Novatek-electro MCK-108 User manual

«NOVATEK-ELECTRO» LTD

Intelligent Industrial Electronics

PUMPING PLANT

CONTROLLER

MCK-108

OPERATING MANUAL

Quality control system on the development and production complies with requirements ISO 9001:2015

Dear customer,

Company NOVATEK-ELECTRO LTD. thanks you for purchasing our products.

You will be able to use properly the product after carefully studying the Operating Manual.

Keep the Operating Manual throughout the service life of the product.

UKRAINE, Odessa www.novatek-electro.com

~ 2 ~

MCK-108

NOVATEK-ELECTRO

ATTENTION! ALL REQUIREMENTS OF THIS OPERATING MANUAL ARE COMPULSORY TO BE MET!

WARNING! –PRODUCT TERMINALS AND INTERNAL COMPONENTS ARE UNDER

POTENTIALLY LETHAL VOLTAGE.

TO ENSURE THE PRODUCT SAFE OPERATION IT IS STRICTLY FORBIDDEN THE

FOLLOWING:

TO CARRY OUT MOUNTING WORKS AND MAINTENANCE WITHOUT DISCONNECTING THE

PRODUCT FROM THE MAINS;

TO OPEN AND REPAIR THE PRODUCT INDEPENDENTLY;

TO OPERATE THE PRODUCT WITH MECHANICAL DAMAGES OF THE CASE.

IT IS NOT ALLOWED WATER PENETRATION ON TERMINALS AND INTERNAL ELEMENTS OF THE

PRODUCT.

During operation and maintenance the regulatory document requirements must be met, namely:

–Regulations for Operation of Consumer Electrical Installations;

–Safety Rules for Operation of Consumer Electrical Installations;

–Occupational Safety when in Operation of Electrical Installations;

~ 3 ~

NOVATEK-ELECTRO MCK-108

This Operating Manual is intended to familiarize you with the design, the requirements for safety, operation

and maintenance procedures of the pumping plant controller MCK-108 (hereinafter referred to as either MCK-108

or the device).

MCK-108 complies with the requirements of:

IEC 60947-1; ІEC 60947-6-2; CISPR 11; IEC 61000-4-2.

Harmful substances in amounts exceeding maximum permissible concentrations are not available.

TERMS AND ABBREVIATIONS

List of Used Abbreviations:

EL –Emergency Level CPG - Contact Pressure Gauge

UL –Upper Level AR time - Automatic Reset time

LL –Lower Level

DR –Dry Run

MS –Magnetic Starter

Conduction-measuring sensor of liquid level is a sensor, the operating principle whereof is based on the increase

of electrical conduction between the common and the signal electrodes, if there is liquid between them.

Contact pressure gauge (CPG) measures pressure, produced by liquid. For instance, one can determine the

liquid level in the tank by measuring pressure at the bottom of a tank (an outlet pipe).

The pressure gauge used in MCK-108 must correspond to type V (must have two contacts one of which must

be a break contact (closed at low pressure); the second contact must be a make one (closing at high pressure); if

pressure is between the high and the low levels, both contacts must be broken).

Note - As usual, CPGs with two contacts have universal (transfer) contacts and the necessary type of CPG can be

set be the user.

Filling mode - In this mode,MCK-108 controls the pump, filling the outer tank by pumping water from the well.

Drainage mode is used for pumping liquid out of the well, for instance - in sewerage stations.

Two pumps may be used in the filling mode. For balancing the tear-and-wear, the user can set the alternate

operation of the pumps.

To prevent failure of the electric motor while draining the well one may use a dry run sensor (conduction-

measuring dry run sensor is located in the well). After deactivation of the pump electric motor due to dry run failure,

the pump activation delay is provided for the time of filling the well (the delay time is determined by the AR time

(automatic reset time) parameter and can be set by the user).

1. APPLICATION

The MCK-108 is designed to create technological processes automation systems, related to control and

maintaining of a set level of liquid substances in different kinds of tanks by controlling an electric motor (or electric

motors) of one or two pumps.

