Nova Biomatique Intelligent Growing Systems iGS-110 User manual

2

Welcome to the world of smart climate control. We are pleased you have cho-

sen the intelligent Growing Systems iGS-110 product to benefit from the

added yield and quality climate controlled environments can give you ! Apart

from its reliability and precision, you will benefit from incorporated smart fea-

tures that will work with you to optimize your climate control.

The first part of this manual aims at giving you a quick start and a global

overview of all basic functions and configuration options. The second part will

give you a more detailed explanation on the control loops, configuration

options and smart features that the iGS-110 works with.

We are always interested in any comments or suggestions you might have.

TABLE OF CONTENTS

Part-1Setting up the controller 3

Contents and description of the iGS-110 Temp/RH smart controller 3

Tips on proper installation 4

Controller Outputs 5

Output 1: Temperature control 5

Output 2: Humidity control 5

Output 1: Mixed control 6

Setting operating modes for output 1and 26

Selecting the temperature units 7

Adjusting Day and Night Setpoint values 7

Display functions 7

Displaying the Dynamic Differential 8

Part-2More on the iGS-110 Temp/RH smart controller 8

Temperature control sequence 8

Humidity control sequence 8

Mixed Temperature and Humidity Control Sequence 9

Dynamic Differential 9

Controller Hints 10

Error Messages 11

Maintenance and warnings 11

iGS-110 Specifications 11

iGS-50 Specifications 11

Safety notice 12

Product warranty 12

Product repairs 12

iGS-110 Operating Modes 13

Temperature Control Modes 13

Relative Humidity Control Modes 14

Tips on proper installation

The iGS-110 temperature/humidity control box should be placed as close as

possible to the plant canopy where light can be sensed by the photosensor.

Taking care not to expose the controller too close to the air evacuation

points, heating/cooling and humidity management equipment. The control

box is equipped with an internal fan that speeds up sampling the air. Do not

expose these vent holes to potential sources of moisture or dirt. A lint filter is

held by Velcro pieces under the controller. The filter should never be removed

indefinitely.

Take care in not exposing the photosensor to insufficient light during the day

and light during the desired night cycle.

When fixing the control (iGS-110) and output (iGS-50) box, take care in not

over-tightening the screws in the flap holes. The enclosure is made out of

solid ABS plastic but a strong compression impact with a big screw can crack

the enclosure. Make sure that the

wall upon which the control and

output boxes will be fixed is flat.

Take care in not bending the

enclosures.

The iGS-50 control Box can be

fixed anywhere around the control

box without kinking or binding the

6 feet connection cable.

Once both enclosures are properly

installed, plug the 120 Volts power

cords into a 15 A 120 Volts electri-

cal outlet. Then connect the cable

supplied with the controller into

the RJ-45 jack situated under each

enclosure (control and output

box). The controller will turn-on

and warm-up.

Disconnecting the cable from

either side will interrupt the con-

troller s operation. Once recon-

nected the controller will reboot.

All operating modes and values

entered before the interruption

will be retrieved automatically

from memory.

Also refer to the safety notice on

page 12.

Now that we have done the Plugging , let s get into the Growing .

