NOUVOLED VELA 250B User manual

VELA 250B

User Manual

Content

1. Caution and Installing

1.1Declaration......................................................................1

1.2 Maintainance .................................................................1

1.3 Product precautions.........................................................1

1.4 Product description..........................................................1

1.5 DMX connect .................................................................2

1.6 Fixture installing...............................................................2

2. LCD display .............................................................................4

2.1 Menu key.........................................................................4

2.2Menu...............................................................................5

2.2.1 Manual set.................................................................5

2.2.2 Set.............................................................................6

2.2.3 System .....................................................................7

3. Function DMX ...........................................................................8

3.1DMX chart .........................................................................8

4. Common error..........................................................................11

1.1 Notes and Installation Notes and Installation

Thank you for choosing our company's products! This product has good

performance and complete packaging when it leaves the factory. For your safe

and effective use of this product, please read this instruction manual carefully

and completely before you use this product. This manual contains important

information for installation and use. Please install and operate in accordance

with the requirements of the manual. At the same time, please keep this

manual properly for use at any time. Our company does not assume all

responsibility for damage to lamps or other performance due to personal

failure to follow the instructions during installation, use, and maintenance.

This manual is subject to technical changes without notice。

⚫Maintenance

⚫Please disconnect the power before performing maintenance。

⚫The lamp should be kept dry and avoid working in a humid environment。

⚫Intermittent use will effectively extend the life of the lamp。

⚫In order to obtain good ventilation and lighting effects, it is necessary to

clean the fan, fan net and lens frequently。

⚫Do not wipe the lamp housing with organic solvents such as alcohol to

avoid damage。

⚫Product precautions

⚫This lamp is for professional use only.

⚫Before operation, make sure that the power supply voltage matches the

power supply voltage required by the equipment.

⚫Do not place the product in a place that is easy to loose or shake.

⚫Stop using the lamp in time if the lamp is abnormal during use.

⚫In order to ensure the service life of the product, this product must not be

placed in a humid or leaking place, and it must not be used in an

environment where the temperature exceeds 60 degrees.

⚫When the bulb is in use, the power supply voltage should not change more

than ±10%. Too high voltage will shorten the life of the bulb, and too low

voltage will affect the light color of the bulb.

⚫After the power is cut off, it takes 20 minutes before the lamp is fully cooled

before being powered on again.

⚫The rotating parts of the lamp and the pasted accessories must be

checked regularly. If there is any looseness, the shaking should be

reinforced in time to prevent accidents.

⚫To ensure the normal use of this product, please read this manual

carefully。

⚫1.2 Product introduction

⚫Light source power: 250W;

⚫Voltage: AC 200V~240V/50~60Hz;

⚫Color wheel: each color wheel is composed of 13 color chips + white

light;

⚫Gobo plate: 14 pattern effects;

⚫540° pan, 270° tilt。

⚫Overheat protection;

⚫Control mode: DMX512/master-slave/auto;

⚫IP20 protection level

1.2 Signal line connection

The lamp is equipped with standard DMX input and output 3-pin or 5-pin XLR

sockets. Please use shielded twisted pair signal wire specially designed for

DMX 512; the signal wire is generally connected at a distance of 150 meters,

and DMX512 signal amplifier must be added for long distance signal

transmission.

Use a shielded twisted pair signal cable to connect from the DMX output port of

the controller to the DMX input port of the first device, and from the DMX

output port of the first device to the DMX input port of the second device, and

so on, Until all the lamps are connected, install a terminal plug on the output

3-pin jack of the last connected lamp of each connection. (Weld a 4/1W, 120Ω

resistor between the 2 and 3 pins of the 3-pin XLR plug).

Important note: the wires cannot touch each other or the metal shell。

➢Figure 1 Diagram of DMX signal line connection

Calculation method of lamp start address code:

The starting address code of the current fixture is equal to (the starting address

code of the previous fixture) + (the number of channels of the fixture)

1: The starting address code value of the first lamp is A001.