There is no amount of harmful substances, exceeding the maximum allowable concentration.

Maintaining of a set level of liquid substances is performed:

- in case of single-phase motor with capacity of up to 1 kW - by controlling the integrated pump relay;

- in case of three-phase motor or single-phase motor with capacity of over 1 kW - by controlling the magnetic

starter coil (contactor).

MCK-108 provides controlling of the electric motor (electric motors) of one or two pumps in an automated

mode according to one of the algorithms integrated into the device.

MCK-108 provides working with liquids of various electrical conduction - tap water and polluted water, milk and

food products (low-acid, alkaline etc.).

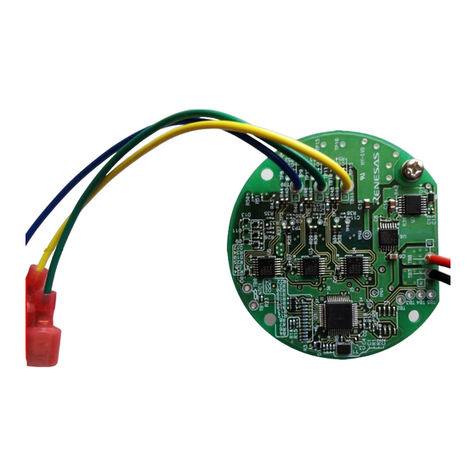

1.1Controls and overall dimensions of MCK-108 are specified in figure 1.

1.2 Designation of contacts

1 –sensor "DR" (Dry Run);

2 –normally broken contact of the functional relay;

3 –normally closed contact of the functional relay;

4 –common contact of the functional relay;

5 –common contact of the pump relay;

6 –normally broken contact of the pump relay;

7, 8 –power supply;

9 –sensor "LL" (Lower Level);

10 –sensor "UL" (Upper Level);

11 –sensor "EL" (Emergency Level);

12 –common contact for sensors.

~ 4 ~

MCK-108

NOVATEK-ELECTRO

1 –LED Func (Function) glows green if the functional relay contact is closed;

2 –LED Pump glows green if the pump relay contact is closed;

3 –Switch Dr –Fi (Drainage –Filling) sets either the drainage or the filling mode;

4 –Switch CPG –S. L. (CPG –Level Sensor) sets either the contact pressure gauge (CPG) or level sensors mode;

5 –Switch Off - DR allows operation of the dry run sensor;

6 –Switch Off - EL allows operation of the emergency level sensor;

7 –Switch 1 –2 sets the number of pumps in use;

8 - Handle Тhs adjusts the sensor response delay time (hydraulic shock);

9 –Handle Таradjusts the automatic reset (AR) time after failure of DR sensor;

10 –Handle Sens adjusts sensor resistance for various environments;

11 –LED DR (Dry Run) glows green if the liquid level is higher than the dry run sensor; glows red if the liquid level is

lower than the dry run sensor; and blinks green if the liquid level is higher than the dry run sensor, but AR time has not

elapsed yet; does not light up if switch Off –DR is in “Off” position.

12 –LED LL (Lower Level) glows green the liquid level is higher than the lower level sensor. If the liquid level is

lower than the lower level sensor, in the filling mode it glows red, while in the drainage mode it blinks green;

13 –LED UL (Upper Level) glows red if the liquid level is higher than the upper level sensor;

14 –LED EL (Emergency Level) glows red if the liquid level is higher than the emergency level sensor, if the liquid

level is lower than the emergency level sensor or switch Off –EL is in “Off” position LED does not glows.

Figure 1- Controls and overall dimensions of MCK-108

1.3 Operation conditions

- Operating temperature range –from -35 to +55 ºC;

- Atmospheric pressure –from 84 to 106,7 кPa;

- Relative humidity 30 … 80 % (at +25 ºС temperature).