4

PART-1SETTING UP THE CONTROLLER

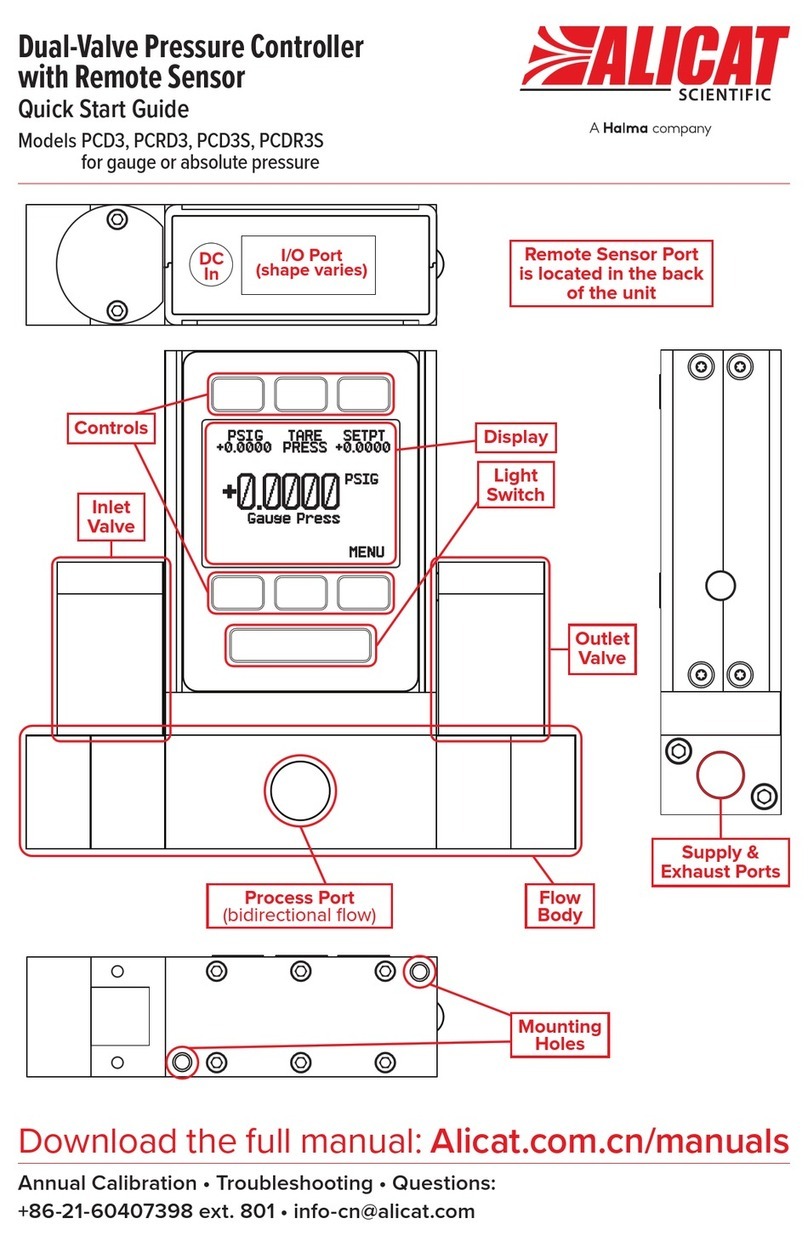

Contents and description of the iGS-110 Temp/RH controller

The iGS-110 Temp/RH smart controller is composed of the following items :

The product is completed by this user manual and a complimentary intelli-

gent Growing Systems user sticker.

Four Digit numeric display

Modify Key : momentarily depres-

sing this key will adjust the display

to show the value indicated by the

MODIFY light. Repeatedly hits on

this key will switch the modify

light from the top position to the

bottom and then back-up.

Dust filter and air input

Output box connector

Up and Down keys :

use these keys to

scroll available val-

ues or operating

modes.

Internal fan air output

Output #1: Temperature control.

Both outputs will turn on auto-

matically according to operating

mode 1-xx.

Output #2: Humidity control.

Both outputs will turn on auto-

matically according to operating

mode 2-xx.

6feet cable to connect with the

iGS-110 Temp/RH Controller

6feet 125Vac 15A power cord

Photosensor

3

The iGS-110 control

The iGS-50 control

Modify light indicators : The red

lights indicate which value is

being displayed according to the

selected sensor. When none of

the Modify light indicators are on,

the sensor s real value is being

displayed.

Select sensor key : Momentarily

depressing this key will change

the value displayed between

Humidity and Temperature.

Select Sensor light indicators :

The red lights indicate which sen-

sor the display is about. To

change the display use the

SELECT SENSOR Key.

Output 1: mixed control

Output 1can also perform a mixed type of control that can be used to cool

and dehumidify your grow room. For more details, refer to section Combined

Temperature and Humidity Control Sequence on page 9.

Setting operating modes for output 1and 2

Once you have chosen the operating mode associated with the role you want

each output to perform you have to enter it into the controller.

Temperature control operating mode :

1- Depress repeatedly if necessary the MODIFY

key until operating mode light turns ON.

