NovaTec MCS-600 Series User manual

Phone 410-789-4811 Parts Email: parts@novatec.com

Main Fax: 410-789-4638 Sales: sales@novatec.com

222 E. Thomas Ave. Baltimore, MD 21225 USA

© 2018 NOVATEC, Inc. All Rights Reserved

MCS-649 & -696 IM 9 FEB 2018

MCS-648 & -696 SERIES

Conveying Control

MCS-648 & -696 IM 9 FEB 2018 Page 2 of 40

TABLE OF CONTENTS

SECTION PAGE

1PURPOSE OF THIS MANUAL ............................................................................................................4

1.1 Explanation of Symbols....................................................................................................................4

2SAFETY PRECAUTIONS AND WARNINGS......................................................................................5

3GENERAL DESCRIPTION .................................................................................................................. 6

4SPECIFICATIONS ...............................................................................................................................7

5PLC OVERVIEW.................................................................................................................................. 8

5.1 General.............................................................................................................................................8

5.2 Startup And Power Loss ..................................................................................................................8

6OPERATING PRINCIPLES ................................................................................................................. 9

6.1 Material Conveying System (MCS)..................................................................................................9

6.2 Vacuum Power Unit (VPU)...............................................................................................................9

6.3 Molding Machine (MMS)..................................................................................................................9

6.4 VPU FIFO Queue...........................................................................................................................10

6.5 Alarms............................................................................................................................................10

7ADDING NODES (DEVICENET PLUG & PLAY)..............................................................................11

7.1 DeviceNet Remote I/O...................................................................................................................11

7.2 DeviceNet I/O Data Map................................................................................................................11

7.3 Status Lights ..................................................................................................................................11

7.4 Network Switches...........................................................................................................................11

7.5 Connector Pin-Outs........................................................................................................................12

7.6 Typical Field Wiring........................................................................................................................12

8NODE ADDRESSES..........................................................................................................................14

8.1 Loading Station Nodes...................................................................................................................14

8.2 VPU Nodes ....................................................................................................................................14

8.3 Unused Nodes ...............................................................................................................................14

9INSTALLATION .................................................................................................................................15

9.1 Mechanical Installation...................................................................................................................16

9.1.1 Material Conveying Lines......................................................................................................16

9.1.2 Vacuum Power Unit...............................................................................................................16

9.1.3 Cyclone Filter.........................................................................................................................17

9.1.4 Station Valves........................................................................................................................17

9.1.5 Single Inlet Vacuum Chamber...............................................................................................17

9.1.6 Compressed-Air Blowback....................................................................................................17

9.1.7 Purge Valves.........................................................................................................................17

9.2 Electrical Installation ......................................................................................................................18

10 CONTROLS EXPLANATION ............................................................................................................19

10.1 PanelView Plus 1000.....................................................................................................................19

10.2 Startup............................................................................................................................................19

11 OPERATOR SCREENS..................................................................................................................... 20

11.1 Main Menu .....................................................................................................................................20

11.2 Vacuum Pumps..............................................................................................................................22

MCS-648 & -696 IM 9 FEB 2018 Page 3 of 40

11.3 MCS Station Status........................................................................................................................25

11.4 Station Setup..................................................................................................................................27

11.5 Alarm Banner .................................................................................................................................30

11.6 Alarm History..................................................................................................................................31

11.7 System Setup Screen ....................................................................................................................32

11.8 Install Stations................................................................................................................................35

12 MAINTENANCE................................................................................................................................. 36

12.1 At Startup .......................................................................................................................................36

12.2 Monthly...........................................................................................................................................36

12.3 Every 3 Months ..............................................................................................................................36

13 TROUBLESHOOTING....................................................................................................................... 38

13.1 DeviceNet Network ........................................................................................................................38

WARRANTY ...............................................................................................................................................39

WARRANTY PERIODS:............................................................................................................................. 39

LIST OF TABLES PAGE

Table 8-1: Node Addresses .......................................................................................................................14

Table 11-1: Alarm Messages.....................................................................................................................30

Table 13-1: Indicator Lights.........................................................................................................................38

MCS-648 & -696 IM 9 FEB 2018 Page 4 of 40

1 PURPOSE OF THIS MANUAL

This manual describes the installation and operation of Novatec’s MCS-600 Series Material Conveying

System controller. Before installing this product, please read in their entirety, this guide and any

additional guides associated with the system’s auxiliary equipment.