If the temperature of the product after transportation or storage differs from the environment temperature at

which it is expected to operate, then before connection to electric mains keep the product under the operating

conditions within two hours (because the product elements may have moisture condensation).

ATTENTION! The device is not intended for operation in the following conditions:

−Significant vibration and shocks;

−High humidity;

−Aggressive environment with content in the air of acids, alkalis, etc., as well as severe

contaminations (grease, oil, dust, etc.).

2TECHNICAL CHARACTERISTICS

General data for MCK-108 are specified in Table 1.

The main technical characteristics of MCK-108 are specified in Table 2.

The characteristics of the integrated relays output contacts are specified in Table 3.

~ 5 ~

NOVATEK-ELECTRO MCK-108

Table 1 - General Data

Name

Value

Purpose of device

Control and distribution equipment

Rated operating regime

continuous

Protection class

IP20

Electric shock protection class

II

Climatic version

NС3.1

Allowable pollution rating

II

Overvoltage category

II

Rated insulation overvoltage, V

450

Rated impulse withstand voltage, kV

2.5

Connecting terminals wire section, mm2

0.5 –2

Tightening torque of terminal screws, N*m

0.4

Table 2 - The main technical characteristics

Name

Value

Rated supply voltage: single-phase 50 Hz, V

230/240

Voltage, at which operability is maintained:

- minimum, V

- maximum, V

130

265

Mains frequency, Hz

48 –62

Analog Inputs:

- input for connecting level sensor (of pressure)

- general for level sensors (of pressure)

4

1

Main outputs:

- pump relay - make contact for controlling electric motor starter - 10 A 250 V at cos

φ=1, piece

- functional relay –transfer contact - 10 A 250 V at cos φ=1,piece

1

1

Controlled environment resistance for conduction-measuring sensor, kiloohm, not

more than

450

Power consumption (under pressure), not more than, W

3.3

Weight, not more than, kg

0.2

Overall dimensions, mm

Figure 1

Installation onto standard 35 mm DIN rail

The device preserves functionality in any position within the space

Casing material –self-extinguishing plastic

Table 3 - The characteristics of the integrated relays output contacts

Operating

regime

Max. current at

U~250 V, A

Number of trips

х1000

Max. switching

power, VA

Max. current at

Uconst.=30 V, A

cos = 0.4

cos = 1.0

5

10

50

100

4000

3

3 INTENDED USE

3.1 Preparation for operation

3.1.1 Preparation for connection:

–Unpack the product (we recommend to keep the original packing for the entire warranty period of the product

operation);

–Check the product for damage after transportation; in case of such damages detection, contact the supplier

or manufacturer;

–Carefully study the Operating Manual (pay special attention to the connection diagram to power the

product);

–If you have any questions regarding the installation of the product, please contact the manufacturer by

telephone number indicated at the end of this Operating Manual.

3.1.2 General instructions

ATTENTION! MCK-108 ARE NOT DESIGNED FOR LOAD COMMUTATION IN CASE OF SHORT CIRCUITS.

THEREFORE THEY SHOULD BE PROTECTED BY AUTOMATIC CIRCUIT BREAKERS (FUSES) WITH

TRIPPING CURRENT NOT EXCEEDING 10 A.

ATTENTION! ALL CONNECTIONS MUST BE PERFORMED WHEN THE DEVICE IS DE-ENERGIZED.

Error when performing the installation works may damage the product and connected devices.

~ 6 ~

MCK-108

NOVATEK-ELECTRO

To ensure the reliability of electrical connections you should use flexible (stranded) wires with insulation for

voltage of not less than 450V, the ends of which it is necessary to be striped of insulation for 5±0.5 mm and

tightened with bootlaces. Recommended cable cross section for connection is 1 mm2,not less. Wires fastening

should exclude mechanical damage, twisting and insulation abrasion of wires.

IT IS NOT ALLOWED TO LEAVE EXPOSED PORTIONS OF WIRE PROTRUDING BEYOND THE

REMOVABLE TERMINAL BLOCK.

