Novalynx 230-601C User manual

Barometric Pressure

NovaLynx Corporation PO Box 240 Grass Valley CA 95945

DOC 230-601C IS 20210526 +1 (530) 823-7185 nova@novalynx.com

www.novalynx.com

230-601C Barometric Pressure Sensor

The 230-601C Barometric Pressure Sensor offers unparalleled

performance and flexibility for atmospheric pressure measurement. It

combines high accuracy and low power over a wide range of pressures

and temperatures.

The sensor is protected by a weatherproof polycarbonate enclosure. The

enclosure can be wall mounted or pole mounted with the addition of the

395-A-003 Mast Mounting Hardware kit.

The standard 5-conductor cable is 25' (7.6 m) long. If additional cable is

required please specify at the time of order.

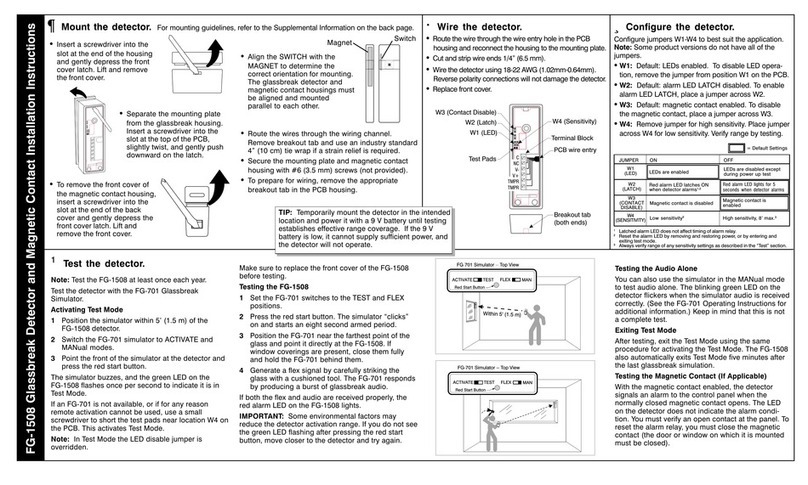

BP Sensor with Enclosure

A

OUTPUT (TX)

+

PWR (7-30 VDC)

-

PWR

4-20 mA SIGNAL

B

OUTPUT (RX)

EARTH GROUND

GREEN

RED

BLACK

WHITE

BROWN

SHIELD

RX-B

I-OUT

REF

+ PWR

TX-A / SDI

Pressure Port

-

-

-

-

-

DWG 820-0004-01

230-601C

BAROMETRIC PRESSURE

DEFAULT OUTPUT

RANGE: 500-1100 hPa

SIGNAL: 4 to 20 mA

Consult RM Young

Model 61402L

instruction manual

for jumper settings to enable other options

INSULATE UNUSED WIRES

Ordering Information

230-601C Barometric Pressure Sensor, 4-20 mA output with enclosure and 25' cable

395-A-003 Mast Mounting Hardware (for use with enclosure)

330-0524 Cable 5C 24AWG Shielded, per foot

Barometric Pressure

NovaLynx Corporation PO Box 240 Grass Valley CA 95945

Phone (530) 823-7185

www.novalynx.com

Mast Mounting Bracket

(U-bolt not shown)

Polycarbonate Enclosure

90 mm

R.M. YOUNG COMPANY

2801 AERO PARK DRIVE, TRAVERSE CITY, MICHIGAN 49686, USA

TEL: (231) 946-3980 FAX: (231) 946-4772

PN: 61402L-90

REV: A040819

1.0 SPECIFICATIONS

Pressure 500 to 1100 hPa standard range

Digital Accuracy* 0.2 hPa (25°C)

0.3 hPa (-40°C to +60°C)

Analog Accuracy** 0.05% of analog pressure range

Analog Temperature

Dependence** 0.0017% of analog pressure

range per °C (25°C reference)

Long Term Stability: 0.08% FS per year

*

Denedas±1standarddeviationfromNIST-traceable

pressure reference in clean, dry air. Includes non-

linearity, hysteresis, repeatability, and calibration

uncertainty.

** Definedas±1standarddeviationfromidealanalog

output. Total analog output accuracy is the root sum

square of digital accuracy, analog accuracy, and analog

temperature dependence.

