NOVAWINCH FENIX 25 Operation and maintenance manual

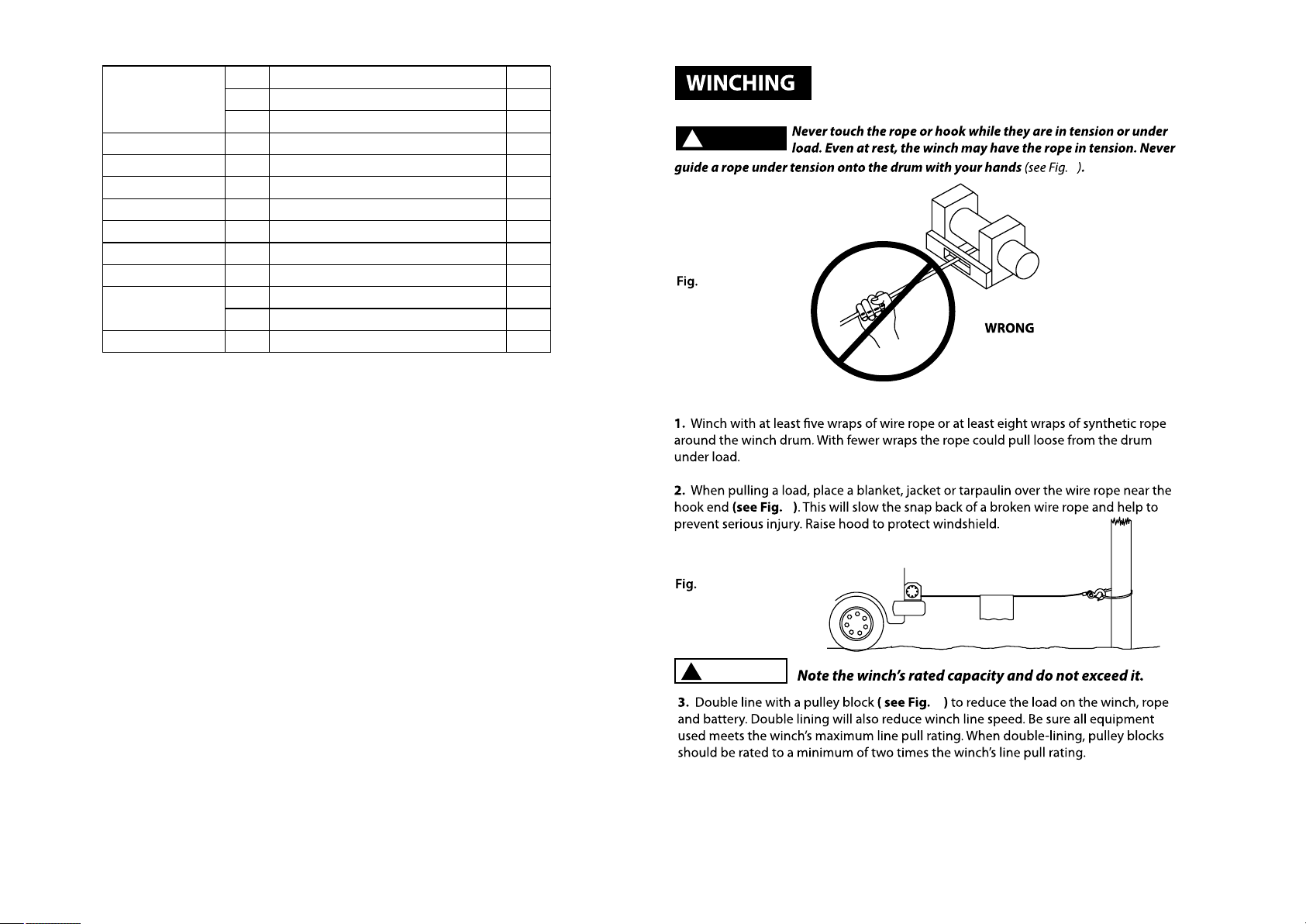

1689 Xianyuan Road,Jinhua,Zhejiang,China

Tel:0086-579-82262697

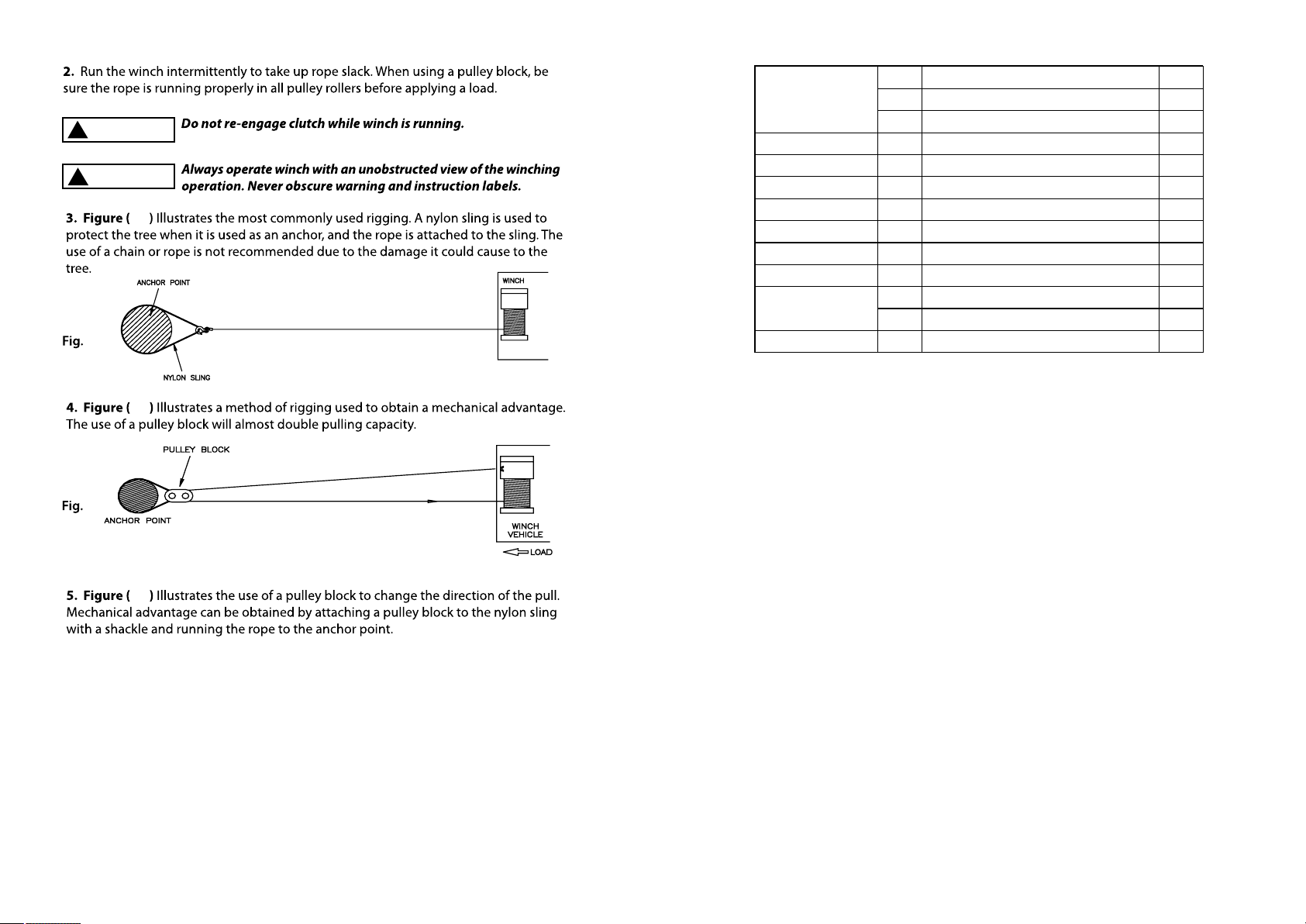

Fax:0086-579-82262706

E-mail: info@nowvow.net

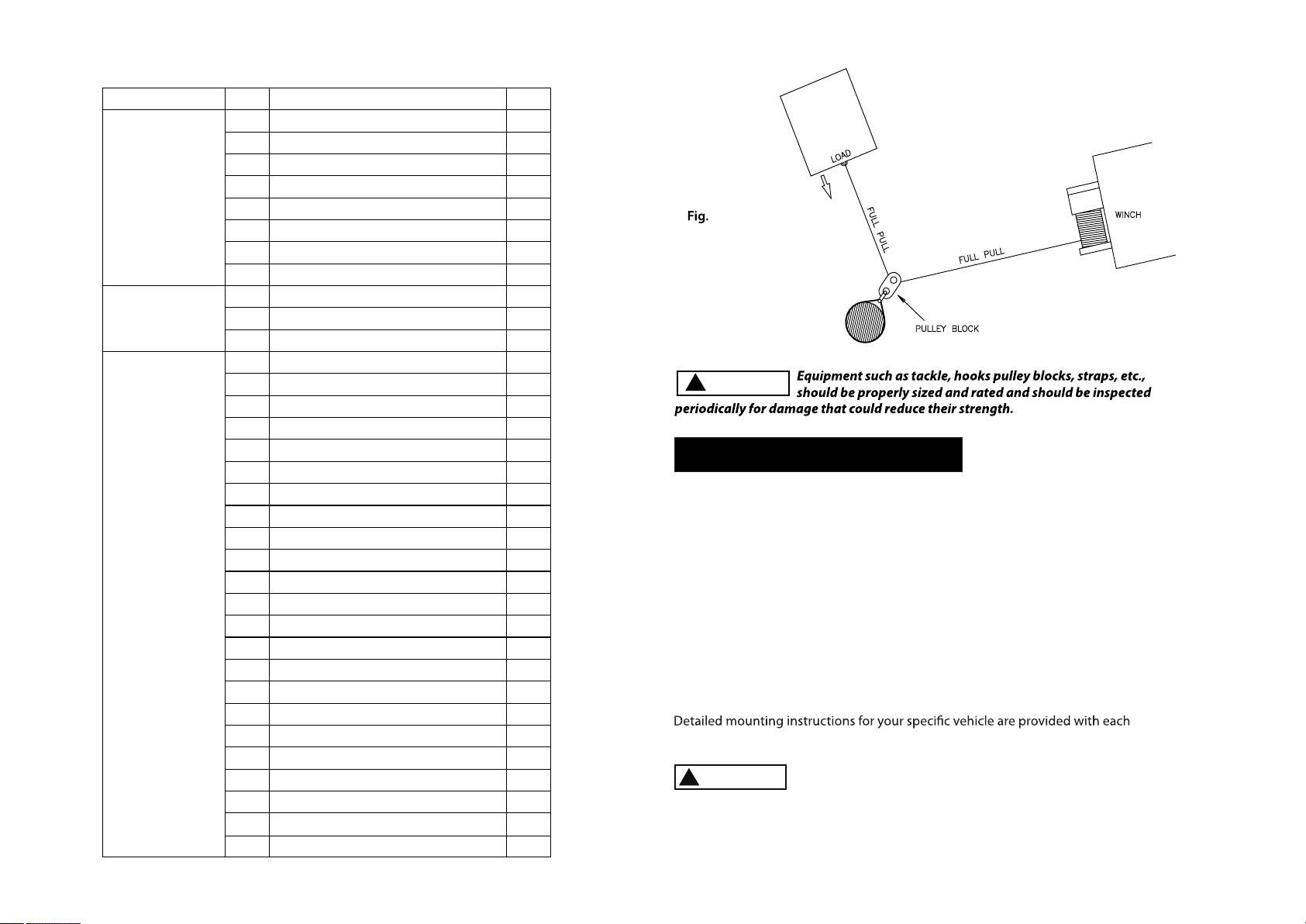

http://www.novawinch.com

PLEASE READ CAREFULLY BEFORE OPERATE THE WINCH

2020.11.18

ELECTRIC WINCH

FENIX 25

FENIX 35

FENIX 45

SAFETY PRECAUTIONS

Always Use

Handsaver

Keep clear of winch,

wire rope and hook

while operating

Read Owner's

Manual

Never Use winch

to lift or move

people

Never Use

winch to hold

loads in place

The responsibility for safe installation and operation of this winch ultimately rests with

you, the operator . Read and understand all safety precautions and operating instruc-

tion before installing and operating the winch. Careless winch operating can result in

serous injury and/or property damage. Never obscure or remove the warning or

instruction labels.

