Novalynx 255-100C-4 User manual

255-100C-4

User Manual

255-100C-4

255-100C-4N

4-20 mA Current Loop Signal Converter

For use with the 255-100 Analog Output Evaporation Gauge

And the 255-200 Evaporation Pan (each sold separately)

255-100C-4N

Phone (530) 823-7185 USA Toll Free (800) 321-3577 Fax (530) 823-8997

NovaLynx Corporation

200-100C-4 Page 2 September 2018

Receiving and Unpacking

Carefully unpack all components and compare to the packing list. Notify NovaLynx Corporation

immediately concerning any discrepancy. Inspect equipment to detect any damage that may have

occurred during shipment. In the event of damage, any claim for loss must be filed immediately with

the carrier by the consignee. Damages to equipment sent via Parcel Post or UPS require the consignee

to contact NovaLynx Corporation for instructions.

Returns

If equipment is to be returned to the factory for any reason, call NovaLynx between 8:00 a.m. and 4:00

p.m. Pacific Time to request a Return Authorization Number (RA#). Include with the returned

equipment a description of the problem and the name, address, and daytime phone number of the

sender. Carefully pack the equipment to prevent damage or additional damage during the return

shipment. Call NovaLynx for packing instructions in the case of delicate or sensitive items. If packing

facilities are not available take the equipment to the nearest Post Office, UPS, or other freight service

and obtain assistance with the packaging. Please write the RA# on the outside of the box.

Warranty

NovaLynx Corporation warrants that its products are free from defects in material and workmanship

under normal use and service for a period of one year from the date of shipment from the factory.

NovaLynx Corporation's obligations under this warranty are limited to, at NovaLynx's option: (i)

replacing; or (ii) repairing; any product determined to be defective. In no case shall NovaLynx

Corporation's liability exceed product's original purchase price. This warranty does not apply to any

equipment that has been repaired or altered, except by NovaLynx Corporation, or that has been

subjected to misuse, negligence, or accident. It is expressly agreed that this warranty will be in lieu of

all warranties of fitness and in lieu of the warranty of merchantability.

Address

NovaLynx Corporation

431 Crown Point Circle, Suite 120

Grass Valley, CA 95945-9531 USA

Phone: (530) 823-7185

Fax: (530) 823-8997

Email: nova@novalynx.com

Website: www.novalynx.com

Copyright © 1988-2018 by NovaLynx Corporation

NovaLynx Corporation

200-100C-4 Page 3 September 2018

CONTENTS

1 FORWARD ....................................................................................................................................................................... 4

2 INTRODUCTION ............................................................................................................................................................... 4

3 TECHNICAL SPECIFICATION ............................................................................................................................................. 4

4 INSTALLATION ................................................................................................................................................................. 5

5 WIRING DIAGRAM ........................................................................................................................................................... 7

6 CALIBRATION ................................................................................................................................................................... 7

7 SINGLE-POINT OFFSET ADJUSTMENT ............................................................................................................................. 8

8 MAINTENANCE ................................................................................................................................................................ 8

APPENDIX A ............................................................................................................................................................................. 9

NovaLynx Corporation

200-100C-4 Page 4 September 2018

1 FORWARD

Thank you for purchasing NovaLynx products. NovaLynx has been designing and manufacturing

weather instruments since 1988. NovaLynx represents several well-known brands of quality

manufacturers, including Gill Instruments, RM Young, Kipp & Zonen, and Vaisala. It is our hope that our

products will meet all your monitoring requirements.

2 INTRODUCTION

The 255-100C-4 Signal Conditioner's output is a 4-20 mA signal proportional to the resistance of a

rotary potentiometer. It is designed to work with the 255-100 Analog Output Evaporation Gauge and

the 255-200 Evaporation Pan (sold separately). These three components combine to provide a means

to gauge evaporation in systems that require 4-20 mA loop-driven signals.

The Signal Conditioner can be purchased as a bare board (Part# 255-100C-4) or enclosed in a weather-

tight (IP65) enclosure (Part# 255-100C-4N). Connections to the circuit board are via screw terminals.

The enclosure has two cable grip fittings for cable entry and a bracket for mounting to a mast up to

1 ⅜" (35 mm) in diameter. Cable is not supplied.

