NOVAWINCH CH500 User manual

PLEASE READ CAREFULLY BEFORE OPERATE THE WINCH

2020.09.10

ELECTRIC WINCH

1689 Xianyuan Road,Jinhua,Zhejiang,China

Tel:0086-579-82262697

Fax:0086-579-82262706

E-mail: info@nowvow.net

http://www.novawinch.net

CH500

DESCRIPTION

UNPACKING

The CH series electric winch is for intermittent duty only. Motor cool-down time is

required. Can be mounted horizontally or vertically. Winch can beutilized in a variety

of lifting operations involving machinery, trucks, boats, farm implements, etc.

Equipped with DC motor, permanently lubricated/sealedgear box, switch with

harness assembly. For additional information, consult Specifications and Performance.

Please unpack carefully and read the instructions before beginning. Inspect carefully

for any damage that may have occurred during transit. Check for loose, missing or

damaged parts.

This equipment must be used as recommended by the manufacturer. Failure to follow

these recommendations could endanger your life or cause property damage.

DANGER

Page 1 Page 14

CH500-Parts list

Mounting Plate

No. Description Qty Remark

Electric Motor

Assembly

Gearbox Assembly

Drum Assembly

Tie Bar Assembly

Accessories

Motor

Stationary Gear Housing Assembly

Rub Reduce Washers

Gear Carrier Assembly

Rub Reduce Washers

T-Series Rotator Gear

Drum Support Plate

Spring Washer φ5

Cap Screw M5×12

Clutch Assembly

Spring

T-Series Base Plate

The big washerφ8

Cap Nut M5

Gear Ring

Retaining Ring Clip

Spring Washer φ5

Cap Screw M5×12

Tie Bar

Drum Support Bushing

Drum Assembly

Screw M5×8

T-Series Bushing

Cap Screw M6×16

Cap Bolt M8×25

Washer-Flatφ8

Locking Washer φ8

Nut M8

Wire rope and hook

Handsaver

Roller Fairlead

Cap Bolt M8×20

Switch Assembly

1

2

3

4

5

6

7

8

9

11

12

17

18

24

29

30

8

9

16

10

13

14

15

19

20

21

22

23

25

26

27

28

31

32

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

2

2

2

1

1

1

1

2

2

4

4

4

1

1

1

2

1

1

1

1

33

34

Protection Relay Set

Relay Connect Wire

GENERAL SAFETY

INFORMATION

Do not use for lifting, supporting, or transporting people, or over areas

where people are present. Disconnect power before servicing.

1.Read and save allinstructions.

2.Do not over load. See Performance information. Do not maintain power to the

winch if the motor stalls. Overloads can damage the winch and create unsafe

operating conditions.

3.Learn to use winch. After installing your winch, take the time to practice using it so

that you are comfortable with it when the need arises. Periodically check the winch

installation to assure that all bolts are tight.

4.Never allow children or untrained personnel tooperate winch.

5.Inspect electric cable fittings for tightness be fore each use.

6.Replace damaged or broken parts immediately with manufacturer’s recommended

replacement parts.

Never connect winch to110VAC power as fatal shock may occur.

7.Use caution when using the winch. Keep people, pets, and property clear

of the path of the load. Do not use winch to lift or move people.

8.Do not use the winch to support an unattended load.

9.Keep the electric cables from heat, oil, and sharp edges. Periodically inspect for

damage.

10.Do not operate the winch under the influence of fatigue、medication、

drugs or alcohol.

WARNING

DANGER

Page 2Page 13

Explosion Drawing With 500

1

2

3

4

6

78910

11

12 13 14

15 16

89

17

18

20

19 21

22

23

26

25

5

21

22

23

28

27

30

29

2.8596

24

32

31

33

34

Page 3

11.Never install winch in such a way that the warning and instruction labels are

obscured. Someone who has not read this manual may need to see them to

understand the proper operation of the winch.

12.Always operate the winch with an unobstructed view of the winching operation.

13.Check for correct direction of rotation before using winch. The winch must be

properly wired to ensure correct direction of drum rotation.

15.Always unplug the remote pendant before working in or around the roller

fairlead or winch drum (the danger zone)to prevent the winch from being

turned on accidentally. Use hand saver when winding end of wire rope.