1.1 Explanation of Symbols

This manual includes both general and task-specific safety precautions. These precautions are

highlighted in the manual by the following categories:

WARNING: This symbol identifies situations thatare potentially hazardous to

personnel or equipment.

NOTE Highlights information provided in text or procedures. This information may

or may not be related to safety.

MCS-648 & -696 IM 9 FEB 2018 Page 5 of 40

2 SAFETY PRECAUTIONS AND WARNINGS

These operating instructions must be read, understood, and implemented by all personnel responsible for

this system.

All mechanical and electrical work must be performed by qualified personnel only.

Always disconnect power before servicing.

Refer to the machine nameplate and drawings supplied with this system for actual power requirements.

Be sure to install the equipment in the proper electrical area according to the NEMA rating

specified. Care must be taken to adhere to all national and local regulations.

Electric power supply should be through a separate disconnect switch with properly sized

overload/fuse protection.

Thread protectors and caps provided on solenoid valves, traps, pipe ends, etc. must be removed

prior to start-up.

The customer is required to operate the equipment with all safety features in proper working

condition.

Novatec shall provide no further guarantee for function and safety in the event of unauthorized

modifications.

MCS-648 & -696 IM 9 FEB 2018 Page 6 of 40

3 GENERAL DESCRIPTION

The Novatec MCS-600 Series controller is a custom-programmed Allen-Bradley PLC-based control

system designed to incorporate existing and future equipment. The Material Conveying System (MCS)

will control up to120 JIT chambers and 20 Vacuum Pump Units (VPU).

Future loading stations are made available to operations on a password protected screen. Assignments

for current and future VPUs and Stations may be changed via a password-protected screen on the HMI.

