Novatek-electro PEF-305 User manual

«NOVATEK-ELECTRO» Ltd

Intelligent industrial electronics

PEF-305

AUTOMATIC

ELECTRONIC

PHASE SWITCH

OPERATION MANUAL

Quality control system on the developmentand production complies with requirements

ISO 9001:2015

Dear customer,

Company NOVATEK-ELECTRO LTD. thanks you for purchasing our products.

You will be able to use properly the product after carefully studying the Operating Manual.

Keep the Operating Manual throughout the service life of the product.

Installation and adjustment of the device must be performed by the skilled professionals having studied this

Operation Manual.

The power of the connected load must not exceed that specified in this manual, since this may cause

overheating the contact group and a fire.

IN COURSE OF TROUBLESHOOTING, MAINTENANCE, INSTALLATION WORKS, IT IS NECESSARY TO

DEENERGIZE THE DEVICE BY DISCONNECTING THE POWER SUPPLY CORD. IT IS FORBIDDEN TO

OPEN AND REPAIR THE DEVICEWITHOUT ANY PROFESSIONAL HELP.

IT IS PROHIBITED TO OPERATE THE DEVICE WITH MECHANICAL DAMAGES OF THE CASE.

Do not use the device in aggressive environments with acids, alkalis, oils, etc. in the air.

The device is safe for use under keeping of the operating rules.

Odessa,Ukrainewww.novatek-electro.com

~ 2 ~

PEF-305

NOVATEK-ELECTRO

1 DESCRIPTION AND OPERATION

1.1 Application

Universal automatic electronic phase switch is designed to supply industrial and household single-phase of

230 V/50 Hz load from three-phase mains to ensure uninterrupted power supply of single-phase consumers and

protect them against unallowable voltage fluctuations in the mains. Depending on the availability and quality of

voltage on the phases, PEF-305 automatically selects the most optimum phase and feeds it with the single-phase

load of any power:

- measurement error is 1% maximum;

- automatic phase switching when its value drops below 180 V AC;

- three-phase power of L1-L2-L3 (L1- priority phase);

- factory settings: switching threshold voltage (180 V AC), switching time (150 ms) and voltage hysteresis (10 V

AC).