16.When lifting a load, slowly take up the slack until it be comes taut. Stop, recheck

all winching connections.

17.Do not machine or weld any part of the winch. Such alterations may weaken the

structural integrity of the winch, and void your warranty.

18.Never allow shock loads to beapplied to winch.

14.Remove and store the remote pendant assembly in a safe place when

not in use to prevent unauthorized use.

Page 12

TROUBLESHOOTING

CHART

Motor will not operate or 1. Damaged or stuck CAUTION Be prepared to

runs in one direction only solenoid disconnect power when

performing this test. If a

solenoid sticks once, it

is likely to stick again

and must be replaced

immediately .

1. Tap solenoid to free stuck

contacts. Check by applying

voltage to the small solenoid

terminal. Be sure solenoid is

grounded back to source. A

solenoid that is not stuck will

make an audible ?click? when

first energized.

2. Switch inoperativ 2. Replace switch.

3. Broken wires or bad connection 3 Check for poor connections.

CAUTION Always use 2

wrenches (See Figure 1).

4. Damaged moto 4 Replace or repair motor.

5. Solenoids not grounded 5. Check the ground path

between battery negative and

solenoid base.

Winch will not shut off Solenoid stuck “ ON “ If a solenoid sticks on, reverse

direction and hold trigger switch

until the power lead can be dis-

connected. A safety disconnect

switch is available as an accessory.

Motor runs extremely hot 1.Long period of operation 1.Allow to cool.

2. Damaged motor 2. Replace or repair motor.

3. Damaged brak 3.Replace or repair brake.

Motor runs but with insufficient 1.Weak batter 1. Recharge or replace battery.

power or line speed Check charging system.

2. Battery to winch wire

extended with same size wire 2. Use larger diameter wire.

3. Poor battery connection 3. Check battery terminals for

corrosion. Clean as required.

4. Poor groun 4.Check and clean connections.

5. Damaged brak 5. Repair or replace brake.

Winch runs backward 1.Motor wires reversed 1. Recheck wiring.

2. Solenoids wired incorrectly 2. Recheck wiring.

Will not hold load 1.Excessive lo 1. Reduce load or double line.