Throughout this manual, you will find notations with the following headings:

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. This notation is also used

to alert against unsafe practices.

Note: Indicates additional information in the installation and operation procedures

of your winch

The following symbols on the product and in the Owners manual are used:

Correct installation your winch is a requirement for proper operation.

WARNING

CAUTION

DANGER

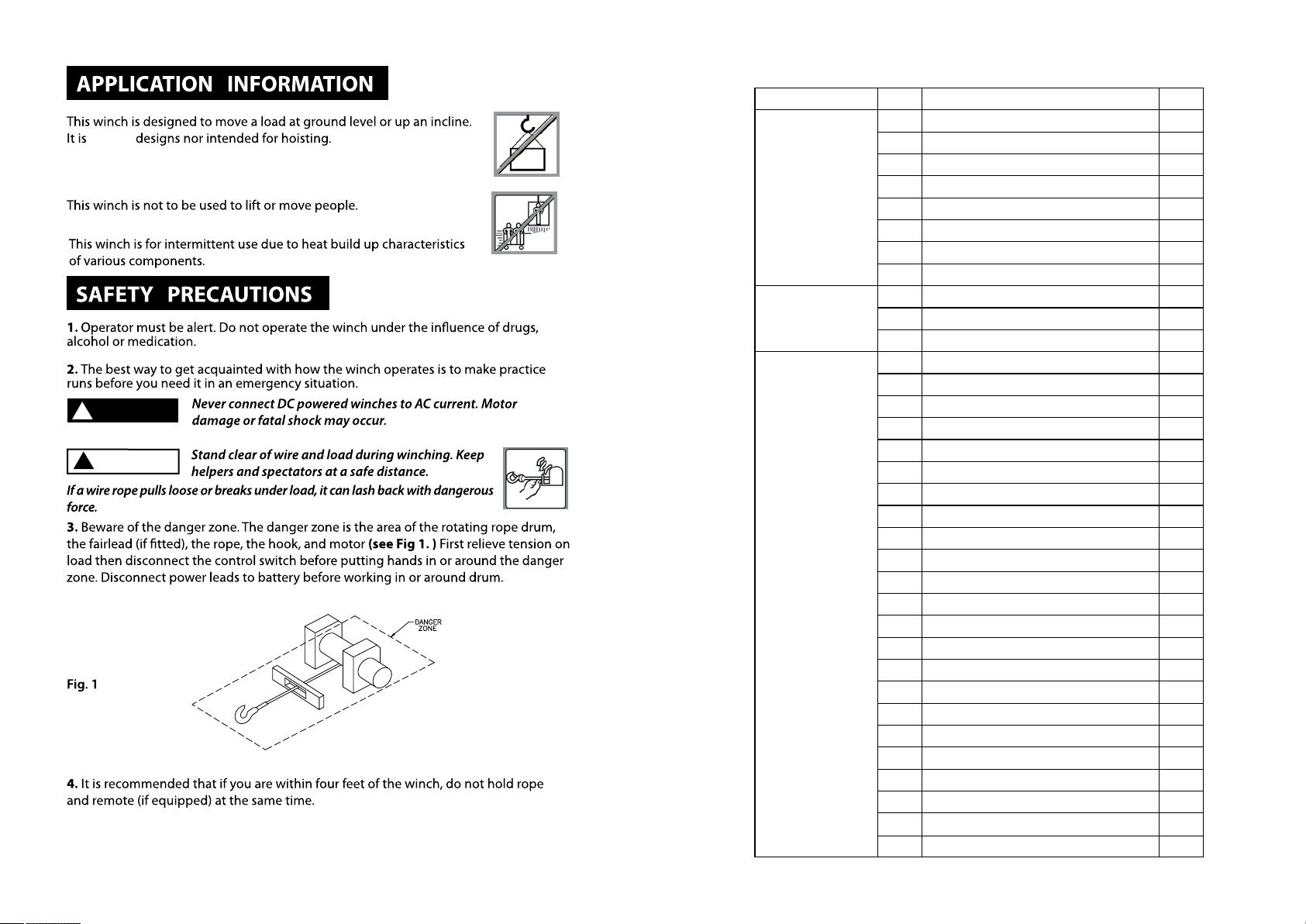

INTRODUCTION

Thank you for purchasing from Novawinch.It is designed and manufacture to provid

years of trouble-free operation.We hope you are pleased with it is performance

Please Note: Winch is designed primarily for intermittent applications. This winch is not

designed to be use in industrial or hoisting application and Novawinch does not warrant

it to be suitable for such use. Novawinch manufactures a separate line of winches for

industrial commercial use.

