©Novinium, Inc. 2016, all rights reserved. NRI 603 –Small Diameter Cables –SPR

Revised: February 19, 2016 Page 1of 11

Table of Contents

Installing Equipment ............................................................................................................................................................... 2

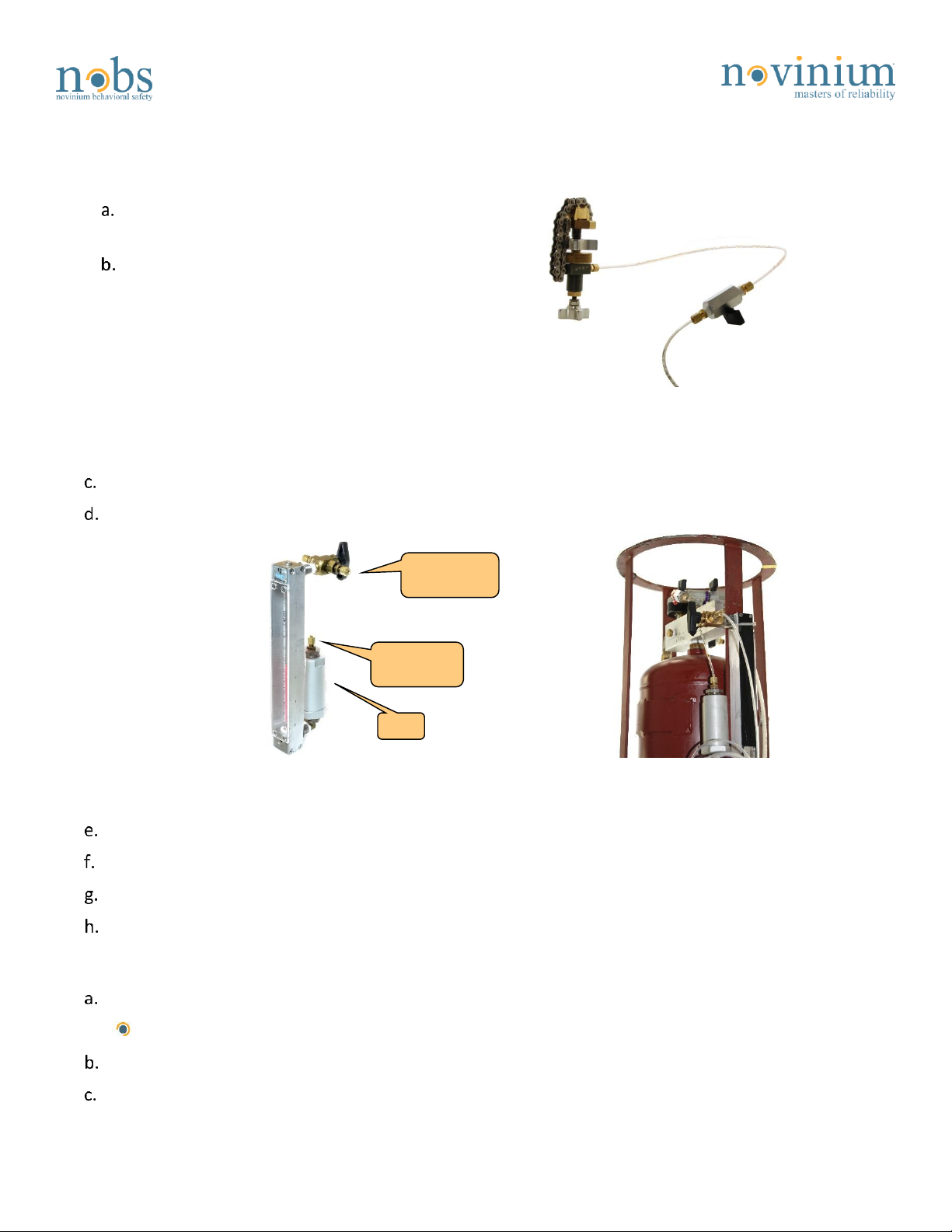

1. Injection tool (IT)......................................................................................................................................................... 2