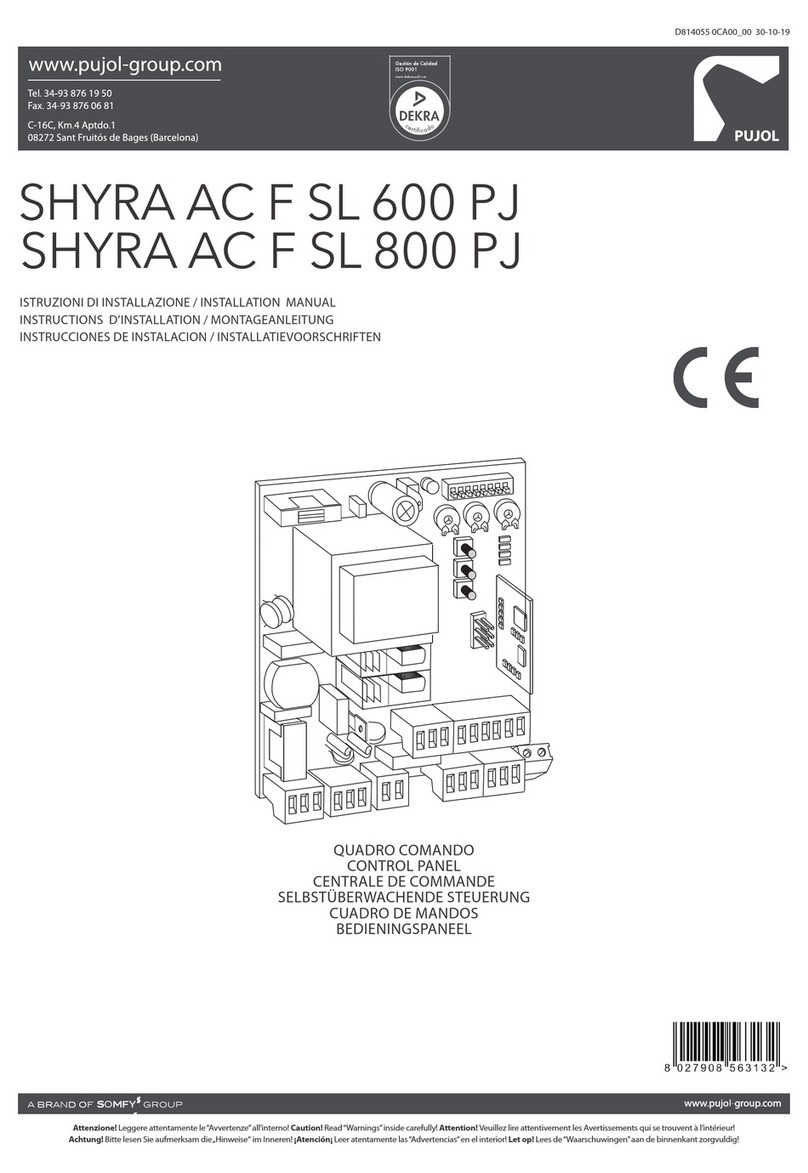

Figure 1: MCS-600 Series Enclosure and Back-Panel.

Optional Ethernet

Module

MCS-648 & -696 IM 9 FEB 2018 Page 7 of 40

4 SPECIFICATIONS

Description

Material Conveying System Controller

Model No

MCS-648

MCS-696

Performance Specifications

Max No. of Dryers

4

8

Max No. of Vacuum Power Units

8

16

Max No. of Vacuum Receivers

48

96

Main PLC

Allen-Bradley CompactLogix L32E

Base Operator Interface

Allen-Bradley PanelView Plus 1000

Remote Operator Interface

N/A

Communications

DeviceNet, Ethernet

Output Voltage to Devices

24 VDC

Input Voltage from Devices

24 VDC

Dimensions (H x W x D) Inches

Main Base Unit

24 x 20 x 8

Remote I/O Base Unit

N/A

Power Requirements

Electrical Classification

NEMA 4 / 12

Base Unit

115 / 1 PH / 60HZ

DeviceNet I/O Power Supply

90 - 264 VAC, 50 - 60 HZ or 110 - 375 VDC, 2-4 Amps

Program Information

Operator Interface

-

PLC

-

MCS-648 & -696 IM 9 FEB 2018 Page 8 of 40

5 PLC OVERVIEW

5.1 General

The MCS-600 Series Material Conveying System Controller utilizes a centrally mounted PLC that

sends commands over the DeviceNet network to various conveying system components. A

remote I/O block controls each pump, station, loader, etc. The physical device and its associated

electronics form a ‘node’. Refer to the specifications page for the maximum number of Loading

Station and Vacuum Pump nodes supported by this system.

This type of control system requires much less wiring in order to install and maintain the material

conveying system.

The MCS’s programming allows for additional equipment to be installed at a later date without re-

programming.

5.2 Startup And Power Loss

When power is first applied to the PLC following a power loss, the system will automatically start loading

enabled stations that have material demand if the AUTO START ON POWER UP mode has been

selected. If a Loading Station or Vacuum Pump is enabled, as indicated by ON, it will remain enabled.

This prevents the operator from having to restart each piece of equipment. When first starting up, each

station will have to be configured with the proper vacuum pump assignment, load, fill and dump times, no

load alarm cycles, material number, and be enabled.

In the System Setup page is the button defining the power up mode:

This button allows the user to select the start-up mode for the

control panel: AUTO or MANUAL power up. In AUTO START ON

POWER UP, the control panel will automatically start filling

stations if they are enabled and demand material when power is applied to the panel. In MANUAL

START ON POWER UP, the system is paused and the user must press the SYSTEM START button to

begin loading stations.

When the system is paused, a large red indicator

button will appear on top of all screens to indicate

that the system is in PAUSED mode. Pressing the

red button will enable the system and put it in

SYSTEM RUNNING mode.

