2 PME120/RHD250 to 4000 (Contrac) ELECTRICAL ROTARY ACTUATOR | OI/PME/RHD250/4000-EN REV. F

Table of contents

Change from one to two columns

1Safety.......................................................................... 3

General information and instructions.................................. 3

Warnings.................................................................................... 3

Intended use .............................................................................4

Improper use.............................................................................4

Notes on data safety ...............................................................4

Warranty provisions.................................................................4

Manufacturer’s address..........................................................4

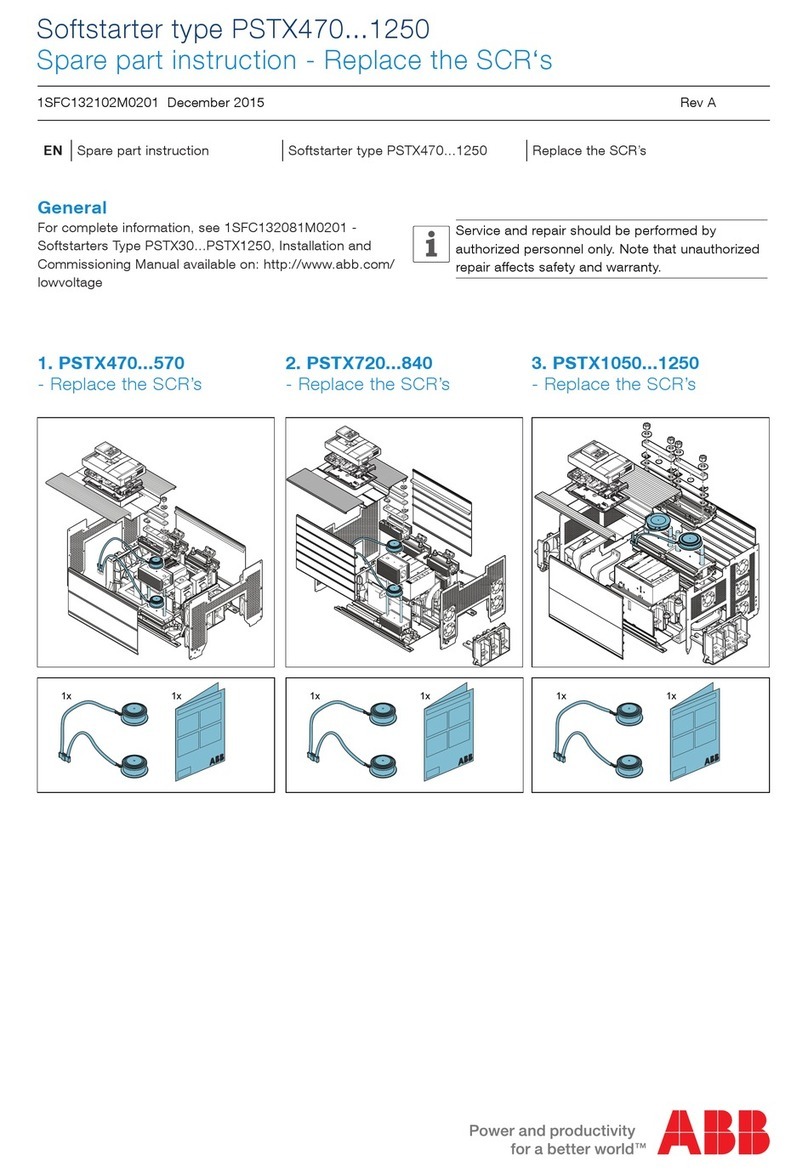

2Design and function .................................................. 5

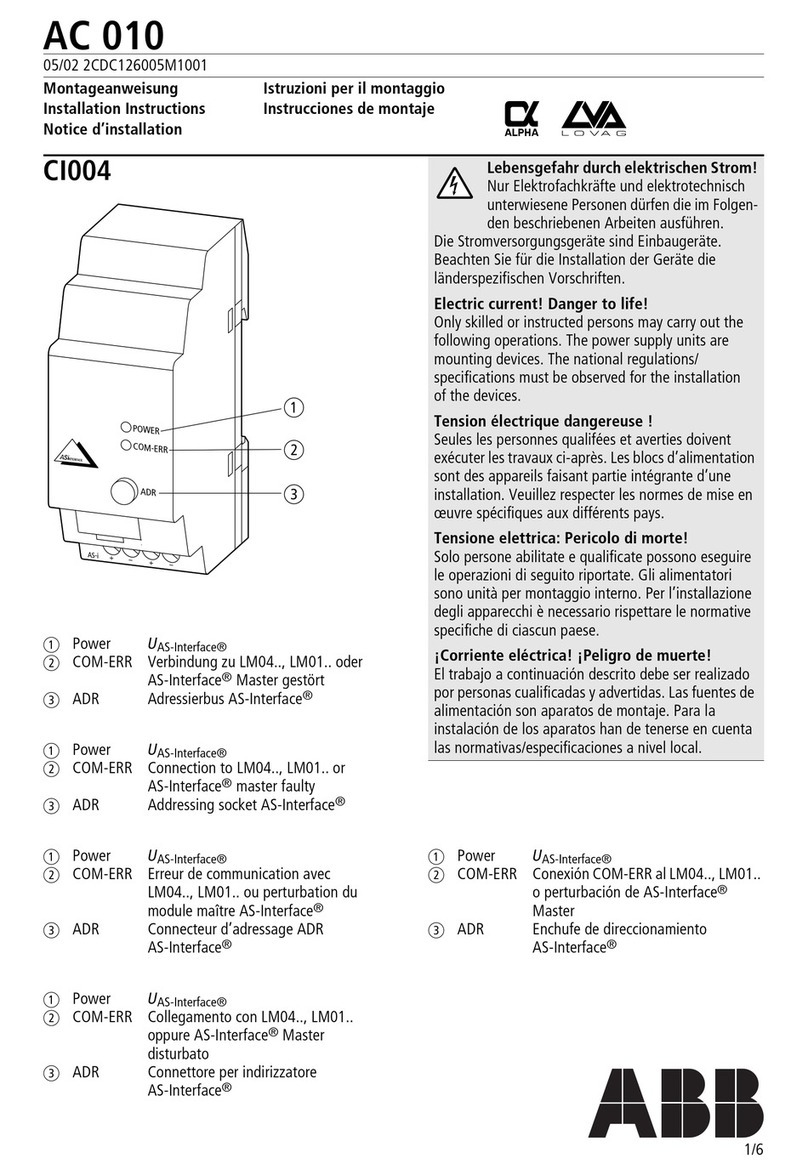

Design ........................................................................................5

Principle of operation..............................................................5

Device designs..........................................................................6

PME120..................................................................................6

RHD ........................................................................................ 7

3Product identification ..............................................9

Name plate ................................................................................9

4Transport and storage............................................10

Inspection................................................................................10

Transporting the device........................................................10

Safety instructions............................................................10

Returning devices...................................................................10

Storing the device ..................................................................10

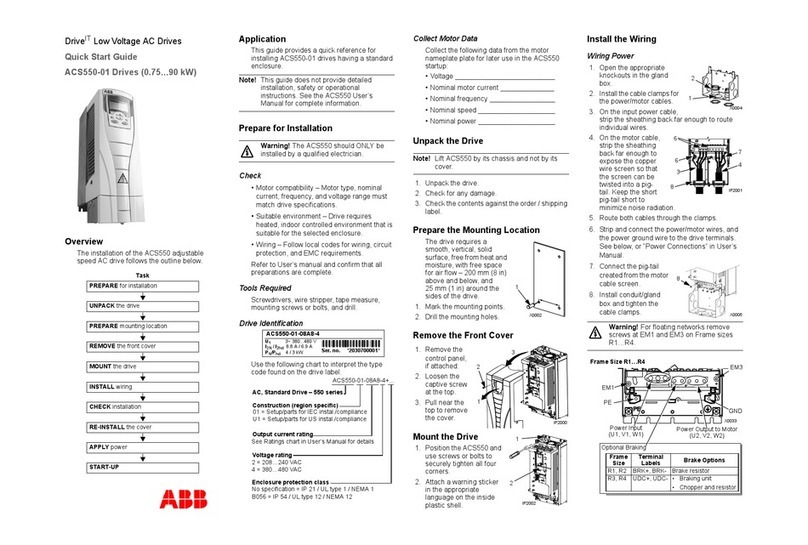

5Installation ............................................................... 11

Safety instructions................................................................. 11

Mounting ................................................................................. 11

Actuator check................................................................... 11

Installation instructions................................................... 11

Fastening the actuator..................................................... 11

Mounting position............................................................. 11

Assembly with the final control element ...................... 12

Installation variants ..........................................................14

Dimensions.............................................................................. 16

Control actuator PME120.................................................16

Direct adapter PME120-AI/-AN ....................................... 17

Control actuator RHD250 ................................................18

Control actuator RHD500 / RHD800 ............................. 19

Control actuator RHD1250 / RHD2500..........................20

Control actuator RHD4000.............................................. 21

Connection pipe and link rod ..........................................22

6Electrical connections.............................................24