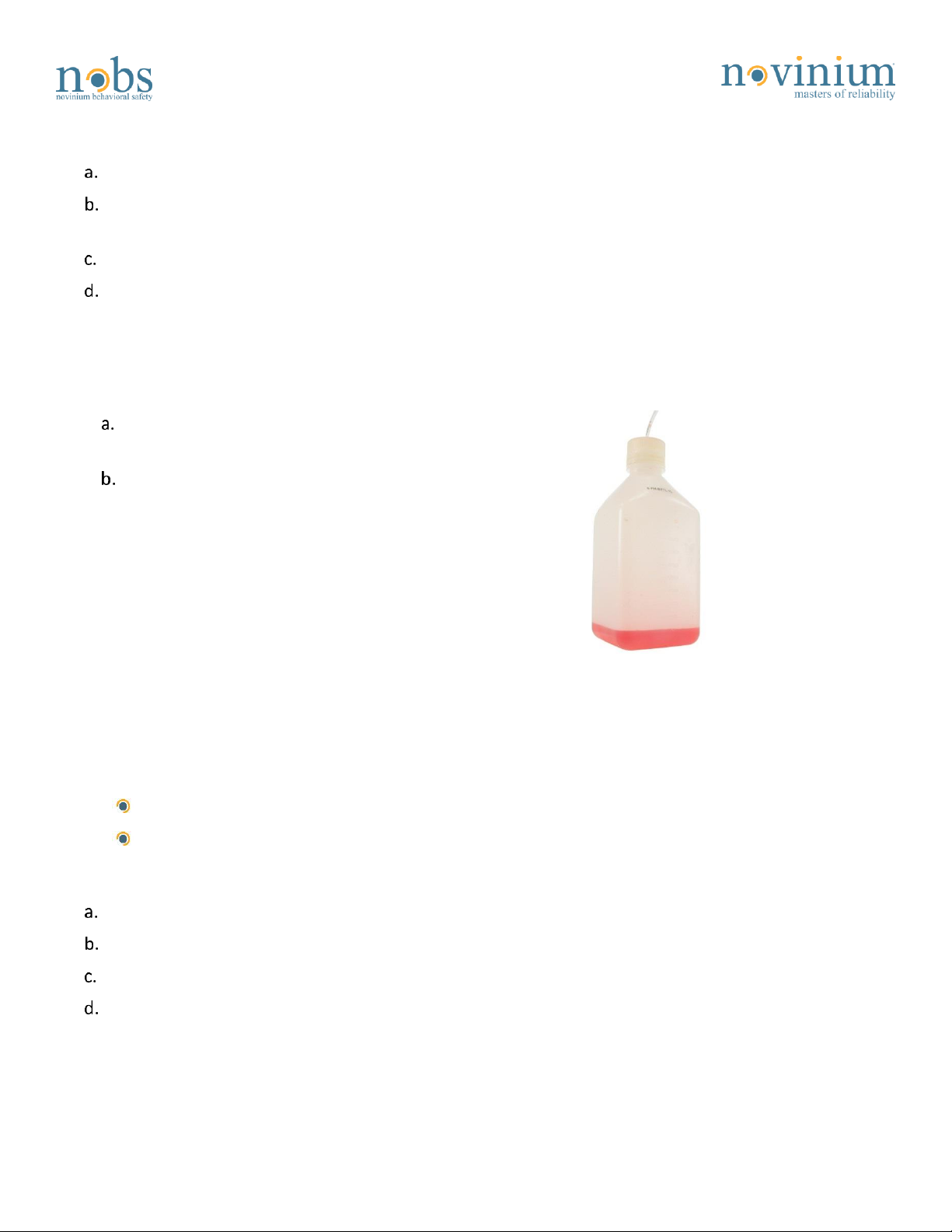

2. Pressurized feed tanks. ............................................................................................................................................... 2

3. Receiver tanks............................................................................................................................................................. 3

Pre-Injection Check ................................................................................................................................................................. 4

1. Check for leaks. ........................................................................................................................................................... 4