2: The number of basic channels of the controller should be greater than or

equal to the total number of channels used by the lamp.

3: Note: When using any controller, each lamp must have its own start address

code. If the start address code of the first lamp is set to A001, the number of

channels of the lamp is 16CH; then The start address code of the two lamps is

set to A017; the start address code of the third lamp is set to A033; and so on,

(this setting method also needs to be determined according to different

consoles)

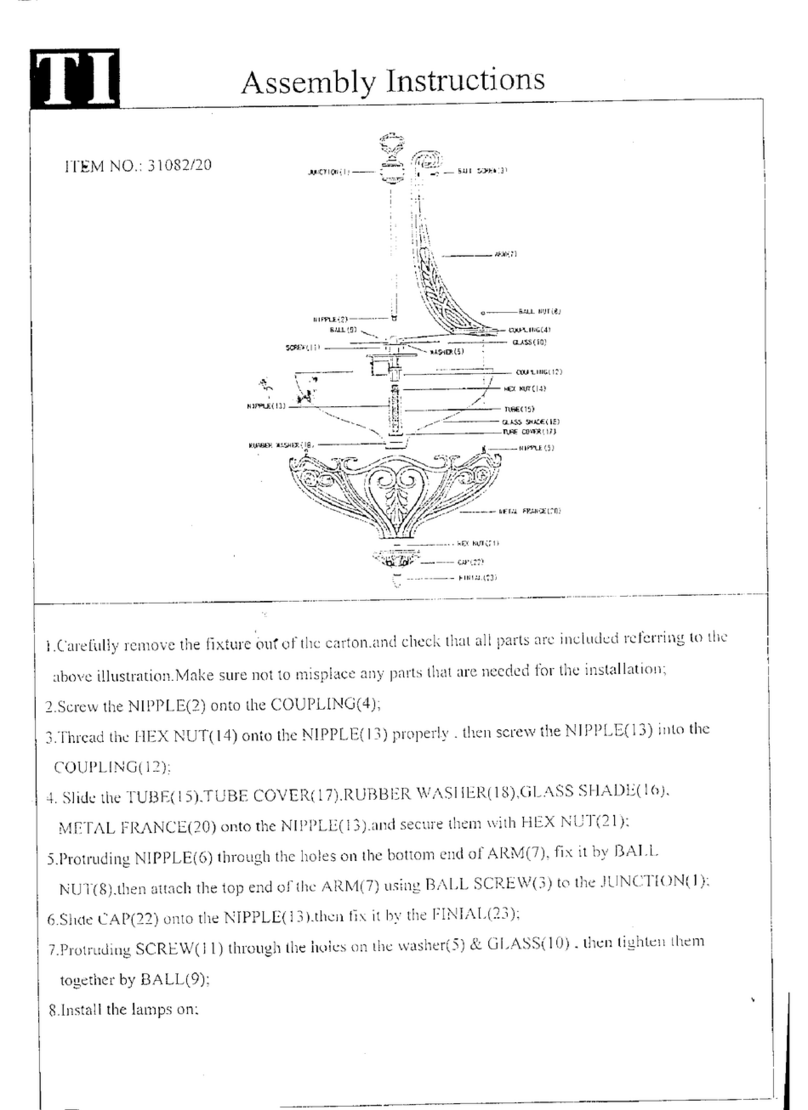

1.2 Fixture Lamp installation

The lamps can be placed horizontally, hung diagonally and upside down.

Pay attention to the installation method when hanging diagonally and upside

down.

As shown in Figure 2, before locating the luminaire, ensure the stability of

the installation site. When reversing the hanging installation, you must ensure

that the luminaire does not fall down on the support frame. You need to use a

safety rope to pass through the support frame and the luminaire lift. Hand

assist hanging to ensure safety and prevent the lamp from falling and sliding.