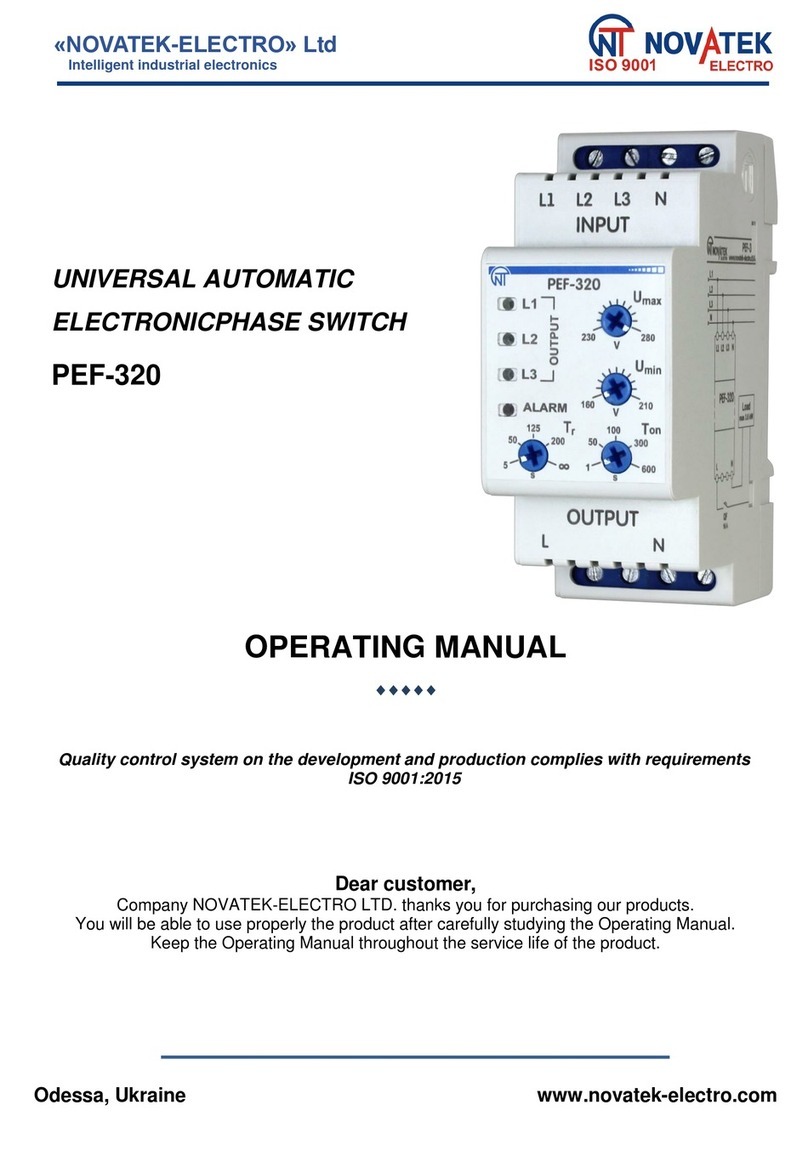

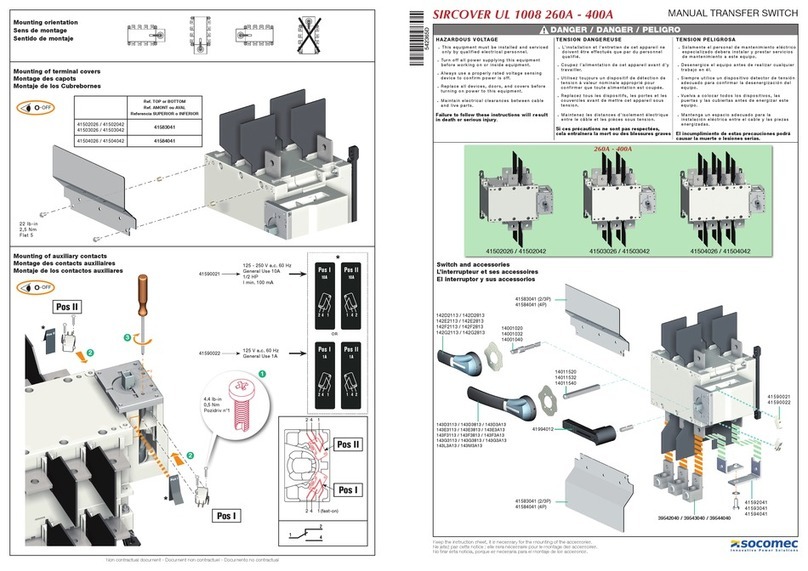

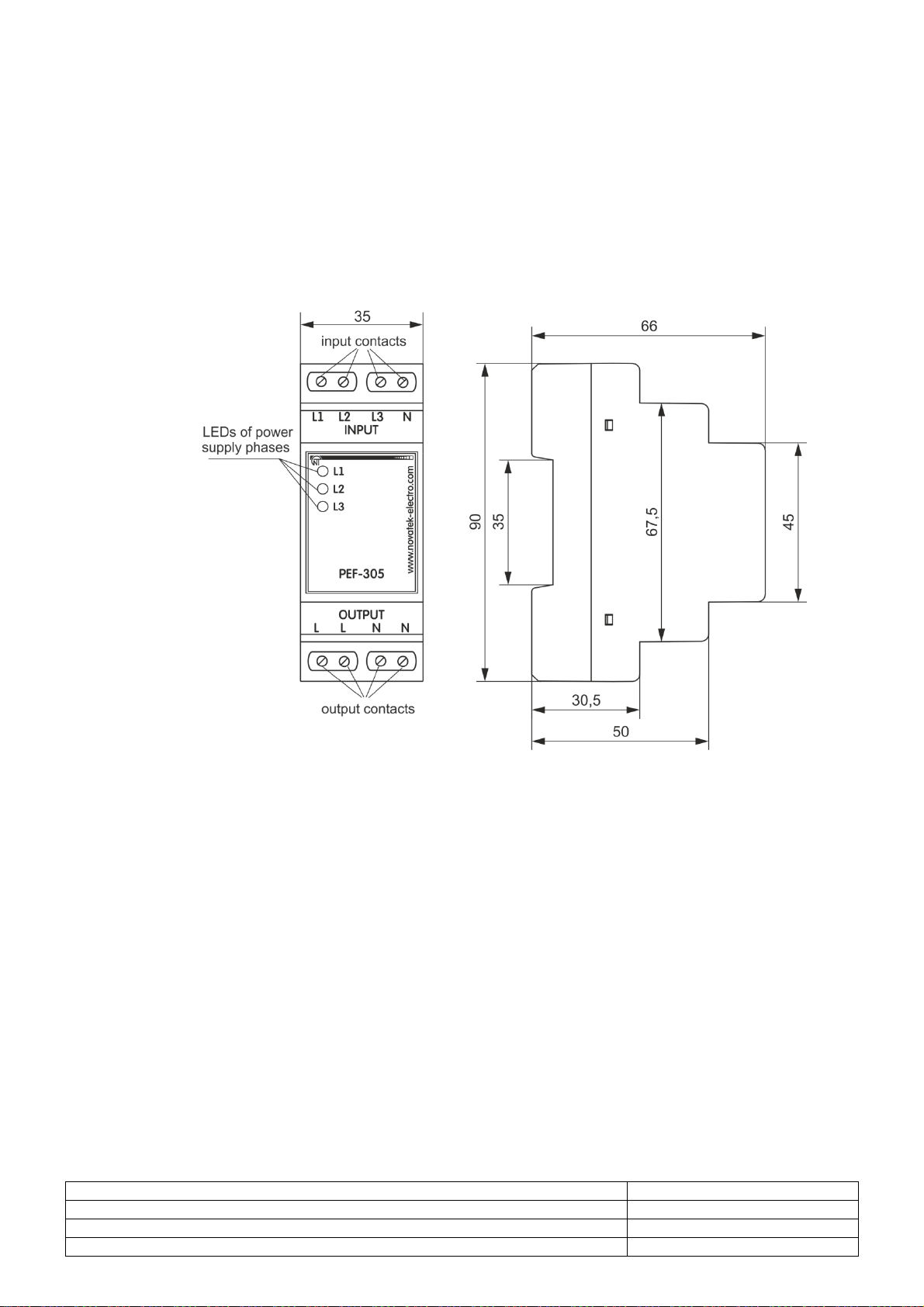

1.2 Controls and overall dimensions ofPEF-305

Fig. 1–Overall dimensions

1.3 Operation conditions

The device is intended for operation in the following conditions:

–Ambient temperature: from minus 20 to +45 °С;

–Atmospheric pressure: from 84 to 106.7 kPa;

–Relative humidity (at temperature of +25 °С): 30 … 80 %.

If the temperature of the device after transportation or storage differs from the ambient temperature at which it is

supposed to be operated, then before connecting to the mains keep the device under the operating conditions

within two hours (because of condensation may be on the device elements).

ATTENTION! The device is not intended for operation in the following conditions:

–Significant vibration and shocks;

–High humidity;

–Aggressive environment with content in the air of acids, alkalis, etc., as well as severe contaminations

(grease, oil, dust, etc.).

2 TECHNICAL SPECIFICATIONS

2.1 Basic Technical Specifications

The basic technical specifications are given in Table 2.1.

Table 2.1 - Basic Technical Specifications

Rated phase voltage, V

3 x 230 V AC + N

Mains frequency, Hz

50 Hz

Protection rating of the device case

IP20

Time of switching over, ms

˜150

~ 3 ~

NOVATEK-ELECTRO

PEF-305

Rated output voltage

230 V AC

Voltage hysteresis

10 V AC

Priority phase

L1

Maximum load capacity of the output

16 Afor devices of classAC1

Relative error of voltage measurement, %, less than

1

Switching threshold voltageL1,L2,L3, V AC, less than

180

Rated power consumption

1.7 W/3.8 VAin three phases

Electric shock protection class

II

Overvoltage category

II

Permissible contamination level

II

Position in space

arbitrary

Overall dimensions, mm

90x35x66

Weight

0.14 kg

Terminals of the device allow connecting wires to them with a cross section of 0.2 to 2.5 mm2

Installation on a standard 35 mm DIN rail

The device meets the requirements of:

EN 60669-1, EN 60669-2-1, EN 61000-4-2,3,4,5,6,11

Harmful substances in quantities exceeding the maximum permissible concentration are absent.