2- Depress repeatedly if necessary the SELECT

SENSOR key until the Temp C or Temp F indi-

cator light turns ON. The display will show the

configuration value 1-04.

3- To change the value of the temperature oper-

ating mode, simply use the UP and DOWN keys

until the desired code is displayed.

Temperature control operating mode :

1- Depress repeatedly if necessary the MODIFY

key until operating mode light turns ON.

2- Depress repeatedly if necessary SELECT SEN-

SOR key until the %RH indicator light turns on.

3- The display will show the configuration value

2-04.

4- To change the value of the temperature con-

trol configuration code, simply use the UP and

DOWN keys until the desired code is displayed.

6

Controller outputs

It is now important to configure the controller s two(2) independent outputs

according to the grower s objectives. Output 1(temperature control) can per-

form heating or cooling during the day, the night or day and night. Output 2

(humidity control) can humidify or dehumidify also during the day, the night

or day and night. Both outputs also offer timer associated functions.

Output 1: Temperature output control configuration.

The output labeled as number 1performs the functions associated with the

temperature control. Usually, if output 1is configured to heat your grow

room, you will plug a heater into the outlet 1. On the other hand, if output 1

is configured to cool your room, you will plug a cooling unit into it.

The temperature output can also be configured to be independent or depen-

dent of the humidity output. When independent, output 1will control the

heater-cooler without considering the actual humidity output status. When

dependent, the temperature output will control the heater-cooler only when

the humidity output is OFF ; when an additional delay is selected (see the

table below), the temperature output will be enable to turn ON only 5or 10

minutes after the humidity output just turned OFF.

Output 2: Humidity output control configuration.

The output labeled as number 2performs control over the humidity mana-

gement equipment that can be used when controlling relative humidity levels

in your grow room.

As for the temperature output, the humidity output can also be configured to

be independent or dependent of the temperature output. When independent,

output 2will control the humidity management equipment without consider-

ing the actual heater-cooler status. When dependent, the humidity sensor will

control its output only when the temperature output is OFF ; once again, when

an additional delay is selected (see the table below), the humidity output will

be enable to turn ON only 5or 10 minutes after the temperature output just

turned OFF.

5

Type of control Output 1independent of Output 2

Cooling Day only 1-61

and Night only 1-62

Dehumidifying Day and Night 1-63

Operating mode 1-____

Operating mode 2-____

* Factory default

Type of

control

Additional OFF delay >0min. 5min. 10 min.

Output 2(RH) turns OFF

while Temp output is ON

Output 2(RH) is indepen-

dent of Temp control

Humidify

Dehumidify

Day only

Night only

Day and night

Day only

Night only

Day and night

2-04

2-14

2-24

2-34

2-44

2-54*

2-01 2-02 2-03

2-13

2-23

2-33

2-43

2-53

2-12

2-22

2-32

2-42

2-52

2-11

2-21

2-31

2-41

2-51

Operating mode 1-____

* Factory default

Type of

control

Heating

Cooling

1-03

1-13

1-23

1-33

1-43

1-53

Additional OFF delay >0min. 5min. 10 min.

Output 1(Temp) turns OFF while

RH output is ON

Output 1(Temp) is independent

of RH control

Day only

Night only

Day and night

Day only

Night only

Day and night

1-04

1-14

1-24

1-34

1-44

1-54*

1-01 1-02

1-12

1-22

1-32

1-42

1-52

1-11

1-21

1-31

1-41

1-51

Displaying the Dynamic Differential

The Dynamic Differential is the window of operation that the controller will

have chosen to optimize setpoint fidelity without provoking annoying repeti-

tive switching or setpoint over and undershoots. The value takes approxi-

mately a full day of normal operation of your grow room to stabilize. The

smaller your Dynamic Differential is, the better the overall grow room equip-

ment is tuned. The Dynamic Differential will vary automatically to change

upon room sizes, heater-cooler power and location, ventilation apparatus,

control sequence and room insulation.

1- In order to display the current Dynamic

Differential for each controlled output

(Temperature and Relative humidity), depress

repeatedly if necessary the MODIFY key until the

Differential light turns ON.