When the lamps are installed and debugged, pedestrians are prohibited

from passing underneath. Regularly check whether the safety ropes are worn

and the hook screws are loose.

Our company will not bear any responsibility for all the consequences

caused by the falling of the lamp due to the unstable installation of the hanging.

Figure 2 Schematic diagram of upside down lamps

1.control panel

2.1 key instruction

Figure 3 Schematic diagram of panel keys

Take "Modify DMX Address Code" as an example to describe the

use of buttons:

1. If the current interface is not the main interface, press the "left"

key (one or more times) to return to the main interface

2. In the main interface, press "Up" or "Down" to select the

"Settings" button

3. Press the "OK" button to enter the "Settings" interface

4. In the "Settings" interface, press the "Up" or "Down" keys to

select "DMX Address"

5. Press "OK" to enter the editing state

6. Press "Up" or "Down" to modify the DMX address code

7. Press "OK" to exit the editing state

2.2.1 Manual

This interface is used to control the current lamp and automatically enter the host

state (do not receive DMX signals, send DMX signals to the bus to the slave).

The manual menu will display 16 channels or 20 channels according to the standard

16-channel or extended 20-channel mode set in the setting menu.

DMX channel

Description

1CH. Gobo wheel

0~255

Press the "OK" key to enter the editing state.

At this time, the hundreds place is selected,

press the "up" and "down" keys to change the

channel value. Press the "OK" key again to

select the ten digits for editing. Press the "OK"

key again to select the ones digit to edit.

Press again to exit the editing state

……

0~255

14CH.frost

0~255

16CH.reset

Press the "OK" button to see the confirmation

dialog box, press the "OK" button again to

enter the reset interface, and all motors are

reset

16CH.lamp control

on

Off

17CH.keep

0~255

Display when the channel mode is

"Extended CH20"

18CH. Color wheel speed

0~255

Display when the channel mode is

"Extended CH20"

19CH. dimmer-prism-frost

speed

0~255

Display when the channel mode is

"Extended CH20"

20CH. Gobo wheel speed

0~255

Display when the channel mode is

"Extended CH20"

Menu

Description

Mode

DMX

Slave state: receiving DMX signal from the console or

host

Auto run1

Master status: self-propelled and send DMX signal to

slave

Auto run 2

random

Voice

control

DMX address

1~512

Press the "OK" key to enter the editing state. At this time,

the hundreds digit is selected, press the "up" and "down"

keys to change the address code. Press the "OK" key again

to select the ten digits for editing. Press the "OK" key again

to select the ones digit to edit. Press again to exit the

editing state

Channel mode

16CH

Standard 16-channel mode, the 17th to 20th channels

are invalid

20CH

Extended 20 channel mode, the 17th to 20th channels

control the speed (see channel table)

X Reverse

off

on

Y Reverse

Off

On

XY exchange

Off

On

Exchange the channels of XY axis (including fine

adjustment)

XY Encoder

On

Use encoder (optocoupler) to judge out-of-step and

automatically correct position

Off

Correct position without using encoder (optocoupler)

DMX

Keep

Continue to run as it was

Clear 0

Motor returns to position and stops running

screen protector

On

Turn off the backlight after 30 seconds of idle

Off

Backlight always bright

Turn on the lamp

Off

Reset directly after power-on, without light bulb (you

need to use the menu or console to manually light the

bulb)

On

The bulb will light up automatically after power on, and it

will be reset only after the bulb lights up successfully

The color wheel

changes linearly

On

The color wheel changes linearly

Off

Non-linear change of color wheel, half color change

Restore default

settings

Press the "OK" button to see the confirmation dialog box,

press the "OK" button again to restore the default

settings

2.2.3 system

description

DIS

Display board software version

MT

Motor board software version

Reset

calibration

X axis calibration

After entering the sub-interface, you can

adjust the reset position of the X-axis, Y-axis

and other motors to compensate for the error

in the hardware installation. The adjustment

range is -128~+127, and +0 means no

adjustment.

