AUMA SA Series User manual

Other manuals for SA Series

3

This manual suits for next models

11

Table of contents

Other AUMA Controllers manuals

AUMA

AUMA SA 07.1 Administrator Guide

AUMA

AUMA SQ 05.2 User manual

AUMA

AUMA TIGRON TR-M30X User manual

AUMA

AUMA Aumatic AC 01.1 User manual

AUMA

AUMA SA 07.2 User manual

AUMA

AUMA VARIOMATIC SARV 10.1 User manual

AUMA

AUMA AUMATIC AC 01.2 Manual

AUMA

AUMA SA 07.2 User manual

AUMA

AUMA SAEx 07.2 User manual

AUMA

AUMA PROFOX PF-M25X User manual

AUMA

AUMA SA 07.1 User manual

AUMA

AUMA SEVEN 2SA7 Instruction manual

AUMA

AUMA SA 48.1 User manual

AUMA

AUMA SV 05.1 User manual

AUMA

AUMA SAEx 07.2 User manual

AUMA

AUMA SG 05.1-FA07 User manual

AUMA

AUMA AUMATIC AC 01.2 User manual

AUMA

AUMA SAEx 25.1 User manual

AUMA

AUMA SAExC 07.1 User manual

AUMA

AUMA TIGRON TR-M30X Manual

Popular Controllers manuals by other brands

Ametek

Ametek ZF2 SCR Series Instruction, Operation and Maintenance Manual

ICD

ICD NeoGCP3 user manual

Penn

Penn A19 Series Mounting and installation

Ricoh