For reliable contact it is necessary to perform tightening of screws of removable terminal block with

the force specified in Table 1.

When reducing the tightening torque, the junction point is heated, the terminal block may be melted and wire can

burn. If you increase the tightening torque, it is possible to have thread failure of the terminal block screws or the

compressionof the connected wire.

To increase the running ability of MCK-108, it is recommended to install protection devices (fuse links

or their equivalents) into the following circuits (enumerated in the order of necessity, hyphen is followed by

the recommended protection device rating):

1) power supply circuits of MCK-108 L, N - 0.5 A;

2) relay output contacts (protection device rating is chosen according to the connected circuits, but

shall not exceed 10 A).

3.1.3 When using the conduction-measuring sensor of liquid level connect the device according to power

according to Figure 2. When using the DR sensor turn the switch Off - DR to "DR" (Dry Run) position. When using

the emergency level sensor turn the switch Off - EL (Off - Emergency Level) to "EL" position.

А–controller of MCK-108

К–contactor starter

М–electric motor of the pump

EL –emergency level sensor

UL –upper level sensor

LL–lower level sensor

DR –dry run sensor

Com. –common electrode

S –automatic protector

Figure 2 - Connection Diagram for MCK-108 when working with one pump

~ 7 ~

NOVATEK-ELECTRO MCK-108

3.1.4 When working with one pump, connect the magnetic starter (hereinafter referred to as MS) of the electric

motor according to Figure 2 and turn the switch 1 –2 to "1" position. When working with two pumps, connect MS of

the electric motor according to Figure 7 and turn the switch 1 –2 to "2" position.

3.1.5 When working in the drainage mode, turn the switch Drn - FI (Drainage –Filling) to "Drn" position.

3.1.6 When working in the filling mode with level sensors, turn the switch CPG –S.L. (CPG –Level Sensor) to

"S.L." (Level Sensor) position and turn the switch Drn - FI (Drainage –Filling) to "FI" (Filling) position.

3.1.7 To connect the pressure sensor to MCK-108, one must connect the following items by using Figure 1 and

Figure 3:

–contacts "1а" and "1b" on CPG with contact "12" on MCK-108;

–contact "2" on CPG with contact "10" on MCK-108;

–contact "3" on CPG with contact "9" on MCK-108;

Figure 3 –Connection to Pressure Sensor

3.1.8 When working in the filling mode with the pressure sensor, turn the switch CPG –S.L. (CPG –Level

Sensor) to “CPG" position and turn the switch Drn - Fi (Drainage –Filling) to "Fi" position.

3.1.9 By using the handle Тhs, adjust the necessary response delay time, which shall exclude false level

sensor tripping due to a possible hydraulic shock.

ATTENTION! Don't make excessive efforts when performing adjusting operations.

3.1.10 Turn the handle Sens to the position, corresponding to the measured liquid resistance.

3.1.11 By using the handle Таr, adjust the necessary AR time, after deactivation of the pump motor due to a dry

run failure. Setting the AR time depends on either the time of filling the well or the liquid flow from the tank.

1 –submersible pump 4 –dry run sensor electrode

2 –MCK-108 5 –pressure sensor (CPG or equivalent)

3 –common electrode

Figure 4–Application of MCK-108 in the filling mode with pressure sensor

3.2 MCK-108 usage

3.2.1 MCK-108 operation with one pump

3.2.1.1 MCK-108 provides operation in the following automated modes:

–filling with pressure sensors (Figure 4);

–filling with level sensors (Figure 5);

–drainage with level sensors (Figure 6).

8 ~

MCK-108

NOVATEK-ELECTRO

When operating with one pump:

- the pump relay uses for pump control;

- the functional relay uses for alarm activation.

The alarm is activated (contacts "5 –6" are closed) in the following cases:

–liquid level is higher than EL;

–liquid level is lower than DR;

–failure of UL, LL or DR sensors.