The controller will display the Temp Differential if any Temp sensor is select-

ed and the Relative humidity differential if the Humidity sensor is chosen (use

SENSOR SELECT key).

PART-2MORE ON THE iGS-110

Temperature Control sequence

When the controller is configured heat your grow room, it will activate both

slots of output 1(Temp control) when the sensor detects levels under the

user defined levels minus the Dynamic Differential. The Dynamic Differential

is subtracted to the setpoint to determine at what level the heating equip-

ment has to stop to attain the actual valid setpoint without over or under-

shooting (warm air might move slowly in your grow room).

When on the other hand the controller is configured to cool down your grow

room, it will activate both slots of output 1(Temp control) when the sensor

detects levels over the user defined setpoint plus the Dynamic Differential. The

Dynamic Differential is added to the actual valid setpoint to determine when to

stop the cooling equipment without under or overshooting.

Humidity control sequence

The humidity control loop uses the same algorithm has the Temp control loop.

If configured to dehumidify, the controller will activate output 2whenever the

relative temperature rises over the user setpoint plus the Dynamic differential

value. If configured to humidify, the controller will activate output 2whenever

the relative temperature falls below the user setpoint minus the Temp

Dynamic Differential.

Keep in mind that if a special timer delay or priority mode was selected (see

output 1and 2operating modes) the outputs will respond according to the

operating mode (extra OFF timer delay, Temp or RH output priority).

8

When you chose the controller to control RH or Temp levels day and night the

controller will use the setpoint value during the day and the night setpoint

value during the night even when in day and night modes.

Selecting the temperature units

The iGS-110 is able to display the current temperature, setpoint and logged

data values either in Celsius ( C) or Fahrenheit ( F). The user selected units

will be maintained even if the controller is turned OFF and ON again, as well

as all other user settings.

The procedure below will allow the user to select his preferred temperature

units (default is C). Once selected, the actual temperature will still be dis-

played either in C or F at all times, as selected by the SELECT SENSOR key ;

however, all MODIFY functions will be available only when the user preferred

unit light (Temp C or Temp F) is ON, as chosen by the SELECT SENSOR

key.To change the temperature units :

To set the iGS-110 to Celsius, depress the SELECT SENSOR key until the TEMP C

light is ON, and make sure that all MODIFY lights are OFF. Then keep the MODI-

FY key depressed for 3seconds until you see [Cels] on the display. You can then

release the key and the iGS-110 will resume operation displaying all tempera-

ture values in Celsius.

To set the iGS-110 to Fahrenheit, depress the SELECT SENSOR key until the

TEMP F light is ON, and make sure that all MODIFY lights are OFF. Then keep

the MODIFY key depressed for 3seconds until you see [Fahr] on the display.

You can then release the key and the iGS-110 will resume operation display-

ing all temperature values in Fahrenheit.

Adjusting day and night setpoint values

To set your target Temp and RH levels for the daytime :

1- Depress repeatedly if necessary the MODIFY

key until the SETPOINT light comes on. The SET-

POINT value will be displayed according to which

sensor is selected (use the SENSOR SELECT key).

2- To change that value, simply use the UP and

DOWN keys.

Holding the UP or DOWN button for more than 4 seconds will increase the

speed at which the value will be modified.

To set your target Temp and RH levels for the night :

1- Depress repeatedly if necessary the MODIFY

key until the NIGHT SETPOINT light indicator

turns on. The night setpoint value will be dis-

played according to which sensor is selected (use

the SENSOR SELECT key).

2- Use the UP and DOWN keys to change the cur-

rent NIGHT SETPOINT value.

Display functions

The controller will flash the temperature (output 1) or relative humidity (out-

put 2) readings on the display when their respective output is activated.

7

Setpoints adjustments for temperature control is adjusted through 0.5 C/1.0 F

increments. Going over 50 C/ 122 F will rollover the display to - 20 C/-4 F.

10

Controller hints

The controller can display hints that help the grower in assessing the effi-

ciency of his climate control set-up.

1- To view the Hint codes depress, repeatedly if

necessary, the MODIFY key until the DIFFERENTIAL

light turns ON.

2- Choose which sensor hint codes you desire by

depressing the SENSOR SELECT key (Temp or RH).

