothe rider.Check steering tightnessprior to ridingby

straddling the frontwheel and turningthe handlebar.If you canturn it withoutthe front

wheel turning, thestem is tooloose. Re-align thehandlebar with thefront wheel andre-

tighten the stembolt.

Seat

Insert the seatassembly into theframe of thebicycle and adjustthe seat tothe desired

height. Theseat post mustbe inserted toat least the"Minimum Insertion" line marked on

the seat post.Move the quickrelease lever tothe closed position.Youshould feel

considerable resistance whilemoving the lever. If not,re-open and re-tightenthe lever,then

move it tothe closed positionso it isin line withthe frame. Positionthe top ofthe seat

parallel with theground. Push thefront of theseat up anddown to firmlymesh the serrations

together.The serrations mustmesh completely togetherto insure astable riding position.

Check for tightnessby twisting theseat from sideto side, andfrom front toback. If theseat

moves at theseat clamp orquick release, repositionand re-tighten theappropriate

clamping mechanism.

Pedals

Start each pedalspindle by handto avoid strippingthe threads, thentighten with a15mm

narrow open-ended wrench.It is veryimportant that youcheck the crankset for correct

adjustment and tightnessbefore riding yourbicycle. Thenew crank maybecome loose with

initial use. Oncethe pedals havebeen attached, checkthat the crankarm rotates smoothly

and that thereis no lateralmovement.

WARNING:Attachment ofan incorrect pedalinto a crankarm will causeirreparable

damage.

Final Check

All other partslike front wheel,front disc brakes,headlights etc. wereassembled by the

factory; no otherassembly needed.

Tire Pressure:Check the tirepressure and inflateto the rangerecommended on thetire

sidewalls.

WARNING:Before riding, ensureall nuts, boltsand fittings onthe bicycle havebeen

correctly tightened.

GENERAL SAFETYRULES

· Bicyclists are expectedto obey thesame laws asall other roadvehicles. Theseinclude

giving way topedestrians and stoppingat red lightsand stop signs.For further information,

contact the Departmentof Transportationin your State.

· Ride in apredictable manner.Always ridewith traffic.

· Always use handsignals to indicateturning and stopping.

· Ride defensively. To other roadusers, you maybe hard tosee.

· Concentrate on what'sahead. Avoid pot holes,loose gravel, wetroad markings, oil,curbs,

speed bumps, drainagegrates and otherobstacles if atall possible.

· Cross train tracksat a 90-degreeangle or walkyour bicycle across.

· Expect the unexpected,such as openingcar doors orcars backing outof concealed

driveways.

· Be extra carefulat intersections andwhen attempting topass other vehicles.

· Familiarize yourself withall of thebicycle's features. Practicegear shifts, braking,and the

use of toeclips and straps,if fitted.

· Wear properriding attire andavoid open toeshoes. When wearingloose pants, useleg

clips or elasticbands to preventthem from beingcaught in thechain.

3 OF 13

· Do not carrypackages or passengersthat will interferewith your visibilityor diminish

control of thebicycle.

· Do not useitems that mayrestrict your hearing.

· When braking, alwaysapply the rearbrake first, thenthe front.The front brakeis more

powerful and ifit is notcorrectly applied, youmay lose control.Never lock upthe brakes.

· Maintain a safestopping distance fromall other riders,vehicles, and objects.Safe braking

Distances are subjectto the prevailingweather conditions.

Wet WeatherRiding

CAUTION: Riding inwet weather isnot recommended. Followthese precautions:

· Brake earlier andprovide yourself witha longer stoppingdistance.

· Decrease your ridingspeed, avoid suddenbraking and takecorners with additional

caution.

· Wear reflectiveclothing and usesafety lights forgreater visibility whenriding.

· Takeextra care aroundpotholes and slipperysurfaces, such asline markings andtrain

tracks.

Riding At Night

CAUTION: Ride atnight only whennecessary.Follow these precautions:

· Ensure the bicycleis equipped witha full setof clean, correctlypositioned reflectors.

· Use properly functioninglights, with awhite headlight anda red taillight.

· If the lightsare battery powered,make sure thebatteries are wellcharged.

· Certain taillights havea flashing mechanism,which enhances visibility.

· Always wear reflectiveor light coloredclothing.

· Slow down anduse familiar roadswith street lighting,whenever possible.

Hill Technique

· Gear down beforea climb andcontinue gearing downas required tomaintain pedaling

speed.

· If you reachthe lowest gearand are struggling,stand up onyour pedals.This will giveyou

more power fromeach pedal revolution.

· When descending, usethe high gearsto avoid rapidpedaling.

· Do not exceeda comfortable speed;maintain control andtake additional care.

Cornering Technique

· Brake slightly beforecornering and prepareto lean yourbody into thecorner.

· Keep the insidepedal at the12 o'clock positionand slightly pointthe inside kneein the

direction you areturning. Keep theother leg straight;don't pedal throughfast or tight

corners.

MAINTENANCE INSTRUCTIONS

Every time youride your bicycle,its condition changes.The moreyou ride, themore

frequently maintenance willbe required. We recommend youspend a littletime on regular

maintenance tasks.The following schedulesare a usefulguide. You should beable to

accomplish most tasks.For additional assistancewe recommend yousee a bicycle

technician.