Output Rate 1.8 Hz (max) to 1 per minute

Current Output 4 to 20 mA or 0 to 20 mA

12-bit resolution (1 in 4000)

Selectable pressure range: 500 to

1100 hPa (standard)

Serial Output Full-duplex RS-232

Half-duplex RS-485

SDI-12

1200 to 38400 baud

Continuous ASCII text

Polled ASCII text

NMEA

0.01 hPa resolution

Supply Voltage 7 to 30 VDC

25 mA max (4-20 or 0-20 mA mode)

1.5 mA max in SDI-12 mode

8.5 mA (RS-232 or RS-485)

Case Fiber-reinforced thermoplastic

Weight 44 g (1.5 oz)

INSTRUCTIONS

MODEL 61402L

BAROMETRIC PRESSURE SENSOR

Format Description

Continuous ASCII Text

(standard)

9600 baud

16sampleaverage

1.8 Hz output

Polled ASCII Text

9600 baud

10sampleaverage

Output when polled

Marine NMEA

4800 baud

10sampleaverage

1 Hz output

SDI-12 1200 baud

Software Output parameters determined by

software settings

See wiring configurations for more information.

In POLLED ASCII mode, the unit sends data only after

receivingapollcommand.ThepollcommandisMa!where

‘a’istheaddressvalue.Thestandardaddressis‘0’(ASCII

48)forapollcommandofM0!Pleaseseesection4.3for

details on changing the poll address.

Uponreceivingaproperlyaddressedpollcommand,theunit

immediately sends data.

4.3 SOFTWARE COMMANDS

Softwarecommandssentviaserialcommunicationmaybe

used to set operational parameters. The sensor must be

configured for serial communication and connected to a PC

orothercompatibledeviceusingaprogramlikeHyperTerm.

New settings are stored in temporary memory and

must be burned to flash with command CMD420 to be

retained.

NotethatallP1jumpers(A,B,C)mustberemovedfor

SOFTWAREformattochangebaudrate,sampleaverage

count, and output rate parameters.

Althoughthesensormayreceivecommandsatany

time, measurement output may be paused by sending

three ESC (ASCII 27) characters or CMD300 1. While

paused, COMMAND mode is indicated by a “>” prompt.

All commands must be terminated with a carriage return

CR (ASCII 13).

Use“?”tolistavailablecommandsasshownbelow.

>?

YOUNG 61402L SERIES BAROMETER

------------------------------------------------

CMD100 n OUTPUT PERIOD (0-60 sec)

CMD105 n AVG SAMPLE COUNT (0-32)

CMD110 n OUTPUT FORMAT

1=ASCII 2=POLLED 3=NMEA 4-RAW 5-DIAG)

CMD120 n MULTIPLIER (10000 = 1.0000)

CMD125 n OFFSET (hPA x 100)

CMD130 n SEA LEVEL CORRECTION (hPA x 100)

CMD140 n IOUT RANGE HI (500-1100)

CMD142 n IOUT RANGE LO (500-1100)

CMD144 n IOUT SCALE (1=0-20mA 4=4-20mA)

CMD150 c POLL ADDR CHAR

CMD 1 60 n BAUD RATE (38400,19200,9600,4800,2400,1200)

CMD300 n 1=STOP, 2=RUN

CMD310 n FORCE IOUT (0-20000 FULL SCALE)

CMD400 n 1=REPORT TEXT, 2=REPORT CODE ONLY

CMD410 GET CAL TABLE

CMD420 STORE SETUP PARAMETERS

>

CMD100 n sets output period in seconds. When set to zero,

the output rate is 1.8 per second.

CMD105 n setstheaveragesamplecount.Highersample

count yields more stable readings but will

lengthen the startup delay.

CMD110 n sets output format.

CMD120 n sets the output multiplier. 10 00 0 repres en ts

1.0000

CMD125 n sets the output offset in hPa x 100

CMD130 n setsthesealevelcorrectioninhPax100

=[Punadjust *( Mult / 10000)] +[(Offset /100)+(Correction Sea Lvl /100)]

2.0 INTRODUCTION

MODEL61402LBarometricPressureSensorisaversatile

electronic barometer featuring high accuracy, low power,

wide operating temperature range, and calibrated 4-20 mA

output, with SDI-12 and RS-232/485 serial data I/O.

The4-20mAoutputandRS-485serialI/Omakethe

61402L ideal for commercial and industrial applications that

commonly use these signals.