1- submersible pump

2- MCK-108

3 –dry run sensor electrode

4 –electrodes - EL –emergency level;

- UL –upper level;

- LL –lower level;

- Com. –common.

Figure 5 –Application of MCK-108 in the filling mode with level sensors

1 - submersible pump

2 - MCK-108

3 –electrodes:

- EL –emergency level;

- UL –upper level;

- LL –lower level;

- Com. –common.

Figure 6–Application of MCK-108 in the drainage mode with level sensors

~ 9 ~

NOVATEK-ELECTRO MCK-108

3.2.1.2 Operation in the automated filling mode with the pressure sensor

In the initial state (if the movable contact is located between the UL and LL contacts), when starting the power

supply, the electric motor will not be activated.

When closing the movable contact with the contact of the UL upper setting, the automatic deactivation of the

electric motor takes place.

When closing the movable contact with the contact of the LL lower setting, the automatic activation of the

electric motor takes place and the cycle is repeated.

3.2.1.3 Operation in the automated filling mode with the level sensors

In the initial state (in case there is no liquid in the tank), when starting the power supply, the pump electric

motor will be activated automatically.

When the liquid level reaches the UL sensor, the automatic deactivation of the electric motor takes place.

When the liquid level in the tank is lower than the LL sensor, the automatic activation of the pump electric

motor takes place to feed the liquid into the tank and the cycle is repeated.

3.2.1.4 Operation in the automated drainage mode with the level sensors

In the initial state (in case the liquid level in the tank is lower than the UL sensor), when starting the power

supply, the pump electric motor will not be activated.

When the liquid level reaches the UL sensor, the automatic activation of the pump electric motor takes place.

When the liquid level in the tank is lower than the LL sensor, the automatic deactivation of the pump electric

motor takes place and the cycle is repeated.

А–MCK-108 controller

К1,К2 –contactor starter

М1 –electric motor of the first pump

М2 –electric motor of the second pump

S1, S2 –automatic protectors

Figure 7 –Connection of two pumps to MCK-108

3.2.2 MCK-108 operation with two pumps

For operating MCK-108 with two pumps, one must connect the contactor starter of the second pump according to

Figure 7.

In the automated operation modes of MCK-108 with two pumps, the operation logic of the device is preserved, but

the functional relay is used to control the electric motor of the second pump and, subsequently, does not respond to

emergency conditions.

Activation of the electric motors of the pumps (activation of the functional relay and the pump relay) takes place in

turn after each deactivated of one of them.

10 ~

MCK-108

NOVATEK-ELECTRO

In the automated drainage mode, if the emergency level has been reached, the electric motors of the pumps

are activated simultaneously.

3.2.3 Emergency conditions

3.2.3.1 Protection of the pump electric motor from the inadmissibly low liquid level in the well

Protection works if the DR sensor is activated.

If the liquid level in the well falls lower than the DR sensor:

- the pump electric motor is deactivated;

- the LED DR starts to glow red;

- the functional relay activates the alarm (at operation with one electric motor).

If the liquid level reaches the DR sensor and the AR time elapses, the pump electric motor will be activated.

If the DR sensor is off, the LED DR goes out.

3.2.3.2 Emergency shutdown of the pump electric motor on tripping of the EL emergency level sensor.

If the EL sensor is activated, on the liquid level reaching the EL sensor:

- in the automated filling mode the work of the pump electric motor is forbidden (when working with two

pumps the work of both pumps electric motors is forbidden);

- in the automated drainage mode the pump electric motor is activated (when working with two pumps the

work of both pumps electric motors is allowed) ;

- the LED EL starts to glow red;

- when working with one pump electric motor, the functional relay activates the alarm.

If the liquid level falls lower than the EL sensor:

- the pump electric motor is activated (when working with two pumps the work of both pumps electric motors is

allowed);

- the LED EL goes out;

- the functional relay deactivates the alarm.

If the EL sensor is off, the LED EL goes out.

