©Novinium, Inc. 2019, all rights reserved. NRI 260 –TDR Diagnosis

Revised: December 27, 2019 Page 2of 20

Table of Contents

TDR Recommended Settings................................................................................................................................................... 3

Making an Electrical Connection.............................................................................................................................................4

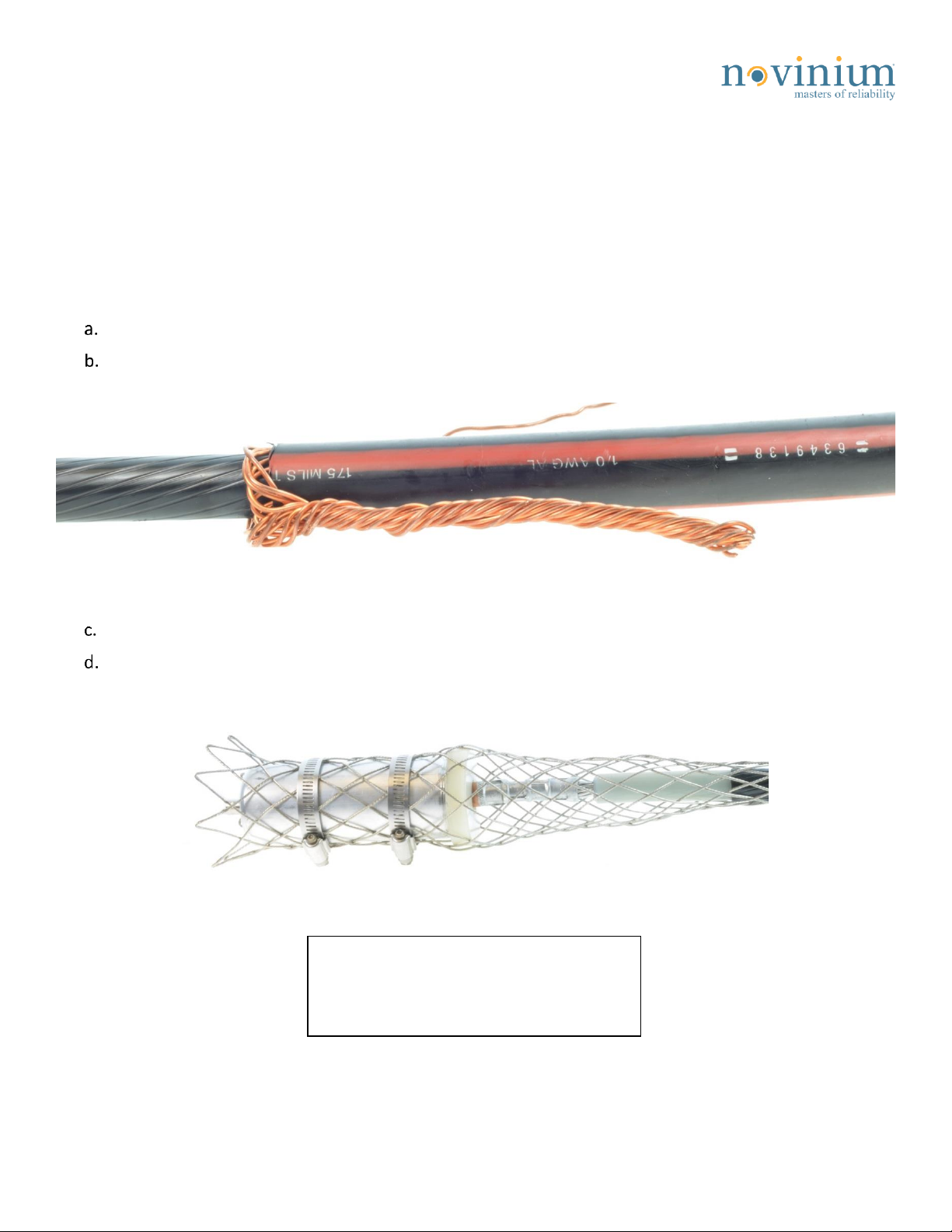

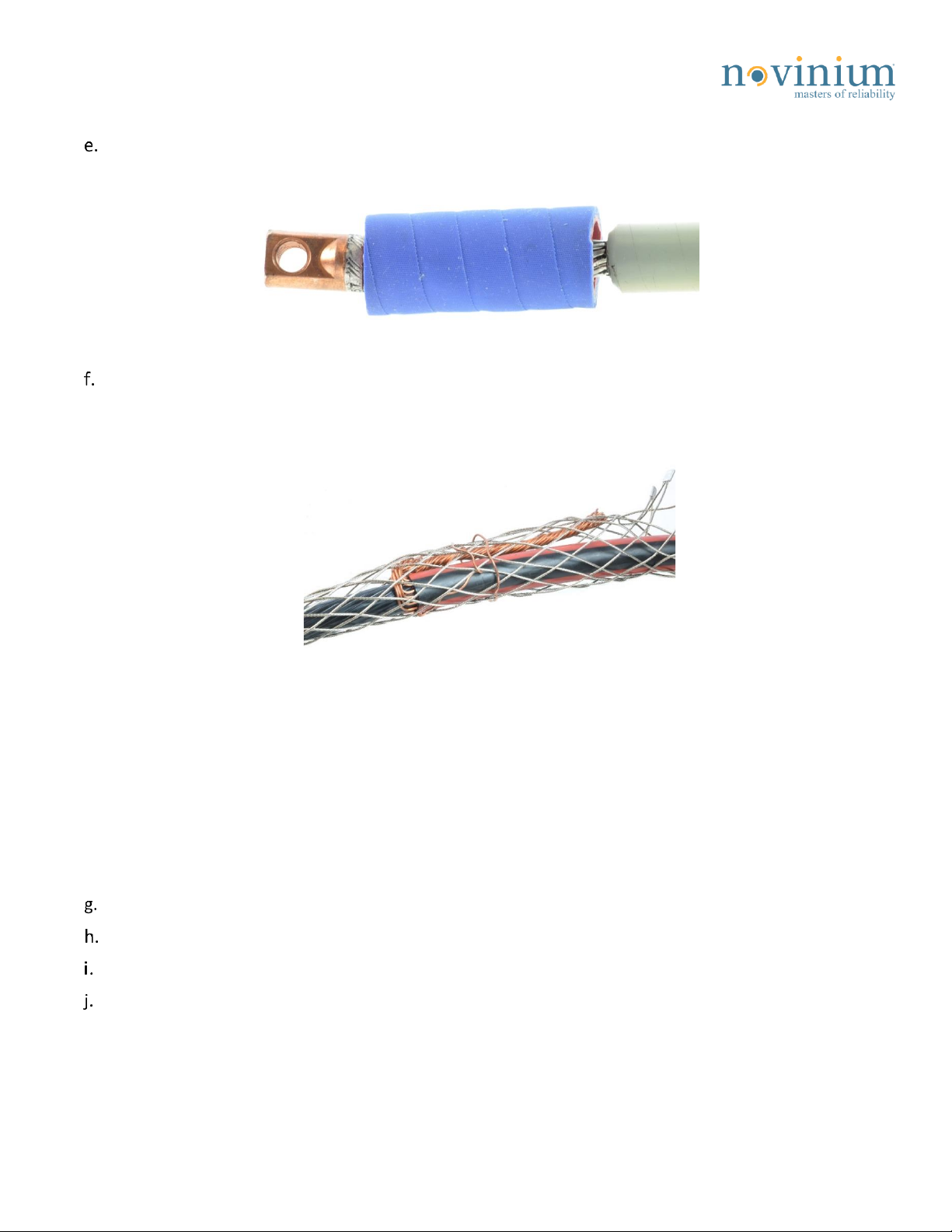

Connecting to URD cables...................................................................................................................................................4

Using alligator clips .............................................................................................................................................................5

Connecting cables with paddle connectors........................................................................................................................6

Connecting feeder cables without connectors...................................................................................................................7