3- Use the UP and DOWN keys to toggles between

hint codes.

Note : The hint codes will only be available after 4full control cycles, (watch

for the blinking rightmost dot on the display).

Write them down and check in the next table. More information to properly

analyze performance is available on the following web site www.igrowing.ca

(October 2002) .

Hint # Description of TEMP hint codes

H-01 TEMP output is ON from 0 to 19 % of the time

H-02 TEMP output is ON from 20 to 39 % of the time

H-03 TEMP output is ON from 40 to 59 % of the time

H-04 TEMP output is ON from 60 to 79 % of the time

H-05 TEMP output is ON from 80 to 100 % of the time

H-06 Current ON-time for TEMP output is at least 4times the average ON-time

H-11 Total differential is between 2.0 C and 2.9 C (3.8 F and 5.2 F)

H-12 Total differential is between 3.0 C and 4.4 C (5.6 F and 7.9 F)

H-13 Total differential is between 4.5 C and 5.9 C (8.0 F and 10.6 F)

H-14 Total differential is between 6.0 C and 7.4 C (10.7 F and 13.3 F)

H-15 Total differential is between 7.5 C and 8.9 C (13.4 F and 16.0 F)

H-16 Total differential is 9C and up (16.1 F and up)

Note : The total differential equals the Dynamic Differential plus 1C/2F.

Hint # Description of RH hint codes

H-21 RH output is ON from 0 to 19 % of the time

H-22 RH output is ON from 20 to 39 % of the time

H-23 RH output is ON from 40 to 59 % of the time

H-24 RH output is ON from 60 to 79 % of the time

H-25 RH output is ON from 80 to 100 % of the time

H-26 Current ON-time for RH output is at least 4 times the average ON-time

H-31 Total differential is 5% or better

H-32 Total differential is between 6% and 8%

H-33 Total differential is between 9% and 11 %

H-34 Total differential is between 12 % and 14 %

H-35 Total differential is between 15 % and 17 %

H-36 Total differential is 18 % and up

Note : The total differential equals the Dynamic Differential plus 1%.

Mixed Temperature and Humidity Control Sequence

Cooling and dehumidifying is often performed simultaneously by the same

venting equipment. You can select this combined mode by setting one of the

following Control Mode numbers for Output 1:

1-61 Day Cooling and Dehumidifying

1-62 Night Cooling and Dehumidifying

1-63 24 H Cooling and Dehumidifying

When any Cooling and Dehumidifying mode is used, the Output 1will activate

the equipment as soon as the temperature is above the temperature setpoint

OR the humidity is above the humidity setpoint. However, the Output 1will not

be deactivated until both conditions have been reached, that is, until the tem-

perature and the humidity are below their respective setpoint.

When using any of these 3modes, take note that the Output 2will then be

forced to operate independently of the Output 1, thus forcing its Control Mode

number to either 2-04, 2-14, 2-24, 2-34, 2-44 or 2-54. For instance, if Output 2

Control Mode number prior to change was 2-22, then the forced mode will be

2-24 ; or if it was 2-41, it will be forced to 2-44 : in short only the last digit will

be forced to 4. Refer to pages 13 and 14 of the User manual to see the com-

plete list of the available Control Mode numbers.

Also take note that the humidity setpoint will be the same for Output 1and

Output 2. For instance, if you want to perform a 2-stage 24-hour Dehumidifying

setup, you must connect one fan in each output and set your Output 1to mode

1-63 (Cooling and Dehumidifying 24 H) and Output 2to mode 2-54

(Dehumidifying 24 H). Then, only Output 1fan will be on when it s too hot, and

both fans will be on when it s too humid.

In a second example, you may need to connect a fan in Output 1and a humidi-

fier in Output 2. By selecting the operating modes 1-63 (Cooling and

Dehumidifying 24 H) and 2-24 (Humidifying 24 H), the iGS-110 will activate the

fan when it s too hot or too humid. However, if you reach a condition where it s

too hot and too dry, the Output 1fan will take care to cool the room, while

Output 2will take care to humidify it.