3 TECHNICAL SPECIFICATION

The 255-100 Analog Output Evaporation Gauge contains a precision 1-turn potentiometer coupled to a

gear which rotates as water level in the evaporation pan slowly decreases. One complete revolution of

the gear represents 10 inches of vertical movement of the float inside the Evaporation Gauge. As a

practical matter, due to the way the plumbing is arranged, the effective measurement range is from

9.4" to a minimum of 2.5" (239 mm to 64 mm).

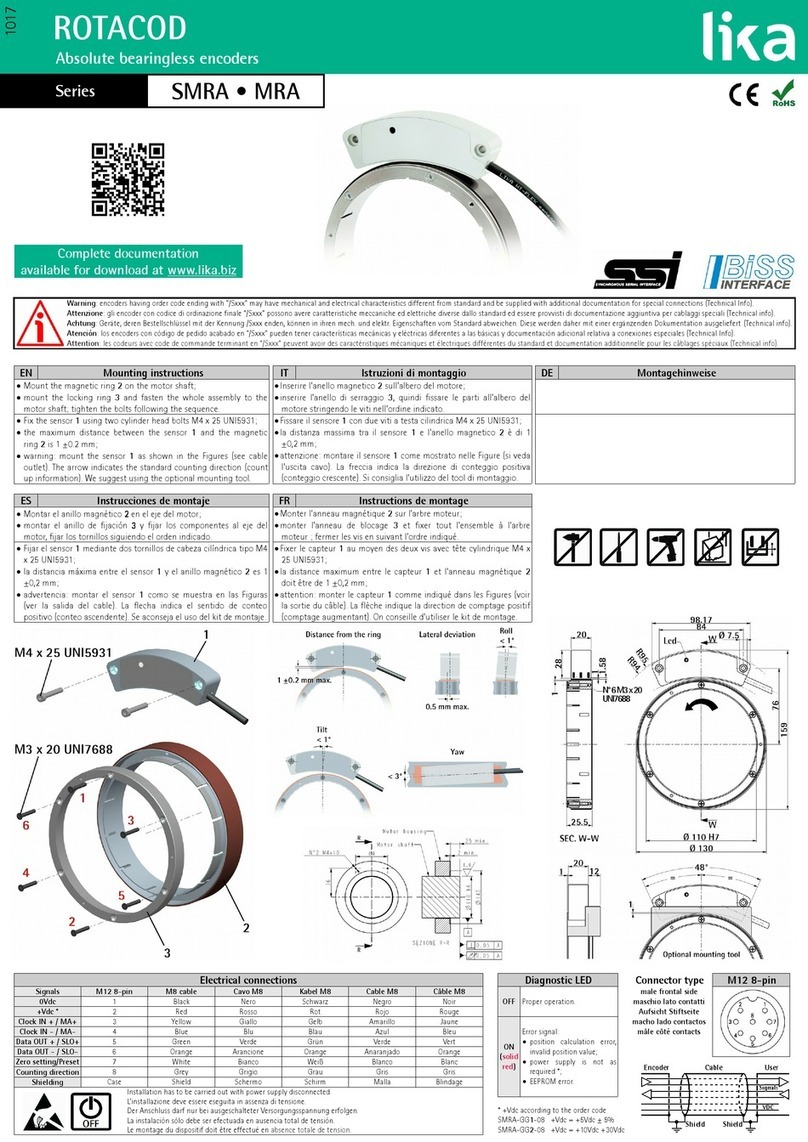

Signal Output at Various Angles

Stripe

Angle

(approx)

Inches 9.2 8.3 7.5 6.7 5.8 5.0 4.2 3.3 2.5 1.7 0.8

mm 233 212 191 169 148 127 106 85 64 42 21

mA 18.7 17.3 16.0 14.7 13.3 12.0 10.7 9.3 8.0 6.7 5.3

30 60 90 120 150 180 210 240 270 300 330

NovaLynx Corporation

200-100C-4 Page 5 September 2018

The potentiometer has an electrical "dead band" which is marked by a white stripe on the gear. The "dead

band" occupies 20 degrees of rotation, so to compensate the sensor is calibrated from 4.0 mA to 19.1 mA.

The formula is ((340/360 *16)+4) = 19.1 mA.

The potentiometer has high accuracy and linearity, but the overall resistance varies from one

potentiometer to another (± 10%). For this reason each Signal Conditioner is calibrated with the

companion Analog Output Evaporation Gauge.