MCS-648 & -696 IM 9 FEB 2018 Page 9 of 40

6 OPERATING PRINCIPLES

6.1 Material Conveying System (MCS)

The program controls the operation of loading the Dryers from the Gaylords to filling the JIT

chambers on the Molding Machines from the Dryers. The MCS controls the operation of the

Vacuum Pump Units (VPU), the station “Tee” valves and the Purge (Source) valves. The MCS

must be in RUNNING mode for any conveying to take place. The MCS will default to STOPPED

mode on power loss. Starting or stopping the MCS will not reset the various station controls.

6.2 Vacuum Power Unit (VPU)

Each VPU is hard piped to multiple stations. Stations may be assigned to any VPU.

CAUTION: Care must be taken to verify that the mechanical connection of a station

valve to a VPU matches the VPU assignment of thatparticular station

A VPU will start when an associated loading station calls for material. The VPU will run for the

LOAD and PURGE portions of a fill cycle, plus a settable SEEK time. If no other station calls for

material, the VPU will shut down after the seek time expires. A new station calling for material

will reset the seek timer and begin a new fill cycle. The seek timer is accessible from the HMI

and has a default value of 120 seconds.

6.3 Molding Machine (MMS)

Each molding machine/press is equipped with a JIT Chamber complete with level switch.

The MMS control station consists of an Enable/Disable maintained pushbutton, Station Status

readout, Source okay/mismatch indication, and connected source readout. Enabling of a MMS

permits it to be automatically serviced by the conveying subroutine. A MMS may be Enabled or

Disabled at any time. If a MMS is in a fill cycle when it is disabled, the cycle will continue to

completion. MMS status indications are:

OFF – The MMS is Disabled

ENABLED – The MMS enabled, not in the fill cycle and the level switch is satisfied

DEMAND – The MMS is not in the fill cycle and the level switch calls for material

LOAD – The MMS is in the load portion of the fill cycle

PURGE – The MMS is in purge portion of the cycle

DUMP – The MMS is in the dump portion of the fill cycle

ALARM – MMS has gone through the no load alarm setpoint of consecutive fill cycles

without satisfying the level prox sensor.

The MMS number is moved into the appropriate VPU FIFO queue if the MMS is in demand. The

default setting for MMS VPU assignment is VPU1. The MMS fill cycle consists of three states,

LOAD, PURGE and DUMP. When the MMS is first in line, the VPU will start if not already

MCS-648 & -696 IM 9 FEB 2018 Page 10 of 40

running and the station T valve will open at the start of the fill cycle. Pellets will be conveyed from

the source to the vacuum chamber. The T valve will remain open for the load and purge times.

When the load time expires the dryer source valve closes and the purge time begins. The purge

time allows any pellets in the conveying line to be carried into the JIT chamber. When the purge

timer expires the station T valve is closed and the dump timer started. The VPU FIFO stack

advances to service the next station at the end of the purge time. Any pellets in the vacuum

chamber will be gravity conveyed into the press hopper.

If the level switch is not satisfied at the end of the dump time, the MMS will be placed back at the

end of the VPU queue. The load, purge, and dump setpoints are changeable via the HMI and

have default values of 15 seconds.

6.4 VPU FIFO Queue

Each VPU has a First In/First Out (FIFO) queue. Any station may be assigned to any VPU. The

queue contains the MMS number (1 to 120). The VPU services each station in the order in which

the demand was entered. A station is removed from the queue at the end of the purge cycle. At

this time the VPU begins to service the next station in the queue, if any. A station is still in

demand at the end of the dump cycle will be reentered into the queue. If there are no other

stations in the queue, the fill cycle will repeat as soon as the dump cycle is complete.

6.5 Alarms

Each MMS has a No Load fault. If the station is serviced the setpoint number of times in

succession without satisfying the level switch, the alarm flag is set. The alarm will be cleared

when the demand is satisfied, or the station is disabled. The number of cycles is field changeable

through the HMI, with the default value set at 3. Entering a value of zero (0) will disable the

alarm. A station will continue to load if the alarm is on.