Brakes

The correct adjustmentand operation ofyour bicycle's brakesis extremely importantfor

safe operation. Brakesshould be checkedfor effectiveoperation before everyride.

Frequent checking foradjustments is necessaryas the controlcable will stretchand the

brake pads willbecome worn withuse.

WARNING:Never ride abicycle unless thebrakes are functioningproperly.

4 OF 13

Inspection

Brake levers shouldbe checked fortightness at leastevery three months.They shouldbe

set in acomfortable position withineasy reach ofthe rider's hands.Brake levers shouldbe

firmly affixedto the handlebar. Thebrake pads shouldbe checked forcorrect positioning

and tightness beforeevery ride, andthe various boltsand nuts atleast every threemonths.

Squeeze each brakelever to makesure they operatefreely and thatthe brake padspress

hard enough onthe rims tostop the bike.There shouldbe about 1mm2mmclearance

between each padand the rimwhen the brakesare not applied.The brakepads must be

properly centered formaximum contact withthe rim. Replacethe brake padsif they areover

worn (when thegrooves or patterncan't be seen).The brakecable wires shouldbe checked

for kinks, rust,broken strands, orfrayed ends.The outer casingshould also bechecked for

kinks, stretched coils,and other damage.If the cablesare damaged, theyshould be

replaced.

Cables and CableHousing

Cables and housingare one ofthe most over-lookedparts on thebicycle. Thefirst indication

that your cablesand housing needto be replacedis an increasedamount of pressure

needed to operatethe brakes orshifters. Before everyride, check thatthere are nokinks or

frays in thecables and housing.Also checkthat the housingis seated properlyinto each

cable stop onthe bicycle. Itis recommended thatthe cables andhousing be replacedat

least every ridingseason to prolongthe life ofyour bike.

WARNING:Do not ridea bicycle thatis not operatingproperly.

Hub Bearing

When checked, thehub bearings ofeither wheel willrequire adjustment ifthere is anyplay.

1.Check tomake sure locknutsare tight.

2.To adjust, removewheel from bicycleand loosen thelocknut on oneside of thehub while

holding the bearingcone with aflat open-end wrench.

3.Rotate theadjusting cone asneeded to eliminateplay.

4.Re-tighten thelocknut while holdingthe adjusting conein position.

5.Re-check thatthe wheel canturn freely withoutexcessive play.

Wheel Inspection

It is importantthat wheels arekept in topcondition. Properly maintainingyour bicycle's

wheels will helpbraking performance andstability when riding.Be aware ofthe following

potential problems:

Dirty or greasyrims

CAUTION: Dirty or greasyrims can renderyour brakes ineffective. When cleaning,use

a clean ragand wash withsoapy water,rinse and airdry.Don't ride whilethe wheels arestill

wet. When lubricatingyour bicycle, donot get oilon the rim.

Straight wheels

Lift each wheeloff theground and spinthem to seeif they arestraight and true.If wheels are

not straight, theywill need tobe adjusted.This is difficult and isbest left toa bicycle

technician.

Broken or loosespokes

Check that allspokes are tightand that noneare missing ordamaged.

CAUTION: Damaged spokes cancause serious injury.

Loose hub bearings

Lift each wheeloff theground and tryto move thewheel from sideto side.

CAUTION: If thereis movement betweenthe axle andthe hub, adjustmentis

required.

5 OF 13

Axle nuts

Check that theyare tight beforeeach ride.

Quick release

Check that theyare set toa closed positionand are properlytensioned before eachride.

CAUTION: Maintain the closedposition and thecorrect adjustment. Failureto do so

may result inserious injury.

Lubrication

Reflectors

Yourbicycle is suppliedwith one front,one rear,two wheel, andtwo pedal reflectors.These

are an importantsafety and legalrequirement. Theyshould remain securelyfitted and in

good, clean conditionat all times.Periodically,inspect all reflectors,brackets, and

mounting hardware forsigns of wearor damage. Replaceimmediately if damaged.

Tires

Tires mustbe maintained properlyto ensure stability. Check thefollowing areas:

Inflation: Use atire gauge tocheck that thetires are inflatedto the pressureindicated on the

tire sidewalls.

CAUTION: If inflating tireswith a servicestation pump, takecare. Over-inflation can

cause a tireblow out.

Bead Seating: Wheninflating or refittingtire, make surethat the beadis properly seatedin

the rim.

Tread: Checkthat the treadshows no signsof excessive wearor flat spots,and that there

are no cutsor other damage.

Valves:Make sure valvecaps are fittedand that valvesare free fromdirt. Allowingdirt in the

valve can leadto a flattire, and seriousinjury.