Y axis calibration

Color calibration

Pattern calibration

Focus calibration

Dimming calibration

Prism 1 calibration

Prism 2 calibration

Atomization

calibration

Sensor

monitoring

X-axis Hall

0 when magnetism is detected, 1 otherwise

Y-axis Hall

0 when magnetism is detected, 1 otherwise

Color wheel hall

0 when magnetism is detected, 1 otherwise

Gobo Hall

0 when magnetism is detected, 1 otherwise

Focusing Hall

0 when magnetism is detected, 1 otherwise

Prism 1 Hall

0 when magnetism is detected, 1 otherwise

Prism 2 Hall

0 when magnetism is detected, 1 otherwise

X axis encoder disk

status

2 digits, each corresponding to a photoelectric

switch in the encoding disk

Y axis encoder disk

status

2 digits, each corresponding to a photoelectric

switch in the encoding disk

X axis encoder disc

step value

When walking in the positive direction, the step

value should increase, and when walking in the

reverse direction, the step value should decrease.

Every time you go to the same point, the value is

the same as normal

Y axis encoder disc

step value

When walking in the positive direction, the step

value should increase, and when walking in the

reverse direction, the step value should decrease.

Every time you go to the same point, the value is

the same as normal

System error

If the red ERR indicator is on, it means that the

lamp is running wrong, and you can enter the

sub-interface to view the details. After viewing,

you can press the "Clear" button to clear the error

record

DMX

monitor

Real-time monitoring of console signals

Mirror info

Description

MT board

connection

failed

The motor board does not respond. There is a problem with the

serial communication line connecting the display board and the

motor board, or there is a problem with the motor board.

X axis reset

failed

X-axis photoelectric switch, or X-axis motor or motor board has a

problem

Y axis reset

failed

Y-axis photoelectric switch, or Y-axis motor or motor board has a

problem

X axis Hall

error

X-axis Hall, or motor board problem

Y axis Hall

error

Y-axis Hall, or motor board problem

Color wheel

reset failed

The color wheel Hall, or the color wheel motor has a problem

Gobo reset

failed

Gobo Hall, or gobo motor has a problem

Focus reset

failed

There is a problem with the focus hall or the focus motor

Lamp control

failed

Failure to turn on or off the bulb, there is a problem with the lighter

or bulb

1. Function

3.1 DMX channel chart

ch

mode

16ch

20ch

1

Color wheel

Color wheel

2

Cut light/strobe

Cut light/strobe

3

Dimming

Dimming

4

Pattern plate

Pattern plate

5

Prism 1

Prism 1

6

Prism rotation 1

Prism rotation 1

7

Prism 2

Prism 2

8

Focus

Focus

9

X

X

10

X fine-tuning

X fine-tuning

11

Y

Y

12

Y fine-tuning

Y fine-tuning

13

XY speed

XY speed

14

Frost

Frost

15

Atomization & Colorful Mirror

Atomization & Colorful Mirror

16

Bulb control & reset

Bulb control & reset

17

Color wheel

no

18

Color wheel speed

19

Dimming-Prism-Atomization Speed

20

Gobo speed

Channel data:

CH

Function

Data

Effect

1

Color wheel

000-004

005 -009

010 - 014

015 - 019

020 - 024

025 - 029

030 - 034

035 - 039

040 - 044

045 - 049

050 - 054

055 - 059

060 - 064

065 - 069

070 - 074

075 - 079

080 - 084

085 - 089

090 - 094

095 - 099

100 -104

105 -109

110 -114

115 -119

120 -124

125 -129

130 -134

135 -139

140 -199

200 - 255

White light

White light + color 1

Color 1

Color 1+color 2

Color 2

Color 2+color 3

Color 3

Color 3+color 4

Color 4

Color 4+color 5

Color 5+color 6

Color 6

Color 6+color 7

Color 7

Color 7+color 8

Color 8

Color 8+color 9

Color 9

Color 9+color 10

Color 10

Color 10+color 11

Color 11

Color 11+color 12

Color 12

Color 12+color 13

Color 13

Color 13+white light

Positive flow (from fast to slow)

