Nouvag Dispenser DP 30 User manual

Infiltration Pump

©NOUVAG AG • 31678 • V20221125 • All rights reserved.

Dispenser DP 30

Instructions for use

EN

2©NOUVAG AG • 31678 • V20221125 • All rights reserved

Dispenser DP 30 Instructions for use

Foreword

Congratulations on your purchase of a Nouvag product.

Thank you for the confidence shown in our products.

Please consult the instruction manual for the use and maintenance of the device in order to ensure that it will func-

tion properly and efficiently for many years.

You will find the conformity statement and list of authorized service representatives attached.

Please read these instructions for use carefully before operating!

Explanation of symbols

Post market surveillance

Warning! Note Refer to

instructions for use

Manufacturer Date of manufacturing Expiration date

Do not use if the

packaging is damaged Not for reuse Dispose as electrical and

electronic waste

Bio hazard Tubing set is latex free Tubing set contains

phthalates

Batch number Order number Serial number

Medical device EOSTERILE Sterilized with ethylene

oxide

European authorized

representative

Protected against

permanent immersion

Potential equalization

connection

Indication of pump flow

direction

Tubing set with attached instrument is Type BF applied part Pedal

Certified by the Canadian Standards Association (CSA) for Canada

and the USA

CE symbol with notified

body

In the event of problems with the product or in the event of a serious incident, please immediately compile the

following form:

https://nouvag.com/media/attachments/2022/05/19/for_8-308.pdf

and send it as a pdf to the following email: complaint@nouvag.com.

3

©NOUVAG AG • 31678 • V20221125 • All rights reserved

Instructions for use Dispenser DP 30

1. Product description 4

Intended use and operation

Target Group

Contraindications

Technical data, Dispenser DP 30

Ambient conditions

Warranty coverage

2. Safety information 5

EMC Manufacturer’s Declaration of Conformity

Integrated peristaltic pump

Possible risks and side effects

Modification and misuse

Essential requirements

During use

3. Scope of delivery 7

4. Device overview 8

5. Startup 9

Connection to the power supply

Potential equalization connection according to DIN 42801

Device preparation

Device setup

6. Operation 11

Switching the device on and off

Regulation of the infiltration process

Peristaltic pump

Functional check

7. Cleaning and disinfection 12

Control unit and pedal

Tube set REF 6022

8. Maintenance 13

Replacing the control unit fuse

Safety inspections

Information on disposal

9. Malfunctions and troubleshooting 14

10. Spare parts list with order numbers 14

11. Service center 14

4©NOUVAG AG • 31678 • V20221125 • All rights reserved

Dispenser DP 30 Instructions for use

1. Product description

Intended use and operation

The Dispenser DP 30 serves as Infiltration pump into the connective tissue and is used in the following field of appli-

cations:

Tumescent infiltration for liposuction (Liposuction)

Infiltration pump for venous treatment, varicose veins (Angiology)

The Dispenser DP 30 may only be operated by trained and qualified personnel in professional settings.

Target group

Adult patients, in good health status.

Contraindications

Infectious wounds liposuction may only be performed after the treatment of the infection and necrotic tissue.

In principle, generally poor health of the patient

Liposuction shortly after a strict diet of the patient

Morbid obesity (obesity) large suction volumes increase the risk of death due to fluid shifts.

Intravascular infusion of liquids

Relevant cases in the literature must be considered.

Technical data

Voltage, switchable 100 V~ / 115 V~ / 230 V~, 50 / 60 Hz

Fuse power supply 2 fuses T 1 AL, 250 V AC

Power consumption 40 VA

Volumetric displacement 0 ... 12.5 l/h

Maximum pressure with closed tube set 2,0 bar

Applied part Type BF *

Protection class Class I

Dimensions (W x D x H) 260 x 250 x 110 mm

Net weight control unit 2,4 kg

Maximum weight at the stand for the irrigation fluid bottle 2,0 kg

The mentioned volumetric displacement is only valid for aqueous solutions without any instrument connected

* Applied part is the tube set with its attached instruments.

Ambient conditions

Transport and storage Operation

Relative humidity 10 ... 90 % max. 80 %

Temperature 0 ... 60 °C 10 ... 30 °C

Atmospheric pressure 700 ... 1060 hPa 800 ... 1060 hPa

Warranty coverage

Purchasing the Dispensers DP 30 entitles you to a 1-year warranty. If you return the warranty card for registration

within four weeks of the date of purchase, warranty coverage will be extended for a further 6 months. Consumable

parts are not covered by the warranty. Improper use or repair, or failure to observe these instructions, relieve us from

any obligation arising from warranty provisions or other claims.

5

©NOUVAG AG • 31678 • V20221125 • All rights reserved

Instructions for use Dispenser DP 30

2. Safety information

It is essential to bear the following information in mind:

Every use of the Dispenser DP 30 different to the product description defined in chapter “Intended use and opera-

tion”, causes risks for patients and trained personnel. If physical examinations and therapies are carried out without

use of the devices then the device must be removed from the place of treatment. Avoid any connection or close

adjacency to other devices.

EMC Manufacturer’s Declaration of Conformity

The use of (RF) Radio Frequency emitting devices and equipment as well as the occurrence of negative environmen-

tal factors in the close area of the Dispenser DP 30 may cause unexpected or adverse operation. The connection or

the placing of other devices in close vicinity is not allowed.

Use only accessories and cables as specified in the product description. Further observe the EMC manufacturer decla-

ration of conformity.

Integrated peristaltic pump

The integrated peristaltic pump is used for infiltration of watery solutions into the human connective tissue. The

infiltration pump is not designed for intravascular infusion of liquids.

Possible risks and side effects

Improper use can result in tissue or organ injuries to the patient or cuts to the user or a third person.

In rare cases, a treatment can lead to mild neurological disorders. In very rare cases, a treatment can lead to

endovenous heat-induced thrombosis.