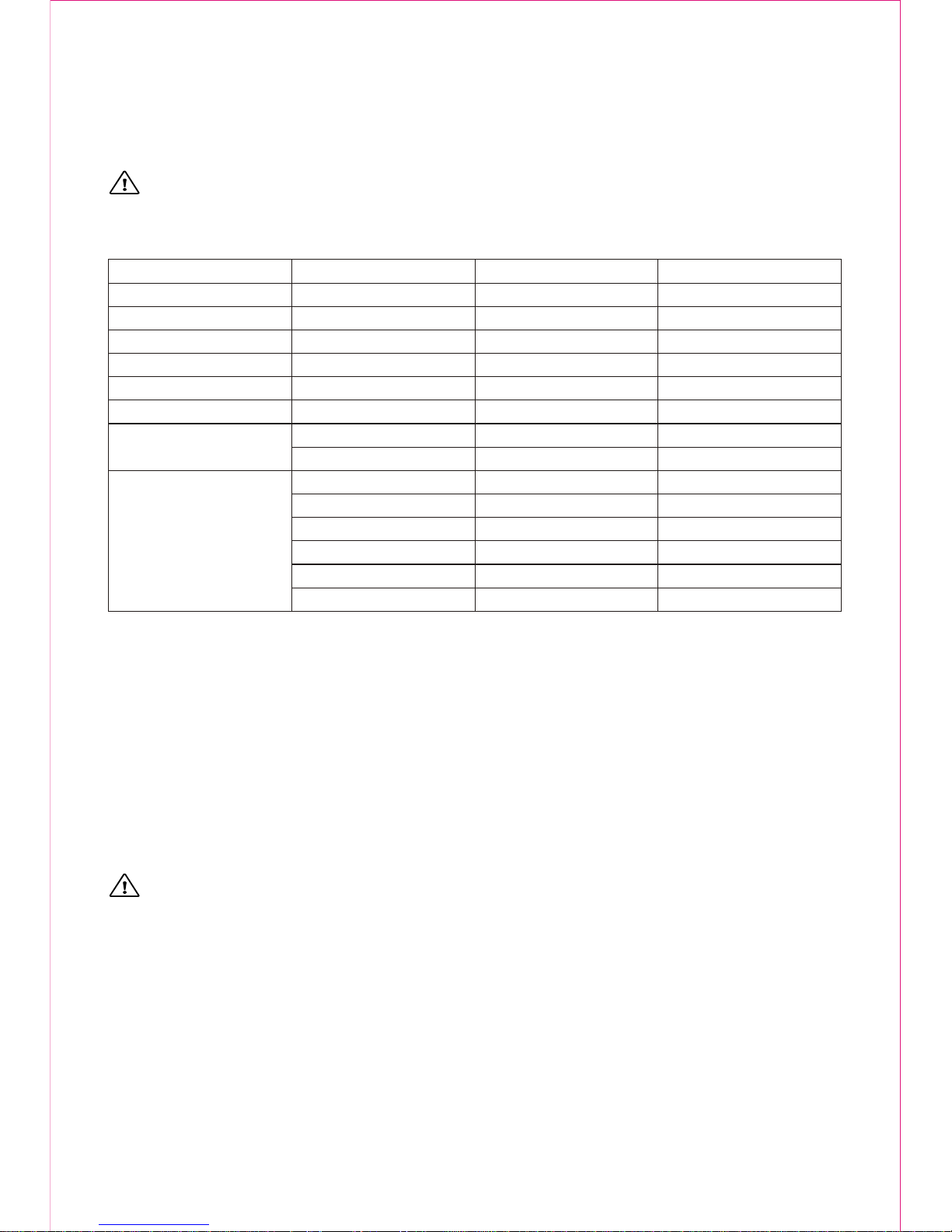

Recommended TirePressures

The recommended pressureon the sidewallof the tireshould match thefollowing chart. Use

this as ageneral guide.

6 OF 13

Frequency

Weekly

Monthly

Every Six Months

Yearly

Component

chain

derailleur wheels

derailleur

brake calipers

brake levers

shift levers

freewheels

brake cables

bottom bracket

pedals

derailleur cables

wheel bearings

headset

seat pillar

Lubricant

chain lube orlight oil

chain lube orlight oil

oil

oil

oil

lithium-based grease

oil

lithium-based grease

lithium-based grease

lithium-based grease

lithium based grease

lithium based grease

lithium based grease

lithium based grease

How to Lubricate

brush on or squirt

brush on or squirt

oil can

3 drops fromoil can

2 drops fromoil can

disassemble

2 squirts fromoil can

disassemble

disassemble

disassemble

disassemble

disassemble

disassemble

disassemble

Note: The frequency ofmaintenance should increase withuse in wet ordusty conditions. Do notover lubricate-remove

excess lubricant toprevent dirt build-up.Never use adegreaser to lubricateyour chain.

BMX: 35-50 PSI

MTB: 46-65 PSI

Road Touring: 70-90 PSI(Recommended)

Road Racing: 110-125 PSI

Hybrid/Cross: 60-100 PSI

How To Fix aFlat Tire

If you needto repair atire, follow thesesteps:

1.Remove thewheel from thebicycle.

2.Deflate thetire completely throughthe valve. Loosenthe tire beadby pushing itinward.

3.Press oneside of thetire bead upover the edgeof the rim.

Note: Use tire levers.Using a screwdrivermay damage therim.

4.Remove thetube, leaving thetire on therim.

5.Patch theleaks using atube repair kit,or replace thetube.

Note: Make sure thatthe size ofthe replacement tubematches the sizestated on thetire

sidewall and thatthe valve isthe correct typefor your bicycle.

6.Match theposition of theleak in thetube with thetire to locatethe possible causeand

mark the locationon the tire.

7.Remove thetire completely andinspect it fornails, glass, etc.The insideof the rimshould

also be inspectedto make surethere are noprotruding spokes, rustor other potential

causes. Replace therim tape, whichcovers the spokeends, if damaged.