Congratulations on you choice!

Page 1

Synthetic Rope

Hook

Hand saver

Hawse Fairlead

Mounting plate

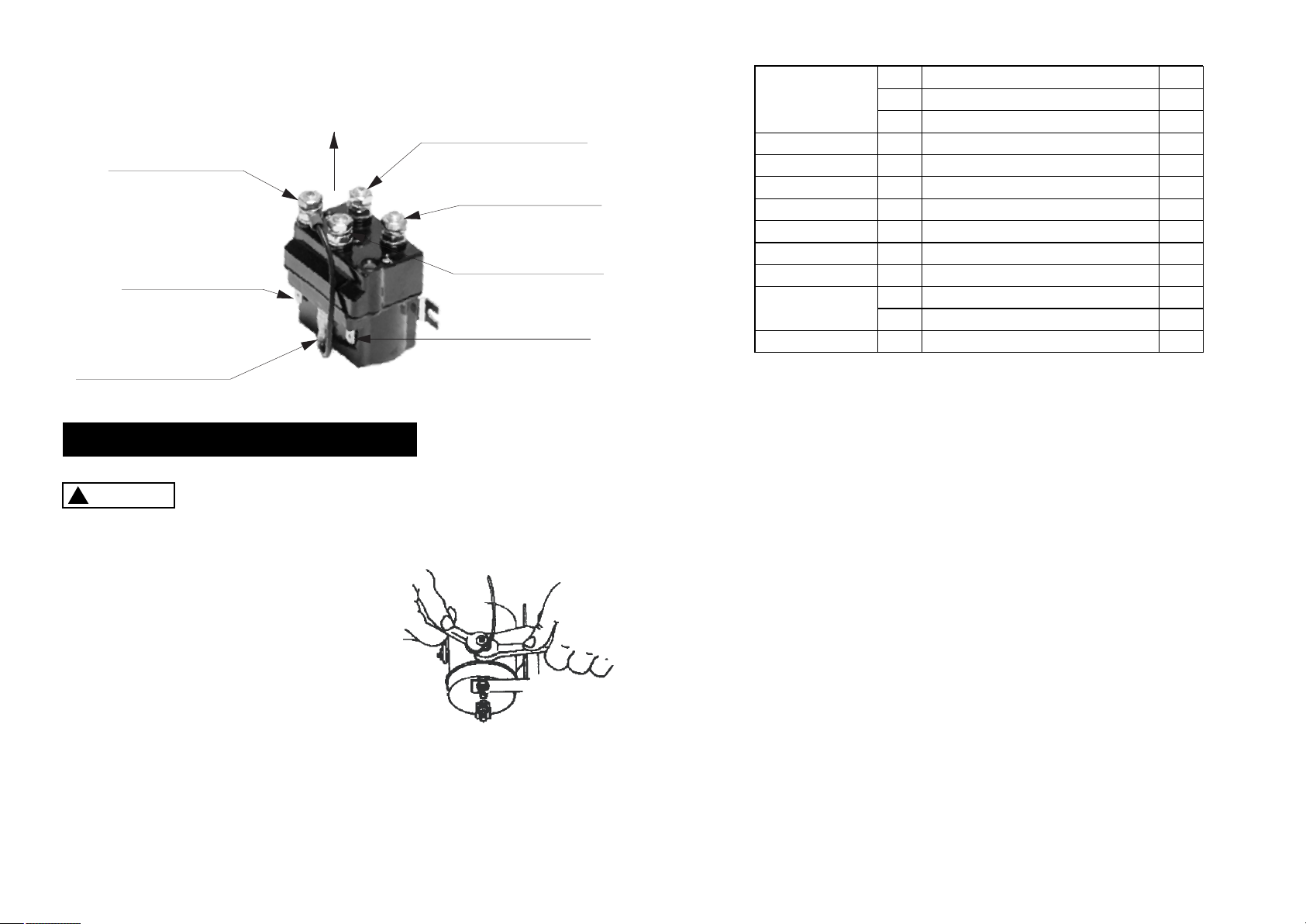

Solenoid

The thumb switch

The triangle plug

Cable set

Remote control

"Circiut breaker"

Circiut breaker cover

Screws and nuts

35

36

37

38

39

40

41

42

43

44

45

46

47

1

1

1

1

1

1

1

1

1

1

1

1

1

Synthetic Rope

Hawse Fairlead

Mounting plate

Solenoid

The thumb switch

The triangle plug

cables

Remote control

Circiut breaker

Hardware set

Page 40

Page 2

FENIX 4500SR-Parts list

"Hexagon socket cap screws M5*20"

Drum barrel

X-ring

Coupling I

"Rectangular spring"

Coupling

Spring φ4.8*18*0.8

Hexagonal drive shaft

Welded drum

Tie bar

Gear box cap

O ring

anti-wear gasket Ⅲ

3rd stage planetary gear assembly

2nd stage gear ring

2nd stage planetary gear assembly

1st stage planetary gear assembly

1st stage sun gear

Deep groove ball bearing

Gear box

hexagon socket head cap screws M5*25

Cross recessed countersunk head tapping screws ST3.5*12

"Clutch cam"