Reverse flow (from slow to fast)

2

Strobe

000-003

004-103

104-107

108-207

208-212

Shutter closed

Stroboscopic from slow to fast

Shutter open → (controlled by dimming channel)

Pulse strobe from slow to fast

Shutter open → (controlled by dimming channel)

213-251

252-255

Random strobe from slow to fast

Shutter open → (controlled by dimming channel)

3

Dimmer

000-255

4

Gobo wheel

000 - 004

005 - 009

010 - 014

015 - 019

020 - 024

025 - 029

030 - 034

035 - 039

040 - 044

045 - 049

050 - 054

055 - 059

060 - 064

065 - 069

070 - 074

075 - 079

080 - 084

085 - 089

090 - 094

095 - 099

100 - 104

105 - 109

110 - 114

115 - 119

120 - 124

125 - 129

130 - 134

135 - 139

140 - 200

201 - 255

Solid figure 1

Solid picture 2

Solid figure 3

Solid figure 4

Solid Figure 5

Solid figure 6

Solid figure 7

Solid figure 8

Solid figure 9

Solid figure 10

Solid figure 11

Solid figure 12

Solid figure 13

Solid figure 14

Fixed image 1 (from slow to fast)

Fixed image 2 (from slow to fast)

Fixed image 3(Slow to fast)

Fixed image 4 (from slow to fast)

Fixed image 5 (from slow to fast)

Fixed image 6 (from slow to fast)

Fixed image 7 (from slow to fast)

Fixed image 8 (from slow to fast)

Fixed image 9 (from slow to fast)

Fixed image10 (from slow to fast)

image11 (from slow to fast)

Fixed image 12 (from slow to fast)

Fixed image 13 (from slow to fast)

Fixed image 14 (from slow to fast)

Reverse flow (from fast to slow)

Positive flow (from slow to fast)

5

Prism 1

000-127

128-255

Prism 1 pops up

Prism 1 cut in

6

Prism

rotation

000-127

128-190

191-192

193-255

Prism angle adjustment

Reverse rotation (from fast to slow)

stop

Forward rotation (from slow to fast)

7

Prism 2

000-127

128-255

Prism 2 pops up

Prism 2 cut in

8

Prism 2

rotation

000-127

128-190

191-192

Prism angle adjustment

Reverse rotation (from fast to slow)

stop

193-255

Forward rotation (from slow to fast)

9

focusing

000-255

Pattern definition from far to near

10

X axis

000-255

Horizontal 540 degree scan

11

X-axis fine

adjustment

000-255

Level 1.2 degree fine adjustment

12

Y axis

000-255

Vertical 270 degree scan

13

Y-axis fine

adjustment

000-255

Vertical 1.2 degree fine adjustment

14

XY speed

000-255

Speed from fast to slow

15

Atomization &

Colorful Mirror

000-127

128-191

192-255

no

Colorful mirror cut in

Atomized slice cut in

16

Bulb control

000-099

100-105

200-205

250-255

Invalid area

Turn off the bulb

Light up the bulb

All motors reset

17

Keep

000-255

Speed from fast to slow

18

Color speed

19

Dimming-Pri

sm-Atomizati

on Speed

20

Gobo wheel

speed

2. Common faults

1. For some common faults, corresponding solutions are

proposed. Any problems that cannot be solved should be handled

by professionals. Before servicing the lamp, please disconnect the

power supply.