Dynamic Differential

The iGS-110 controller performs its duties according to a special dynamic differen-

tial adjustment algorithm.

The controller will automatically adjust the operational differential when the Temp

levels overshoot or undershoot the desired setpoint level (or night setpoint during

the night). This dynamic algorithm adjusts the working parameters of the controller

to the reality found in your grow room. It can vary between 1C and 10 C/2F and

18 F (actually the maximum Dynamic Differential will be the biggest value between

20% of the setpoint or 10 C/18 F). The controller will always aim at not climbing

higher than the used setpoint addedwith a 1C/2F. In the case of cooling, the 1

C/2F will be substracted to the setpoint. When controlling temperature levels, the

controller will apply the same algorithm. In this case, the Dynamic Differential will

vary between 3and 20% over the entire Relative Humidity range (0-100%).

9

If the controller is set to heat the room at 20 C, the Dynamic

Differential will modify itself until the control sequence never over-

shoots 21 C when heating and undershoots 19 C when cooling.

12

Safety Notice

IMPORTANT SAFETY INSTRUCTIONS

DANGER : TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, CAREFULLY FOL-

LOW THESE INSTRUCTIONS.

Output Box Safe Installation

The iGS-50 Output Box must be mounted on a vertical wall using 4wood

screws provided with the unit. We recommend that the Output Box be located

at no more than 5feet from a standard 125 V15 A electrical receptacle due

to the length of the attached power cord.Control Box Safe Installation

The iGS Control Box (iGS-1X0and iGS-2X0Series) must also be mounted on a

vertical wall using 4wood screws provided with the unit. We recommend that

the Control Box be located at the eye level at no more than 6feet from the

Output Box due to the length of the included interconnection cable. We also

recommend to disconnect the cable between both boxes before servicing.

This product complies with CSA 22.2-14 and UL 508 A standards for Canada

and United States.

Product warranty

Nova Biomatique inc. warrants their intelligent Growing Systems controllers

and accessories to be free of defects in material and workmanship for a peri-

od of one year from the date of original purchase (proof of purchase needed).

The warranty applies only to the original purchaser of the product. The war-

ranty is limited to the repair or replacement, at Nova Biomatique s discretion,

of any defective part of the controller or accessories which are covered by the

warranty. The warranty does not cover the following : defects resulting from

installation, shipping (insurance is recommended), misuse, negligence or

tampering, or improper use.

Product repairs

Nova Biomatique inc. will repair the intelligent Growing Systems controllers

within 10 days of reception at our offices. For repairs not covered by the war-

ranty, the customer will be contacted and informed on the cost and delays and

will be asked for a verbal approval. Only when the customer agrees to the

repairs in question will the controller be repaired. Shipping fees are the cus-

tomer responsabilty except in the case of a repair covered by the warranty

where Nova Biomatique inc. will assume the return shipping fees only.

To send for repairs or upgrades, you must call for a product return number.

This call will insure that we have all the information necessary to properly

diagnose your controller and to send it back to you.

Toll free line: 1-888-577-6274

Nova Biomatique

155b, Avenue Industrielle, La Pocati re,

Quebec, Canada, G0R 1Z0

Error Messages

As the controller performs its operating functions it will continuously check

itself for system faults. When a fault is detected the controller will flash an

error code at least once every 32 seconds. The following table describes the

error codes :

Maintenance and warnings

The controller needs a change or clean of the lint air filter situated at the bot-

tom of the controller enclosure. Keeping the filter free of debris will improve

the controller s work and prolong the products lifetime.

Keep the photo-sensor clear of debris or dirt.

Take care in not directing a water jet towards the control box (iGS-110) and

the output box (iGS-50). These enclosures can withstand light splashing but

should not be drenched with water to protect the internal sensor and circuit-

ry and prevent possible electrical hazards.