8.Remount oneside of thetire onto therim.

9.Using ahand pump, inflatethe tube justenough to giveit some shape.

10.Place thevalve stem throughthe hole inthe rim andwork the tubeinto the tire.Note: Do

not let thetube twist.

11.Using your handsonly,remount the otherside of thetire by pushingthe edge towardthe

center of therim. Start oneither side ofthe valve andwork around therim.

12.Before thetire is completelymounted, push thevalve up intothe rim sothat the tiresits

squarely in position.

13.Fit therest of thetire, rolling thelast, most difficult, part onwith your thumbs.Note: Avoid

using tire leversas these canpuncture the tubeor damage thetire.

14.Check thatthe tube isnot caught betweenthe rim andthe tire beadat ay point.

15.Using ahand pump, inflatethe tube untilthe tire beginsto take shape.Check that thetire

bead is evenlyseated all theway around therim. When properlyseated, fully inflatethe tire

to the pressuremarked on thesidewall. Use atire gauge tocheck.

16.Place thewheel into theframe checking thatall gears, brakesand quick releaselevers

are properly adjusted.

Handlebar Stem

The handlebar stemfits into thesteering column. Itis held firm

by the actionof a binderbolt and expanderwedge which, when

tightened, binds withthe inside ofthe fork steerertube.

When removing thestem, loosen thestem bolt twoor three

turns, and thentap it toloosen the wedgeinside.

Tolubricate, first wipeoff anygrease and grime.Next, apply a

thin film ofgrease to thepart, including thewedge that willbe

inserted into theframe. Theheight of thehandlebar can be

adjusted for comfort.The stemis marked withthe words max.

height/minimum insertion.

WARNING:Never ride abicycle if thestem has beenraised so thatthe max.

height/minimum insertion linecan be seen.

WARNING:Over tightening thestem bolt orheadset assembly maycause damage to

the bicycle and/orinjury to therider.

When re-fitting thestem, make surethe handlebar iscorrectly aligned andtightened using

the appropriate hexwrench.

7 OF 13

Testthe security ofthe handlebar withinthe stem, andthe stem withinthe fork steerertube,

by clamping thefront wheel betweenyour knees andtrying to movethe handlebar upand

down, and fromside to side.The handlebarshould not movewhen applying pressure.

Handlebars

The exact positioningof the handlebaris a matterof personal comfort.Make sure the

handlebar and thefork are facingforward. If youneed to replacethe fork, pleaseconsult a

qualified bicycle technician.

WARNING:Never ride unlessthe handlebar clampingmechanism has beensecurely

tightened.