6©NOUVAG AG • 31678 • V20221125 • All rights reserved

Dispenser DP 30 Instructions for use

Modification and misuse

Modifications/manipulations on the Dispenser DP 30 and its accessories are not permitted. Failure to follow these

instructions can have unpredictable consequences for the user, the patient or third parties. For consequential

complications, resulting from illicit modifications/manipulations the manufacturer assumes no responsibility and

the guarantee is void.

Nouvag recommends the use of Klein tumescent anesthesia solution. The use of other solutions is on the respon-

sibility of the surgeon. When infiltrating tumescent anesthesia solution, do not exceed 0.05% w/w anesthetic

concentration.

Essential requirements

The Dispenser DP 30 may only be operated under constant supervision of medical personnel. The absence of a

warning buzz to indicate malfunctions of the device requires the permanent control of the volumetric displace-

ment of the pump.

During use

Do not use the device if the shipping box has

holes/cracks on the flat surfaces, and/or if the

Styrofoam protective packaging is broken.

The Dispenser DP 30 may only be operated by

qualified and trained personnel!

The use of third-party products is the responsibili-

ty of the operator. Functionality and patient safety

cannot be guaranteed with third-party accesso-

ries.

Repairs may only be performed by authorized

Nouvag service technicians!

Improper use or repair of the device, or failure to

observe these instructions, relieves Nouvag from

any obligation arising from warranty provisions or

other claims!

Prior to using the device, before startup, and be-

fore operation, the user must always ensure that

the device and accessories are in good working

order and are clean, sterile and operational..

Ensure that the operating voltage setting corre-

sponds to the local mains voltage.

The device is not sterile on delivery. Please ob-

serve the cleaning instructions on Chapter 8.

At choice of the instrument the user has to make

sure it confirms to EN ISO 10993, means that it’s

biocompatible.

Do not use device in the vicinity of flammable

mixtures!!

The employment of the Dispenser DP 30 other

than that for which it was designed (see chapter

1.1) is not permitted. The responsibility is solely

carried by the operator.

7

©NOUVAG AG • 31678 • V20221125 • All rights reserved

Instructions for use Dispenser DP 30

4. Scope of delivery

REF Description Quantity

4180 Dispenser DP 30 control unit 1

1770 Stand for irrigation fluid bottle 1

31678 Dispenser DP 30 Instructions for use 1

Selectively – Set No. 4186, Dispenser DP 30 control unit with ON/OFF pedal

REF Description Quantity

1513nou ON/OFF pedal, IPX8 1

Selectively – Set No. 4187, Dispenser DP 30 control unit with VARIO pedal

REF Description Quantity

1501nou VARIO pedal, IPX8 1

8©NOUVAG AG • 31678 • V20221125 • All rights reserved

Dispenser DP 30

Bedienungsanleitung, Dispenser DP 30, REF 31678, V24/21 7

DE

1

2

3 4

5

6

7

8

9

10

5 Geräteübersicht

Frontansicht

1. Kontrollleuchte, Power ON/OFF

2. Bedienpanel mit Skala der Pumpfördermenge

3. Drehregler zur Einstellung der Pumpfördermenge

4. Entriegelungstaste zur Schlauchset-Aufnahme

5. Schwenkarm mit integrierter Schlauchaufnahme

6. Schlauchset

7. Stativ für Infiltrationsflüssigkeits-Flasche

8. Quetschrolle

9. Entlüftungsventil

10. Infiltrations-Flüssigkeits-Behälter

11. Typenschild mit Typenbezeichnung, Referenz-Nummer,

Seriennummer, Angaben zur Spannungsversorgung und

Geräte-Sicherungs-Angabe

12. Pedalbuchse, Geräte-Rückseite

13. Potentialausgleich

14. Netzmodul mit Netzstecker-Buchse

15. Netzmodul mit Netz-Hauptschalter

16. Netzmodul mit Länder-Spannungs-Einstellung

Rückansicht

12

11 14 13 15 16

Dispenser DP 30

Bedienungsanleitung, Dispenser DP 30, REF 31678, V24/21 7

DE

1

2

3 4

5

6

7

8

9

10

5 Geräteübersicht

Frontansicht

1. Kontrollleuchte, Power ON/OFF

2. Bedienpanel mit Skala der Pumpfördermenge

3. Drehregler zur Einstellung der Pumpfördermenge

4. Entriegelungstaste zur Schlauchset-Aufnahme

5. Schwenkarm mit integrierter Schlauchaufnahme

6. Schlauchset

7. Stativ für Infiltrationsflüssigkeits-Flasche

8. Quetschrolle

9. Entlüftungsventil

10. Infiltrations-Flüssigkeits-Behälter

11. Typenschild mit Typenbezeichnung, Referenz-Nummer,

Seriennummer, Angaben zur Spannungsversorgung und

Geräte-Sicherungs-Angabe

12. Pedalbuchse, Geräte-Rückseite

13. Potentialausgleich

14. Netzmodul mit Netzstecker-Buchse

15. Netzmodul mit Netz-Hauptschalter

16. Netzmodul mit Länder-Spannungs-Einstellung

Rückansicht

12

11 14 13 15 16

Dispenser DP 30 Instructions for use

5. Device overview

Front view

Rear view

1 Indicator light for Power On/Off

2 Operating panel with pump displacement scale

3 Control dial to set pump displacement volume

4 Release key for tubing set bracket

5 Peristaltic pump

6 Tubing set

7 Stand for irrigation fluid bottle

8 Roller clam

9 Venting valve

10 Irrigation fluid

11 Type plate with type designation, reference number,

serial number, information on power supply and

device fuse

12 Pedal socket, device rear

13 Potential equalization

14 Power entry module with power plug socket

15 Power entry module with power switch

16 Power entry module with national voltage setting

9

©NOUVAG AG • 31678 • V20221125 • All rights reserved

Dispenser DP 30

8 Bedienungsanleitung, Dispenser DP 30, Ref. 31678, V24/21

6 Inbetriebnahme

Anschluss an die Spannungsversorgung

Um das Risiko eines elektrischen Schlages zu vermeiden, darf das Gerät nur an ein Versorgungsnetz mit

Schutzleiter angeschlossen werden.