Clutch lever

O shape sealing ring Φ4.5*Φ1.5

Clutch soulplate

Clutch spring

Clutch handle

Clutch spring

φ5/flat washer

Cross recess pan head screw M5*10

Elastic cylindrical pin

Square nut

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

1

3

2

2

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

3

1

1

1

3

1

1

1

1

1

1

4

4

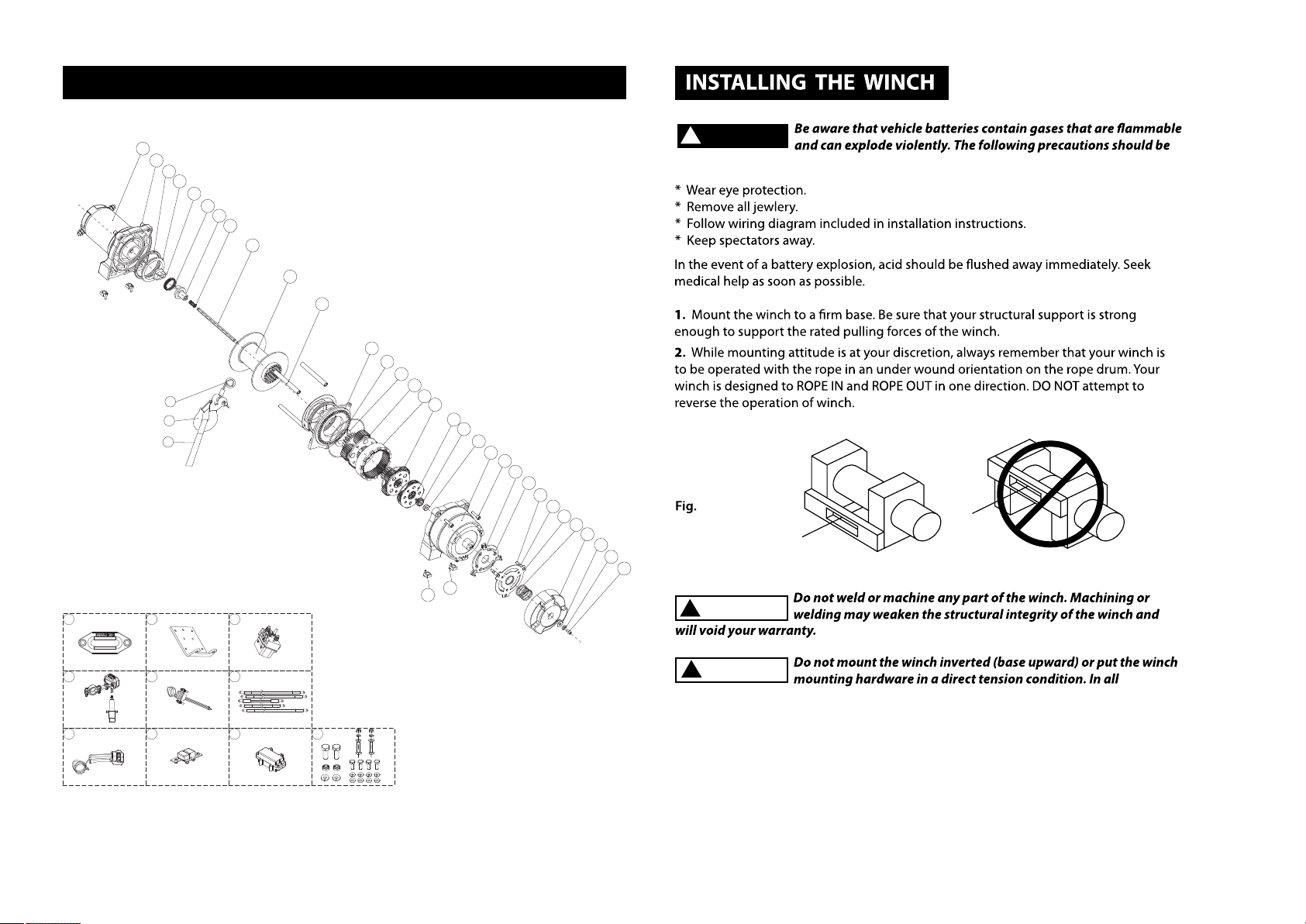

Drum Assembly

Gearbox

Assembly

Motor Assembly

No. Description Qty

Motor Assembly

Page 39

R

WARNING

!

DANGER

!

neither

Page 3

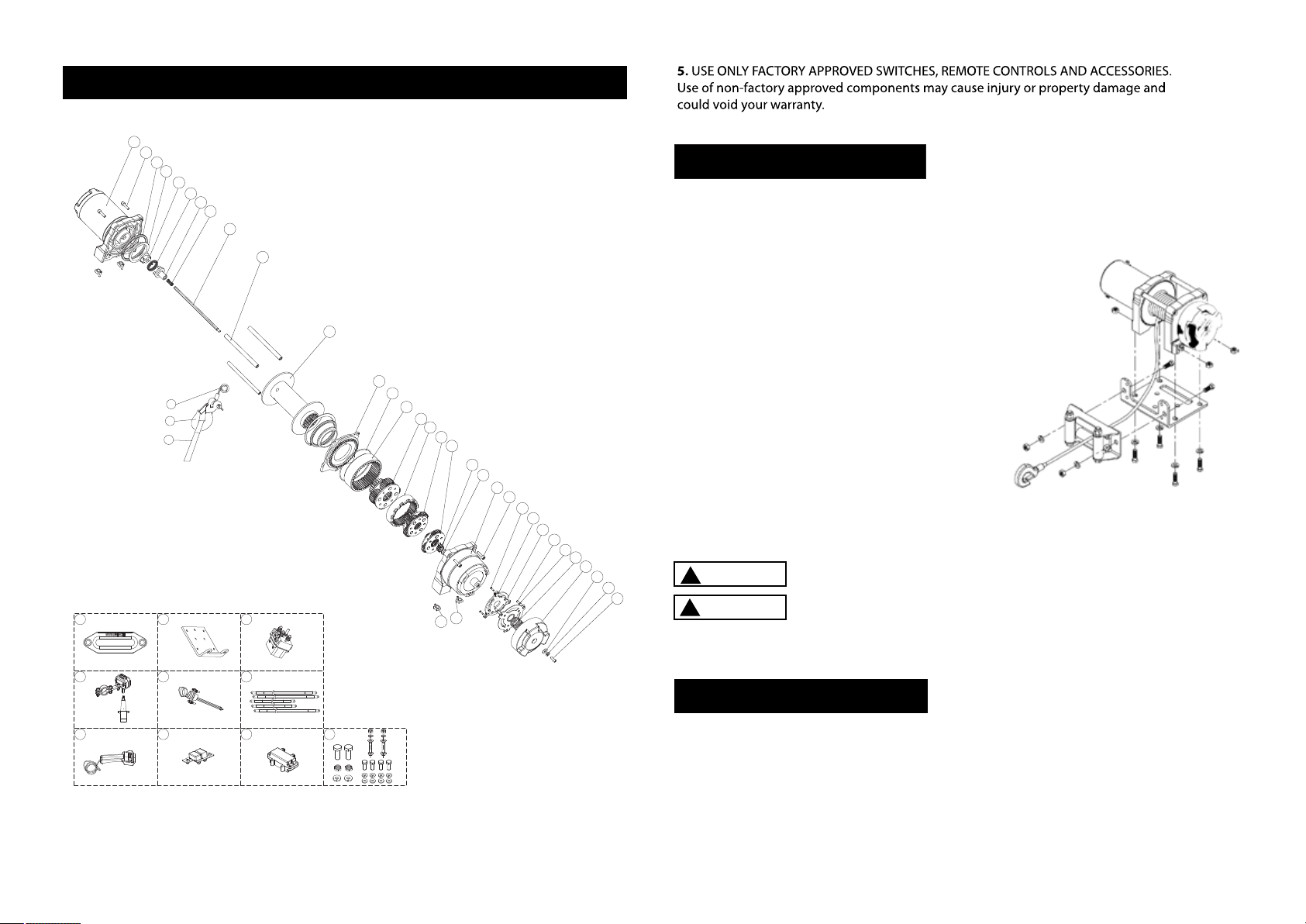

WINCH INSTALLATION

Step ( 3 )

Secure winch ( Fig. 2 ) to mounting kit or structural

support using bolts, lock washers and square

nuts supplied with winch.

Fig. 2 - Winch mounting

Step ( 4 )

Secure roller fairlead or hawse ( Fig. 2 ) to mounting plate or structural support using

hardware supplied

!

WARNING

!

CAUTION

!

Be sure that both the mounting plate and winch hardware have been

properly tightened.

No part of the vehicle ( skid plates, wiring, auxiliary lights, tires,etc. )

should impede the operation of your Novawinch. When mounting,

check all vehicle and winch parts for free operation. Be sure that the winch mounting

location does not significanty reduce ground clearance.

SOLENOID MOUNTING

1. The solenoid disconnects your winch from the battery when the vehicle is turned off.

2. The solenoid should be mounted close to the battery and in a location that is

clean and dry as possible.

Note: The solenoid should not be mounted in an orientation in which the contact

posts are in a downward position.