The maximum current allowed for all the devices connected to all 120 V out-

lets should never exceed a total of 12A.

iGS-110 Specifications

Input : 15 VDC 400mA

Internal Fan : 3-5 cfm (with lint filter)

Temperature range : -20 C to 50 C/-4F to 122 F

Temperature precision : –1 C/–2 F

Temperature calibration : factory calibrated, 5year

RH range : 0-100%

RH precision : –3.5%

RH calibration : factory calibrated, 3-5 years

Front Panel : Splashproof keyboard membrane

Operating temperature : 0-60 C, 0-95% (non-condensing)

iGS-50 Specifications

Input : 120 V60 Hz 15 A

Output Voltage : 120 V60 Hz

Output Maximum Current :

11

Load Type Current Rating

General purpose (inductive) 15 A total for both duplex receptacles

Resistive 15 A total for both duplex receptacles

Motor 1/2 HP total for both duplex receptacles

4

Name

Climate Sensor malfunction

Error # Conditions to SET Conditions to RESET

Climate sensor is out of

order

Climate sensor resumed

operation

14

Notes :

1- When Temp Control Mode is 1-x4(eg. 1-04 or 1-14 or 1-54) and RH Control Mode is

2-x4 (eg. 2-24 or 2-44), then both outputs can be activated simultaneously and inde-

pendently.

2- When Temp Control Mode is 1-x4 and RH Control Mode is different from 2-x4, then

Temp output is given the highest priority and will turn the RH output OFF whenever

Temp control is required.

3- When RH Control Mode is 2-x4 and Temp Control Mode is different from 1-x4, then

RH output is given the highest priority and will turn the Temp output OFF whenever RH

control is required.

4- When both Control Modes are different from 1-x4 or 2-x4, then both outputs are

given the same low priority, meaning that only one output can be activated at a time on

a first need/first served basis.

HH

01 Turn RH output OFF while TEMP is ON

Day 02 Turn RH output OFF while TEMP is ON + 5min.

Humidifier 03 Turn RH output OFF while TEMP is ON + 10 min.

04 RH output is fully independent of TEMP control

11 Turn RH output OFF while TEMP is ON

Night 12 Turn RH output OFF while TEMP is ON + 5min.

Humidifier 13 Turn RH output OFF while TEMP is ON + 10 min.

14 RH output is fully independent of TEMP control

21 Turn RH output OFF while TEMP is ON

24H22 Turn RH output OFF while TEMP is ON + 5min.

Humidifier 23 Turn RH output OFF while TEMP is ON + 10 min.

24 RH output is fully independent of TEMP control

31 Turn RH output OFF while TEMP is ON

Day 32 Turn RH output OFF while TEMP is ON + 5min.

Dehumidifier 33 Turn RH output OFF while TEMP is ON + 10 min.

34 RH output is fully independent of TEMP control

41 Turn RH output OFF while TEMP is ON

NIght 42 Turn RH output OFF while TEMP is ON + 5min.

Dehumidifier 43 Turn RH output OFF while TEMP is ON + 10 min.

44 RH output is fully independent of TEMP control

51 Turn RH output OFF while TEMP is ON

24H52 Turn RH output OFF while TEMP is ON + 5min.

Dehumidifier 53 Turn RH output OFF while TEMP is ON + 10 min.

54 RH output is fully independent of TEMP control

Relative Humidity Control Modes Control mode number is 2- HH

iGS-110 Operating Modes

Temperature Control Modes Control mode number is 1- TT

13

TT

01 Turn TEMP output OFF while RH is ON

Day 02 Turn TEMP output OFF while RH is ON + 5min.

Heatstat 03 Turn TEMP output OFF while RH is ON + 10 min.

04 TEMP output is fully independent of RH control

11 Turn TEMP output OFF while RH is ON

Night 12 Turn TEMP output OFF while RH is ON + 5min.

Heatstat 13 Turn TEMP output OFF while RH is ON + 10 min.

14 TEMP output is fully independent of RH control

21 Turn TEMP output OFF while RH is ON

24 H22 Turn TEMP output OFF while RH is ON + 5min.

Heatstat 23 Turn TEMP output OFF while RH is ON + 10 min.

24 TEMP output is fully independent of RH control

31 Turn TEMP output OFF while RH is ON

Day 32 Turn TEMP output OFF while RH is ON + 5min.

Coolstat 33 Turn TEMP output OFF while RH is ON + 10 min.

34 TEMP output is fully independent of RH control

41 Turn TEMP output OFF while RH is ON

NIght 42 Turn TEMP output OFF while RH is ON + 5min.