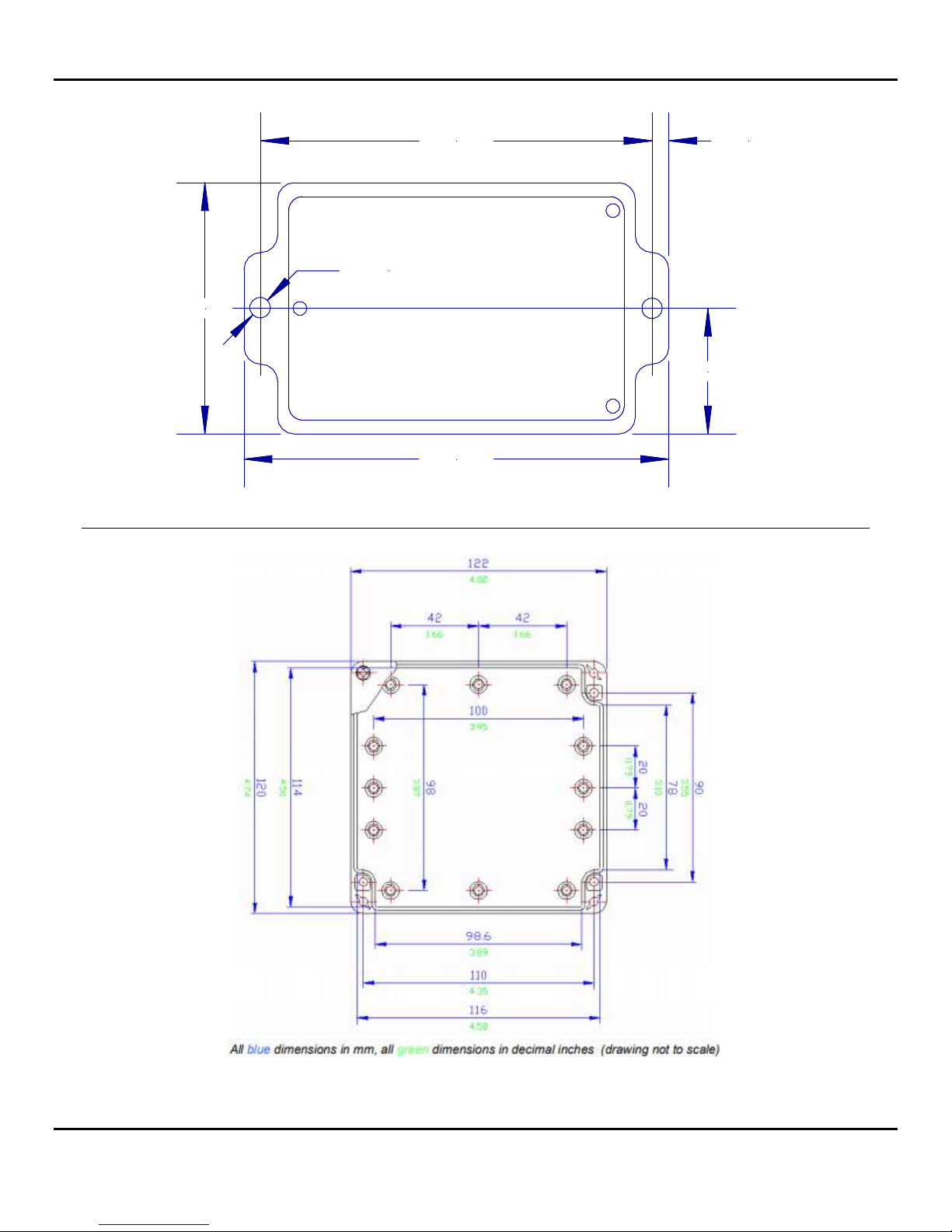

4 INSTALLATION

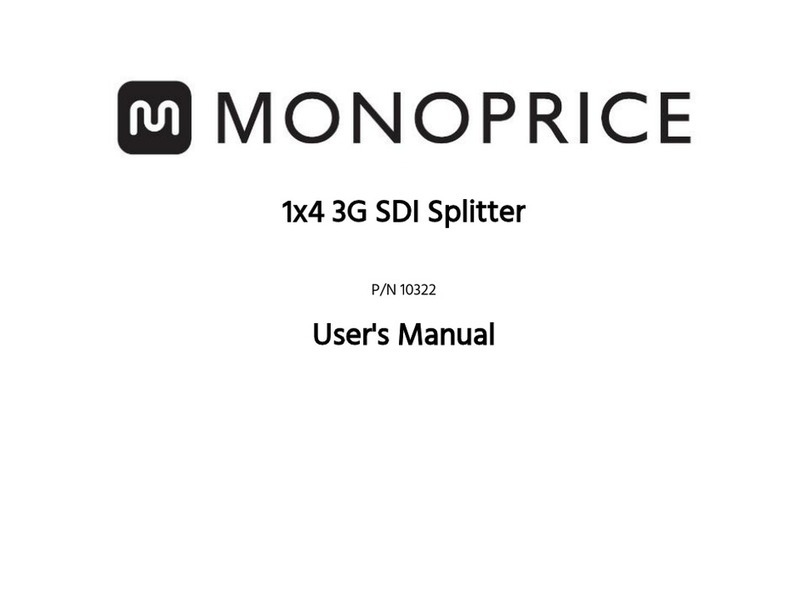

The 200-100C-4 Signal Conditioner circuit board must be housed in a weatherproof enclosure. The

circuit board is mounted to a small plate which has two mounting holes for easy attachment to a flat

surface (Figure 1). One of the mounting holes also secures a terminal strip above the circuit board.

The 200-100C-4N includes a weatherproof enclosure and hardware for mounting to a mast up to 1 ¼"

(3.2 cm) in diameter. The mast mounting hardware can be removed and the enclosure mounted to a

flat surface instead if required. There are four mounting holes, accessible when the lid of the enclosure

is removed (Figure 2). Mount the enclosure with the cable grips at the bottom.