Ricoh Interactive Whiteboard Controller Type 1 operating instructions

RIB

RIB T2-CRX Simplified instructions

Ruckus Wireless

Ruckus Wireless SmartZone 100 Quick setup guide

Megmeet

Megmeet MC200E Series Quick start user manual

EUCHIPS

EUCHIPS EUP40D-1HMC-0 manual

Honeywell

Honeywell HercuLine 2000 Series quick start guide

Mitsubishi Electric

Mitsubishi Electric MELSERVO-J5 MR-J5-G Series user manual

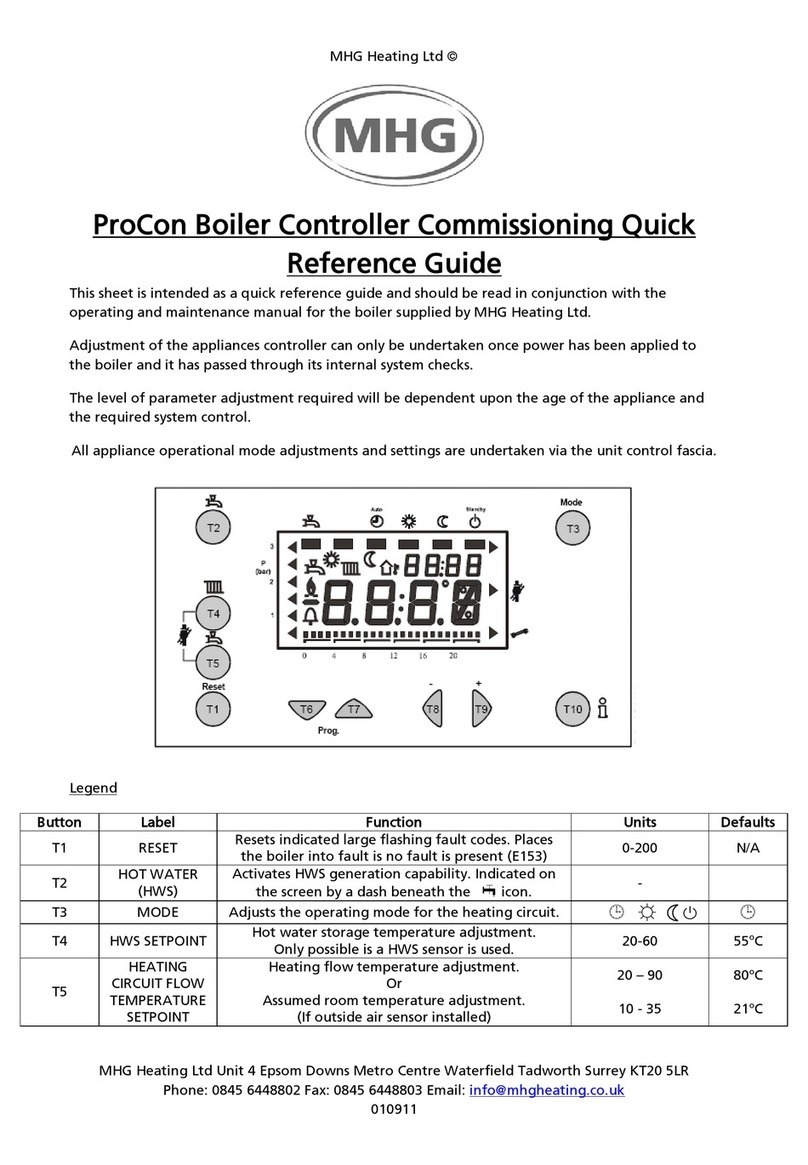

MHG Heating

MHG Heating ProCon Boiler Controller Quick reference guide

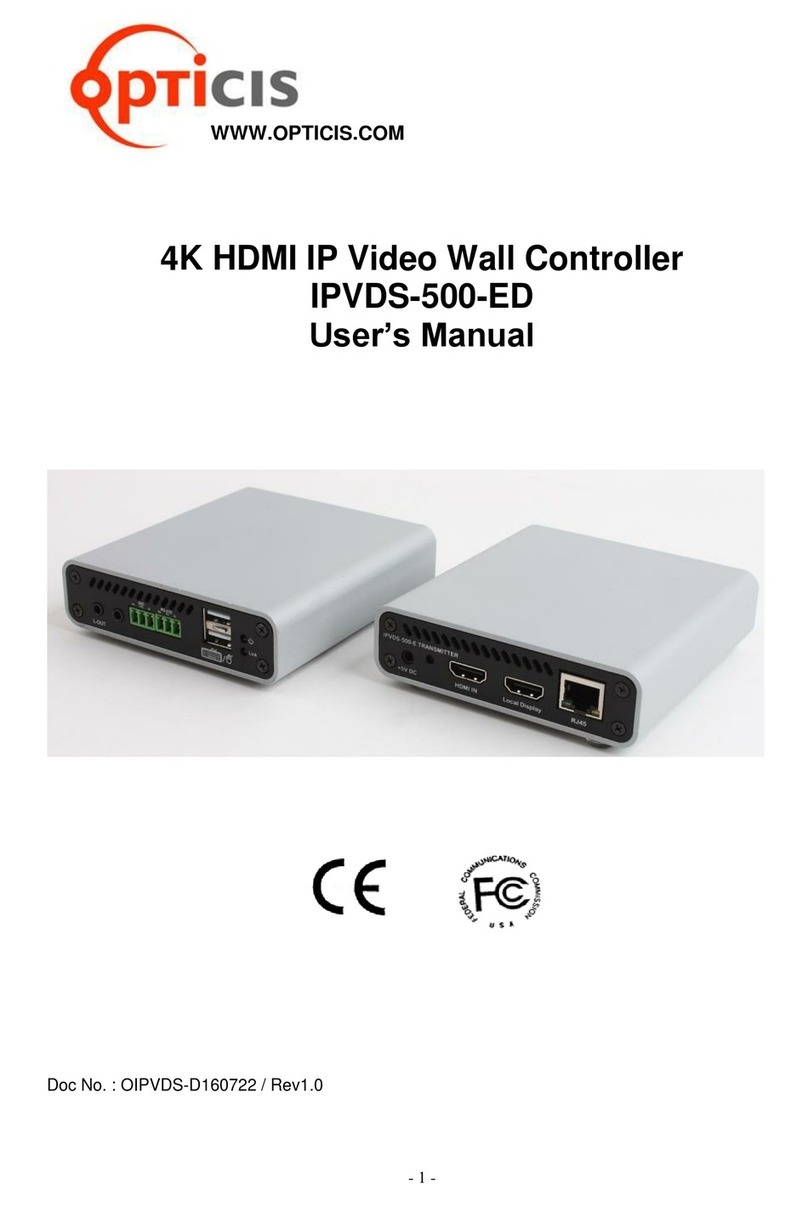