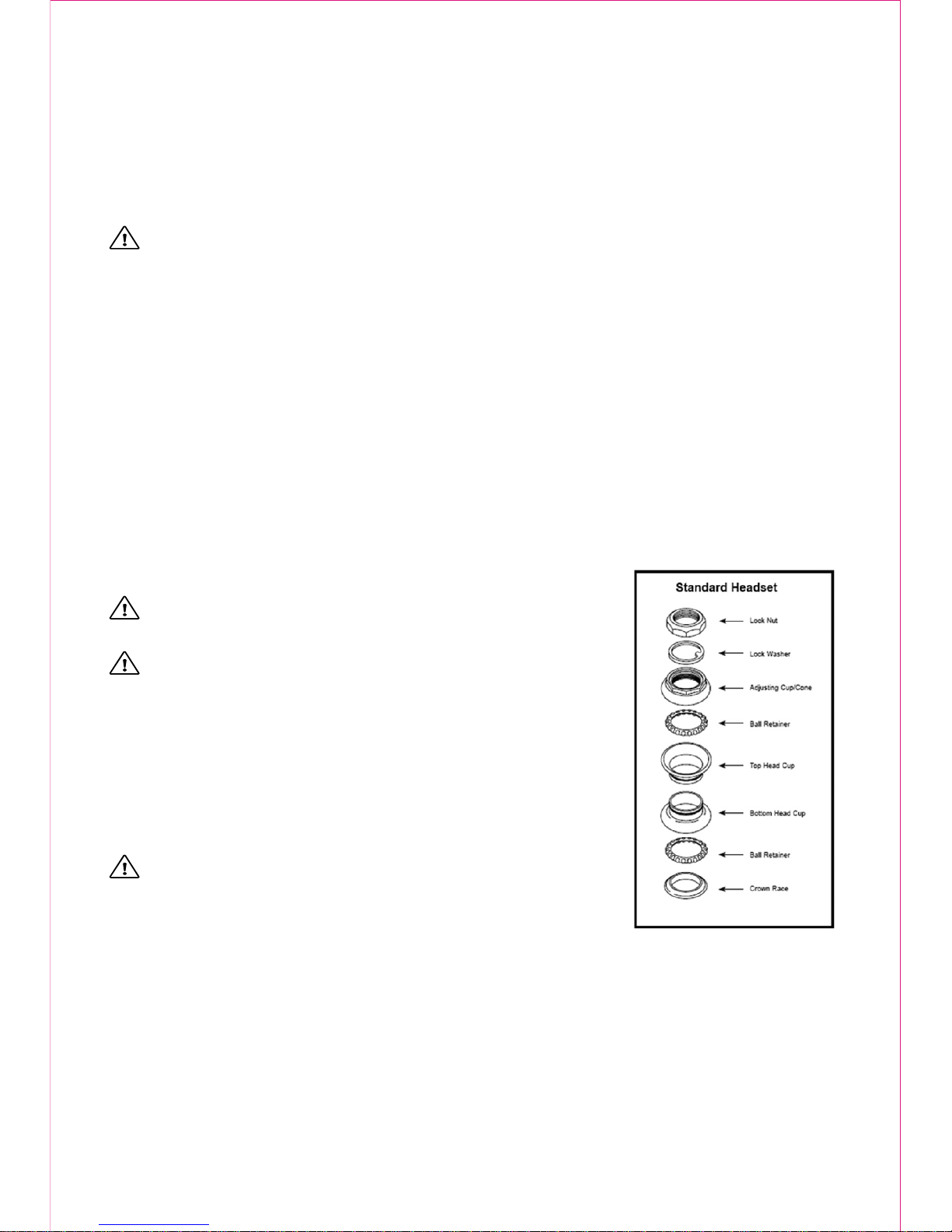

Headset Inspection

The headset bearingadjustment should bechecked every month.This isimportant because

the headset locksthe fork intothe frame, andif loose, cancause damage orresult in an

accident. Stand overthe frame toptube with bothfeet on theground. Applythe front brake

firmly and rockthe bicycle backand forth. Ifyou detect anylooseness in theheadset, it will

need adjustment.

Check that theheadset is notoverly tight byslowly rotating thefork to theright and left.If

the fork tendsto stick orbind at anypoint, the bearingsare too tight.

Note: If your bikeis equipped witha threadless headset,please see aqualified bicycle

technician for repairsand adjustments.

Headset Adjustment

Loosen the toplocknut (or removeit completely) alongwith the reflectorbracket, if fitted.

Turn theadjusting cup clockwiseuntil finger tight.Replace the lockwasher and reflector

bracket, and thenre-tighten the locknut using asuitable wrench.

Note: Do not overtighten or bearingdamage will occur.

WARNING:Always make surethat the headsetis properly

adjusted and thatthe headset locknutis tight beforeriding.

WARNING:Over tightening thestem bolt orheadset

assembly may causedamage to thebicycle and /orinjury to the

rider.

Saddle and SeatPost

Inspection:

The seat fixingbolt and theseat post binderbolt should be

checked for tightnessand adjustment everymonth. On

removing the seatpost from theframe, you willnotice a mark

with words max.height/minimum insertion.

WARNING:To avoid damage,the minimum insertionmark

must be insidethe frame.

Lubrication:

Remove the seatpost from theframe and wipeoff anygrease,

rust or dirt.Apply athin film ofnew grease tothe part thatwill be insertedinto the frame.Re-

insert, adjust, andtighten the seatpost.

Adjustment:

The seat canbe adjusted inheight, angle, anddistance from thehandlebars to suitthe

individual rider.Saddle angle isa matter ofpersonal preference butthe most comfortable

position will usuallybe found whenthe top ofthe seat isalmost parallel tothe ground, or

slightly raised atthe front.

The saddle canalso be adjustedby sliding itforward or backalong the mountingrails.

When fitting, positionthe seat postinto the clampunder the seatand place itin the frame

without tightening.Adjust it tothe desired angleand position, andtighten the clamping

8 OF 13

Indicator

Power indicator lightis red

Power and Chargingindicator light isred

Power indicator lightis red andcharging indicator lightis green

Charger State

Power on

Charging State

Full State

Please see thelabel on thecharger for additionalinstruction.

mechanism.

Testit by graspingthe seat andtrying to turnit sideways. Ifit moves, tightenthe binder bolt.

Note: Remember thatthe minimum insertionmark must remaininside the frameassembly.