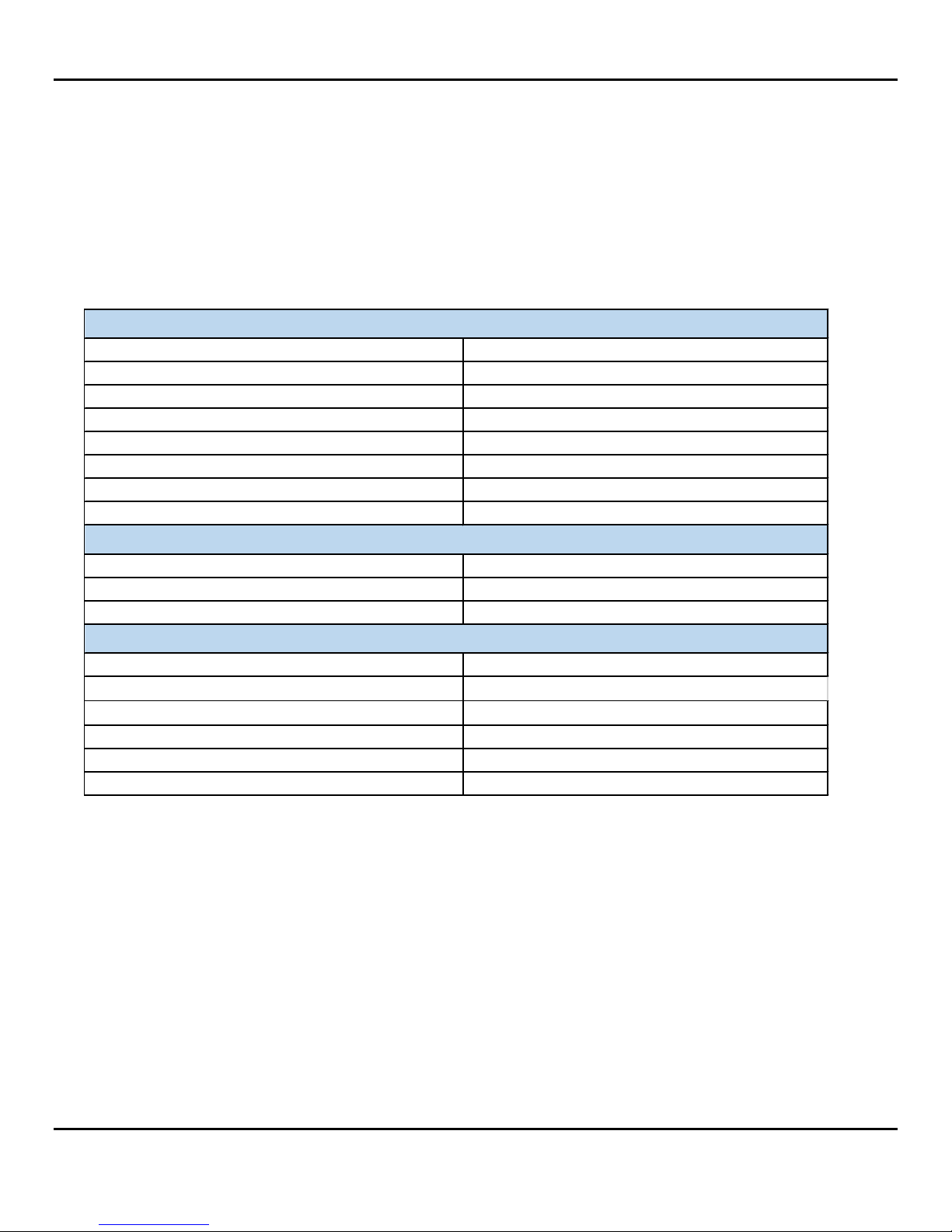

Accuracy 0.25%

Linearity 0.25%

Rotation 360° continuous

Electrical angle 340° ± 1°

Resistance 1,000 ohms ± 10%

Operating temperature -40° to +140° F (-40° to +60°C)

Mechanical range 0 to 10 inches (0-254 mm)

Electrical range 0 to 9.444 inches (0-239.9 mm)

Output span (340 degrees) 4 to 19.1 mA = 0 to 9.444 inches (0 to 239.9 mm)

Supply voltage 8 to 30 Vdc

Connection type 2-wire current loop

Cable Not included

Cord grip diameter range (255-100C-4N only) 0.181" to 0.312" (4.6 to 7.9 mm) diameter

Mounting (255-100C-4N only) 1 ⅜" (35 mm) diameter pipe mount

200-100C-4 Dimensions (circuit board) 3.0 x 2.0 x 1.6 inches (7.6 x 5.1 x 4.1 cm)

200-100C-4N Dimensions (NEMA box) 4.8 x 4.7 x 2.2 inches (12.2 x 12.0 x 5.6 cm)

Weight / Shipping 1 lbs (0.45 kg) / 2 lbs (0.91 kg)

Potentiometer Specification

Transmitter Specification

Overall Specification

NovaLynx Corporation

200-100C-4 Page 6 September 2018

ø 0.185"

3.800"

3.500" 0.150"

1.125"

2.250"