Stimmt die angezeigte Spannung nicht mit der örtlichen Netzspannung überein, muss die graue Sicherungs-

halterung auf die richtige Spannung eingestellt werden:

A) Gerät ausschalten.

B) Netzkabel ausstecken.

C) Mit einem Schraubendreher Sicherungsfach öffnen.

D) Sicherungshalterung herausziehen.

E) Graue Sicherungshalterung herausziehen und wieder so einsetzen, dass am kleinen Fenster der örtli-

che Netzspannungswert erscheint.

F) Graue Sicherungshalterung wieder einschieben und Sicherungsfach schließen.

G) Angezeigte Netzspannung auf Sicherungsfach überprüfen.

H) Netzkabel wieder am Gerät einstecken.

Potentialausgleichs-Anschluss nach DIN 42801

An der Rückseite des Gerätes ist ein Potentialausgleichsstecker nach DIN 42801 angebracht.

Der zusätzliche Potentialausgleich hat die Aufgabe, Potentiale zwischen verschiedener leitfähigen Material-

teilen, die gleichzeitig berührbar sind, auszugleichen oder Potentialunterschiede zu verringern.

Um Patient, Anwender und Dritte vor Berührungsspannungen zu schützen, muss dieser Anschluss benutzt

werden.

Der Potentialausgleichsstecker ist mit folgendem Symbol gekennzeichnet:

Gerätevorbereitung

1. Stativ für Kühlflüssigkeit in Stativhalter einstecken.

2. Pedalstecker in Pedalbuchse, auf der Rückseite des Steuergeräts einstecken.

3. Schlauchset-Montage (siehe nachfolgende Bilder):

Schlauchset kontrollieren nach Verfallsdatum und Unversehrtheit der Verpackung. Unsterile

Schlauchsets können zu schweren Infektionen und im schlimmsten Fall zum Tod führen.

Beim Einlegen des Schlauchsets ist die Pfeilmarkierung auf dem Schwenkarm der Pumpe zu

beachten. Sie gibt die Flussrichtung der Infiltrations-Flüssigkeit an.

Es darf nur das Nouvag Schlauchset verwendet werden, ansonsten kann die Funktion nicht gewährleistet

werden.

Instructions for use Dispenser DP 30

Connection to the power supply

In order to prevent the risk of electric shock, the device may only be connected to a power network with a PE

protective earth conductor.

If the voltage shown does not correspond to the local mains voltage, the grey fuse holder must be set to the correct

voltage:

6. Startup

1 Switch off device.

2 Unplug the power cable.

3 Use a screwdriver to open the fuse slot.

4 Remove the fuse holder.

5 Remove the grey fuse holder and reinsert it so that the local mains voltage setting is shown in the small window.

6 Slide the grey fuse holder back in and close the fuse slot.

7 Check the mains voltage shown on the fuse slot.

Potential equalization connection according to DIN 42801

At the back of the device a potential equalization plug is installed, according to DIN 42801.

The additional potential equalization has the task of equalizing potentials between different parts of conductive

materials that can be touched at the same time, or reducing potential differences.

This connection must be used, to protect the patient, the user and third parties from touch voltages.

The equipotential plug is marked with the following symbol:

Device preparation

1 Insert the stand for the irrigation fluid into the stand holder.

2 Plug the pedal plug into the pedal socket at the rear of the control unit.

3 Assemble the tubing set (see images).

Check the expiry date of the tubing set and ensure that the packaging is not damaged. Using non-sterile tubing

sets can result in serious infection, and in extreme cases, can be fatal.

Use only the Nouvag tubing set, otherwise the function cannot be guaranteed.

When inserting the tubing set, notice the arrow marked on the tubing set bracket. It indicates the direction of flow

of the infiltration liquid.

10 ©NOUVAG AG • 31678 • V20221125 • All rights reserved

Dispenser DP 30

Bedienungsanleitung, Dispenser DP 30, REF 31678, V24/21 9

DE

A) Pumpen-Entriegelungstaste zum Öffnen der Pumpe drücken.

B) Schwenkarm mit integrierter Schlauchaufnahme öffnet sich.

C) Schlauchset in die vorgesehene Schlauchaufnahme so einhängen, dass das Schlauchset-Ende mit

dem Einstechdorn die Pumpe in Richtung Geräterückseite verlässt. Sitz des Schlauchs prüfen.

D) Schwenkarm mit eingespanntem Schlauchset hinunterdrücken bis Schwenkarm einrastet.

4. Einstechdorn am Ende des Schlauchsets in die Gummimembran des Verschlusses der In-

filtrations-Flüssigkeits-Flasche einstechen und Flasche am Stativ aufhängen.

5. Quetschrolle am Schlauchset bis zum Anschlag öffnen.

6. Entlüftungsventil am Einstechdorn öffnen.

7. Steuergerät an Steckdose anschließen.

Vergewissern Sie sich, dass die eingestellte Betriebsspannung und die landestypische Netzspan-

nung übereinstimmen!

Der Beutel der Infiltrationsflüssigkeit darf maximal 2 kg wiegen. Schwerere Beutel als erlaubt,

können zum Umkippen des Geräts führen.

Die Flüssigkeitsmenge darf nicht durch die Quetschrolle am Schlauchset reguliert werden, son-

dern wird durch den Drehschalter und das Pedal reguliert. Öffnen Sie die Quetschrolle deshalb

bis zum Anschlag.

4. 5. 6.

B C D A

Dispenser DP 30

Bedienungsanleitung, Dispenser DP 30, REF 31678, V24/21 9

DE

A) Pumpen-Entriegelungstaste zum Öffnen der Pumpe drücken.

B) Schwenkarm mit integrierter Schlauchaufnahme öffnet sich.