2. Worn or damaged brake 2. Repair or replace brake.

Symptom Possible Cause(s) Corrective Action

Page 4

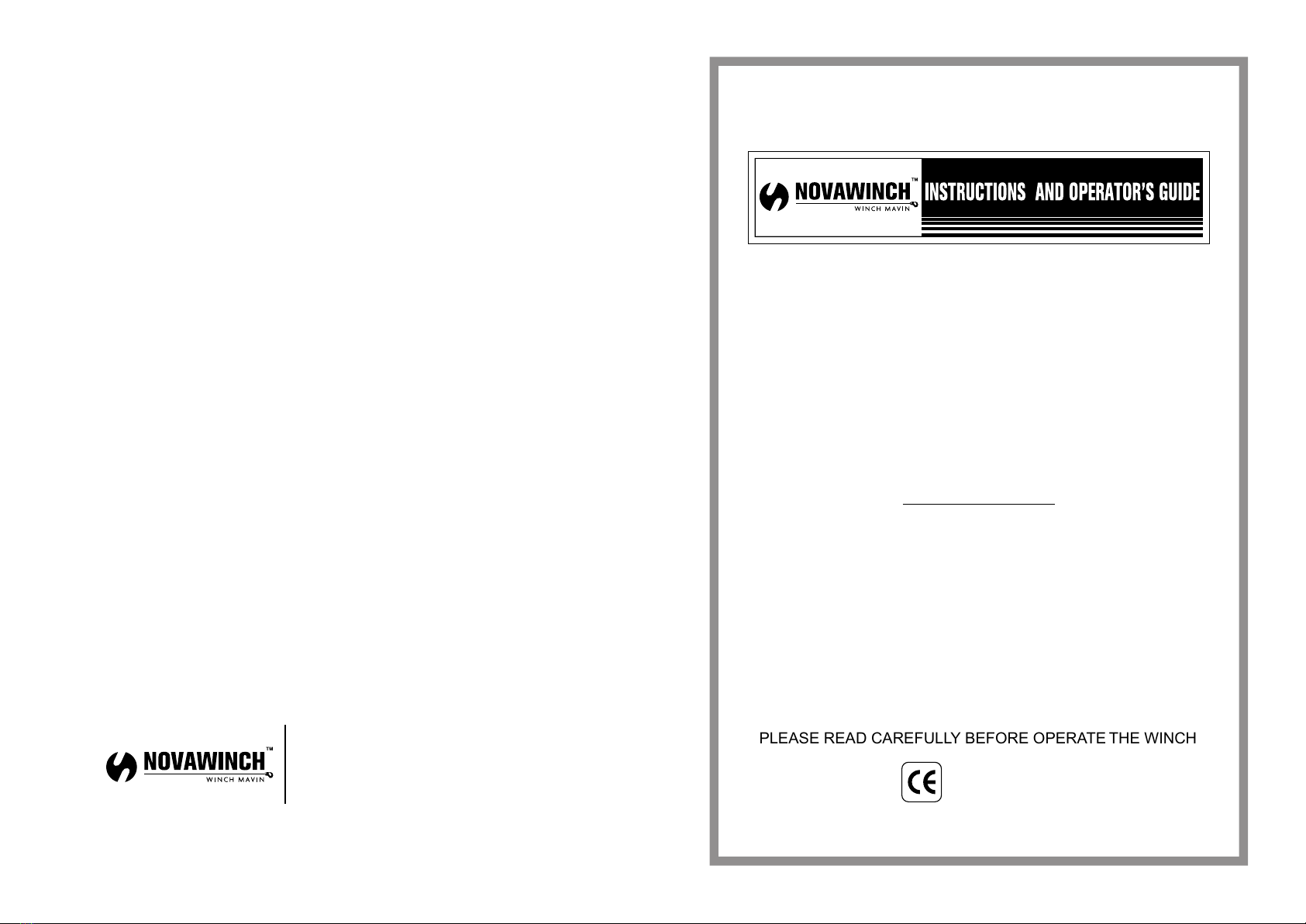

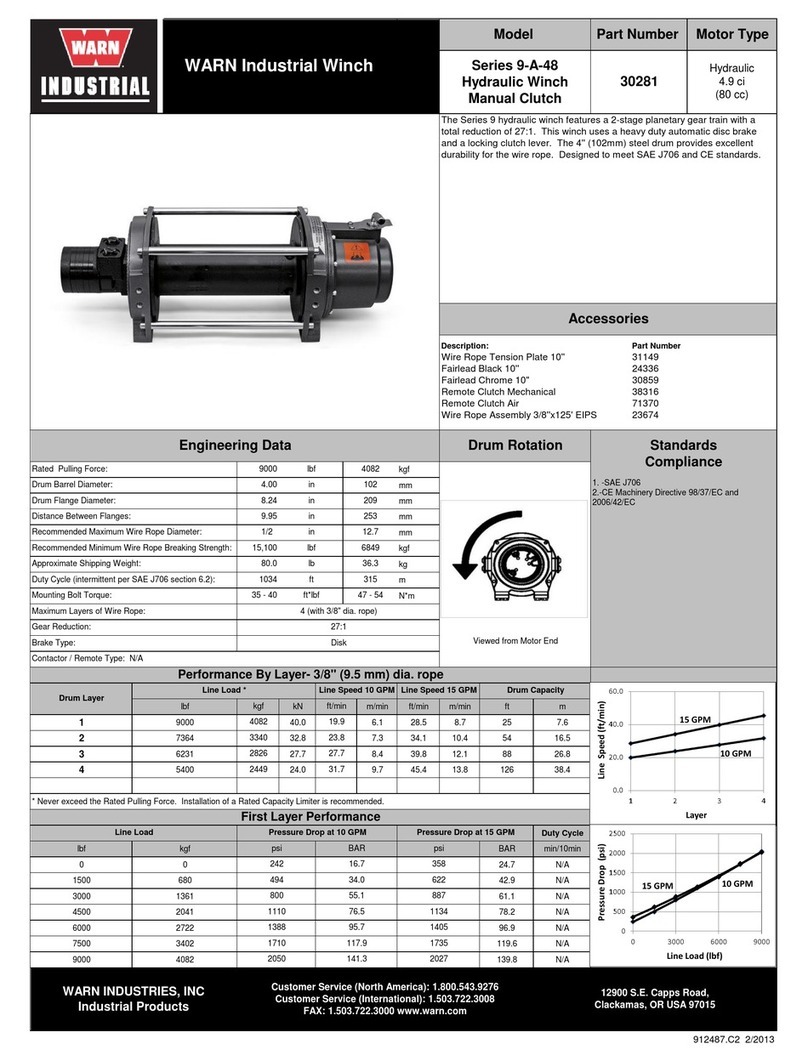

CH500

GENERAL DESCRIPTION

DIMENSIONS

Page 11

LUBRICATION

a

b

c

a. This is the start of a kink. At this time, the wire rope should best raightened.

b. The wire rope was pulled and the loop has tightened to a kink. The wire rope is now

permanently damaged and must be replaced.

c. Kinking causes the wire strands under the greatest tension to break and thus

reduces the load capacity of the wire rope. The wire rope must be replaced.

The winch is permanently lubricated. There may be grease leakage out of winch,

especially during first few operations. This is normal and it is not necessary to grease

or oil any internal part of winch at anytime.

Periodically lightly lubricate wirerope with penetration oil and wipeoff excess.