Coolstat 43 Turn TEMP output OFF while RH is ON + 10 min.

44 TEMP output is fully independent of RH control

51 Turn TEMP output OFF while RH is ON

24H52 Turn TEMP output OFF while RH is ON + 5min.

Coolstat 53 Turn TEMP output OFF while RH is ON + 10 min.

54 TEMP output is fully independent of RH control

Coolstat 61 Day

and 62 Night

Dehumidifier 63 Day and night

Printed in Canada ' & Nova Biomatique Inc.

Revision 1.30

Table of contents

Popular Controllers manuals by other brands

Halma

Halma ALICAT SCIENTIFIC PCD3 quick start guide

Oracle

Oracle Acme Packet 4500 Hardware installation and maintenance guide

Embention

Embention MC24 manual

CARLO GAVAZZI

CARLO GAVAZZI Sx2WEB Series manual

Ewellix

Ewellix CAT 33 Installation, operation and maintenance manual

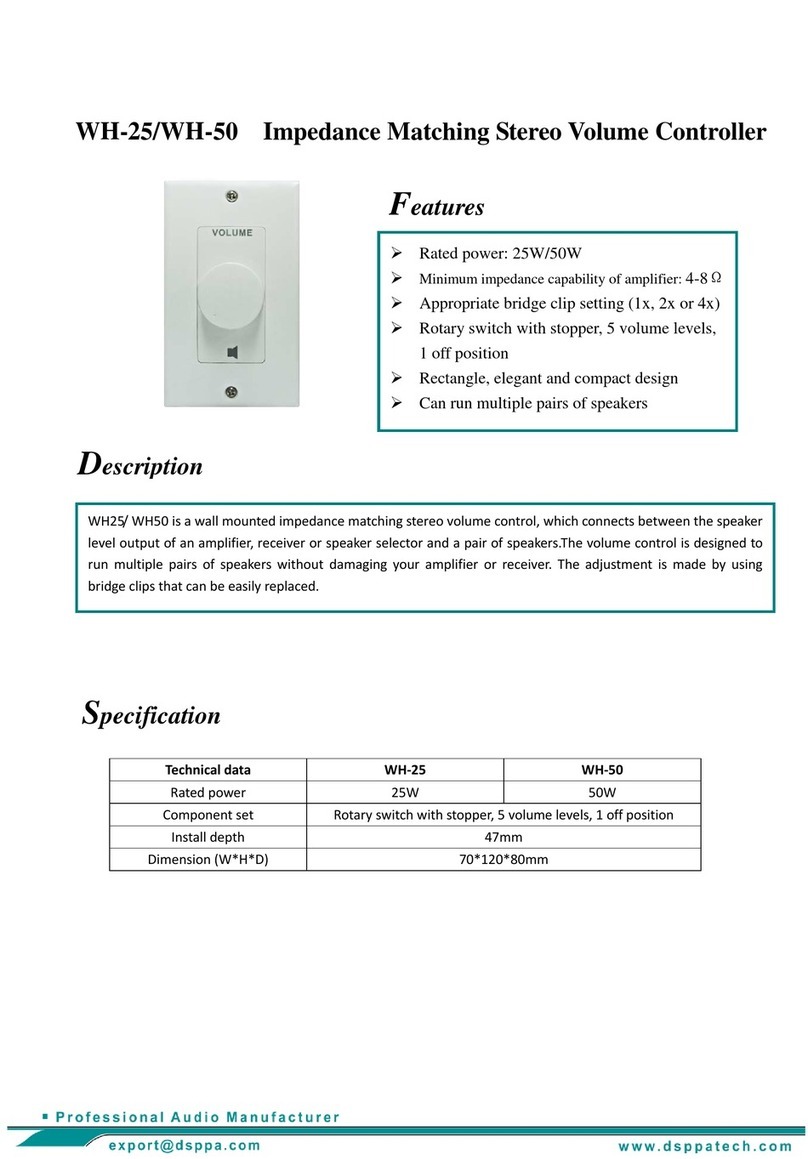

DSPPA

DSPPA WH-25 quick start guide