C) Schlauchset in die vorgesehene Schlauchaufnahme so einhängen, dass das Schlauchset-Ende mit

dem Einstechdorn die Pumpe in Richtung Geräterückseite verlässt. Sitz des Schlauchs prüfen.

D) Schwenkarm mit eingespanntem Schlauchset hinunterdrücken bis Schwenkarm einrastet.

4. Einstechdorn am Ende des Schlauchsets in die Gummimembran des Verschlusses der In-

filtrations-Flüssigkeits-Flasche einstechen und Flasche am Stativ aufhängen.

5. Quetschrolle am Schlauchset bis zum Anschlag öffnen.

6. Entlüftungsventil am Einstechdorn öffnen.

7. Steuergerät an Steckdose anschließen.

Vergewissern Sie sich, dass die eingestellte Betriebsspannung und die landestypische Netzspan-

nung übereinstimmen!

Der Beutel der Infiltrationsflüssigkeit darf maximal 2 kg wiegen. Schwerere Beutel als erlaubt,

können zum Umkippen des Geräts führen.

Die Flüssigkeitsmenge darf nicht durch die Quetschrolle am Schlauchset reguliert werden, son-

dern wird durch den Drehschalter und das Pedal reguliert. Öffnen Sie die Quetschrolle deshalb

bis zum Anschlag.

4. 5. 6.

B C D A

Dispenser DP 30 Instructions for use

A Press the release key for tubing set bracket (on top of the control unit) to open the pump.

B The compartment with the integrated tubing bracket opens.

C Place the tubing set into the tubing bracket provided in such a way that the end of the tubing setwith the spike

exits the pump to the rear of the control unit. Check that the tubing is secure.

D With the tubing set inserted, press the compartment downwards until it clicks into place.

4 Insert the spike at the end of the tubing set into the infiltration fluid bottle and hang the bottle onto the stand.

5 Open the roller clamp on the tubing set as far as it will go.

6 Open the vent valve at the spike.

7 Connect the control unit to the power socket.

Ensure that the operating voltage setting corresponds to the local mains voltage!

The container of infiltration fluid may weigh a maximum of 2 kg. Heavier containers than allowed can cause the

device to tip over.

Do not regulate the amount of infiltration fluid using the roller clamp on the tube set; with the Dispenser DP 30,

this is regulated instead using the control dial and the foot pedal. For this reason, make sure to open the roller

clamp as far as it will go.

Device setup

Place the Dispenser DP 30 and all required accessories and instruments on an even, non-slip surface and make

sure you have good access to all controls.

Do not allow the operating range of the device (including the cable) to be compromised by limiting factors.

The system operation panel and the infiltration liquid bottle must be fully visible at all times.

It must be explicitly ensured that no objects can fall on the pedal.

The power plug at the rear of the device must be accessible at all times.

11

©NOUVAG AG • 31678 • V20221125 • All rights reserved

Dispenser DP 30

Bedienungsanleitung, Dispenser DP 30, REF 31678, V24/21 11

DE

7 Bedienung

Gerät ein-, bzw. ausschalten

Mit dem Hauptschalter «I/O», auf der Rückseite des Geräts, wird das Steuergerät ein- und ausgeschaltet.

Das Ausschalten kann jederzeit erfolgen und ist nicht von einer Ausschaltprozedur abhängig.

Das grüne LED-Lämpchen, oben links auf dem Bedienpanel, leuchtet, wenn der Hauptschalter aktiviert

wurde und das Gerät betriebsbereit ist.

Regulierung des Infiltrationsvorgangs

Drehregler in Verbindung mit ON/OFF-Pedal:

Die gewünschte Förderleistung wird mit dem Drehregler eingestellt. Durch die Betätigung des ON/Off-Pe-

dals startet der Pumpvorgang. Die Förderleistung kann jederzeit per Drehregler verändert werden.

Drehregler in Verbindung mit VARIO-Pedal:

Die maximale Förderleistung kann jederzeit mit dem Drehregler verändert werden, auch während das Pedal

gedrückt wird. Durch die Steuerung über das VARIO-Pedal wird die Förderleistung der Pumpe bis zum ein-

gestellten Maximalwert reguliert.

Schlauchpumpe

Drehregler im Uhrzeigersinn aus der OFF-Position drehen. Pumpe startet, Flüssigkeit tritt aus dem offenen

Schlauchende. Durch Drehen bis zum Maximalwert wird die Zunahme der Förderleistung kontrolliert.

Wird während des Betriebes der Pumpe die Pumpen-Entriegelungstaste betätigt, stoppt die Pumpe.

Funktionskontrolle

Vor jeder Inbetriebnahme des Dispenser DP 30 und dessen Zubehör hat sich der Anwender vom ordnungs-

gemäßen, fehlerfreien Zustand der einzelnen Komponenten zu überzeugen. Dies beinhaltet Sauberkeit, Ste-

rilität, die Einlegerichtung des Schlauchsets und die Funktion der Schlauchpumpe. Nach dem Einschalten

leuchtet die grüne LED-Lampe auf dem Bedienpanel.

Um die Funktionsfähigkeit des Gerätes zu prüfen, drücken sie das Pedal bis zum Anschlag und drehen sie

das Einstellrad langsam über den gesamten Leistungsbereich, bis zum oberen Anschlag. Die maximale Fluss-

rate von 400 ml/min. muss nun erreicht werden.

Bei Problemen prüfen sie ob die Rollenklemme am Schlauchset so weit wie möglich geöffnet ist und ob der

verdickte Rohrabschnitt am Schlauchset korrekt in der Schlauchhalterung liegt.

Mit ON/OFF-Pedal Mit VARIO-Pedal

Instructions for use Dispenser DP 30

7. Operation

Switching the device on and off

Use the power switch “I/O” at the rear of the control unit to switch the control unit on and off. The device may be

switched off at any time irrespective of any procedure for switching off the device.

The green indicator light up left on the operation panel is on, when the main switch is switched on and the device is

ready for operation.

Regulation of the infiltration process

Control dial in conjunction with ON/OFF pedal The desired volumetric displacement is set with the control dial.