Figure 6

3. Prevent kinks before they occur. (See Figure 6)

Page 5

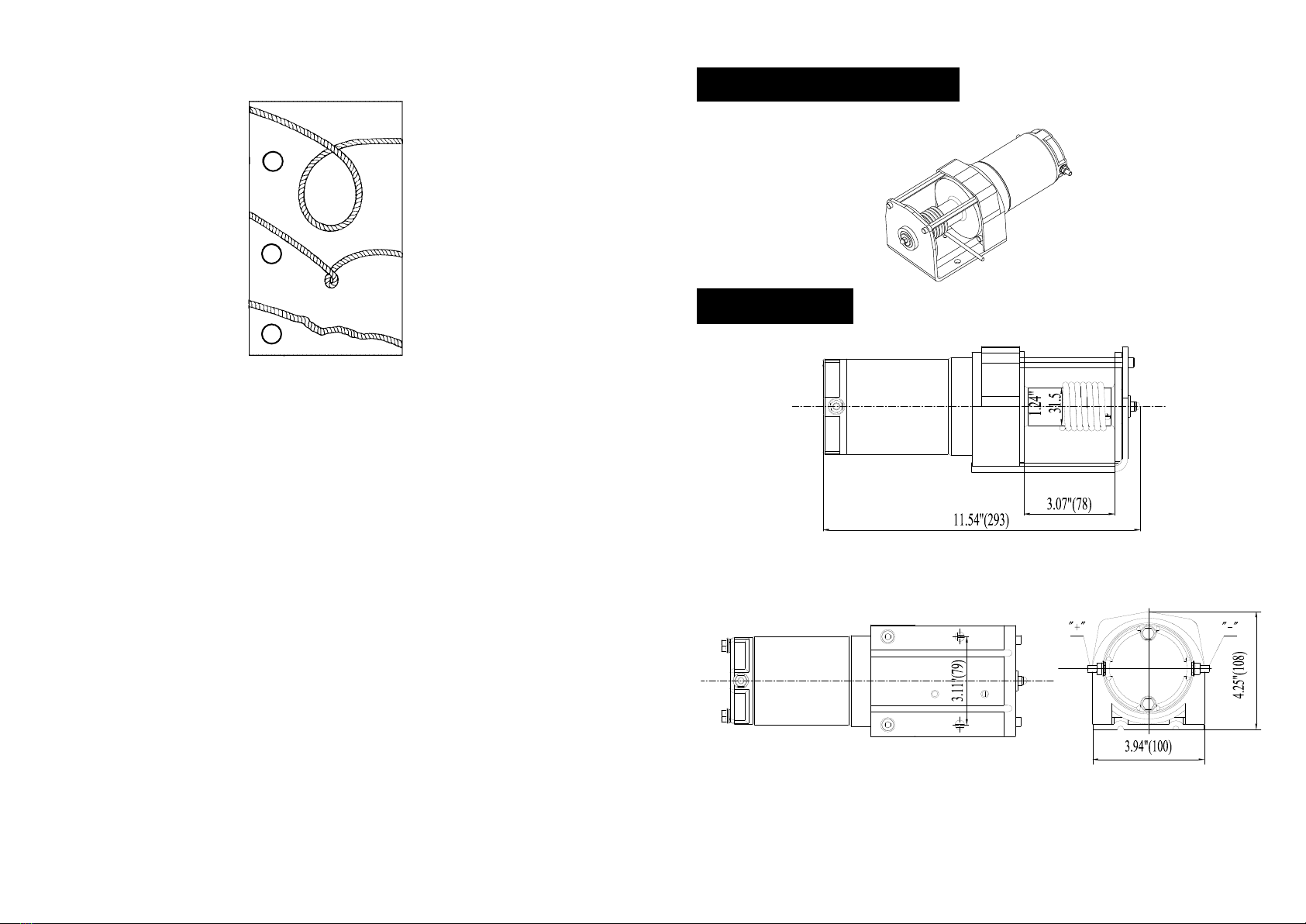

Line pull lbs

kgs

Line speed fpm

mpm

Motor current amps

12V DC Line speed and motor current (first layer)

0

0

11.2

3.4

18

500

226

8.2

2.5

32

Layer of cable

Rated line pull

per layer

lbs

kgs

Cable capacity

per layer

ft

m

500lb Line pull and cable capacity

12

500 395

226 180

5.5 12.4

1.7 3.8

327

148

15.7

4.8

3

Rated line pull

Motor(Series wound)

Gear train

Gear ratio

Braking action

Fairlead

Wire rope

Dimensions

Bolt pattern

Net weight

CH500lb Specifications

500lbs(226kgs)

DC 12V: 0.54hp/0.40kW

1 stage planetary gear

153:1

Differential self-locking

3/16"×15.7’(Ф4.8×4.8m)

11.81"×3.93"×4.25"(300mm×100mm×108mm)

3.12"(79.5mm)

4.7kg

4-way roller fairlead

Page 10

6. Replace wire rope when frayed.

Figure 5

Right Wrong

2.Never hook wire rope back onto itself. Hooking wire rope onto itself can damage

rope. Use a nylon sling (See Figure 5). When using a sling, make sure that sling is

properly seated in saddle of hook.

Avoid continuous pulls from extreme angles. This will cause wire rope to pile

up at one end of drum. This can jam wire rope in winch causing damage to rope

or winch itself.

3.Do not use wire rope as a ground for welding.

4.Never touch welding electrode towire rope.

5.Keep wire rope tight and even on drum.

TIPS FOR EXTENDING THE LIFE OFYOUR WINCH

1.Keep a tightly wound wire rope drum. Do not allow the wire rope to become loosely

wound. A loosely wound drum allows a wire rope under load to work its way down

into the layers of wire rope on the drum. When this happens, the wire rope maybe

come wedged within the body of the windings, damaging the wire rope. To prevent

this prob-lem, keep the wire rope tightly and evenly wound on the drum at all times.

A good practice is to rewind the wire rope under ten-sion after each use. One way to

do this is to attach the hook to as mall load and winch that load to rewind rope.

CAUTION

2. To maximize winch and wire ropelife, use pulley block to doubleline heavier loads.

Keep clear of winch wire rope and hook when operating winch. Never put your

finger through the hook. Placing finger(s) in hook could result in injury.

WARNING

Page 6Page 9

Figure 3

HANDLING THE WIRE ROPE

Use heavy leather gloves when handling wire rope. Do not allow wire rope to slide

through hands.

1.Never winch with less than 5 turns of wire rope around winch drum, since wire rope

and fasten-er may not withstand the load. Always use hand saver bar when guiding

hook for the last few feet of rope (See Figure 4)

Figure 4

WARNING

REPLACING THE WIRE ROPE

Replace damaged wire rope with the manufacturer’s recommended replacement part

or a factory approved equivalent identical in strength, quality, lay, and stranding. Pa-

ss the attaching end of wire rope through the fairlead and attach it to the drum. When

inserting the wire rope into the drum, insert it into the correct end of the hole provided

(See Figure 3). Tighten the set screw securely. It is important that the wire rope be

wound tightly onto the drum.