Figure 1

Figure 2

NovaLynx Corporation

200-100C-4 Page 7 September 2018

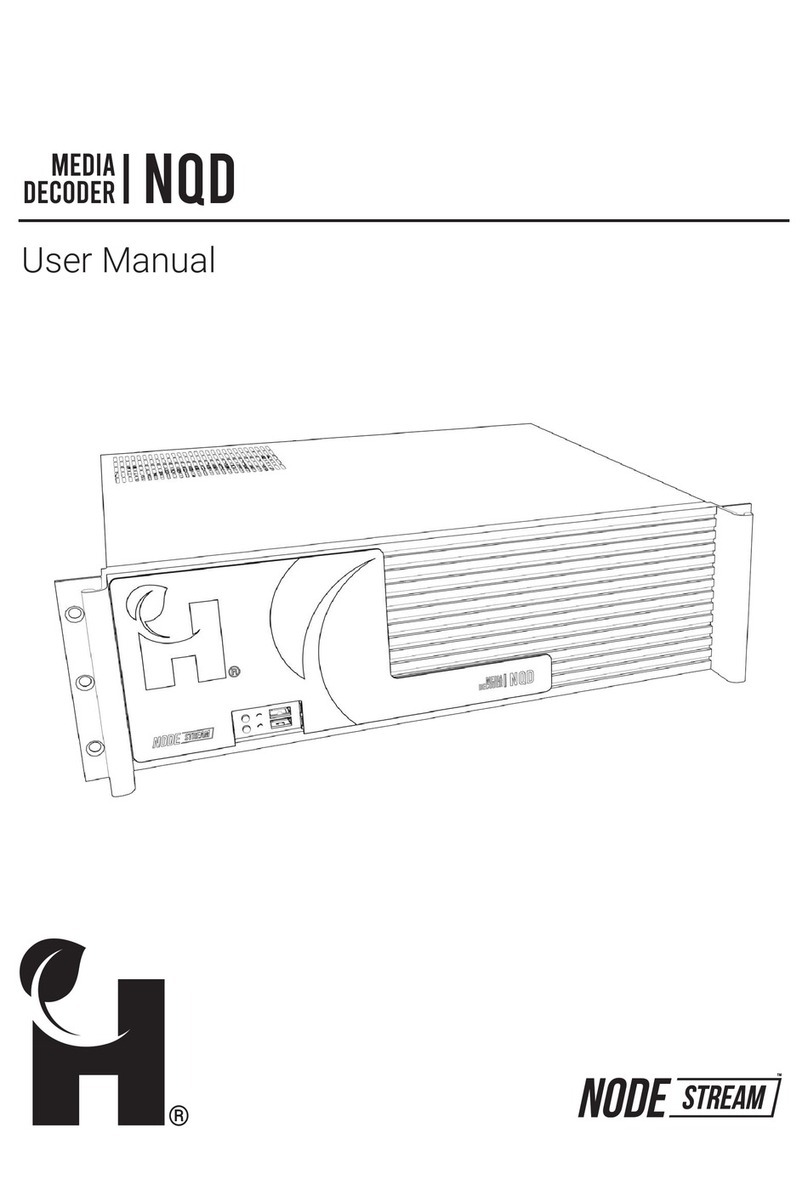

5 WIRING DIAGRAM

12

White - Signal in

Black - Reference

Shield - Earth ground

4-20 mA Loop +

4-20 mA Loop -

Red - Excitation

Analog Output

Evaporation Gauge

Model 255-100

255-100C-4 WIRING DIAGRAM

The Analog Output Evaporation Gauge (sold separately) includes 50 feet of shielded cable. The cable

can be extended up to a total of 250 feet if required. If the cable is extended be sure to spice the shield

also in order to reduce electrical noise.

CAUTION: Be sure to observe correct polarity when connecting to the 4-20 mA loop circuit. Internal

diodes will protect the Signal Conditioner if wired backwards, but the output will be meaningless.

Cable for connecting the 4-20 mA loop is not supplied. Use a wire gage adequate to provide a

minimum of 8 volts at the Signal Conditioner after voltage drop over the cable is accounted for. The

cable grips will accept 0.181" to 0.312" (4.6 to 7.9 mm) diameter cable.

6 CALIBRATION

When ordered together with an Analog Output Evaporation Gauge the 255-100C-4 Signal Conditioner

is individually factory calibrated to the Gauge. Recalibration is not necessary unless the Gauge is

replaced (see Appendix A for instructions).

At installation, the float/chain assembly of the Analog Output Evaporation Gauge must be correctly

installed on the gear, otherwise the sensor output will be meaningless. Instructions for setting the

position of the gear with respect to the chain are given in the 255-100 Analog Output Evaporation

Gauge manual.

NovaLynx Corporation

200-100C-4 Page 8 September 2018

7 SINGLE-POINT OFFSET ADJUSTMENT

One can verify/adjust the output of the 255-100C-4 Signal Conditioner using either a 4-20mA calibrator

or good quality milliamp meter and 9 or 12 volt battery (see Appendix A for connections).

Measure the depth of the water in the Evaporation Pan and calculate the mA output using one of the

formulas below. Measure the mA output of the Signal Conditioner. If the results do not match then

move the chain one tooth clockwise or counterclockwise and recheck.*

Evaporation Pan Level in millimeters: mA = Depth (mm) x 0.063 + 4

Evaporation Pan Level in inches: mA = Depth (inch) x 1.6 + 4

* The gear has 40 teeth, so moving the chain 1 tooth raises or lowers the float 0.25" (6.35 mm). If finer

adjustment is needed it may be possible to program the offset in your monitoring equipment.

8 MAINTENANCE

The 200-100C-4 Signal Conditioner requires no maintenance under normal operating conditions. If any

problems with the signal are detected, check the following:

Inspect the cables for damage and repair as necessary.