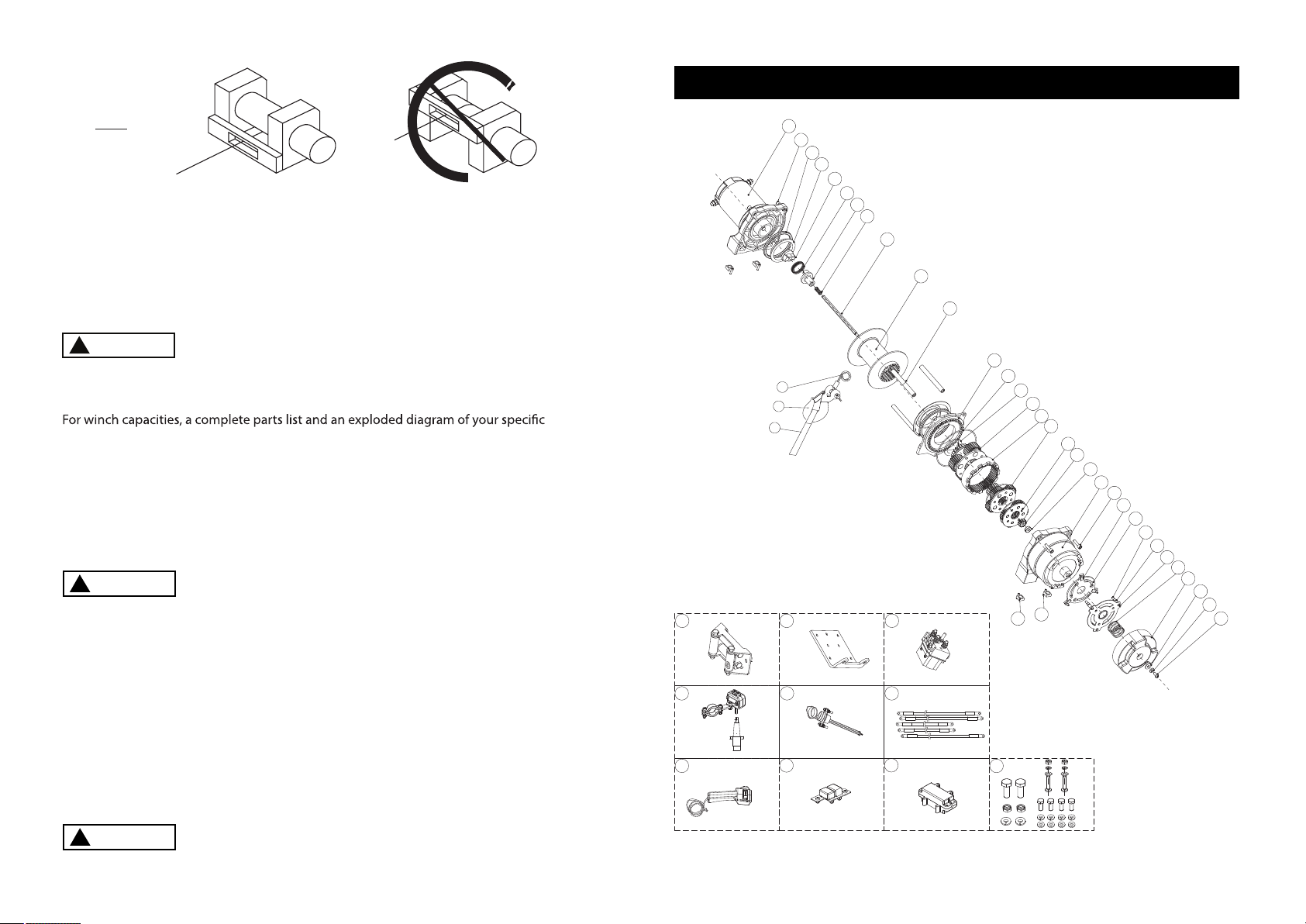

Explosion Drawing with 4500SR

1

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

2

21

23

24

26

27 28

29

30

31

22

25

34 33

32

35

36

37

44

41

38 39

42 43

45 46

40

47

Page 38

Page 4

3.Ensurethesolenoidlocation selected provides sufficient clearance form all metal

structures,such as frame tubes.

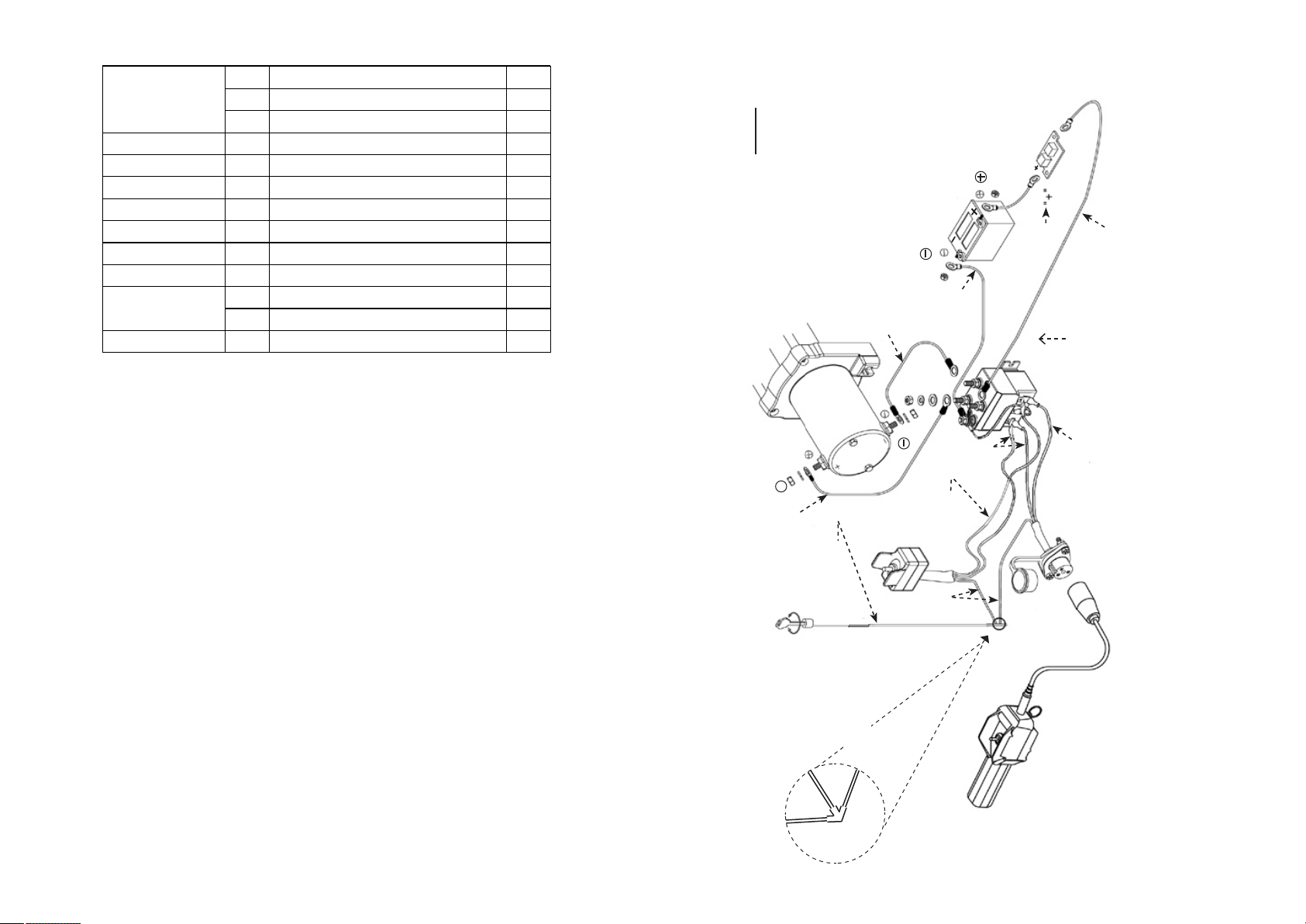

A.+ ,YELLOW wire #1 terminal

to motor positive “+”

B.- ,BLUE wire #2 to terminal

motor nagtive “-”

C. ,RDE wire to circute terminal

breaker unmarked side.

D. ,BLACK wire,toterminal

Battey Negative (-) Terminal.

E.Center spade connector,connects

the small black jumper wire,only,

(assembled as shown).

F.outerleftspade

connector,GREENwires.

G.outerrightspade

connetor,BLACKwires.

(Top of Solenoid)

TOGGLE SWITCH INSTALLATION

CAUTION

!

When attaching wires to the motor or solenoid terminals, hold the

inner nut with a wrench while tightening the outer nut with a second

wrench. Do not allow the terminals to rotate in their housings. Rotation may cause

internal wire breakage or part misalignment ( Fig 4).

Fig. 4 - Proper Terminal Tightening

Step ( 1 )

Check to ensure that the vehicle ground and positive leads from the battery are

disconnected before performing any electrical work.

Wire Rope

Hook

Hand saver

Roller fairlead

Mounting plate

Solenoid

The thumb switch

The triangle plug

Cable set

Remote control

"Circiut breaker"

Circiut breaker cover

Screws and nuts

1

1

1

1

1

1

1

1

1

1

1

1

1

35

36

37

38

39

40

41

42

43

44

45

46

47

Wire Rope

Mounting plate

Roller fairlead

Solenoid

The thumb switch

The triangle plug

cables

Remote control

Hardware set

Circiut breaker

Page 37

Page 5

DANGER

!

DO NOT ATTEMPT TO INSTALL WIRING WHEN THE BATTERY IS

CONNECTED. Automotive batteries contain flammable and explosive

gases. Wear eye protection during installation and remove all metal jewelry. Do not lean

over battery while making connections.