Full scale current output may be set to span any portion of

the 500 to 1100 hPa operating range. Serial output options

include continuous or polled ASCII text output, NMEA marine

output or SDI-12. The sensor is supplied with the following

standard configuration:

Current Output 4-20 mA = 500 to 1100 hPa

RS-232 Continuous ASCII text output 9600 baud

16samplesaveraged

1.8 Hz update rate

3.0 INSTALLATION

Thesensoroperatesoveratemperaturerangeof-40°Cto

+60°C and must remain dry. Electrical connections are made

with the 5-position terminal plug included with the sensor.

Jumper settings may be used to select operating options.

Access jumpers by loosening two screws in the sensor

enclosureandremovingthecover.Seelastpageforwiring

details and jumper settings.

4.0 OPERATION

Operation begins approximately 1 second after power is

applied. Output will appear after a delay determined by

thenumberofsamplesaveragedandtheoutputrate.With

defaultvalues(1.8Hzoutputand10samplesaveraged),

output begins after an initial 5 second delay then remains

continuous at the 1.8 Hz rate. Parameters for output rate

andnumberofsamplesaveragedmaybechangedusing

software commands.

4.1 CURRENT OUTPUT

Calibrated4-20mAcurrentoutputisalwaysactive.The

connection scheme appears in the Wiring configurations

section.

The current output scale may be mapped to any part of the

500 to 1100 hPa pressure range using the IOUT HI and

IOUT LO software parameters. The standard setting maps 4

to 20 mA with 500 to 1100 hPa. With this setting:

hPa = 37.5 * mA + 350

Effectiveresolutionisabout0.15hPa

Greatereffectiveresolutionmaybeachievedbymapping

the current output to a narrower range of pressure with the

IOUT HI and IOUT LO parameters. For example, with IOUT

LO set to 950 hPa and IOUT HI set to 1050 hPa:

hPa = 6.25 * mA + 925

Effectiveresolutionisabout0.025hPa

Please see section 4.3 below for details on changing the

IOUT HI and LO parameters.

4.2 SERIAL OUTPUT

The61402Lmaybeconguredforfull-duplexRS-232,half-

duplex RS-485, or SDI-12 by using the lower jumper pair. In

addition, the upper jumpers must be set as follows:

Lower Upper Output

RS-232 (A,B,C) Continuous ASCII Text

RS-485 (B,C) Polled ASCII Text

SDI-12 (C only) SDI-12

Standardbaudrateis9600butseveralbaudratesbetween

1200and38400areavailable.

SDI-12baudrateisxedat1200.

CMD140 n sets the IOUT Pressure Range HI

CMD142 n sets the IOUT Pressure Range LO IOUT

Pressure Range HI must be greater than IOUT

Pressure Range LO

CMD144 n sets the IOUT Scale:

1 = 0 to 20mA, or 4 = 4 to 20 mA.

CMD150 c sets the poll address character for ASCII and

SDI-12 modes. Any ASCII character from ‘0’

(ASCII 48) to ‘z’ (ASCII 122) may be used. For

SDI-12 limit the characters from 0 to 9.

CMD160 n setsthebaudrate.Acceptablevaluesare

38400, 9600, 4800, 2400, and 1200. Note

that the baud rate change occurs immediately

afterthecommandisreceived.Therefore,in

order to continue communicating, the serial

communication program that issued the

command must also change to match.

CMD300 n causes the sensor to pause or resume

measurement. 1 = Stop, 2 = Run.

CMD400 n

causes the sensor to issue a report

summarizing parameter settings.

1=Text(parametervaluesandlabels)

2=CodeOnly(parametervaluesonly).

CMD420 burns the current parameter settings to flash

memory. This step musttakeplacetoretain

changes to settings otherwise parameters will

reverttopreviousvaluesatthenextpowerup.

4.4 SDI-12 COMMANDS

SDI-12 stands for serial data interface at 1200 baud. It is

often used to interface battery powered data recorders with

microprocessorbaseddevicesdesignedforenvironmental

data acquisition. SDI-12 is used typically when low power

isaconcern.TheSDI-12devicenormallyremainsina

low power, standby state until it is polled at which time

ameasurementissent.SDI-12caneffectivelyaddress

multiple sensors on the same cable.

Model 61402L uses the SDI-12 (V1.4) serial communication

protocol to initiate measurements and set sensor operation

parameters. The default sensor address is 0 (zero), and

canbechangedtoanyvalidsingle-charactervalueif

needed. Additional details about the SDI-12 protocol may

be found at www.sdi-12.org.