The VPUs have motor failure alarms. The motor failure alarm is set whenever the motor is called

to run, but the motor aux contact input is not made after 3 seconds. The alarm is cleared only by

pressing the “ALARM RESET” button on the alarm history or banner page or the vacuum pump

status pages. Once a vacuum pump is in an alarm state, the controller will not allow that vacuum

pump to attempt to convey until the alarm is cleared.

MCS-648 & -696 IM 9 FEB 2018 Page 11 of 40

7 ADDING NODES (DEVICENET PLUG & PLAY)

Each network device is assigned its own DeviceNet Node by installing a remote busstop® station at the

device. Refer to the wiring diagrams included with this manual for additional information.

7.1 DeviceNet Remote I/O

The DeviceNet busstop station has four inputs and four outputs. The input and output circuits are

combined in one connector.

Each connector has both an input LED and

an output LED associated with it. The LED

turns green if the I/O point is on. Inputs are

monitored for short-circuit protection as a

group. Outputs are monitored for short-

circuit protection as a group.

The node address can be set using the

rotary switches located under the device

cover or through software node

commissioning. The unit can automatically

detect the network communication rate.

The busstop station supports explicit

messaging, poll, change of state, and cyclic

I/O messages. These connections are

established through UCMM or predefined

master/slave connection set.

7.2 DeviceNet I/O Data Map

Func

Byte

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

In

0

IGS

OGS

I-3

I-2

I-1

I-0

Out

0

-

-

-

-

O-3

O-2

O-1

O-0

Abbreviations

I = Input Data (0=OFF, 1=ON) O = Output Data (0=OFF, 1=ON)

OGS = Output Group Status (0=Working, 1=Fault) IGS = Input Group Status (0=Working, 1=Fault)

7.3 Status Lights

Each DeviceNet station contains network and module status indicator lights. Refer to the

Troubleshooting section for details.

7.4 Network Switches

Network

Switches

0 - 63

4 Combined Inputs/

Outputs, “C” Type

(C0-C3)

C2

C3

C0

C1

Ground

Connection

DeviceNet

Connectors

MCS-648 & -696 IM 9 FEB 2018 Page 12 of 40

Set the network switches to the unique address assigned to the equipment as described in

Section 8.

7.5 Connector Pin-Outs

DeviceNet Connector Through Bus

Connector: 5-Pin minifast

1 = Shield

2 = V +

3 = V -

4 = CAN_H

5 = CAN_L

Combined I/O Connectors

Single Sensor

Part Verification Array

Connector: 5-Pin eurofast

Type “C”

1 = V +

2 = Output Signal

3 = GND

4 = Input Signal

5 = PE

Single Output

Push Button

7.6 Typical Field Wiring

Typical field wiring terminations for the busstop block are listed below. This arrangement may

vary depending on system requirements and complexity. C2 and C3 can be field configured for a

Material Purge Valve, Vacuum Receiver Blowback, or Vacuum Receiver Proportioning Valve.

The “Devicenet I/I Mapping” button will appear on the main menu when the password level is

“level3” or higher.

The defaults are:

Connector

Connected Device

C0

Input – Material Low Level Limit Switch

MCS-648 & -696 IM 9 FEB 2018 Page 13 of 40

C1

Output – Station Valve

C2

Output – Vacuum Receiver Proportioning Valve

C3 Output – Vacuum Receiver Blowback

MCS-648 & -696 IM 9 FEB 2018 Page 14 of 40

8 NODE ADDRESSES

Refer to the table below for a complete list of addressable nodes.

8.1 Loading Station Nodes

Each loading station has its own DeviceNet Node. The node number must match the default

station number. Station 1 is node 1 and station 17 is node 17, for example. The program is

written as if all loading stations are installed. To add a node after the original installation and

start-up, set the node number equal to the station number and connect the node to the DeviceNet

trunk. The I/O devices connected to each node are connected to the same point on every node.

Thus the I/O and programming for each loading station and node match up.

NOTE Node and station numbers are not required to be sequential.

8.2 VPU Nodes

Each VPU has its own DeviceNet Node. The I/O devices connected to each node are connected

to the same point on every node. Thus the I/O and programming for each node and VPU match

up.