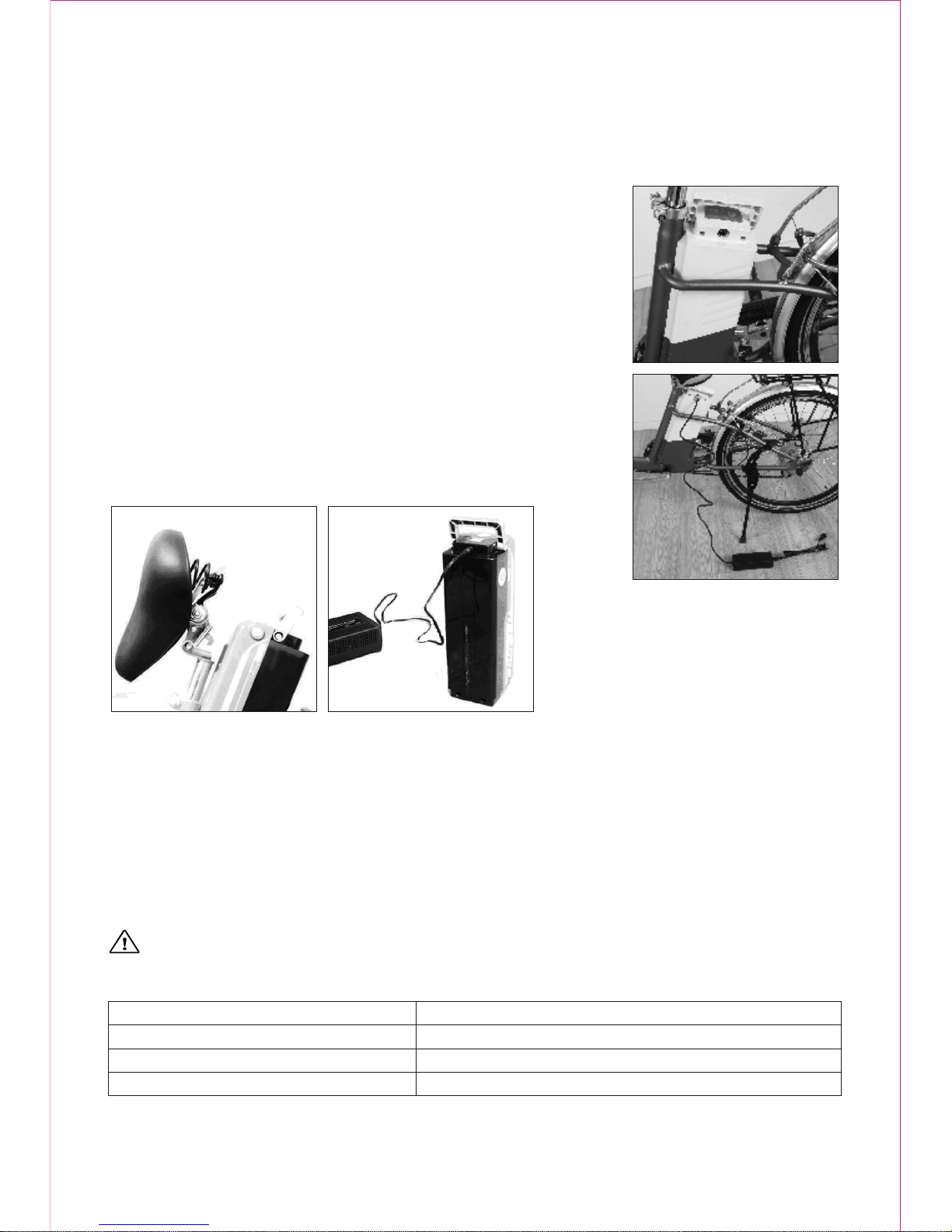

CHARGING THE BATTERY

The battery ofthe electric bicyclecan be chargedwith the bicycle

or independently.

Please use thespecial charger provided.

Charging the batteryon the bicycle

1.Stop theelectric bicycle atsuitable place andturn the main

switch to OFFposition.

2.Turnthe handle ofbattery box toexpose the charginginlet.

3.Insert theplug into thecharging inlet.

4.When finished,unplug it andclose the handle.

Charging the batteryafter removing

1.Place thebicycle on aneven surface.

2.Turnthe main switchto the OFFposition and takeout the key.

3.Insert thekey into thebattery lock andturn 180° counter

clockwise.

4.Lift thebar under thesaddle so thatthe saddle isvertical. Pull

the handle ofbattery box toremove the battery

Installing the battery

1.Hold thehandle of batterybox and re-insertthe battery.

2.Turnthe key 180°clockwise, then removethe key.

3.Pull backthe handle ofbattery box.

4.Return thesaddle to itsnormal position.

5.Connect theplug.

Charging Method

1.Plug ofcharger into thecharging socket ofthe battery.

2.Plug ofcharger into anoutlet (110V).

WARNING: Thebattery should bekept upright whencharging.

Indication of ChargerState

9 OF 13

Charging Environment

A dry, level surface

Should be outof direct sunlight

Make sure thereis proper ventilation

Keep away fromchildren and pets

Temperaturerange should be0-40 C duringcharging

Cautions for chargingthe battery

Please refer tothe charger instructionsfor detailed information.

Battery should becharged once every2 months whennot used.

Remove the batterywhen not usedfrequently.

Charge the batterybefore using.

WARNING:

Battery should onlybe charged usingthe charger provided.

Keep the batteryand charger awayfrom children andpets.

Do not touchthe charger plugand power supplywith wet hands.

Do not turnthe pedal whencharging (on thebicycle).

Do not usethe charger forother electric bicyclesand electrical products.

Charger will becomewarm when charging.Do not cover.

Store the chargerin a dry, secure environment.

Follow all operatinginstructions.

Keep the chargerfree of dirt,dust, and moisture.

Dispose of thebattery in aproper manner.

OPERATINGTHE ELECTRIC BICYCLE

This electric bicycleis motor-driven.

This product complieswith the statestandards.

The product performsat its beston flat, evensurfaces. Hills anduneven surfaces will

increase the burdenon the motorand battery. Please usethe pedals forbetter performance.

This will increasethe driving distanceand prolong thelife of thebicycle and thebattery.

Power Supply

Insert the keyinto the mainpower switch.Turn itclockwise to activateit.

The controller shouldindicate that thepower is on.The handleindicator should belit. The

electric bike isnow ready.

CAUTION: Please turn themain power switchto the OFFposition when finishedriding.

Riding with theMotor

When riding thebicycle, you canadjust the speedfrom 315 1/2MPH (525 km/h).

Tostop the motor, simply letoff thethrottle and applythe front orrear brake.