The pumping process is started by actuating the ON/OFF pedal. The volumetric displacement can be varied at any

time using the control dial.

Control dial in conjunction with VARIO pedal The maximum volumetric displacement can be varied at any time

using the control dial, even while the pedal is being pressed. Control using the VARIO pedal regulates the volumetric

displacement of the pump up to the set maximum value.

Peristaltic pump

Turn control dial clockwise from the OFF position. Pump starts, liquid emerges from the open tube end. Turning the

dial up to the maximum value controls the increase in volumetric displacement.

The pump stops immediately when the release button of the pump compartment is pressed.

Functional check

Prior to Dispenser DP 30 startup or use of accessory equipment, the user must always ensure that each individual

component is in good working order, free of defects, clean, sterile and operational. The tube set has to correspond

with the correct flow direction and the pump has to function. The green LED is on after the device is switched on.

To check if the device is in working order, press the pedal as far as it will go and slowly turn the control dial on the

device through the entire performance range. The maximum flow rate of 210 ml/min. must be reached at the top end

of the scale at the control dial.

In the event of problems, please check that the roller clamp on the tubing set is open as far as it will go and that the

thickened tube section on the tubing set has been correctly inserted in the tubing bracket.

With ON/OFF pedal With VARIO pedal

12 ©NOUVAG AG • 31678 • V20221125 • All rights reserved

Dispenser DP 30 Instructions for use

8. Cleaning and disinfection

The following point is important with regard to caring for the material:

Perform cleaning and disinfection after every treatment!

Control unit and pedal

Wipe the outside using tested surface disinfectant or 70 percent of isopropyl alcohol. The front plate of the control

unit is sealed accordingly for this purpose and can be wiped clean.

Tube set REF 6022

Sterility cannot be guaranteed by reusing and re-sterilization of tubing sets. The characteristics of the material

change in a manner that can result in failure of the system. This may result in serious infections or even patient

death worst-case.

Single-use tubing sets may not be reused!

Tube sets must be disposed of properly after use.

Don’t use tube set when pack was open or dam-

aged!

Don’t use tube set when expiry date is timed out.

Use only Nouvag tubing sets with REF 6022a/b.

13

©NOUVAG AG • 31678 • V20221125 • All rights reserved

Dispenser DP 30

Bedienungsanleitung, Dispenser DP 30, REF 31678, V24/21 13

DE

9 Wartung

Austausch der Steuergerätesicherung

Defekte Steuergerätesicherungen können vom Anwender selbständig ausgewechselt werden. Sie befinden

sich auf der Rückseite des Gerätes im Sicherungsfach neben dem Hauptschalter:

Gerät ausschalten

Netzstecker ziehen.

Sicherungsfach mit Hilfe eines Schraubendrehers öffnen.

Defekte Sicherung T 1,00 AL 250 V AC auswechseln.

Sicherungshalterung wieder einschieben und Sicherungsfach schließen.

Prüfen der angezeigte Netzspannung auf dem Sicherungsfach.

Netzstecker wieder einstecken.

1. Verschluss Sicherungsfach

2. Sichtfenster für eingestellte Spannung

3. Sicherungsfach

4. Sicherung 1

5. Sicherung 2

Sicherheitstechnische Kontrollen

Die wesentlichen Leistungsmerkmale wurden definiert und mit der Risikoanalyse zum Gerät bewertet. Die

Analyse ist in der Risikomanagement Akte beim Hersteller hinterlegt.

Verschiedene Länder fordern in Verordnungen Sicherheitstechnische Kontrollen (STK) von Medizingeräten.

Die Sicherheitstechnische Kontrolle ist eine für Betreiber von Medizinprodukten vorgeschriebene periodi-

sche Sicherheitsprüfung. Das Ziel dieser Maßnahme ist das rechtzeitige Erkennen von Gerätemängeln und

Risiken für Patienten, Anwender und Dritte.

Die STK für den Dispenser DP 30 ist alle 2 Jahre und nur durch autorisierte Stellen durchzuführen und zu

dokumentieren.

Die Serviceanweisungen, Schaltbilder und Beschreibungen sind auf Anfrage beim Händler erhältlich.

Die NOUVAG AG bietet Kunden die Sicherheitstechnische Kontrolle an. Die Anschriften finden Sie im An-

hang der Bedienungsanleitung unter «Servicestellen». Für weitere Auskünfte kontaktieren Sie bitte unseren

technischen Kundendienst.

Weitere internationale Servicestellen sind auf der Nouvag Webseite aufgelistet:

www.nouvag.com > Service > Servicestellen

Hinweis zur Entsorgung

Bei der Entsorgung von Gerät, Gerätbestandteilen und Zubehör müssen die erlassenen Vorschriften des

Gesetzgebers befolgt werden.

Im Sinne des Umweltschutzes können Altgeräte an den Händler oder den Hersteller zurückgegeben wer-

den.

Kontaminierte Einweg-Schlauchsets müssen speziell entsorgt werden. Bitte beachten Sie die landesüblichen

Entsorgungsvorschriften.

Ausgediente Elektro- und Elektronikgeräte sind Sondermüll und dürfen nicht mit dem Hausmüll entsorgt

werden. Es gelten die ortsüblichen Entsorgungsvorschriften.

12

3

45

Instructions for use Dispenser DP 30

9. Maintenance

Replacing the control unit fuse

Users can replace faulty control unit fuses themselves. These are located at the rear of the device in the fuse slot

beside the power switch:

1 Switch off device.

2 Unplug the power plug.

3 Open the fuse slot using a screwdriver.

4 Replace the faulty fuse T 1.25 AL 250 V AC.

5 Slide the fuse holder back in and close the fuse slot.

6 Check the mains voltage shown on the fuse slot.

7 Plug in the power plug again.

Safety inspections

The essential requirements have been defined and within the risk analysis assessed. The approved results have been

filed in the risk management act with the manufacturer.