3 DESIGN AND PRINCIPLE OF OPERATION

3.1 Design

The device is made in a plastic case designed for mounting on a 35 mm DIN-rail, 2 modules are of type S. The

case is made of impact-resistant, self-extinguishing plastic. A sketch of the case with overall and mounting

dimensions is shown in Fig. 1.

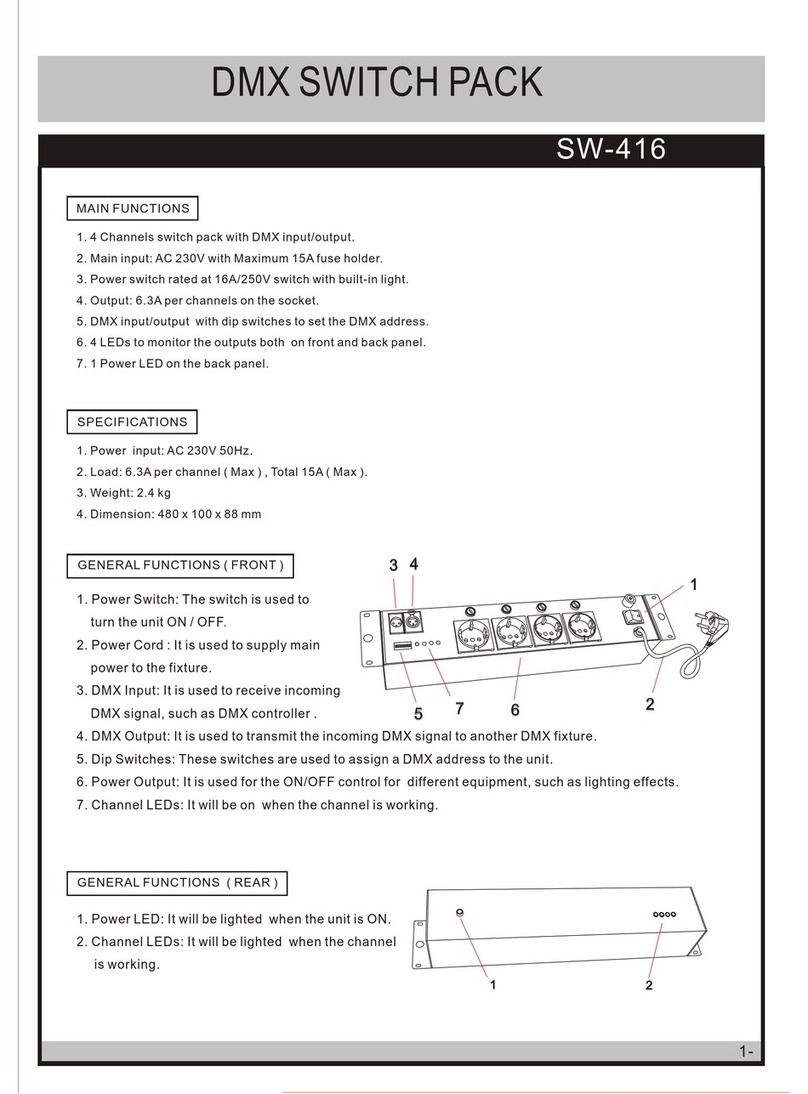

3.2 Principle of operation of PEF-305

The electronic phase switch PEF-305 is a

microprocessor-based digital device.

After the supply voltage PEF-305 is ready for

operation. If the value of the voltage on phase L1 is

greater than 180 V AC, it will automatically switch to

phase L2 within less than 150 ms. Similarly, if the voltage

of phase L2 drops below 180 V AC, it will automatically

switch to phase L3.