Safety instructions.................................................................24

Conductor cross-section on universal plug.......................24

Conductor cross-section on electronic unit......................25

Cable glands.......................................................................25

Selection of suited connection cables...........................25

Integrated PME120-AI Electronic unit.................................26

Analog / Digital..................................................................26

PROFIBUS DP®....................................................................27

Electronic unit EAN823 (Contrac) for PME120-AN............28

Analog / Digital..................................................................28

PROFIBUS DP®....................................................................29

Electronic unit EAS822 (Contrac) for PME120-AN............ 30

Analog / Digital ................................................................. 30

Electronic unit EBS853 (Contrac) / EBS861 (Contrac).....31

Analog / Digital ..................................................................31

PROFIBUS DP® ................................................................... 32

Electronic Unit EBN852 (Contrac)....................................... 33

Analog / Digital ................................................................. 33

Analog / Digital ................................................................. 34

7Commissioning ........................................................35

8Operation..................................................................35

Safety instructions ................................................................ 35

Automatic mode / Handwheel mode................................. 35

Manual operation................................................................... 35

Handwheel operation in combination with positioning

loop monitoring ................................................................ 36

9Diagnosis / error messages ...................................37

Electrical test values ............................................................. 37

10Maintenance .............................................................38

Safety instructions ................................................................ 38

General..................................................................................... 38

Inspection and overhaul ....................................................... 38

Maintenance plan.............................................................. 38

Removing the motor and adjusting the brakes ............... 39

Oil change ............................................................................... 39

PME oil types .....................................................................40

RHD oil types .....................................................................40

11Repair ....................................................................... 42

Returning devices .................................................................. 42

12Recycling and disposal ........................................... 42

Notice on RoHS II-Directive 2011/65/EU........................... 42

13Approvals and certifications ................................. 43

14Additional documents............................................ 43

15Appendix .................................................................. 44

Return form.............................................................................44

Installation declaration......................................................... 45