The performance of safety inspections on medical devices is required by law in several countries. The safety inspec-

tion is a regular safety check that is compulsory for those operating medical devices. The objective of this measure is

to ensure that device defects and risks to patients, users or third parties are identified in time.

The STI (Safety Technical Inspection) for the Dispenser DP 30 shall be executed every 2 years by authorized experts.

Results shall be documented.

The service manual, wiring diagrams, and descriptions are available upon request from the manufacturer.

Nouvag offers a safety inspection service for its customers. Addresses can be found in the appendix of this operation

manual under “Service centers”. For further information please contact our technical service department.

Information on disposal

When disposing of the device, device parts and accessories, the regulations prescribed by law must be observed. To

ensure environmental protection, old devices can be returned to the dealer or manufacturer.

Contaminated single-use tubing sets are subject to specific disposal requirements. Please observe prevailing na-

tional disposal regulations.

When discarding the device components and accessories, please comply with the issued statutory regulations.

With regard to the preservation of the environment old equipment may be returned to the distributor or manufac-

turer.

1 Fuse slot locking mechanism

2 Display window for voltage setting

3 Fuse slot

4 Fuse 1

5 Fuse 2

14 ©NOUVAG AG • 31678 • V20221125 • All rights reserved

Dispenser DP 30 Instructions for use

10. Malfunctions and troubleshooting

Malfunction Cause Solution Refer to the operating instructions

Device is not func-

tional

(Indicator light is off)

Control unit not switched on Set the power switch “I/O”

to “I”

„Switching the device on and off“ :

Page 11

Power connection not estab-

lished

Connect the control unit to

the mains power supply

„Connection to the power supply“ :

Page 9

Incorrect operating voltage Check the mains voltage „Connection to the power supply“ :

Page 9

Faulty fuse Replace fuse „Replacing the control unit fuse“ :

Page 13

Pump doesn’t work

(Indicator light is on)

Control switch is on too low

position or “Off”

Raise pump performance by

turning control switch up

„Regulation of the infiltration pro-

cess“ : Page 11

Tubing set incorrectly insert-

ed

Insert tubing set correctly

(note the direction)

„Device preparation“ : Page 9

Incorrect operation Check operating instructions „Device preparation“ : Page 9

Pedal was not pressed Press pedal „Regulation of the infiltration pro-

cess“ : Page 11

Roller clamp is closed Open roller clamp all the way „Device preparation“ : Page 9

Pedal doesn’t work

(Indicator light is on)

Pedal is not connected Connect pedal with the sock-

et on rear of device

„Device overview“ : Page 8

„Device preparation“ : Page 9

Incorrect operation Check operating instructions „Device preparation“ : Page 9

„Regulation of the infiltration pro-

cess“ : Page 11

If the problem cannot be solved please contact your supplier or an authorized service center. The addresses are provided in the appendix of this

instructions for use under “Service center”.

11. Spare parts list with order numbers

Accessories

Description REF

ON/OFF pedal, IPX8 1513nou

VARIO pedal, IPX8 1501nou

Stand for irrigation fluid bottle 1770

Tubing set with spike, roller clamp and Luer Lock, sterile, 4 m, single-use 6022a/b

To order additional parts, please contact our customer service department.

12. Service center

Switzerland

Nouvag AG • St. Gallerstrasse 25 • CH – 9403 Goldach

Phone +41 71 846 66 00

Germany

Nouvag GmbH • Schulthaissstrasse 15 • DE – 78462 Konstanz

Phone +49 7531 1290 - 0

A complete list of Nouvag certified service centers are found on the Nouvag website at: www.nouvag.com/service

15

©NOUVAG AG • 31678 • V20221125 • All rights reserved

Instructions for use Dispenser DP 30

Appendix

16 ©NOUVAG AG • 31678 • V20221125 • All rights reserved

Electromagnetic compatibility (EMC)

Remark:

The Product subsequently referred to herein always denotes the Dispenser DP 30.

Changes or modifications to this product not expressly approved by the manufacturer may result in increased emissions or decreased immunity

performance of the product and could cause EMC issues with this or other equipment. This product is designed and tested to comply with

applicable regulations regarding EMC and shall be installed and put into service according to the EMC information stated as follows.

WARNING

Use of portable phones or other radio frequency (RF) emitting equipment, including accessories (antennas e.g.) in distances below

30 cm (12 inches) to the product, may cause unexpected or adverse operation.

WARNING

The product is suitable for use in hospitals other than in the vicinity of active devices of the HF surgical devices or except in HF

screening rooms used for magnetic resonance imaging.

WARNING

The product shall not be used adjacent to, or stacked with, other equipment. If adjacent or stacked use is necessary, the product

shall be tested to verify normal operation in the configuration in which it is being used.

Essential Performance

The essential performance is that the infiltration of tumescent solution in the fat tissue taking into account the infiltration flow rate and pressure is

maintained. The maximum infiltration flow rate deviation is ± 25%, the infiltration flowrate is between 60 and 230ml/min and the maximum pressure

is 2.5bar.

Compliant Cables and Accessories

WARNING

The use of accessories, transducers and cables other than those specified may result in increased emissions or decreased immunity

performance of the product.

The table below lists cables, transducers, and other applicable accessories for which the manufacturer claims EMC compliance.

NOTE: Any supplied accessories that do not affect EMC compliance are not listed.

Description Length max.

Power supply cord REF 22261 / 22262 / 22264 / 22266 3.0m

Foot pedal IPX8 REF 1501nou / 1513nou 2.9m

Guidance and manufacturer’s declaration

–

electroma

g

netic emissions

The Product is intended for use in the electromagnetic environment specified below. The customer or the user of the Product should

assure that it is used in such an environment.

Emissions test Compliance Electromagnetic environment - guidance

RF emissions

CISPR 11

Group 1 The Product uses RF energy only for its internal function.

Therefore, its RF emissions are very low and are not likely to

cause any interference in nearby electronic equipment.