Step ( 2 )

Route the wiring harness, attaching the harness to hard points on the vehicle with

cable ties.

Note: When routing the wires, the appropriate terminals should be located near the

battery, switch mounting point, and winch. Your installation requirements will vary

depending upon your vehicle and winch. Make sure wires are long enough to reach

the battery, switch mounting point and winch.

Step ( 3 )

Using the supplied clamps, bracket and hardware, mount switch in a convenient

location. See Fig. 5.

Fig. 5

Ensure that the wiring harness does not interfere or come in contact

with any hot or moving engine, suspension, steering, braking or

exhaust parts.

WARNING

!

ALWAYS USE THE SWITCH MOUNTING BRACKET, SCREWS, AND LOCK

NUTS PROVIDED. Screw lengths are sized for correct penetration into

switch box. Excess penetration may result in short circuits that could lead to wire over

heating.

CAUTION

!

Step ( 4 )

It is recommended that the switch be installed on the left handlebar.

Step ( 5 )

Once the switch is mounted, route the jacketed green and black leads back to where

the solenoid is mounted. Splice the red lead into wire that energizes with ignition

switch on and de-energizes with ignition off.

WIRING INSTALLATION

Step ( 1 )

Connect the YELLOW 6 ga. wire to the #1 “+” positive terminal on the motor and connect

the BLUE 6 ga. wire to #2 “-” negative terminal to the motor. (see Fig. 6)

Route the opposite ends of the YELLOW 6 ga. and the BLUE 6 ga. wires back to the

solenoid. On the top of the solenoid, connect the YELLOW 6 ga. wire to terminal A “+”

positive. Also, on top of the solenoid connect the BLUE 6 ga. wire to terminal B “-”

negative. (see Fig. 3)

FENIX 4500WR-Parts list

No. Description Qty

Motor Assembly

"Hexagon socket cap screws M5*20"

Drum barrel

X-ring

Coupling I

"Rectangular spring"

Coupling

Spring φ4.8*18*0.8

Hexagonal drive shaft

Welded drum

Tie bar

Gear box cap

O ring

anti-wear gasket Ⅲ

3rd stage planetary gear assembly

2nd stage gear ring

2nd stage planetary gear assembly

1st stage planetary gear assembly

1st stage sun gear

Deep groove ball bearing

Gear box

hexagon socket head cap screws M5*25

Cross recessed countersunk head tapping screws ST3.5*12

"Clutch cam"

Clutch lever

O shape sealing ring Φ4.5*Φ1.5

Clutch soulplate

Clutch spring

Clutch handle

Clutch spring

φ5/flat washer

Cross recess pan head screw M5*10

Elastic cylindrical pin

Square nut

1

3

2

2

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

3

1

1

1

3

1

1

1

1

1

1

4

4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

Motor Assembly

Drum Assembly

Gearbox

Assembly

Page 36

Page 6

On the top of the solenoid, connect the RED 6 ga. wire to the terminal C.

Route the opposite end of the RED 6 ga. wire to the circuit breaker and connect the RED

6 ga. wire to the unmarked side of the circuit breaker. (see Fig. 6)

Step ( 2 )

Step ( 3 )

On the top of the solenoid, connect the BLACK 6 ga. wire to terminal D. (see Fig. 3)

On the solenoid, check that the short BLACK jumper wire lead, is installed from the

solenoid’s center at spade connector E, to the solenoid’s terminal D. (see Fig. 3).

Step ( 4 )

Step ( 5 )

Attach the BLACK wire from the rocker switch to the outer right spade,G connector, of the

solenoid.Attach the BLACK wire from the optional socket assembly to the same outer

right pade connector,G note;the solenoid top side up(see Fig.6 and 3)

Step ( 6 )

Attach the GREEN wire from the rocker switch to the outer left spade connector G on the

solenoid.Attach the GREEN wire from the optional socket assembly to the same outer

left spade connector G.note;the solenoid top side up(see Fig.6 and 3)

Step ( 7 )

Connect the RED WIRE, from the rocker switch and optionally from the socket assembly

to your ATV’s Ignition Switch key controlled wire. This wire must only have power when

the key is in the on position. A fuse protected key controlled wire is preferred. Fuse

should be rated for at least 4 amps. Cover-wind the connection with muti-layers of CE

approved electrical insulation tape, (see Fig. 6).

Connect the short RED 6 ga. wire to the end of the circuit breaker, marked positive.

Connect the other end of this RED wire to the “+” positive battery terminal. (see Fig. 6)

Step ( 8 )

Route the opposite end of the BLACK wire from, solenoid terminal D, and connect to the

“-” negative terminal on the battery. (see Fig. 6)

Step ( 9 )

Step ( 10 )

Check that all wiring is clear of sharp edges and pinch points. Check that all wiring is

firmly connected to it’s proper terminal or spade connector. Secure loose wiring with tie

wraps and electrical insulation tape.

1

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

2

21

23

24

26

27 28

29

30

31

22

25

35

36

37

34 33

32

44

41

38 39

42 43

45 46

40

47

Explosion Drawing with 4500WR

Page 35

1. +

2. -

Winch

Battery

Circuit Breaker

Solenoid

Socket

Assembly

Rocker

Switch

Hand held

Remote

YELLOW

6 ga. wire

BLUE

6 ga. wire

BLACK

6 ga. wire

RED

6 ga. wire

BLACK WIRE

GREEN WIRE

BLACK WIRE

MARKING

Fig. 6

Splice and tape

wires together

Motor

Vehicle Ignition

Key Switch

RED

WIRE

To Key Ignition

Switch, wire

To Rocker

Switch, wire

To Socket

Assembly, wire

Top

Page 7

Synthetic Rope

Hawse Fairlead

Mounting plate

Solenoid

The thumb switch

The triangle plug

cables

Remote control

Circiut breaker

Hardware set

Synthetic Rope

Hook

Hand saver

Hawse Fairlead

Mounting plate

Solenoid

The thumb switch

The triangle plug

Cable set

Remote control

"Circiut breaker"

Circiut breaker cover

Screws and nuts

35

36

37

38

39

40

41

42

43

44

45

46

47

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 34

Page 8

!

WARNING

!

Before testing winch operation, be sure to reel off approximately

two feet of rope.

TEST DRIVE

1. Double check that all wiring is correct and that there are no exposed terminals that

can short to the vehicle frame.

2. Turn the ignition key to the ON position. Check winch for

REMOTE SOCKET MOUNTING - optional

1. Determine the mounting location for the remote socket.

2. Drill three holes using the included dimensions as a guide.

3. Once the remote socket is mounted, route the jacketed green and black leads back

to where the solenoid is mounted. Splice the red lead to a key controlled electrical

wire on the ATV.

Fig. 7 - Socket Assembly mounts

from the outside, inward.

THE COMPLETE KIT

Winch

Solenoid

Rocker

Switch

Hand held

Fig. 8

Assembly

Socket

Drum Assembly

Gearbox

Assembly

Motor Assembly

No. Description Qty

Motor Assembly

FENIX 3500SR-Parts list

"Hexagon socket cap screws M5*20"

Drum barrel

X-ring

Coupling I

"Rectangular spring"

Coupling

Spring φ4.8*18*0.8

Hexagonal drive shaft

Welded drum

Tie bar

Gear box cap

O ring

anti-wear gasket Ⅲ

3rd stage planetary gear assembly

2nd stage gear ring

2nd stage planetary gear assembly

1st stage planetary gear assembly

1st stage sun gear

Deep groove ball bearing

Gear box

hexagon socket head cap screws M5*25

Cross recessed countersunk head tapping screws ST3.5*12

"Clutch cam"