LOCATION

Step (1)

Step (2)

INSTALLATION

Mount the winch to a firm base. The structure the winch is attached to must be capable

of with standing a load greater than 1-1/2 times the winch′s rated line pull.

The winch can be mounted in a horizontal or vertical position. Do not mount the winch

where there would be the possibility of it being submerged in water. The winch is not

waterproof.

This winch must be mounted with the pull in the underwind direction. Improper

mounting could damage your winch, cause the brake to not work and void your

warranty.

Install structural support for winch. See "Dimensions" section for winch dimensions.

Mount the winch to the mount that you have designed. Mounting bolts supplied are the

correct length for use with a 1/4"(6.3mm) thick mounting plate.

Do not substitute any bolt with strength weaker than grade 5.

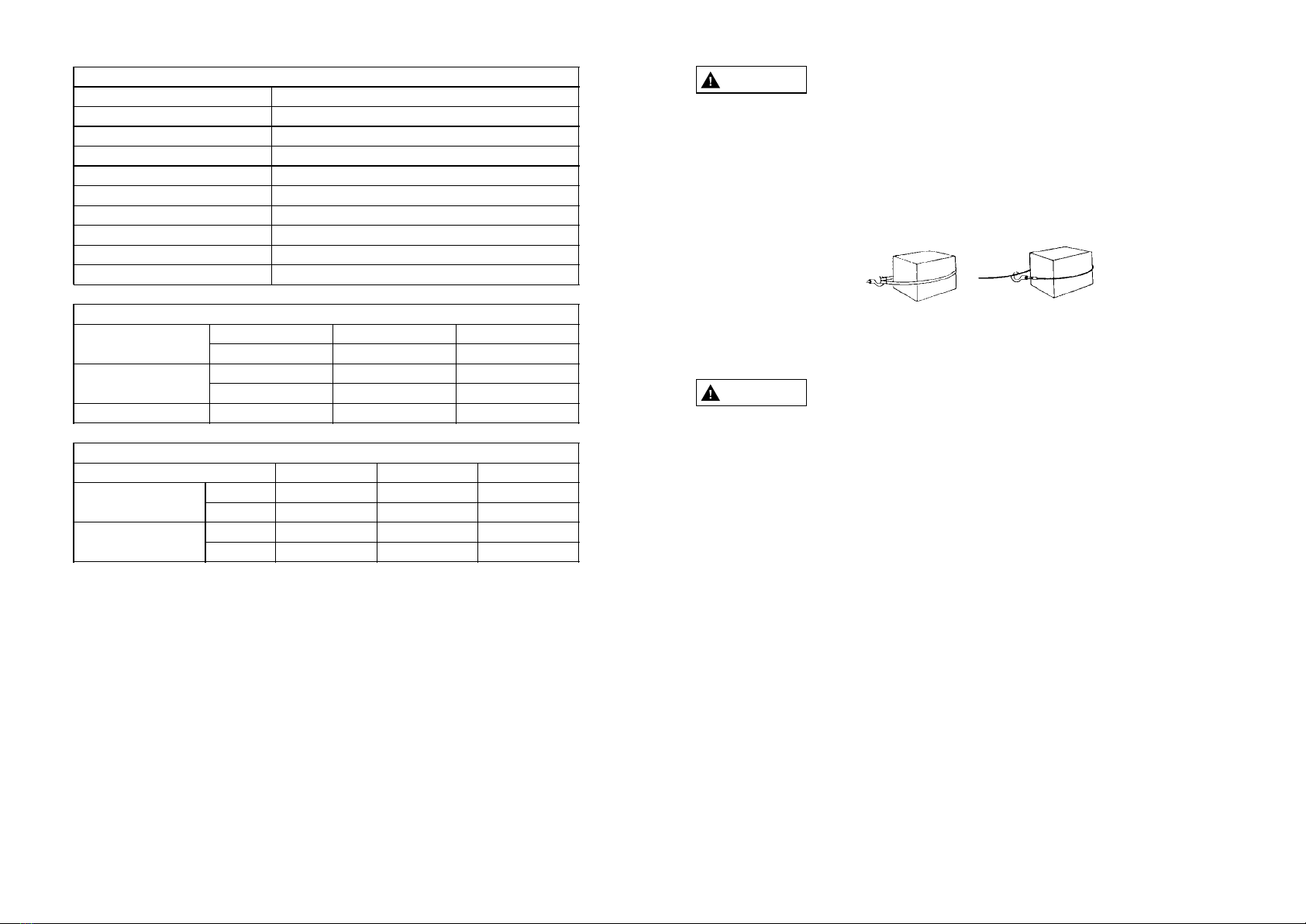

When attaching wire to the motor terminals and solenoids (relays),hold the inner nut