RF emissions

CISPR 11

Class B The Product is suitable for use in all establishments, including

domestic establishments and those directly connected to the

public low-voltage power supply network that supplies buildings

used for domestic purposes.

Harmonic emissions

IEC 61000-3-2

Class A

Voltage fluctuations/flicker emissions

IEC 61000-3-3

complies

Guidance and manufacturer’s declaration

–

electromagnetic immunity

The Product is intended for use in the electromagnetic environment specified below. The customer or the user of the Product should

assure that it is used in such an environment.

Immunity tests IEC 60601

Test level

Compliance level Electromagnetic environment - guidance

Electrostatic discharge

(ESD)

IEC 61000-4-2

+/- 8 kV contact

+/- 2 kV, +/- 4 kV, +/- 8 kV,

+/- 15 kV air

+/- 8 kV contact

+/- 2 kV, +/- 4 kV, +/- 8 kV,

+/- 15 kV air

Floors should be wood, concrete or ceramic

tile. If floors are covered with synthetic

material, the relative humidity should be at

least 30 %.

Electrical fast

transient/burst

IEC 61000-4-4

+/- 2 kV with 100kHz

for power supply lines

+/- 1 kV with 100kHz

for input/output lines

+/- 2 kV with 100kHz

for power supply lines

+/- 1 kV with 100kHz

for input/output lines

Mains power quality should be that of a typical

commercial or hospital environment.

Surge

IEC 61000-4-5

+/- 0.5 kV, +/- 1 kV

differential mode

+/- 0.5 kV, +/- 1 kV, +/- 2 kV

common mode

+/- 0.5 kV, +/- 1 kV

differential mode

+/- 0.5 kV, +/- 1 kV, +/- 2 kV

common mode

Mains power quality should be that of a typical

commercial or hospital environment.

Voltage dips, short

interruptions and voltage

variations on power

supply input lines

IEC 61000-4-11

0 % UT; for 0,5 cycle

with 0, 45, 90, 135, 180, 225,

270, 315 degree

0 % UT; for 1 cycle

0 % UT; for 0,5 cycle

with 0, 45, 90, 135, 180, 225,

270, 315 degree

0 % UT; for 1 cycle

Mains power quality should bet hat of a typical

commercial or hospital environment.

If the user of the Product requires continued

operation during power mains interruptions, it

is recommended that the Product be powered

Dispenser DP 30 Instructions for use

17

©NOUVAG AG • 31678 • V20221125 • All rights reserved

70 % UT; for 25/30 cycles

0 % UT; for 5 sec

70 % UT; for 25/30 cycles

0 % UT; for 5 sec

from an uninterruptible power supply or a

battery.

Power frequency

(50/60Hz) magnetic field

IEC 61000-4-8

30 A/m 30 A/m Power frequency magnetic fields should be at

levels characteristic of a typical location in a

typical commercial or hospital environment.

Note: UT is the a.c. mains voltage prior to application of the test level.

Guidance and manufacturer’s declaration

–

electromagnetic immunity for not life support equipment

The Product is intended for use in the electromagnetic environment specified below. The customer or the user of the Product should

assure that it is used in such an environment.

Immunity tests IEC 60601

Test level

Compliance level Electromagnetic environment - guidance

Portable and mobile RF communications

equipment should be used no closer to any part

of the Product, including cables, than the

recommended separation distance calculated

from the equation applicable to the frequency of

the transmitter.

Recommended separation distance:

Conducted RF

IEC 61000-4-6

3 V rms

0.15 MHz to 80 MHz

6 V rms

inside ISM bands between

150 kHz to 80 MHz

80% AM bei 1 kHz

3 V rms

0.15 MHz to 80 MHz

6 V rms

inside ISM bands between

150 kHz to 80 MHz

80% AM bei 1 kHz

d = 0,35 P

Radiated RF

IEC 61000-4-3

3 V/m

80 MHz to 2.7 GHz

80% AM bei 1 kHz

3 V/m

80 MHz to 2.7 GHz

80% AM bei 1 kHz

d = 0,35 P 80 MHz to 800 MHz

d = 0,7 P 800 MHz to 2,7 GHz

Where P is the maximum output power rating in

the transmitter in watts (W) according to the

transmitter manufacturer and d is the

recommended separation distance in metres

(m).

Field strengths from fixed RF transmitters, as

determined by an electromagnetic site survey a,

should be less than the compliance level in each

frequency range b.

Interference may occur in the vicinity of

equipment marked with the following symbol:

Note 1: At 80 MHz and 800 MHz, the higher frequency range applies.

Note 2: These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from

structures, objects and people.

a Fixed strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile radios,

amateur radio, AM and FM radio broadcast and TV broadcast cannot be predicted theoretically with accuracy. To access the

electromagnetic environment due to fixed RF transmitters, and electromagnetic site survey should be considered. If the

measured field strength in the location in which the Product is used exceeds the applicable RF compliance level above, the

Product should b observed to verify normal operation. If abnormal performance is observed, additional measures may be

necessary, such as reorienting or relocating the Product.

b over the frequency range 150 kHz to 80 MHz, field strengths should be less than 3 V/m.

Instructions for use Dispenser DP 30

18 ©NOUVAG AG • 31678 • V20221125 • All rights reserved

Electromagnetic immunity against high-frequency wireless communication devices

Test frequenc

y

MHz

Frequency

band

MHz

Communication

service

Modulation Maximum

Performance

W

distance

m

Test level

V/m

385 380 to 390 TETRA 400 Pulse modulation

18 Hz 1.8 0.3 27

450 430 to 470 GMRS 460,

FRS 460

FM

± 5 kHz Hub

1 kHz Sinus

2 0.3 28

710

704 to 787 LTE Band 13, 17 Pulse modulation

217 Hz 0.2 0.3 9 745

780

810

800 to 960

GSM 800/900,

TETRA 800,

iDEN 820,

CDMA 850,

LTE Band 5

Pulse modulation

18 Hz 2 0.3 28

870

930

1720

1700 to 1990

GSM 1800,

CDMA 1900,

GSM 1900,

DECT,

LTE Band 1, 3,

4, 25; UMTS

Pulse modulation

217 Hz 2 0.3 28

1845

1970

2450 2400 to 2570

Bluetooth,

WLAN 802.11

b/g/n,

RFID 2450,

LTE Band 7

Pulse modulation

217 Hz 2 0.3 28

5240

5100 to 5800 WLAN 802.11 a/n Pulse modulation

217 Hz 0.2 0.3 9 5500

8785

Recommended separation distances between

portable and mobile RF communications equipment and the not life support equipment

The Product is intended for use in an electromagnetic environment in which radiated RF disturbances are controlled. The customer or the

user of the Product can help prevent electromagnet interference by maintaining a minimum distance between portable and mobile RF

communications equipment (transmitters) and the Product as recommended below, according to the maximum output power of the

communications equipment.