8.3 Unused Nodes

Each DeviceNet scanner Module is limited to a total of sixty-three (63) nodes. An additional

DeviceNet module may be installed to add more nodes to the system.

Table 8-1: Node Addresses

DeviceNet Scanner Module 1

Installed in MCS-648 / 696

DeviceNet Scanner Module 2

Installed in MCS-696 only

Node

Address

Device

Node

Address

Device

0

PLC

0

PLC

1 - 48

Loading Stations 1 - 48

1 - 48

Loading Stations 49 - 96

49 - 56 Vacuum Power Units 1 - 8

49 - 56 Vacuum Power Units 9 - 16

57 - 58

Purge (for gaylords, etc.)

57 - 58

Purge (for gaylords, etc.)

59

Proofing (Sources)*

59

Proofing (Sources)**

60

Proofing (not used)*

60

Proofing (Destinations)**

61

Spare/Alarm

61

Spare

62 Hand-held scanner

62 Hand-held scanner

63

Programmer’s Laptop

63

Programmer’s Laptop

AutoID Proofing Standard Device Mapping

* Module 1 (NODE 59) – Sources 1 through 16 mapped to Network 1 Nodes 1 – 16.

* Module 1 (NODE 60) – Not used.

MCS-648 & -696 IM 9 FEB 2018 Page 15 of 40

**Module 2 (NODE 59) – Sources 17 through 32 mapped to Network 1 Nodes 17 – 32.

**Module 2 (NODE 60) – Destinations mapped to Network 2 Nodes 1 – 48.

9 INSTALLATION

After unpacking and inspecting the MCS Controller, four basic activities will be performed. These activities

are:

1. Completely install stations and station valves, pumps, and other mechanical components.

Run material conveying lines.

2. Locate and mount the electrical controls for the main base unit, pumps, dryers, etc.

3. Install the node DeviceNet blocks and run communication wiring. Wire the equipment to the

node blocks per the wiring diagram. Install DeviceNet power supplies.

4. Assign addresses to pumps and stations.

All national and local electrical, building, and safety codes need to be followed. Proper grounding of all

equipment is important. Check the electrical wiring schematic for wiring numbers and details. The

following paragraphs describe installation of typical system components. Some of them are optional and

may not be required for your system.

CAUTION: The conveying lines must be grounded to prevent "shocks" from static electricity

that are generated by some materials as they are conveyed. This is an extremely important

step.

All electronics are susceptible (to varying degrees) to electrostatic damage and, although as

much protection as possible has been designed into the system, this cannot completely

eliminate upsets due to electrostatic voltage being accidentally introduced into the electronic

circuitry.

Generally, grounding the case of the container from which the material is being conveyed

(including the lines) to the same potential as the green wire ground of the conveying system

eliminates most of this problem.

MCS-648 & -696 IM 9 FEB 2018 Page 16 of 40

9.1 Mechanical Installation

9.1.1 Material Conveying Lines

The single most important activity performed to ensure satisfactory operation of a

pneumatic conveying system is the actual installation of the equipment. All components

should be located so that material lines and vacuum lines are as short as possible.

Elbows or other changes in direction should be minimized. The material conveying line

should be horizontal and/or vertical and as direct as possible with no slope. Care needs

to be taken that all connectors are vacuum tight. All rigid conveying tubing should be

properly supported by the customer to provide a safe and secure installation.

It is generally recommended to use flexible hose and clamps to connect material pick up

lances, vacuum chambers, etc, to material or vacuum lines. The flexible hose should only

be as long as needed since excess hose will reduce the efficiency of the system. The

hose should not sag.

Rigid tubes and elbows should be connected together with bolted couplers. Each tube

end should be square cut, round, and without burrs. The tube ends should butt together

when installed, with the bolted coupler centered over the joint.

9.1.2 Vacuum Power Unit

Locate the vacuum power unit so that access to the secondary filter element mounted to

the unit is available. Secure to the floor or platform as necessary. Attach high voltage

(check nameplate) to the motor starter located in the motor starter junction box mounted

to the vacuum power unit FROM A FIELD-SUPPLIED DISCONNECT SWITCH or to the

optional combination starter with integral fused disconnect switch. An electrical ground

wire is also required. Attach DeviceNet cables as shown in the wiring diagrams supplied

with this manual.