Avoid powerfailure by makingsure the batteryis charged.

Riding without theMotor

This electric bicyclecan also beridden using thepedals.

Since an electricbicycle is heavierthan a normalbicycle, extra forceis required topedal it.

Battery voltage indication

This electric bicycleis installed withpower volume indicator

The power volumeindicator will lighton when thebattery is fullycharged.

The indicator willgradually diminish withuse. Battery shouldbe charged whenthere is only

one indicator lighton.

Instruction

Please take into consideration howfar you planon going whenassessing whether the

battery needs charging.

10 OF 13

Estimated distance witha fully-charged, newbattery

On a flatroad: 1224 mile(2545 km) range.

Note: There are anumber of factorsthat can affect riding distance:How many timesyou

stop and start,the amount ofweight on thebicycle, the slopeand condition ofthe road, wind

conditions, temperature, andtire pressure.

Temperaturehas a directeffect onthe battery. Lower temperaturesdecrease battery

performance.

Load Goods

Recommended max. loadof this electricbicycle (weight ofthe passengers andgoods) is

165 lbs. (75kg).NOTE: Increased weight willaffect travelspeed and milerange.

The loading capacityand goods sizeof the bracketand luggage tankare shown below:

Toomany goods willimpact traveling distanceand battery andmotor performance.

WARNING:Do not exceedmaximum load weightand size. Overloadingand improperly

affixed loadscan result inunsafe riding conditionsand serious injury.

Instructions for parkingand storing theelectric bicycle

Stop the electricbicycle on evenand solid surface.

Hold the rackand kick thesupport.

CAUTION: Lock the supportrods after parkingthe bicycle.Turn themain power switch

to OFF positionor refer tothe power lockindication mark.

Turnthe main powerswitch to theOFF position

If the mainpower switch isnot turned off, it cancause driving systemfailure due to

inadequate power supply, and mayresult in aloss of batteryperformance.

Takeout the key

Takethe key outto avoid theftafter the bicycleis stopped.

Check before operating

Make sure tothoroughly inspect theelectric bicycle beforedriving.

Max Load

Size of Goods

Bracket

Luggage Tank

Width

Length

Height

6 lbs. (3kg)

22 lbs. (10kg)

3.9" (10cm) leftand right ofthe luggage tank

3.9" (10cm) behindthe luggage tank

15.7" (40cm) upthe luggage tank

11 OF 13

Confirm before driving

1.Make surethe handlebar isstable.

2.Ring ofbell.

3.Inspect thebrakes and brakelevers.

Hold the frontand rear brake,confirm that thereis 1/2"

of distance betweenthe brake andbrake handle

Check the wearof brake rubber

Please replace thebrake rubber ifthe slot isless than 1/32"

(1mm).

Slot of brakerubber exceeds 1/32"(1mm).

4.Height ofsaddle and handlebar

The saddle isthe proper heightwhen your feettips touch theground when sittingon the bike.

Yourelbows should beslightly bent whenholding the handlebar.

5.Power volumeof battery

Turn themain switch toON position, confirmremaining power throughthe power indicator.

6.Installation ofbattery

Confirm the batteryis tightly installedin the bicycle.

7.Check thewheel shaft

Confirm that thefront and rearwheels are tight(recommended torque isshown below)

Rotation Torque of FrontShaft Nut: 265-354in-lbs. (300-400kgfcm) (30-40Nm)

Rotation Torque of RearShaft Nut: 398-637in-lbs. (450-720kgfcm) (45-72Nm)

8.Air pressureand damage totires

Confirm the airpressure of tires.Low air pressuremay cause

broken wheels orswaying. Inspect thetires for damage,

including foreign objectssuch as nailsand glass.

9.Confirm thatthe pedals arestable.

If there isplay in thepedals, tighten thebolts immediately.

10.Make surethe saddle istight and freefrom movement.

11.Check the chaintension.

Please adjust thechain if itexceeds 46" (1015mm).

12.Confirm thechain is lubricated(30# machine oil)and works smoothly.

Length contacting with floor

3 1/24" (9-10cm)

Test condition

Weight of passenger

132 lbs. (60kg)

