Page | 5

Modification PCB ...................................................................................................................19

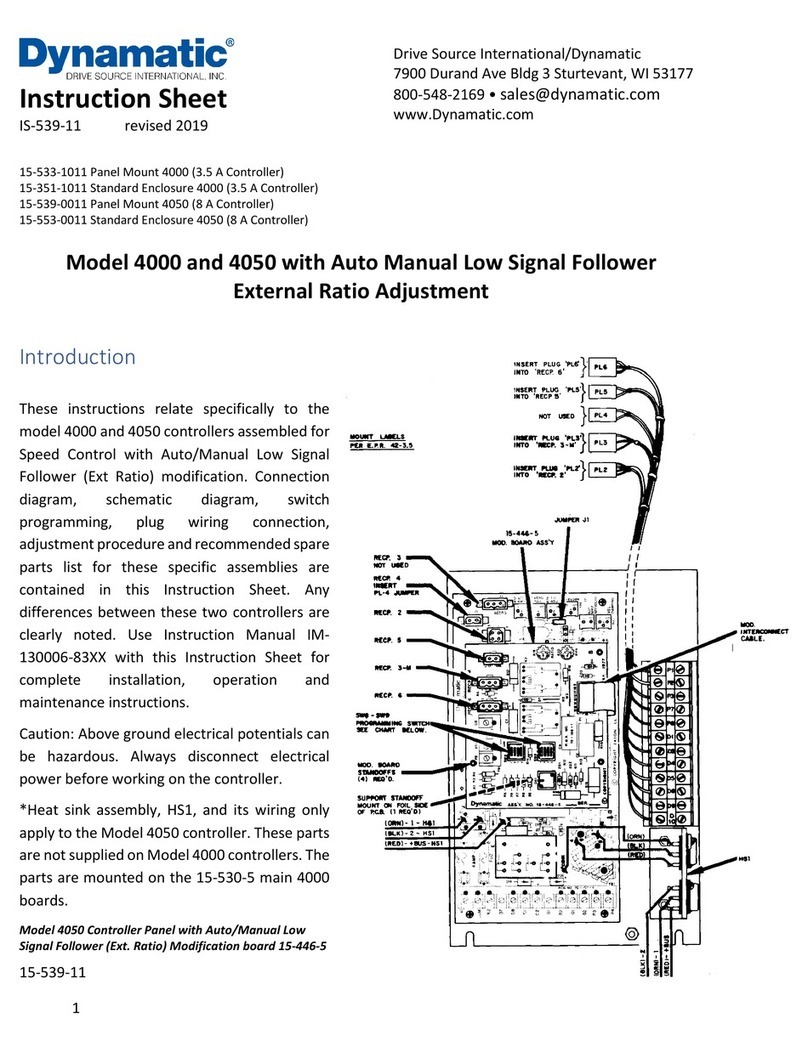

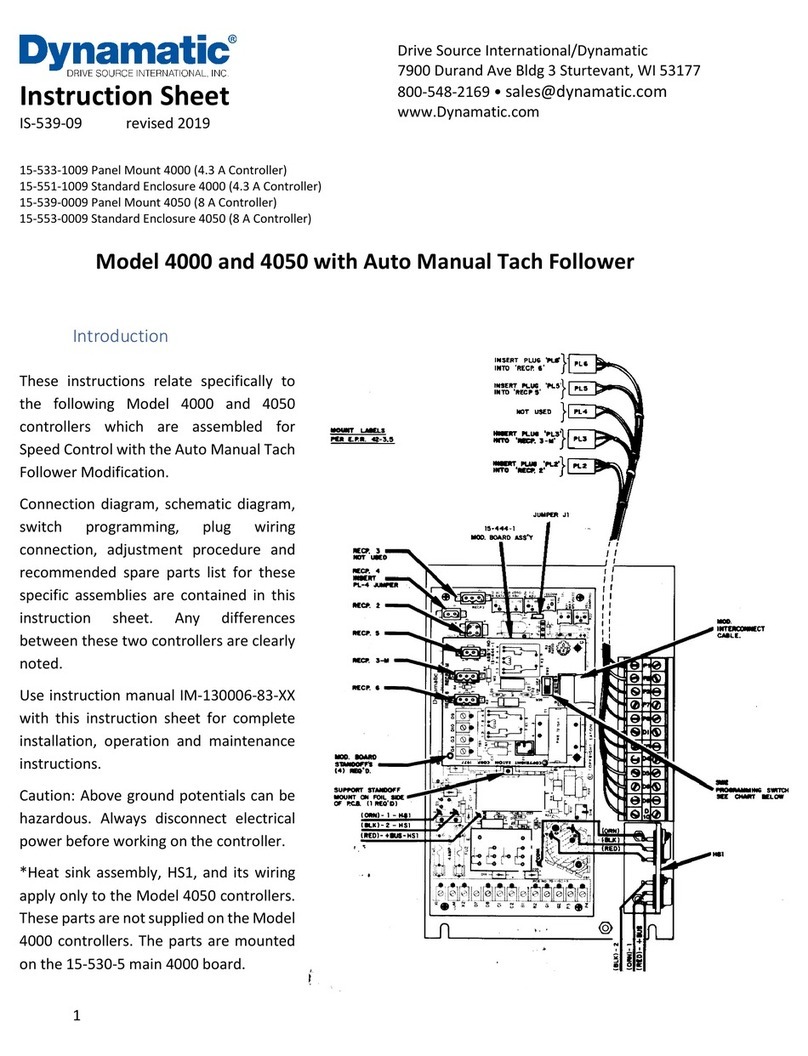

Figure 3-2 Modification PCB Standoff................................................................................ 19

Wiring..................................................................................................................................... 20

Programming Dip Switch .......................................................................................................21

Figure 3-3 Dip Switch Installation & Programming............................................................ 21

Figure 3-4a Connection Diagram Model 4050 Stamping Press Controller with Torque

Limit, Speed Trip and Minimum Speed Adjustment 115V, 208V, 390V, 230/460V or 575V Input

and 8.0 Adc Output (15-541-*) ....................................................................................................... 22

Figure 3-4b Schematic Diagram for Model 4050 Stamping Press Controller (15-541-*)

continued… .....................................................................................................................................23

Figure 3-5a Connection Diagram for 4050 Stamping Press Controller with Torque Limit.

Speed Trip and Minimum Speed Adjustment 208/230/460V Input and 5.5 Adc Output (15-541-

0007) ...............................................................................................................................................24

Figure 3-5b Schematic Diagram for 4050 Stamping Press Controller with Torque Limit

continue ..........................................................................................................................................25

Figure 3-6a Connection Diagram for 4050 Stamping Press Controller with Torque Limit

and Minimum Speed Adjustment (without Speed Trip) 115V, 208V, 390V, 230/460V or 575V

Input and 8.0 Adc Output (15-451-002*)........................................................................................ 26

Figure 3-6b Schematic Diagram for 4050 Stamping Press Controller (15-451-002*)

continued… .....................................................................................................................................27

Figure 3-7a Connection Diagram for Model 4050 Stamping Press Controller with Torque

and Minimum Speed Adjustment 115V input and 8 Adc. Output (15-539-0019).......................... 28

Figure 3-7b Schematic Diagram for Model 4050 Stamping Press Controller (15-539-0019)

continued… .....................................................................................................................................29

Figure 3-8a Connection Diagram for Model 4050 Stamping Press Controller with

minimum Speed Adjustment (without Torque Limit) 115 V input and 8 Adv output (15-539-0020)

........................................................................................................................................................30

Figure 3-8b Schematic Diagram for Model 4050 Stamping Press Controller (15-539-0020)

continued ........................................................................................................................................ 31

Section 4 ......................................................................................32

Operation................................................................................................................................... 32

Basic Controller Theory.......................................................................................................... 32

Figure 4-1 Simple Closed Loop System ..............................................................................32

Torque Limit Modification 15-44-2........................................................................................ 33

Linear Acceleration Option .................................................................................................... 33

Fixed Brake Option................................................................................................................. 34

Spring Set Brake Option .........................................................................................................34

Speed Trip Option ..................................................................................................................34

Figure 4-2 Model 4050 Controller Block Diagram .............................................................35