Rated maximum output power

of transmitter

W

Separation distance according to frequency of transmitter

m

150 kHz to 80 MHz

d = 0,35 P

80 MHz to 800 MHz

d = 0,35 P

800 MHz to 2.5 GHz

d = 0,7 P

0,01 0,04 0,04 0,07

0,1 0,11 0,11 0,22

1 0,35 0,35 0,7

10 1,1 1,1 2,2

100 3,5 3,5 7

For transmitters rated at a maximum output power not listed above, the recommended separation distance d in metres (m) can be

estimated using the equation applicable to the frequency of the transmitter, where P is the maximum output power rating of the transmitter

in watts (W) according to the higher frequency range applies.

Note 1: At 80 MHz and 800 MHz, the separation distance fort the higher frequency range applies.

Note 2: These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from

structures, objects and people.

Dispenser DP 30 Instructions for use

19

©NOUVAG AG • 31678 • V20221125 • All rights reserved

Instructions for use Dispenser DP 30

Nouvag AG • St. Gallerstrasse 25 • CH – 9403 Goldach

Phone +41 71 846 66 00

Nouvag GmbH • Schulthaissstrasse 15 • DE – 78462 Konstanz

Phone +49 7531 1290 – 0

Other manuals for Dispenser DP 30

1

Table of contents

Other Nouvag Water Pump manuals

Popular Water Pump manuals by other brands

TECALEMIT

TECALEMIT TECPUMP 900 12 VDC instruction manual

AMT

AMT 315C Specifications information and repair parts manual

Johnson Pump

Johnson Pump AQUA JET WPS 3.4 instruction manual

Circoflo PRO

Circoflo PRO CFM-MXVP0111 installation guide

Neptun

Neptun NPFP-E 15000 Original operating instructions

Xylem

Xylem GOULDS NPO instruction manual

Gardena

Gardena 11000 AS CLEAR Operator's manual

KSB

KSB Amarex KRT Installation & operating manual

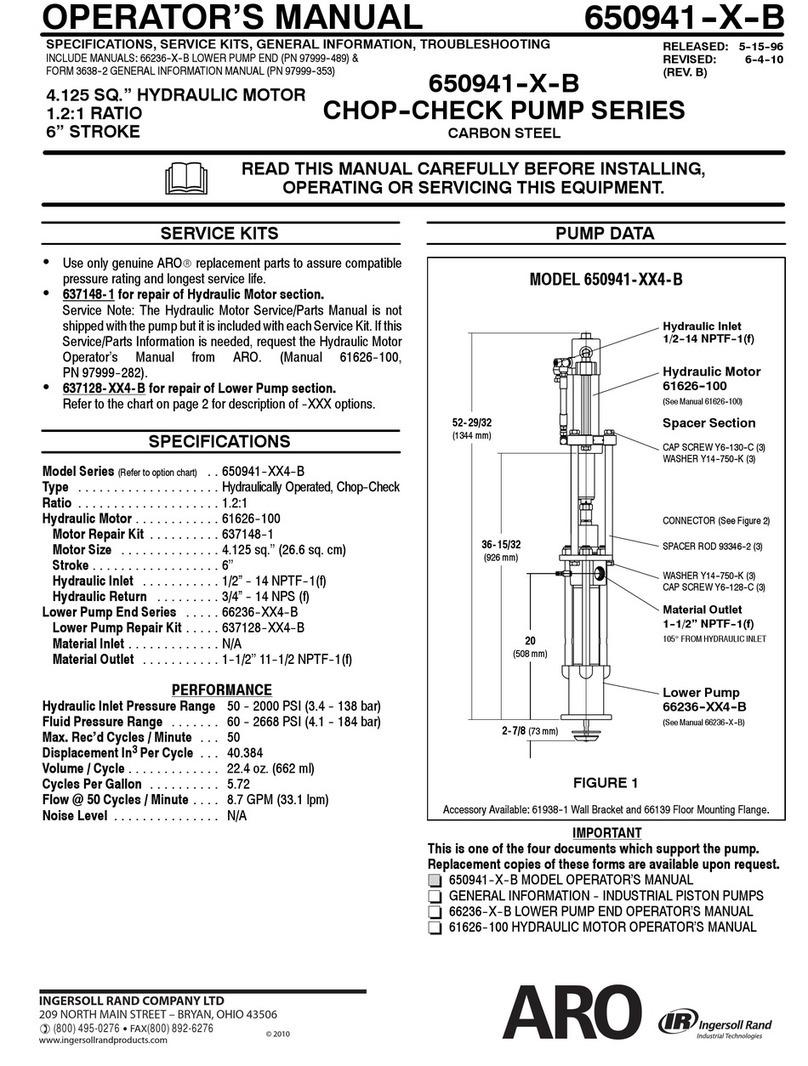

Ingersoll-Rand

Ingersoll-Rand MP PUMPS CHEMFLO 2 Operator's manual

Ingersoll-Rand

Ingersoll-Rand ARO 650941-XX4-B Series Operator's manual

Moro

Moro TURBO PM100 Use and maintenance manual

MasterCraft

MasterCraft 062-3425-4 instruction manual