3.2.3.3 Failures of the (pressure) level sensors are specified in Table 4

Table 4

Name of Failure

Cause

Indication

Failure of the lower level

sensor (LL)

If the UL or EL sensor has tripped (except for

the operation mode with the pressure sensor),

the LL sensor shall indicate the absence of

liquid.

Or if the UL or EL sensor has tripped (in the

operation mode with the pressure sensor), the

LL sensor shall indicate a closed condition.

The LED LL blinks red

Failure of the upper level

sensor (UL)

If the EL sensor has tripped, the UL sensor

shall indicate the absence of liquid.

The LED UL blinks red

At failure of the UL sensor, MCK-108 will continue operating, using the emergency level sensor as an UL

sensor.

3.2.3.4 EEPROM Failure

When EEPROM failure, calibration of resistance of liquid off and MCK-108 is locked, giving the following error

message –in turn and with 1 Hz frequency EL, UL, LL, DR LEDs starts to glow and upside-down. Then the cycle is

repeated.

ATTENTION! In case of EEPROM failure the MCK-108 needs to be laid off and sent for repair.

3 MAINTENANCE

3.1SAFETY PRECAUTIONS

THE TERMINALS AND THE PRODUCT INTERNAL ELEMENTS CONTAINS POTENTIALLY LETHAL

VOLTAGE.

DURING MAINTENANCE IT IS NECESSARY TO DISABLE THE PRODUCT AND CONNECTED

DEVICES FROM THE MAINS.

3.2 Maintenance of the product must be performed by qualified service personnel.

3.3. Recommended frequency of maintenance is every six months.

3.4. MAINTENANCE PROCEDURE:

1) Check the connection reliability of the wires, if necessary, clamp with the force specified in Table 1;

~ 11 ~

NOVATEK-ELECTRO MCK-108

2) Visually check the integrity of the housing, in case of detection of cracks and damages to remove the

product from service and send for repair;

3) If necessary, wipe with cloth the front panel and the product housing.

Do not use abrasives and solvents for cleaning.

4 TRANSPORTATION AND STORAGE

MCK-108 in the manufacturer's package must be stored in an indoor area at the temperature from minus 45 to

+60 C and relative humidity not exceeding 80 %, provided there are no vapours, causing any damaging impact on the

package and the materials of the device.

5 OPERATION LIFE AND MANUFACTURER’S WARRANTY

5.1. The lifetime of the product is 10 years. Upon expiration of the service life, contact the manufacturer.

5.2. Shelf life is 3 years.

5.3. Warranty period of the product operation is 5 years from the date of sale.

During the warranty period of operation (in the case of failure of the product) the manufacturer is responsible

for free repair of the product.

ATTENTION! IF THE PRODUCT HAS BEEN OPERATED IN VIOLATION OF THE REQUIREMENTS OF

THIS MANUAL, THE MANUFACTURER HAS THE RIGHT TO REFUSE IN WARRANTY SERVICE.

5.4. Warranty service is performed at the place of purchase or by the manufacturer of the product.

5.5. Post-warranty service of the product is performed by the manufacturer at current rates.

5.6. Before sending for repair, the product should be packed in the original or other packing excluding

mechanical damage.

Earnest request: indicate the reason for return in the notice of faults field at the return of the device or in case of

submitting for warranty service or post-warranty service.

6 ACCEPTANCE CERTIFICATE

The pumping plant controller MCK-108 No._________ is produced and accepted according to the

requirements of the effective technical documentation and is acknowledged to be suitable for operation.

Chief of quality department Date of Issue

STAMP ______________ _____________

7 INFORMATION ON CLAIMS

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

"Novatek-Electro" Ltd.

59, Admiral Lazarev str.,

Odessa, 65007, Ukraine

tel:+38 048 738-00-28; +38 0482 37-48-27;

fax: +38 0482 34 36 73

www.novatek-electro.com

Date of Sale ________________ VN 180625

Table of contents

Other Novatek-electro Controllers manuals