opticis

opticis IPVDS-500-ED user manual

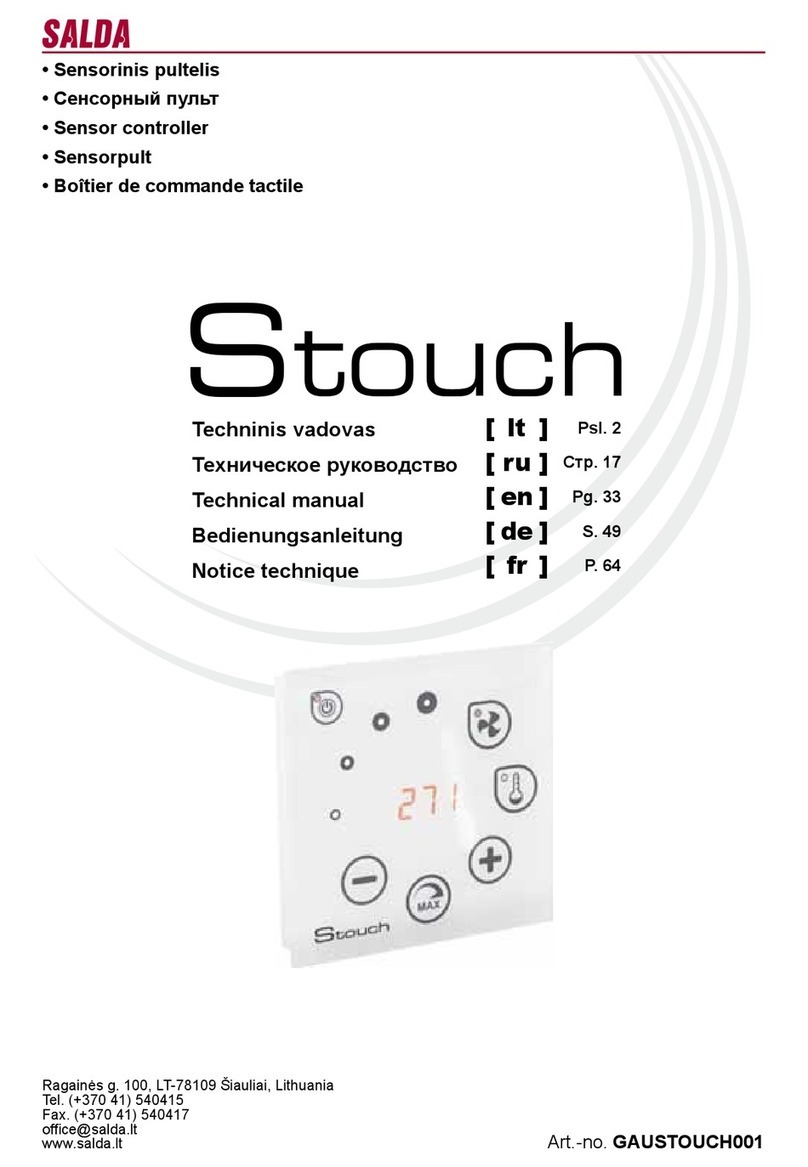

Salda

Salda Stouch Technical manual

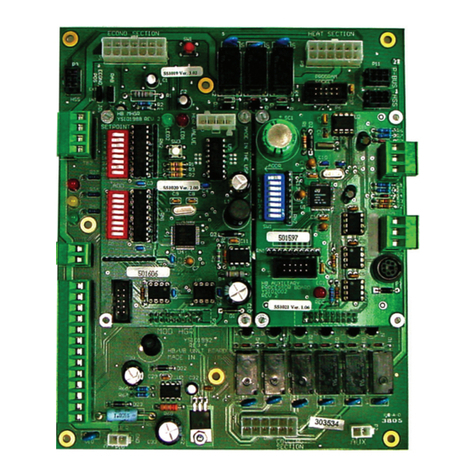

AAON

AAON AA-HB-TGD-01F Technical guide

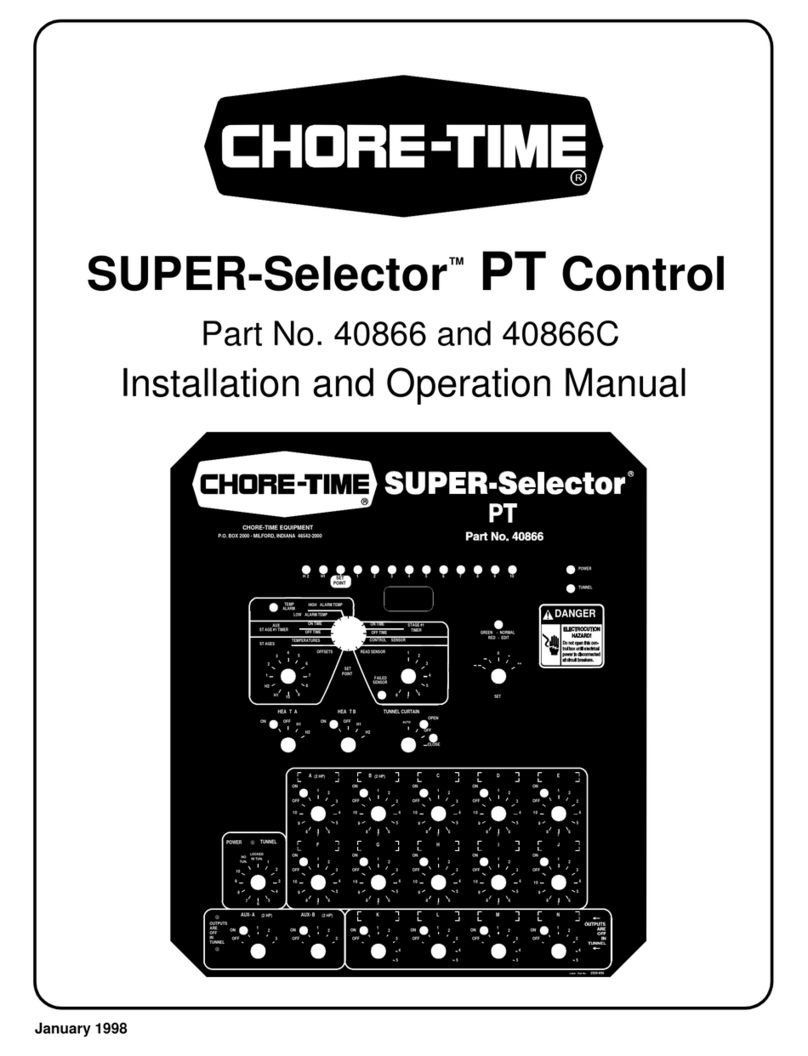

Chore-Time

Chore-Time SUPER-Selector PT 40866 Installation and operation manual

Rohde & Schwarz

Rohde & Schwarz SpycerBox Cell Important information

Fisher

Fisher 4660 instruction manual

Mitsubishi Electric

Mitsubishi Electric MELSEC iQ-F Series Quick connection guide