2. Light bulb does not light up

⚫Check whether the voltage matching the lamp is installed;

⚫Check whether the connection of the power supply of the lamp

or the control switch is bad;

⚫Check whether the power supply is insufficient;

⚫Check if the DMX512 controller has sent instructions。

3.After the lamp is reset normally, it does not accept the control

of the console

⚫Check whether the numerical start address and function options

of the lamp are correct;

⚫Check whether the connection of the communication control line

is correct, the communication line is too long or has been

interrupted;

⚫Check whether the control equipment is invalid, and check

whether the serially connected signal amplifier is invalid;

⚫Check whether the communication line is too long or other

equipment interferes with each other;

⚫Optimize wiring, shorten the length of control signal lines, and

separate high-voltage and low-voltage lines;

⚫Add signal amplifier;

⚫The signal line adopts high-quality shielded twisted pair;

⚫Connect a signal terminal resistor (120 ohm) at the end of the

lamp。

3. fixture cannot be started

⚫Check whether the power supply parameters are consistent with

the lamps;

⚫Check that the lamp has poor contact due to extrusion

deformation, internal parts vibration, moisture and other

reasons during long-distance transportation

⚫Or fall off.

⚫Please check whether the internal wire product connector of the

lamp is off or loose.

⚫Check whether the electronic components of the lamp (such as

electronic transformers, PCB boards, motor control boards, etc.)

are loose, short-circuited and burned out。

4.When working, the X-axis or Y-axis of the lamp does not work

properly

⚫Check one by one according to the previous step;

⚫Check whether the transmission belt corresponding to the X and

Y axis directions in the lamp is off or broken;

⚫Check whether the data feedback receiver (optocoupler)

corresponding to the X and Y directions in the lamp is damaged;