A voltage drop in phase L3 below 180 V AC will cause

the power supply to the load connected to the output to

be turned off. If this phase shuts down due to a decrease

in voltage below 180 V AC, it will turn on again at a value

of more than 190 V AC (10 V hysteresis). The priority is

the L1 phase. If the parameters of phase L1 are normal,

the load will always be powered from this phase.

Example:

- If the load is powered from phase L3 and the normal

parameters of phase L1 are restored, the automatic

switching to phase L1 will occur. If the voltage on this

phase is more than 180 V AC, the corresponding LED

lights up. Voltage values below 180 V AC are indicated

by the LED off. Time for this phase off and on is the same

and is 150 ms.

Fig. 2-Connection diagram

4 PREPARATION FOR OPERATION AND INSTRUCTIONS FOR OPERATION

4.1 General instructions

Prepare cables for connecting the device to the power source and external devices. To ensure the reliability of

electrical connections, it is recommended to use copper wires, the ends of which should be carefully cleaned to 5

±0.5 mm before connecting. Stripping of cable cores should be done so that their bare ends do not protrude beyond

the terminal block after connecting to the device. Recommended wire size is 0.2 - 2.5 mm².

An error during installation can damage the device and the devices connected to it.

Fastening of wires should exclude mechanical damage, twisting and wearing wire insulation.

The relay is manufactured completely ready for operation and does not require special preparations for

operation. In connection with the use of digital technology, the settings in the relay are precisely adjusted; therefore,

~ 4 ~

PEF-305

NOVATEK-ELECTRO

they can be set up without a reference voltmeter. When operating the relay in accordance with the specifications

and this passport during the service life, including during continuous operation, no routine maintenance is required.

5MAINTENANCE

DURING MAINTENANCE IT IS NECESSARY TO DISCONNECT THE DEVICE AND CONNECTED DEVICES FROM

THE MAINS.

Maintenance of the device must be carried out by qualified personnel.

The recommended frequency of maintenance is every six months.

Maintenance Procedure:

1) Check the connection reliability of the wires, if necessary, tighten with an appropriate force;

2) Visually check the integrity of the case; if cracks and chips are found, remove the device from service and

send it for repair;

3) If necessary, wipe the front panel and the case of the device with a cloth.

Do not use abrasives or solvents for cleaning.

6 SERVICE LIFE AND MANUFACTURER WARRANTY

6.1The lifetime of the device is 10 years. Upon expiration of the service life, contact the manufacturer.

6.2.Shelf life is 3 years.

6.3.Warranty period of the device operation is 5 years from the date of sale.

During the warranty period of operation (in the case of failure of the device) the manufacturer is responsible

for free repair of the device.

ATTENTION! IF THE DEVICE HAS BEEN OPERATED WITH THE VIOLATION OF THE

REQUIREMENTS OF THIS USER MANUAL, THE USER WILL LOSE THE RIGHT TO WARRANTY

MAINTENANCE.

6.4.Warranty service is performed at the place of purchase or by the manufacturer of the device.

6.5.Post-warranty service of the device is performed by the manufacturer at current rates.

6.6.Before sending for repair, the device should be packed in the original or other packing excluding

mechanical damage.

7 ACCEPTANCE CERTIFICATE

The quality control department confirms that PEF-305 is manufactured in accordance with the technical

documentation and is considered as fit for service.

SealQCD HeadDate of manufacture:

___________________ _____________________

8 CLAIMS DATA

When returning the device or transferring it to the warranty (post-warranty) service, in the field of information on

claims, specify in detail the reason for return.

The Company is grateful to you for the information about the quality of the device and suggestions for its operation.

For all questions, please contact the manufacturer:

NOVATEK-ELECTRO Ltd, Tel.: +38 (048)738-00-28,

59, Admiral Lazarev Str., Tel./fax: +38 (0482) 34-36-73.

Odessa, 65007, Ukraine. www.novatek-electro.com

Date of sale:____________

Table of contents

Other Novatek-electro Switch manuals