Air pressure

44 PSI (300kpa)

12 OF 13

TROUBLESHOOTING

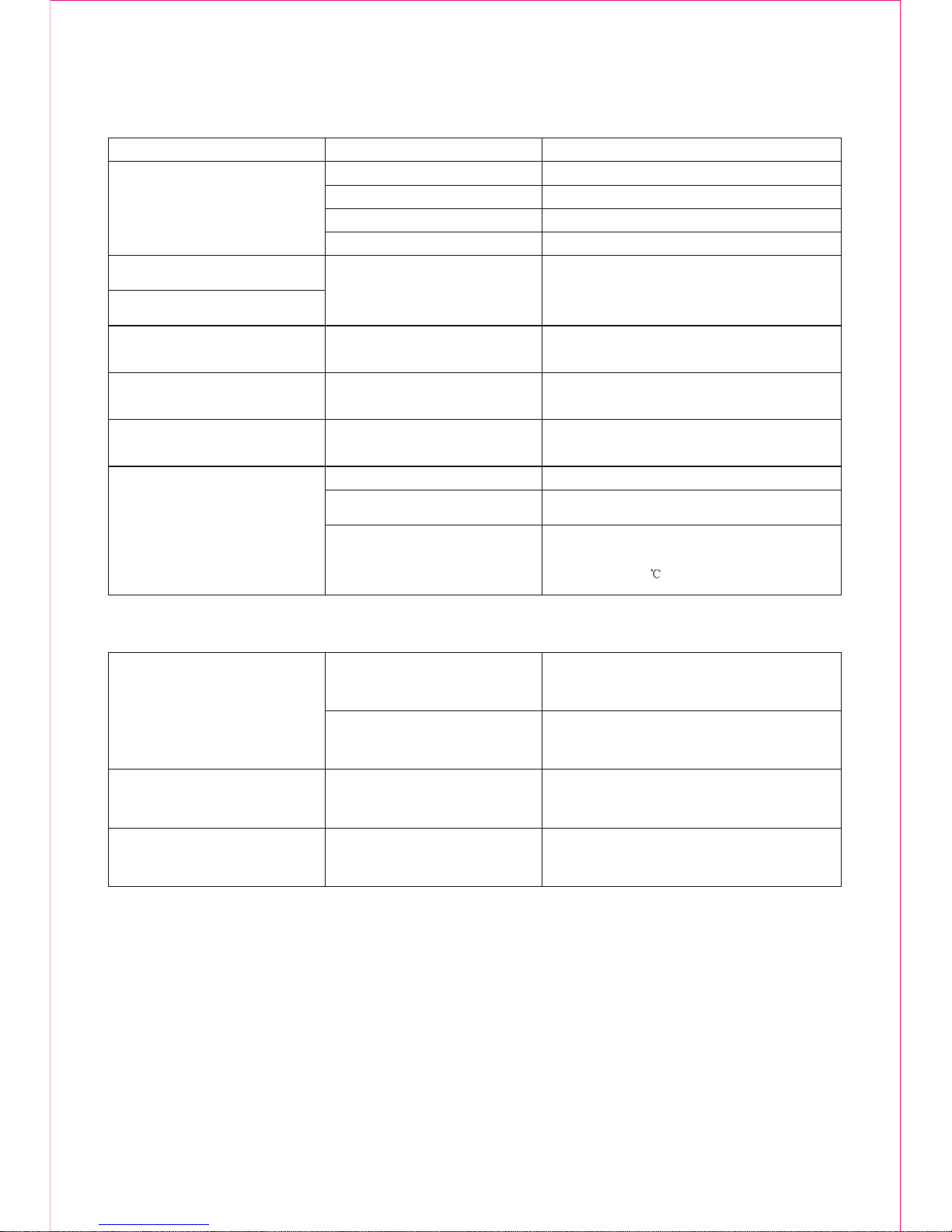

Electric Driving System

Charger

WARRANTY

One-Year LimitedWarranty

Phenomenon

Electric driving systemis unstable

Low speed

Power indicator isoff

Electric driving systemmakes

noise

Electric driving systemgenerates

smoke or odor

Battery power indicatorlights on,

but the motordoesn't work

Drive distance is short

Check

Battery is notcharged

Tire pressure islow

Tire is damaged

Overloading

Does plug tightly connectwith

the battery

Is the batteryfully charged?

Is it usedin a low temperature

environment?

Battery service lifehas expired

Solution

Charge the battery

Inflate the tire

Repair the tire

Limit the goodsat max load

Tightly connect theplug

If this doesn'tsolve the problem,it is possible

that the batteryterminal or wireis loose.

Please contact theseller

Check for foreignobjects in theelectric driving

system or alack of lubricant

Please contact theseller

Electric driving system isfaulty

Please contact theseller

Wire is loose orelectric drive system isfaulty

Please contact theseller

Charge the battery

Operate in warmerenvironment

Please replace the battery.

The Battery servicelife is expiredwhen the dis

charging time isless than 70minutes at 5A

current in the20 environment after charging.

Connect it again.If it stillwon't charge, that

means the chargerhas failed orthe fuse is

damaged

Please contact theseller

Confirm the chargingmethod and charge

again If itstill doesn't charge,you have charger

failure

Please contact theseller

Immediately unplug thepower socket andstop

using.

Please contact theseller

Immediately unplug thepower socket andstop

using.

Please contact theseller

Charge failure

Charger generates noise,odor

and smoke

Charger becomes warm

Is the powersocket tightly

connected with chargingplug?

Is the chargerindicator light on?

It may generateheat when

o

charging (4060 C)

13 OF 13

Northern Tool + EquipmentCo.,

2800 Southcross DriveWest

P.O. Box 1499Burnsville, MN 5337-0499

Made in China

WARNING

Some dust createdby power sanding,sawing, grinding, drilling,and other construction

activities contains chemicalsknown to theState of Californiato cause cancer, birth defects

or other reproductiveharm. Some examplesof these chemicalsare:

Lead from lead-basedpaints

Crystalline silica frombricks and cementand other masonryproducts, and arsenicand

chromium from chemically-treatedlumber.

Yourrisk from theseexposures varies, dependingon how oftenyou do thistype of work.To

reduce your exposureto these chemicals:work in awell ventilated area,and work with

approved safety equipment,such as thosedust masks thatare specially designedto filter

out microscopic particles.

·

·

Tools

Table of contents