After initial power-up with 12 VDC, the sensor is in a low-

power standby state with a quiescent current of 1.60 mA. A

validandproperlyaddressedSDI-12commandwakesthe

sensortoinitiateameasurement,setorcheckoperating

parameters. After command processing has finished, the

sensor returns to the low-power standby state.

SDI-12 ‘M’ or ‘C’ commands initiate a measurement. The

sensor response message indicates the maximum time

neededbeforethemeasurementisready,anddatavalues

willbeavailable.Themaximumtimerangesfrom1to5

seconds depending on the Sample Count.

If an ‘M’ command initiates a measurement, the sensor

sendsaServiceRequestwhenthemeasurementisready

toberetrieved.Whenthepollingdevicereceivesthe

ServiceRequestitthensendsa‘D’commandtorequest

measurement results from the sensor. With ‘C’ commands,

noServiceRequestissent,andthepollingdevicemust

wait the full delay time before sending the ‘D’ command to

request the measurement.

SDI-12 Measurement commands and responses:

COMMAND RESPONSE DESCRIPTION

aM! attts<CR><LF> Take a measurement

aMC! attts<CR><LF> Take a measurement with CRC

checksum

aC! atttss<CR><LF> Take a concurrent measurement

aCC! atttss<CR><LF> Take a concurrent measurement

with CRC checksum

aD0! a+tttt.t+bbbb.b<CRC><CR><LF>

where:

a= Sensor address

ttt = Delay time (seconds)

s/ss = Number of samples to collect

ttt.t = Temperature (selected units)

bbbb.b = Barometric Pressure (selected units)

<CRC> = CRC checksum (only where requested)

<CR><LF> = Carriage return, line feed (ASCII 13, 10)

SDI-12 NON-MEASUREMENT COMMANDS:

The SDI-12 protocol includes standard commands for

identifying the sensor and changing its address.

CMD RESPONSE DESCRIPTION

?! a<CR><LF> Address Query

a! a<CR><LF> Acknowledge Active

aI!

a13YOUNGC092000vvvnnnnnn<CR><LF>

Send Identification: vvv = Firmware Version

nnnnnn = Serial Number

aAb! b<CR><LF> Change Address:

a = Sensor address

b = New sensor address

aV! a0000<CR><LF> Start Verification

EXTENDED COMMANDS:

The SDI-12 command set may be customized with

Extended Commands to accommodate manufacturer

settings and other functions. Extended Commands are

listed below. Where two responses are shown, one is for a

validcommand,theotherisforaninvalid(ERR)command.

COMMAND RESPONSE DESCRIPTION

aXB! aXB, OK<CR><LF>

Save parameter settings to flash.

Cycle power after saving parameters.

aXP!

aXP,V=v,OP=o,ASC=s,MP=m,OS=op,SC=sc<CR><LF>

v = voltage (120 = 12.0 volts)

o =

s =

m =

op = offset (hPa x 10)

sc = sea level correction (hPa x 10)

aXC±nnnn! aXC,SC=±nnnn<CR><LF>

Sea Level Correction (-5000 to +5000 hPa)

aXF±nnnn! aXF,OP=±nnnn<CR><LF>

Offset (-5000 to +5000 hPa)

aXM aXM, M=nnnnn<CR><LF>

Multiplier (10000 = 1.0000)

aXO aXO, O=nn<CR><LF>

Output Period (0 – 60)

aXS aXS, S=nn<CR><LF>

Sample Count (1 – 32)

5.0 MAINTENANCE

The MODEL 61402L barometer requires no regular

maintenance. Periodic calibration certification, if required,

isavailablefromthefactory.

6.0 WARRANTY

This product is warranted to be free of defects in materials

and construction for a period of 12 months from date of

initial purchase. Liability is limited to repair or replacement

ofdefectiveitem.Acopyofthewarrantypolicymaybe

obtained from R. M. Young Company.

7.0 EMC COMPLIANCE

ThisdevicecomplieswithPart15oftheFCCRules.Operation

is subject to the following two conditions: (1) this device may

notcauseharmfulinterference,and(2)thisdevicemustaccept

anyinterferencereceived,includinginterferencethatmaycause

undesired operation.

This equipment has been tested and found to comply with the

limits for a ClassA digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment

is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be

required to correct the interference at his own expense.

ThisISMdevicecomplieswithCanadianICES-001.

