2

GENERAL

Dear customer!

We would like to congratulate you for the purchase of our machine. The hydraulic forestry

winch is a forestry machine with a modern design and a construction which enables

efficient and safe work in the woods. Work in the woods can only be safe if you observe

the instruction for safe use. If you follow the instructions the machine will work perfectly

and there will be no unnecessary expenses.

We recommend you to carefully read the user manual. In case of doubt do not hesitate

to contact us.

We wish you safe work with the machine.

1. Index

GENERAL .........................................................................................................................................2

1. Index...................................................................................................................................2

2. Intended use .....................................................................................................................3

3. Tehnični podatki:...............................................................................................................3

SAFETY INSTRUCTIONS....................................................................................................................4

INSTRUCTIONS FOR USE..................................................................................................................8

1. Description.........................................................................................................................8

2. Required equipment of the tractor.................................................................................8

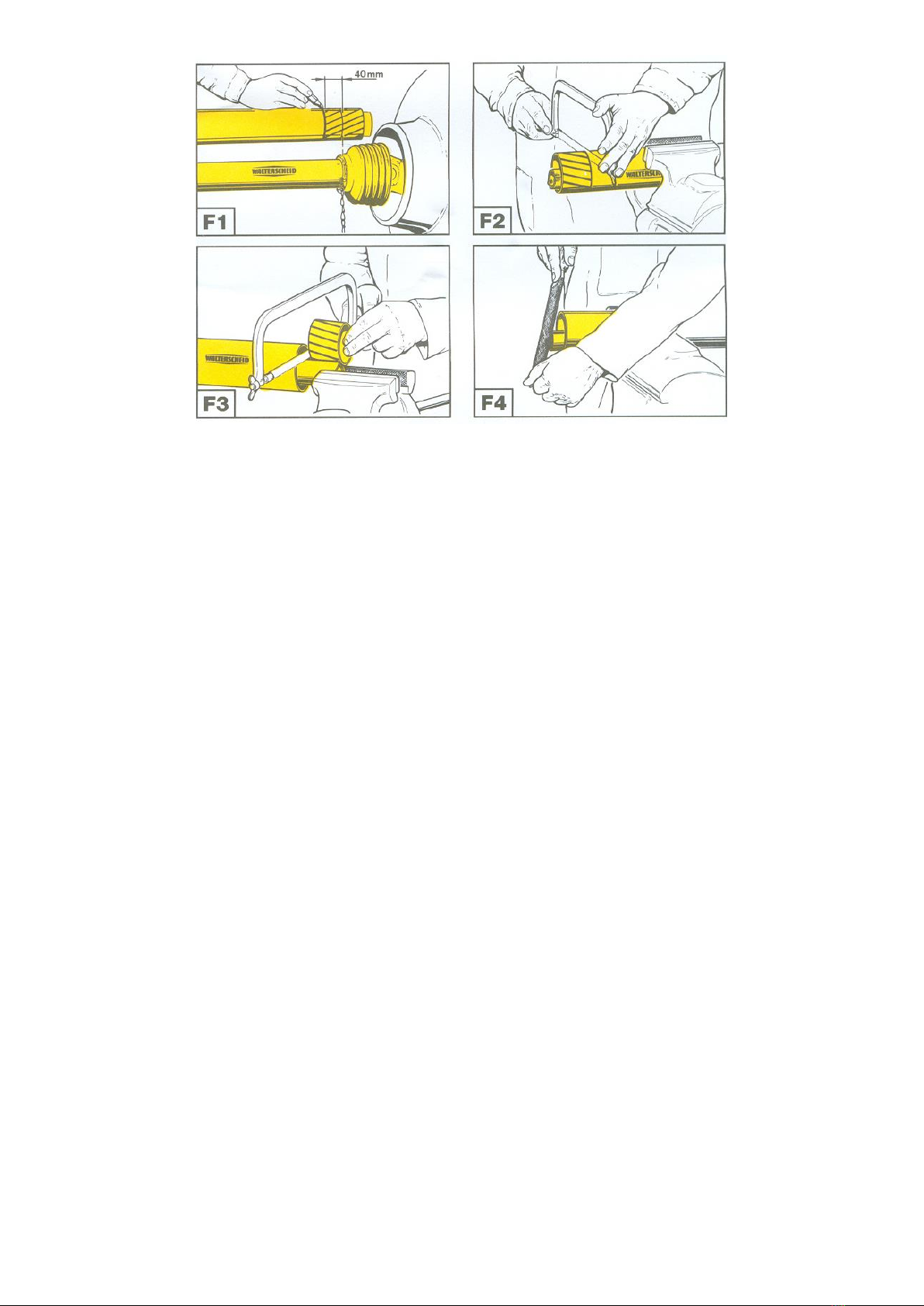

3. Pto shaft adjustment.........................................................................................................8

4. Tractor mounting...............................................................................................................9

5. Wire rope unwinding.........................................................................................................9

6. Towing ..............................................................................................................................10

SETTINGS........................................................................................................................................11

1. Clutch...............................................................................................................................11

2. Safety brake ....................................................................................................................11

3. Brake ................................................................................................................................11

4. Drive chain tensioning....................................................................................................13

7. Wire rope assembly.........................................................................................................14

MAINTENANCE LUBRICATION.....................................................................................................14

TROUBLESHOOTING ......................................................................................................................15

EC DECLARATION OF CONFORMITY ...........................................................................................17

Spare parts list..............................................................................................................................18