10

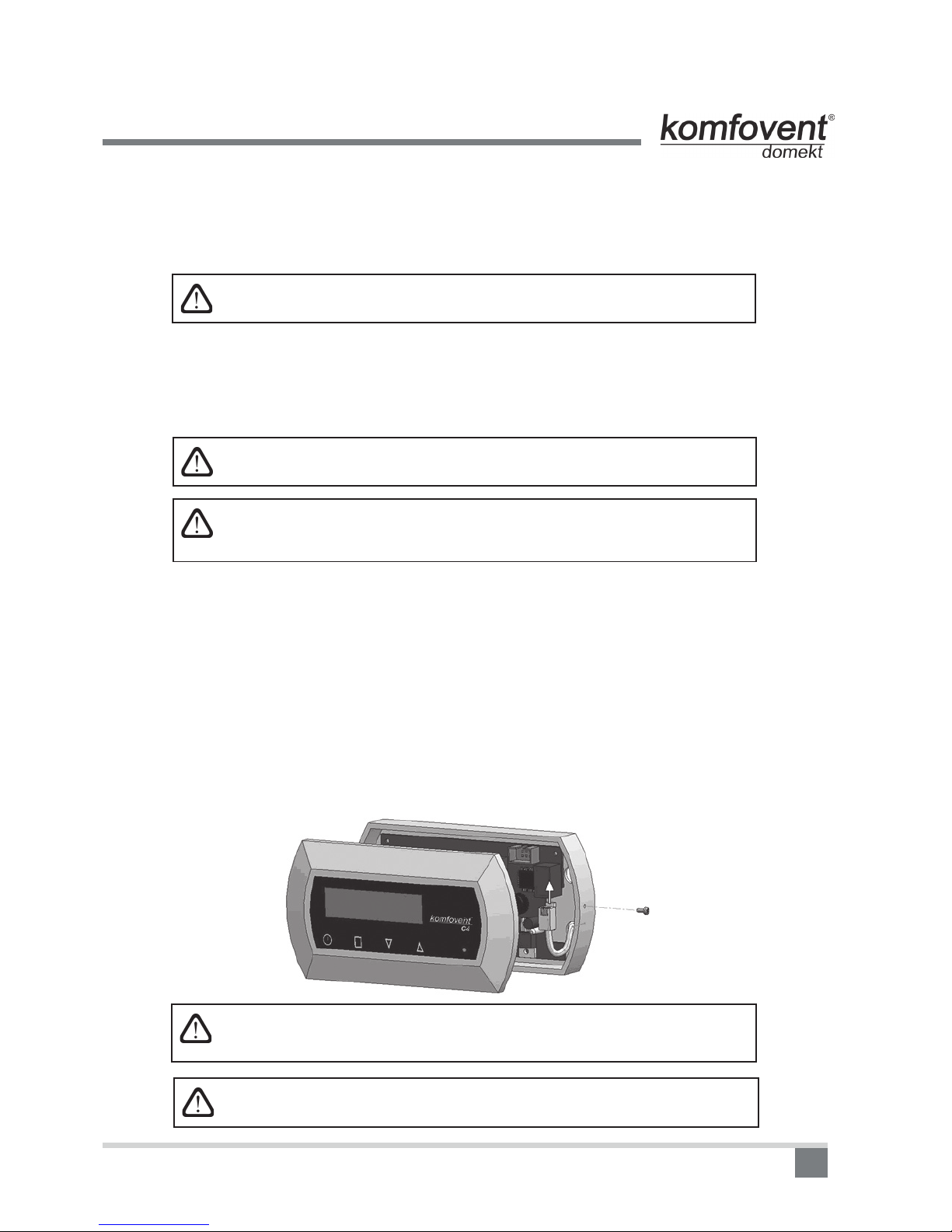

9. Language setting

Language selection menu has been projected on the control panel. To set language the last menu window

should be selected:

10. Menu locking

The PIN code is provided to lock entering to the parameters setting menu. If the menu is locked, only main

parameters can be reviewed also the unit may be switched on or off.

To enter the PIN code, touch + and hold for 4 seconds till corresponding window appears:

To enter the PIN code follow these steps:

1. Touch or to enter the rst digit.

2. Touch to go to the second digit.

3. Repeat the steps above to enter the second and the third digits.

4. After third digit is entered touch to conrm the code.

5. Touch and and hold for 4 seconds to save the code into controller memory.

The menu can be unlocked only with the PIN code. If the code is forgotten,

contact local service team.

2.6. OVR function

OVR (Override) function is intended for remote unit control by an additional external device. After the activation

of this function the current mode of operation will be ignored and the unit will operate at a set intensity.

Applications of the OVR function:

• Maintenance of CO2quantity in room – by adding an additional CO2sensor (with relay), the main user-set

ventilation rate at higher CO2will be switched to the maximum intensity until the room is ventilated, and then again

will return to the user-dened intensity.

• Maintaining relative humidity in the room – after contacting the external relative humidity sensor (with

relay), automatically switching to maximum or different set ventilation intensity the humidity level desired by the

user will be maintained.

• Ventilation on demand – when the motion sensor is connected to the control contacts, ventilation will

be adjusted according to demand, i.e. if people are indoors, ventilation will be carried out according to the set

OVR intensity and if there‘s nobody in the room - the unit will operate according to the main user intensity, for

example, the minimum.

• Ventilation with additional air extraction – connection of additional extracting device, for example, a kitchen

hood or other extraction device without a separate fan, is intended, thus the air extraction is carried out by the unit itself.

After the activation of the function the supply and exhaust air fans start operating at maximum intensity.

Operation Manual