when tightening the outer nut. Do not allow the terminals to rotate. It may cause

internal wire breakage or part misalignment. Be especially careful in preventing the

solenoid (relay) terminals from rotating. Any rotation can damage the solenoid

(see Figure 1) .

WARNING

WARNING

Figure 1

Step (4)

Electrical Connection

Figure 2

Batteries con-tain gases which are flammable and explosive. Wear eye protection

during installation and remove all metal jewelry. Do not lean over battery while

making connections.

Select a convenient location for mounting the Control box. The mounting plate must

be electrically grounded to the battery. If it is not, the winch will not work.

There are four lengths of wire form the remote control, two red and two black. These four

wires can reach battery to the winch. (See figure 2). When routing all wires, be sure to

keep them away from all hot or moving parts.

1. Connect one of the red wire ring terminal to the motor positive terminal.

Connect one of the black wire ring terminal to the motor negative terminal.

2. Connect one of the red wire ring terminal to the battery positive terminal.

Connect one of the black wire ring terminal to the battery negative terminal.

+

-

red wire with terminal

sheathed red thermo-shrink

pipe to motor's positive stud

+

-

black wire with terminal

sheathed black thermo-shrink

pipe to motor's negative stud

red wire with terminal to

battery's positive stud

black wire with terminal

to battery's negative stud

Plug the remote control and with the directional lever in the “rope out” position,

momentarily depress the trigger to check for proper rotation direction of the winch drum.

If the winch run in the wrong direction, reverse the wires connected to the winch motor.

Page 7 Page 8

MAINTENANCE AND REPAIR

We recommend using a 15Amps circuit breaker for 24V model, 30Amp circuit breaker

for 12V model between the battery positive terminal and wire that goes to the switch

or solenoid pack. The circuit breaker prevents to overload to the switch and to the

winch motor.

Periodically check tightness of mounting bolts and electrical connections. Remove

any dirt or corrosion that may have accumulated on the electrical connections.

Circuit Breaker

Your winch has a wrap spring brake that stops and holds loads up to 500 lb. (226 kg).

When the winch is powered out, as in releasing a load, the brake is engaged and the

motor must overpower the brake resistance to rotate the drum. Therefore, it is normal

for the winch to operate faster in one direction than the other. The brake is designed

for the wire rope to be used in the unde rwind position only. Drum must turn counter-

clockwise, looking from motor end, when winching in. DO NOT OVER WIND. Powering

against the brake will cause heat to build up in the drum and may transfer heat to the

wire rope. DO NOT POWER OUT FOR MORE THAN 2 MINUTES.

The drum mayget very hot.

CAUTION

BRAKE OPERATION

OPERATION

The switch assembly must be kept free of dirt and moisture to ensure safe operation.

Do not allow winch motor to over-heat.The winch is for intermittent use only.During

long or heavey pulls the motor will get hot.Allow to cool after 2minutes of “ON” time.

PENDANT OPERATION

CAUTION

Table of contents

Other NOVAWINCH Winch manuals

Popular Winch manuals by other brands

Kolpin Outdoors

Kolpin Outdoors POLARIS SPORTSMAN Assembly & owners manual

Fransgard

Fransgard HW-3019 manual

Polestar

Polestar 12,000 user manual

WARN Works

WARN Works PullzAll user guide

Warn Industries

Warn Industries 30281 quick start guide

Champion Power Equipment

Champion Power Equipment 100776 Operator's manual

PFAFF silberblau

PFAFF silberblau DGUV V54 Translated Operating Instructions

Grizzly

Grizzly H0937 instruction manual

Harken

Harken UniPower Radial Installation and maintenance manual

TOHO

TOHO S Series instruction manual

Cequent Performance Products

Cequent Performance Products KR Series quick start guide

TRAC

TRAC T10108-25 Installation and operating instructions