Clutch lever

O shape sealing ring Φ4.5*Φ1.5

Clutch soulplate

Clutch spring

Clutch handle

Clutch spring

φ5/flat washer

Cross recess pan head screw M5*10

Elastic cylindrical pin

Square nut

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

1

3

2

2

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

3

1

1

1

3

1

1

1

1

1

1

4

4

Page 33

Page 9

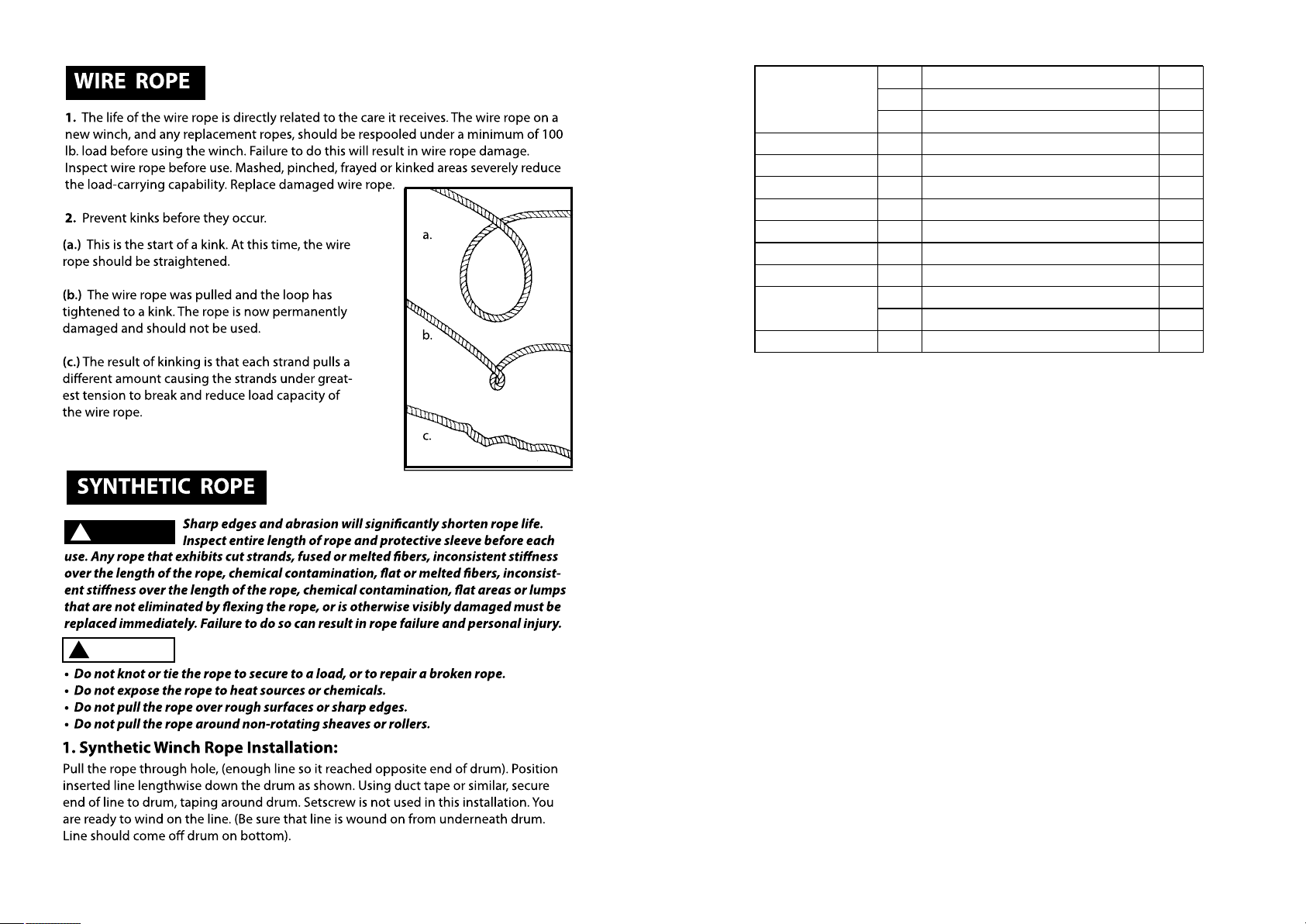

Overwind

Underwind

CAUTION

!

CAUTION

!

installations, the unit must be mounted so that the rope feeds through the hawse or

rollerfairleadonthefrontofthewinch and does not rub across housings.

DANGER

!

taken before making battery connection:

Explosion Drawing with 3500SR

9,5

1

3

4

5

6

7

8

9

10

11

12

13

14

15

17

18

19

20

21

2

22

23

24

25

26

27 28

29

31

35

36

37

16

33

30

32

34

44

41

38 39

42 43

45 46

40

47

Page 32

9

Page 10

DANGER

!

!

WARNING

!

Wire Rope

Hook

Hand saver

Roller fairlead

Mounting plate

Solenoid

The thumb switch

The triangle plug

Cable set

Remote control

"Circiut breaker"

Circiut breaker cover

Screws ahd nuts

1

1

1

1

1

1

1

1

1

1

1

1

1

35

36

37

38

39

40

41

42

43

44

45

46

47

Wire Rope

Mounting plate

Roller fairlead

Solenoid

The thumb switch

The triangle plug

cables

Remote control

Hardware set

Circiut breaker

Page 31

Fig.10

Page 11

FENIX 3500WR-Parts list

"Hexagon socket cap screws M5*20"

Drum barrel

X-ring

Coupling I

"Rectangular spring"

Coupling

Spring φ4.8*18*0.8

Hexagonal drive shaft

Welded drum

Tie bar

Gear box cap

O ring

anti-wear gasket Ⅲ

3rd stage planetary gear assembly

2nd stage gear ring

2nd stage planetary gear assembly

1st stage planetary gear assembly

1st stage sun gear

Deep groove ball bearing

Gear box

hexagon socket head cap screws M5*25

Cross recessed countersunk head tapping screws ST3.5*12

"Clutch cam"

Clutch lever

O shape sealing ring Φ4.5*Φ1.5

Clutch soulplate

Clutch spring

Clutch handle

Clutch spring

φ5/flat washer

Cross recess pan head screw M5*10

Elastic cylindrical pin

Square nut

1

3

2

2

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

3

1

1

1

3

1

1

1

1

1

1

4

4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

Motor Assembly

Drum Assembly

Gearbox

Assembly

No. Description Qty

Motor Assembly

Page 30

Fig.11

Page 12

WARNING

!

DANGER

!

Explosion Drawing with 3500WR

9,5

1

3

4

5

6

7

8

9

10

11

12

13

14

15

17

18

19

20

21

2

22

23

24

25

26

27 28

29

31

35

36

37

16

33

30

32

34

44

41

38 39

42 43

45 46

40

47

Page 29

12

12

Fig. 6

WARNING

!

Page 13

DANGER

!

Synthetic Rope

Hook

Hand saver

Hawse Fairlead

Mounting plate

Solenoid

The thumb switch

The triangle plug

Cable set

Remote control

"Circiut breaker"

Circiut breaker cover

Screws and nuts

35

36

37

38

39

40

41

42

43

44

45

46

47

1

1

1

1

1

1

1

1

1

1

1

1

1

Synthetic Rope

Hawse Fairlead

Mounting plate

Solenoid

The thumb switch

The triangle plug

cables

Remote control

Circiut breaker

Hardware set

Page 28

13

14

14

13

15

Page 14

CAUTION

!

DANGER

!

WARNING

!

"Hexagon socket cap screws M5*20"

Drum barrel

X-ring

Coupling I

"Rectangular spring"

Coupling

Spring φ4.8*18*0.8

Hexagonal drive shaft

Welded drum

Tie bar

Gear box cap

O ring

anti-wear gasket Ⅲ

3rd stage planetary gear assembly

2nd stage gear ring

2nd stage planetary gear assembly

1st stage planetary gear assembly

1st stage sun gear

Deep groove ball bearing

Gear box

hexagon socket head cap screws M5*25

Cross recessed countersunk head tapping screws ST3.5*12

"Clutch cam"

Clutch lever

O shape sealing ring Φ4.5*Φ1.5

Clutch soulplate

Clutch spring

Clutch handle

Clutch spring

φ5/flat washer

Cross recess pan head screw M5*10

Elastic cylindrical pin

Square nut

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

1

3

2

2

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

3

1

1

1

3

1

1

1

1

1

1

4

4

Drum Assembly

Gearbox

Assembly

Motor Assembly

No. Description Qty

Motor Assembly

FENIX 2500SR-Parts list

Page 27

15

16

16

Page 15

WARNING

!