⚫Reboot and reset once

Popular Light Fixture manuals by other brands

Good Earth Lighting

Good Earth Lighting UC1045-WH1-18T81-G manual

Lightolier

Lightolier LSW Series specification

Westinghouse

Westinghouse Outdoor Lighting Fixture owner's manual

Triarch

Triarch Indoor Lighting 29585-GOLD Assembly instructions

GTV

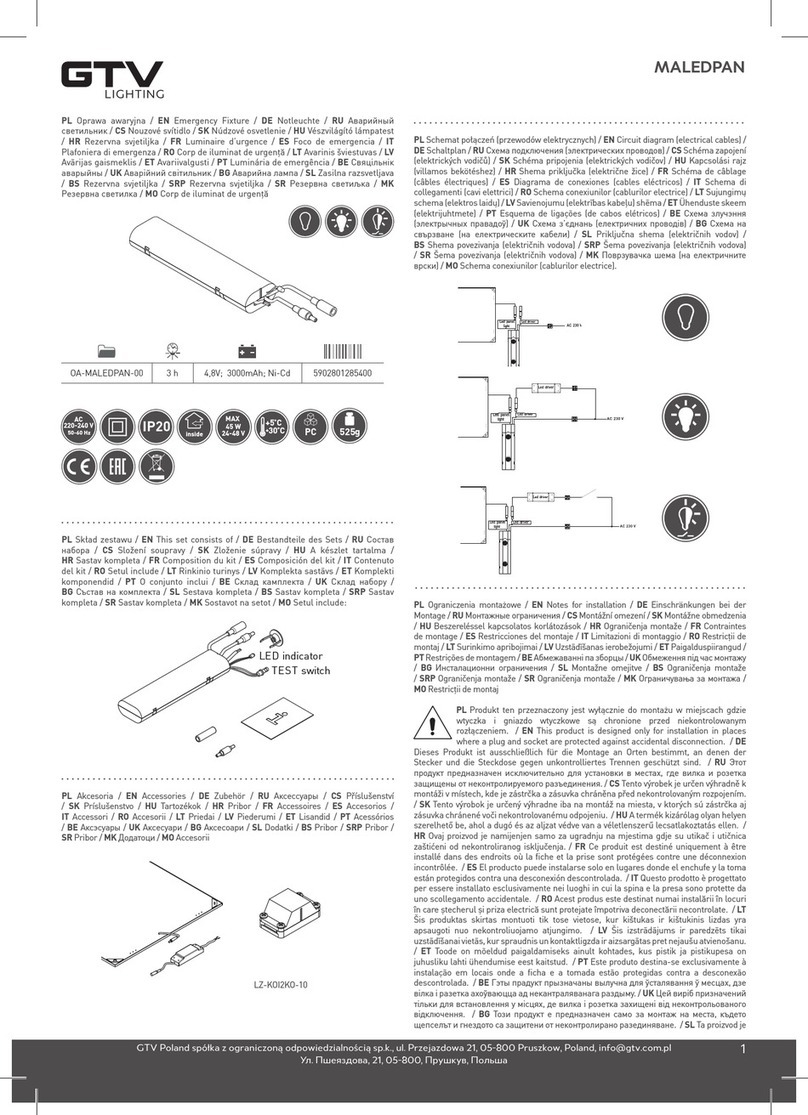

GTV OA-MALEDPAN-00 manual

Kelvix

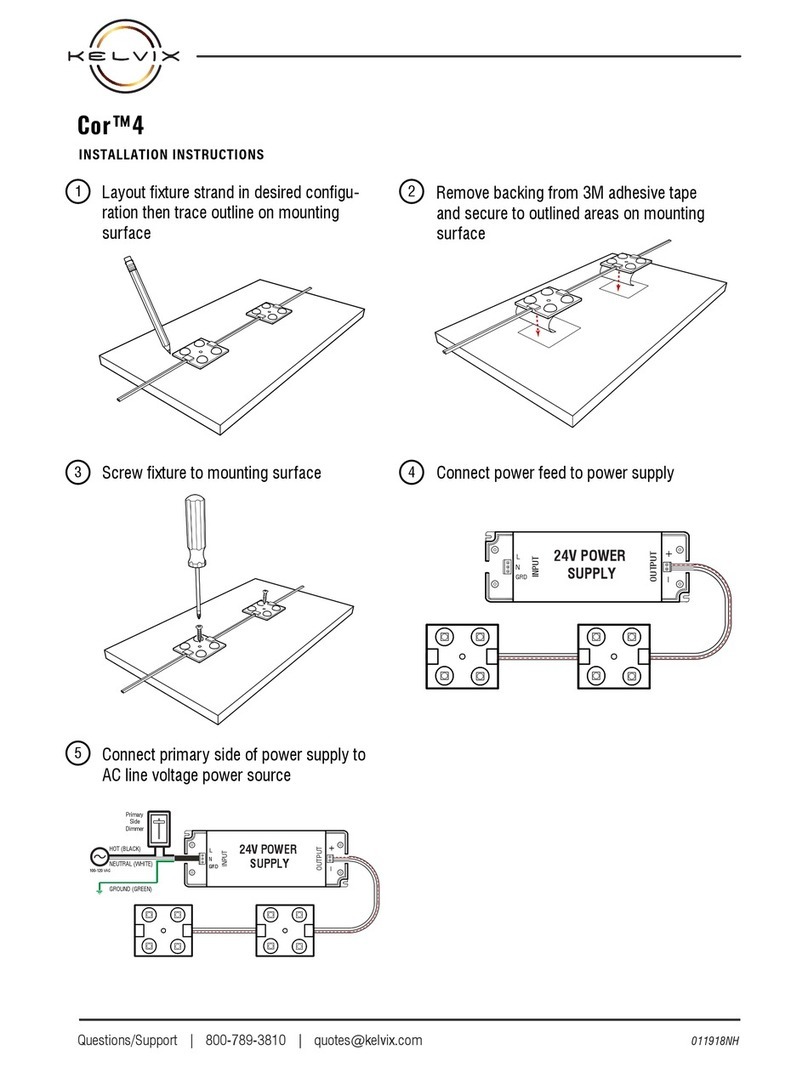

Kelvix Cor 4 installation instructions