Ensure there is no moisture buildup in the enclosure that houses the circuit board as this can

introduce error or damage the board.

Tighten the screw terminals if necessary.

Ensure power is getting to the board and the polarity is correct.

Check the operation of the Analog Output Evaporation Gauge using an ohmmeter (disconnect

the Gauge from the Signal Conditioner for this test)

Measure the water level depth and calculate the corresponding mA output. Adjust the chain if

necessary.

Perform the calibration procedure if required.

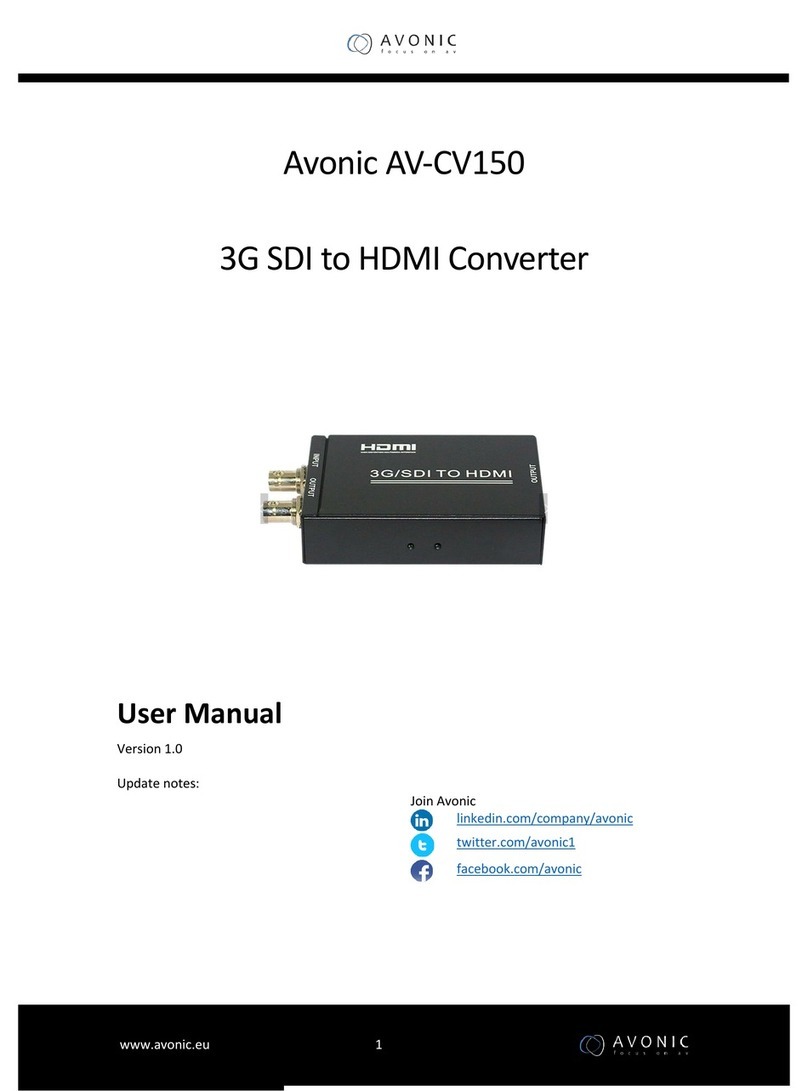

APPENDIX A

255-100C-4 WIRING DIAGRAM

JDC

09-20-2018

255-100C-4

Calibration Procedure

890-0020-01

12

White - Signal

Black - Reference

Shield - Earth ground

Red - Excitation

Analog Output

Evaporation Gauge

Model 255-100

mA COM

R28 GAIN

R26 OFFSET

20°

19.1 mA

4.0 mA

Dead Band

1) Connect a 9V or 12V battery and meter as shown.

2) Rotate the gear until the lowest mA reading is obtained. Adjust R26 OFFSET to 4.00 ±0.080 mA.

3) Rotate the gear counter-clockwise. The output will rise gradually until the dead band

is reached and then jump suddenly to 26-28 mA. Back off slightly to get out of the dead band

and adjust R28 GAIN to 19.1 ±0.080 mA.

4) There is a small interaction between the GAIN and OFFSET pots, so verify the lowest mA reading

is still 4.00 ±0.080 mA.

This manual suits for next models

1

Table of contents