A clean, dry supply of 80 -120 PSIG compressed air must be connected to the pressure

port on the vacuum breaker valve solenoid valve. When the vacuum breaker valve is

energized, it allows ambient air to pass through the vacuum blower. This is done instead

of shutting the pump down to prevent premature wearing of the pump and belt drive

caused by constantly starting and stopping the pump. Eventually the pump will shut

down completely (if not needed) when the search timer expires. Note that the default

time programmed into the search timer of the system is 120 seconds when the system is

first shipped to you. If the pump seems to be shutting down after an usually short or long

period, check the programmed search timer value.

MCS-648 & -696 IM 9 FEB 2018 Page 17 of 40

9.1.3 Cyclone Filter

Locate the cyclone filter as close as possible to the vacuum power unit. Provide access

for the material catch pan or fines drum as necessary. Secure the cyclone filter to the

floor. Attach vacuum lines from the conveying system to the cyclone inlet (tangential inlet

on the side of the cyclone body). Attach the cyclone outlet (top duct) to the vacuum

breaker valve inlet on the vacuum power unit.

9.1.4 Station Valves

Locate near each station’s vacuum chamber. Typically, the station valve is rigidly

attached with bolted couplers to the cyclone filter vacuum lines while running rigid tube or

flex hose to the lid of the vacuum chamber. The station valve solenoid is wired to the

DeviceNet network. Ground the system as necessary. A clean, dry supply of 80 - 120

PSIG compressed air is connected to the pressure port on the station valve’s solenoid

valve.

9.1.5 Single Inlet Vacuum Chamber

Secure the chamber to the hopper or surge bin as required. Orient the material inlet line

and vacuum outlet line as required. Flex hose is normally used to connect the vacuum

chamber to the supply line and station valve. Connect the material level switch wires to

the DeviceNet network.

9.1.6 Compressed-Air Blowback

Some vacuum chambers (single and dual inlet) are provided with a compressed air

blowback solenoid valve for cleaning the filter depending on the application. The pulse

blowback solenoid valve is wired to the DeviceNet network. A clean, dry supply of 80 -

120 PSIG compressed air is required. Connect it to either the compressed air

accumulator tank supplied on large vacuum chambers or directly to the pulse blowback

solenoid valve that is supplied on small vacuum chambers.

9.1.7 Purge Valves

Purge valves are typically installed at the silo, hopper, blender, or other material outlets

where conveying lines must be emptied between load cycles. A clean, dry supply of 80 -

120 PSIG compressed air is required. The solenoid valve located on the body of the

purge valve must be wired to the DeviceNet network as shown in the wiring diagrams

MCS-648 & -696 IM 9 FEB 2018 Page 18 of 40

9.2 Electrical Installation

Always disconnect and lock out the main power supply before wiring power and communication

cables between the MCS controller and the network devices. Refer to the wiring diagram and

general arrangement drawings supplied with this system before making electrical connections.

Use shielded cable for communications wiring.

Keep communication cables as far as possible from high voltage equipment.

Avoid running communication cable across power lines. If you must run cable across power

lines, run the cable at right angles to the line.

Ensure the equipment grounding is properly connected. Shielded cable should be grounded

at one end only and is typically grounded in the main I/O enclosure.

WARNING: Do not install communication cable where it will come into contact

with any buildup of electrical charge!

It may be tempting to run the wire next to the material conveyi

ng lines, but a

substantial buildup of electrical charge can and will occur, especially with certain

types of plastic resins and, if the conveying lines are not grounded, can arc to the

cable disrupting communications and/or possibly causing damage.

MCS-648 & -696 IM 9 FEB 2018 Page 19 of 40

10 CONTROLS EXPLANATION

10.1 PanelView Plus 1000

The PanelView Plus 1000 is an operator interface with touch-screen entry. The color screens are

graphical in nature and display information in text and/or color change. The screens permit data

entry via touch. The PanelView is equipped with DeviceNet and Ethernet I/P communication.