WARNING

!

CAUTION

!

DANGER

!

Explosion Drawing with 2500SR

9,5

1

3

4

5

6

7

8

9

10

11

12

13

14

15

17

18

19

20

21

2

22

23

24

25

26

27 28

29

31

35

36

37

16

34 33

30

32

44

41

38 39

42 43

45 46

40

47

Page 26

17

18

18

Page 16

WARNING

!

WARNING

!

Wire Rope

Hook

Hand saver

Roller fairlead

Mounting plate

Solenoid

The thumb switch

The triangle plug

Cable set

Remote control

"Circiut breaker"

Circiut breaker cover

Screwsandnuts

1

1

1

1

1

1

1

1

1

1

1

1

1

35

36

37

38

39

40

41

42

43

44

45

46

47

Wire Rope

Mounting plate

Roller fairlead

Solenoid

The thumb switch

The triangle plug

cables

Remote control

Hardware set

Circiut breaker

Page 25

19

19

20

20

21

Page 17

If you choose not to purchase a mounting kit, your Novawinch needs to be attached

to a secure and flat mounting location.Note that your winch may note be able to be

operated safely without some equipment included in the kit. If you choose not to

purchase a mounting kit, contact Novawinch for recommended accessories and the

name of a dealer near you.

mounting kit. Read and follow directions carefully.

This winch must be mounted with the rope in the under wound

direction ( Fig. 1 ) Improper mounting could damage your winch

CAUTION

!

and void your warranty.

CAUTION

!

MOUNTING YOUR WINCH

MOUNTING KITS

NOVAWINCH RECOMMENDS THE USE OF A MOUNT KIT FOR SECURE MOUNTING TO

YOUR VEHICLE. ATV Winch mounting kits are available from your Novawinch dealer

for nearly all ATV applications. For information on available kits, contact your

Novawinch product dealer, or go to www.Novawinch.net for the most current list

of kits.

"Hexagon socket cap screws M5*20"

Drum barrel

X-ring

Coupling I

"Rectangular spring"

Coupling

Spring φ4.8*18*0.8

Hexagonal drive shaft

Welded drum

Tie bar

Gear box cap

O ring

anti-wear gasket Ⅲ

3rd stage planetary gear assembly

2nd stage gear ring

2nd stage planetary gear assembly

1st stage planetary gear assembly

1st stage sun gear

Deep groove ball bearing

Gear box

hexagon socket head cap screws M5*25

Cross recessed countersunk head tapping screws ST3.5*12

"Clutch cam"

Clutch lever

O shape sealing ring Φ4.5*Φ1.5

Clutch soulplate

Clutch spring

Clutch handle

Clutch spring

φ5/flat washer

Cross recess pan head screw M5*10

Elastic cylindrical pin

Square nut

1

3

2

2

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

3

1

1

1

3

1

1

1

1

1

1

4

4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

Motor Assembly

Drum Assembly

Gearbox

Assembly

No. Description Qty

Motor Assembly

FENIX 2500WR-Parts list

Page 24

21

22

Page 18

MINIMUM ELECTRICAL REQUIREMENTS

Refer to specifications for your winch model in the Technical Data Manual in this

age. Be sure to select the appropriate battery or power supply to handle this winch. If

the winch is in heavy use, an auxiliary battery and heavy duty alternator are

recommended.

INSTALLATION PROCEDURE

Step ( 1 )

Install mounting kit or prepare a flat, secure mounting location for winch to make sure

the motor, drum, and gearbox are aligned correctly. Carefully follow the instructions

included with the mounting kit.

!

WARNING

!

Be sure structural support is strong enough to support rated

capacity of the winch.

battery.

!

Fig. 22

Overwind

Underwind

Note: It is possible and not uncommon or discouraged to mount your Novawinch in

attitudes other than those shown in this installation manual. While mounting attitude

is at your discretion, always remember that your winch is to operated with the rope

in an under wound orientation on the rope drum ( Fig. 22 ) Your winch is designed to

ROPE IN and ROPE OUT in one direction. Do not attempt to reverse the operation of

your winch.

Do not mount winch inverted, (base upward) or put the

winch mounting hardware in direct tension condition. In all

installations, the unit must be mounted so that the rope feeds through the hawse

or roller fairlead on the front of the winch and does not rub across housings.

CAUTION

!

Novawinch, refer to the Technical Data Sheet included in this package.

For instructions on safe winch operation and tips for prolonging the life of your winch,

refer to the Safty precautions included in this package.

Note: When installing a winch, your installation may vary slightly from the instruc-

tions and diagrams that follow, depending upon your vehicle, winch, mounting kit or

structural support.

!

WARNING

!

Before you start your Novawinch installation, disconnect the

vehicle ground and positive leads from the

Explosion Drawing with 2500WR

9,5

1

3

4

5

6

7

8

9

10

11

12

13

14

15

17

18

19

20

21

2

22

23

24

25

26

27 28

29

31

35

36

37

16

33

30

32

34

44

41

38 39

42 43

45 46

40

47

Page 23

This manual suits for next models

2

Table of contents

Other NOVAWINCH Winch manuals

Popular Winch manuals by other brands

Paccar Winch

Paccar Winch Braden PD35A Installation maintenance and service manual

Comeup

Comeup CP-500T quick start guide

Lux Tools

Lux Tools SW-360 manual

Mile Marker

Mile Marker HI9000 Installation and operator's manual

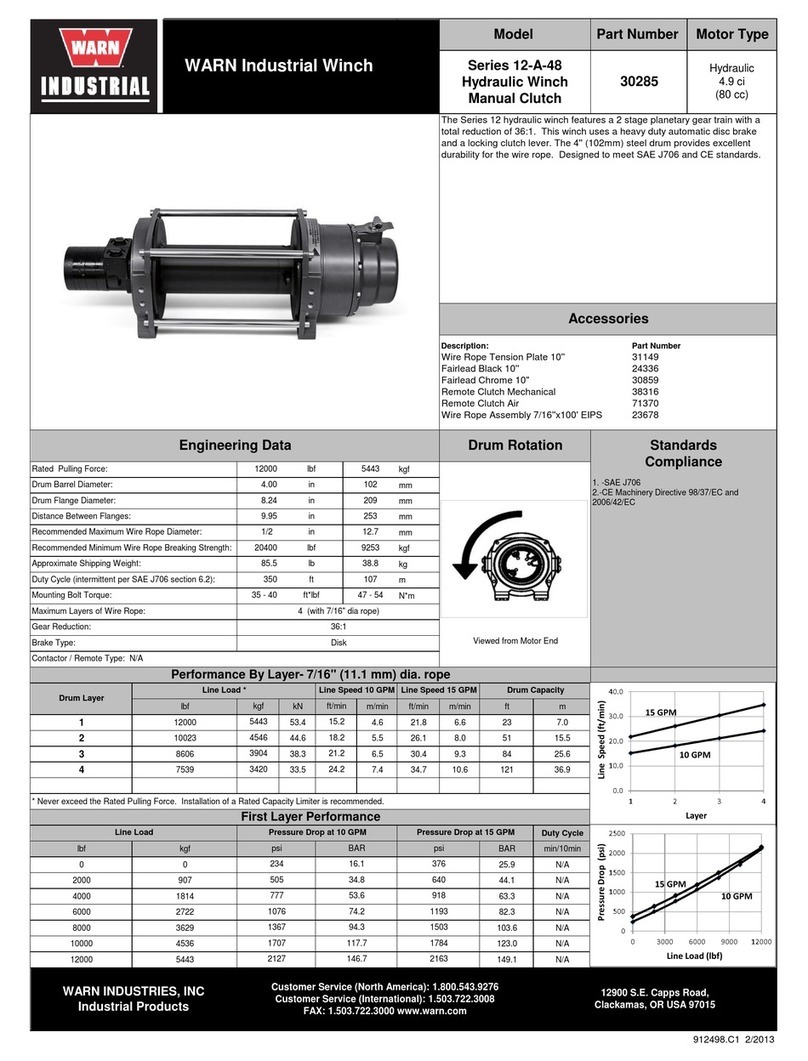

Warn Industries

Warn Industries 12-A-48 Series quick start guide

Comeup

Comeup CP-200 Assembly