Cet appareil ISM est conforme à Ia norme NMB-001 du Canada.

EN55011/CISPR11,Group1,ClassBdevice.

Class B equipment is suitable for use in domestic establishments

andinestablishmentsdirectlyconnectedtoalowvoltagepower

supply network which supplies buildings used for domestic

purposes.

8.0 CE COMPLIANCE

This product has been tested and complies with European

CErequirementsfortheEMCDirective.Pleasenotethat

shielded cable must be used.

1200 BAUD

EXAMPLE:

900 ohms max load resistor = ( 24 V - 6 ) / 0.02A

supply

( V

- 6 )

0.02

load resistor (ohms) =

out

Maximum I

SET LOWER JUMPER PAIR

TO RS-485 OR RS-232

9600 BAUD

16 SAMPLE AVERAGE COUNT

1.8 HZ

WIRING CONFIGURATIONS

Table of contents

Other Novalynx Security Sensor manuals

Popular Security Sensor manuals by other brands

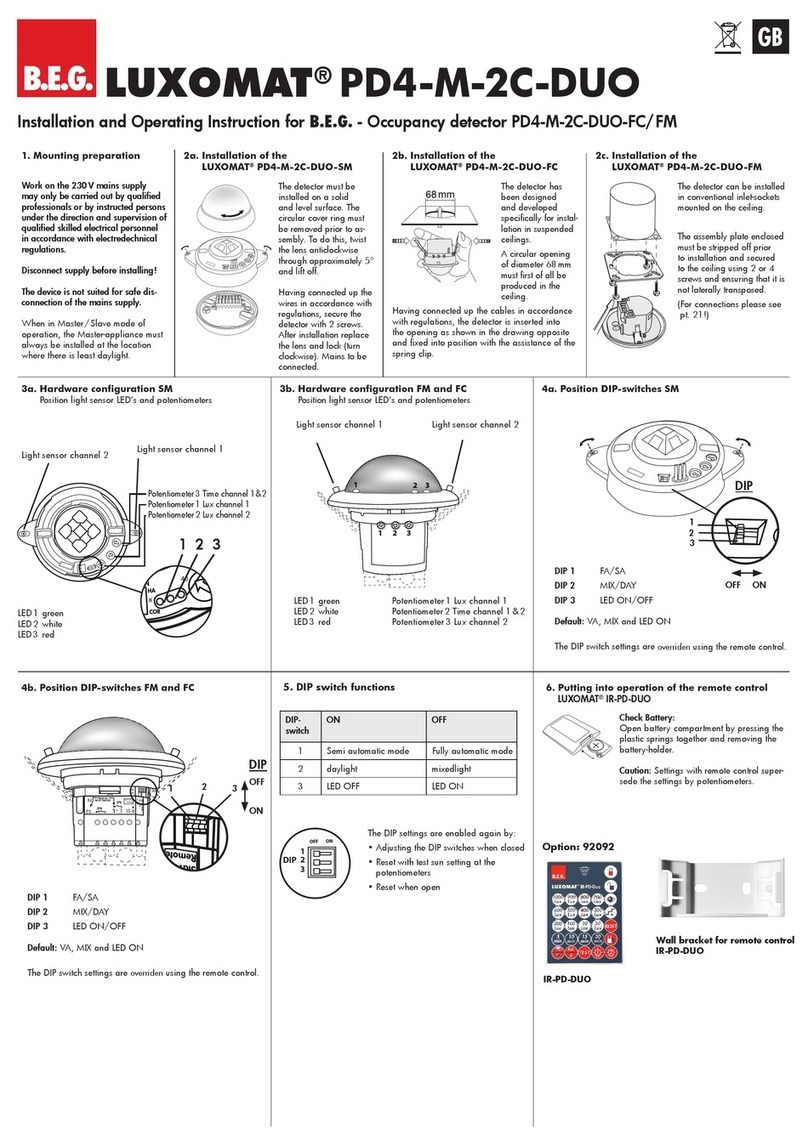

B.E.G.

B.E.G. LUXOMAT PD4-M-2C-DUO Installation and operating instructions

LEGRAND

LEGRAND CP Electronics EBDHS-KNX installation guide

Reed Instruments

Reed Instruments R9200 instruction manual

Powerfix Profi

Powerfix Profi 271367 Operation and safety notes

LEGRAND

LEGRAND Mosaic 0 489 22 manual

Elko

Elko iNELS Air AirWD-100NB instruction manual