The PanelView communicates with the Allen-Bradley CompactLogix L32E PLC using Ethernet.

10.2 Startup

When power is first applied to the PanelView the Main Menu screen is displayed. Since no user

is logged into the system at startup, DEFAULT is indicated in the user display.

Depending on system configuration, some buttons may not be visible on your screen.

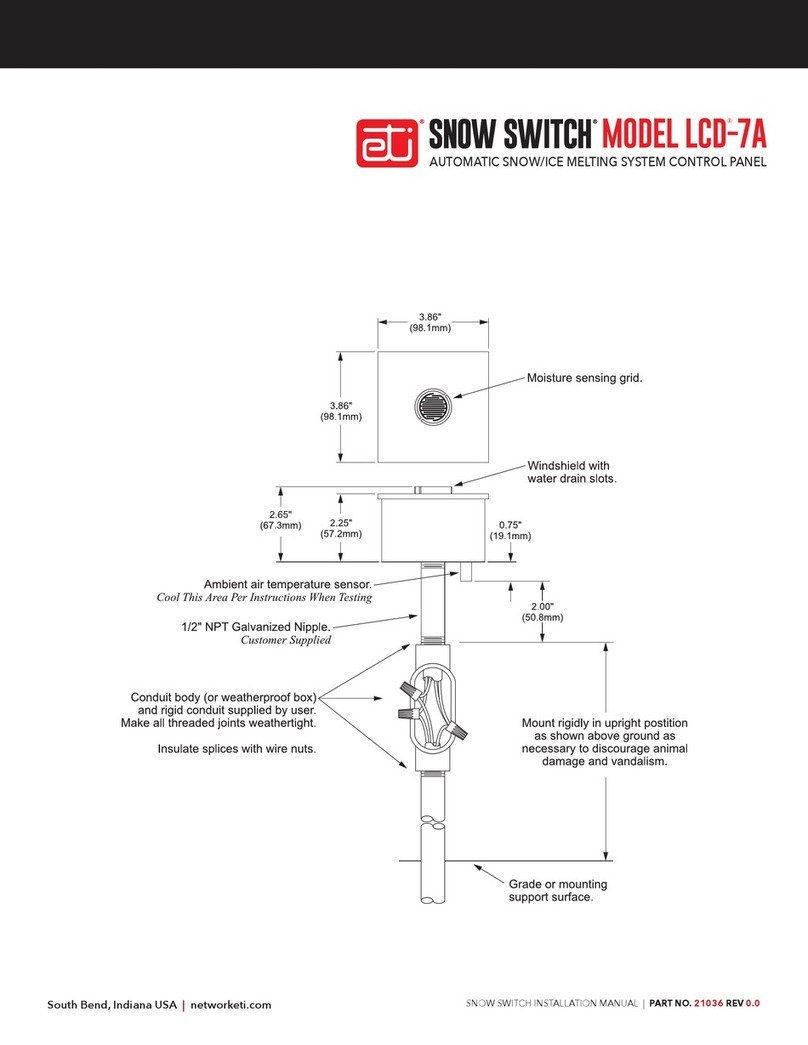

Figure 2: Default Menu

MCS-648 & -696 IM 9 FEB 2018 Page 20 of 40

11 OPERATOR SCREENS

11.1 Main Menu

The Main Menu screen has pushbuttons (PB) to navigate to other screens. The screens include

the MCS (Main Conveying System), VPU (Vacuum Pump Units), and Alarms. Log In and Log

Out buttons are provided along with a display of the current user. The DEFAULT and

OPERATOR users have access to operation screens. An administrator must be logged on to

have access to the CONFIGURATION screens. The only admin Log-On is level3.

When an administrator is logged on, additional pushbuttons become visible. These buttons allow

access to maintenance and setup screens.

Figure 3: Novatec Logon

These buttons allow the user to view, log in, and log out of the current user log in

level. The log in levels and default passwords are listed below:

level1 : 1111

level2 : 2222

level3 : 3333

This manual suits for next models

2

Table of contents