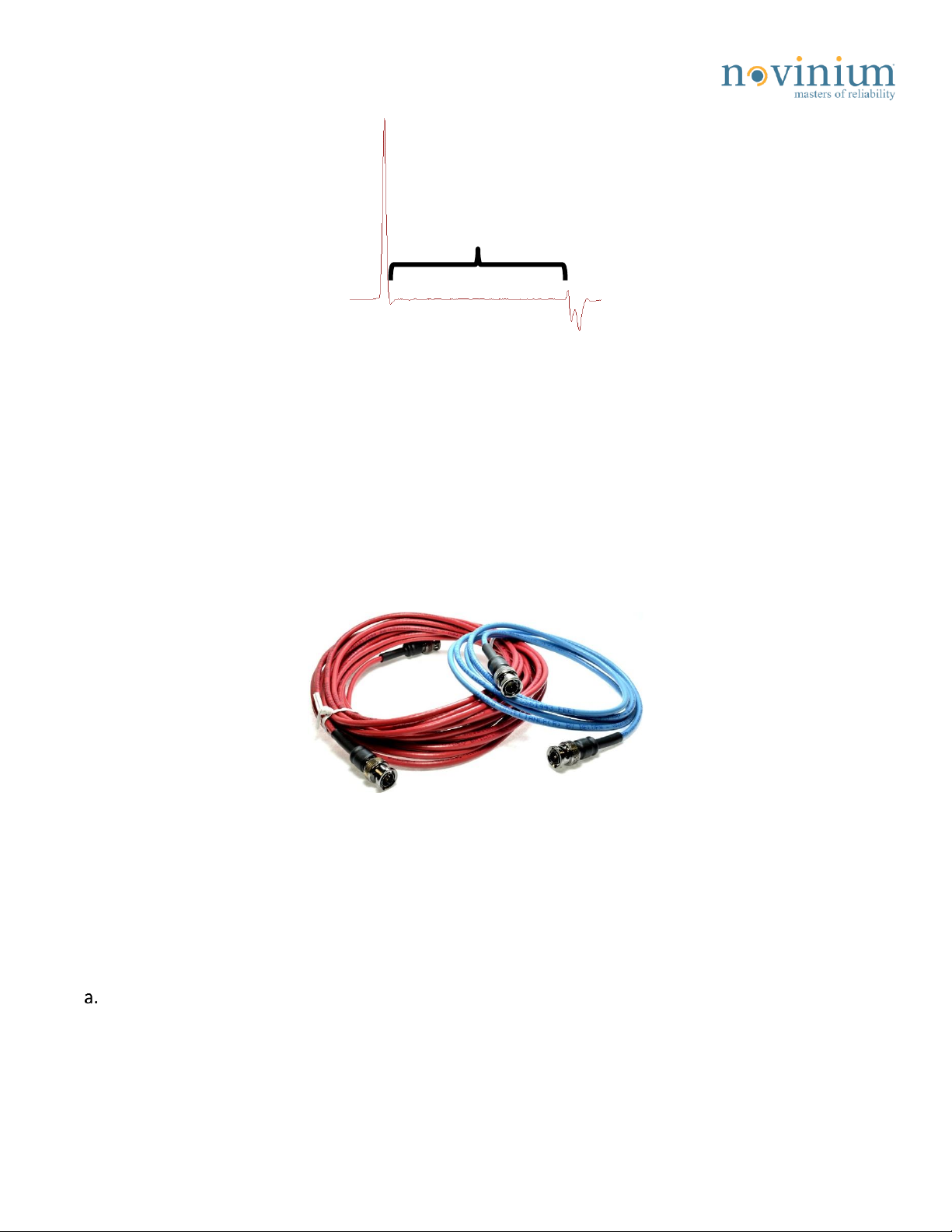

Select a Lead Cable .................................................................................................................................................................7

Checking TDR Settings.............................................................................................................................................................8

1. Startup settings.....................................................................................................................................................8

Calibrating the Velocity of Propagation (VOP)........................................................................................................................9

1. Initial VOP..............................................................................................................................................................9

2. Confirm the VOP. .................................................................................................................................................. 9

Analyzing the TDR .................................................................................................................................................................10

1. Consistency is key. ..............................................................................................................................................10

2. Find the beginning of the cable. .........................................................................................................................10

3. Find the end of the cable. ...................................................................................................................................12

4. Identify anomalies...............................................................................................................................................13

5. Measure the distances of anomalies. .................................................................................................................16

6. Swap cable leads.................................................................................................................................................17

TDR from Termination 2 .......................................................................................................................................................17

Signal Strength......................................................................................................................................................................18

Saving the Waveform............................................................................................................................................................18

Tips and Troubleshooting .....................................................................................................................................................19

1. Two measurement rule.......................................................................................................................................19