Recording Tank Levels............................................................................................................................................................. 5

1. Record the injection start time and feed tank level. .................................................................................................. 5

Starting the Injection .............................................................................................................................................................. 5

1. Flow check................................................................................................................................................................... 5

2. Flush water and other fluids. ...................................................................................................................................... 5

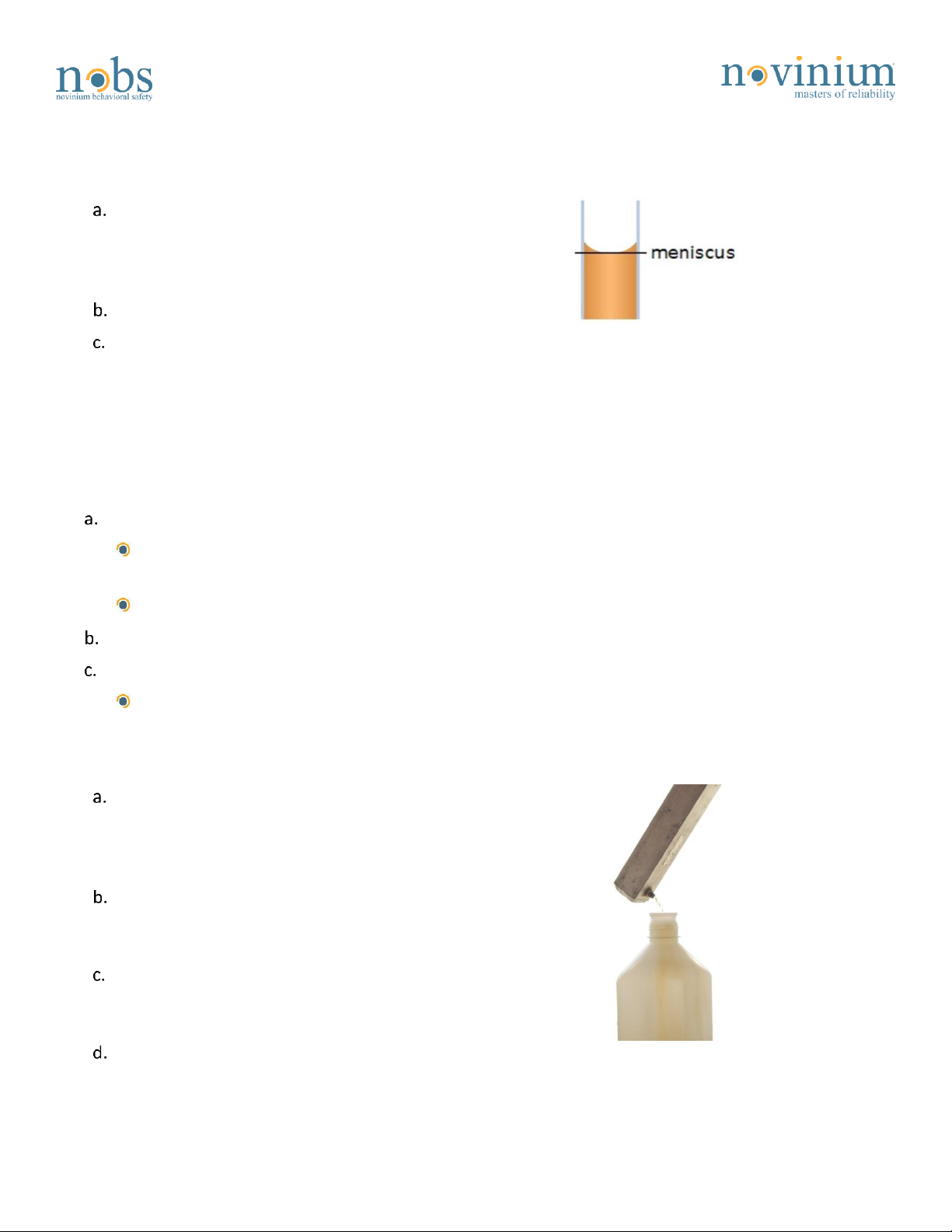

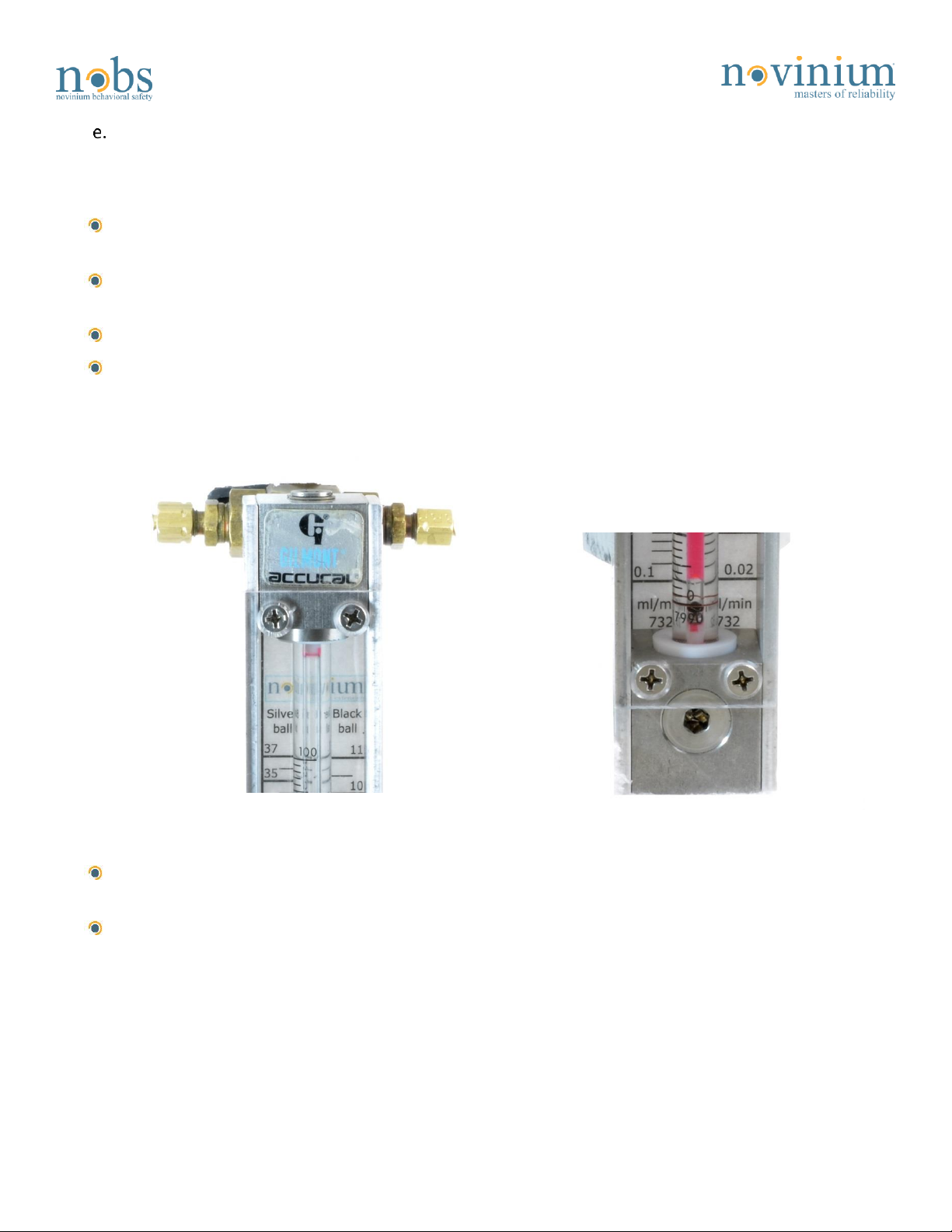

3. Read the liquid flow meter. ........................................................................................................................................ 6

Estimating Fluids ..................................................................................................................................................................... 7

1. Estimate the current supplied fluid. ........................................................................................................................... 7

2. Estimate time for fluid arrival. .................................................................................................................................... 8

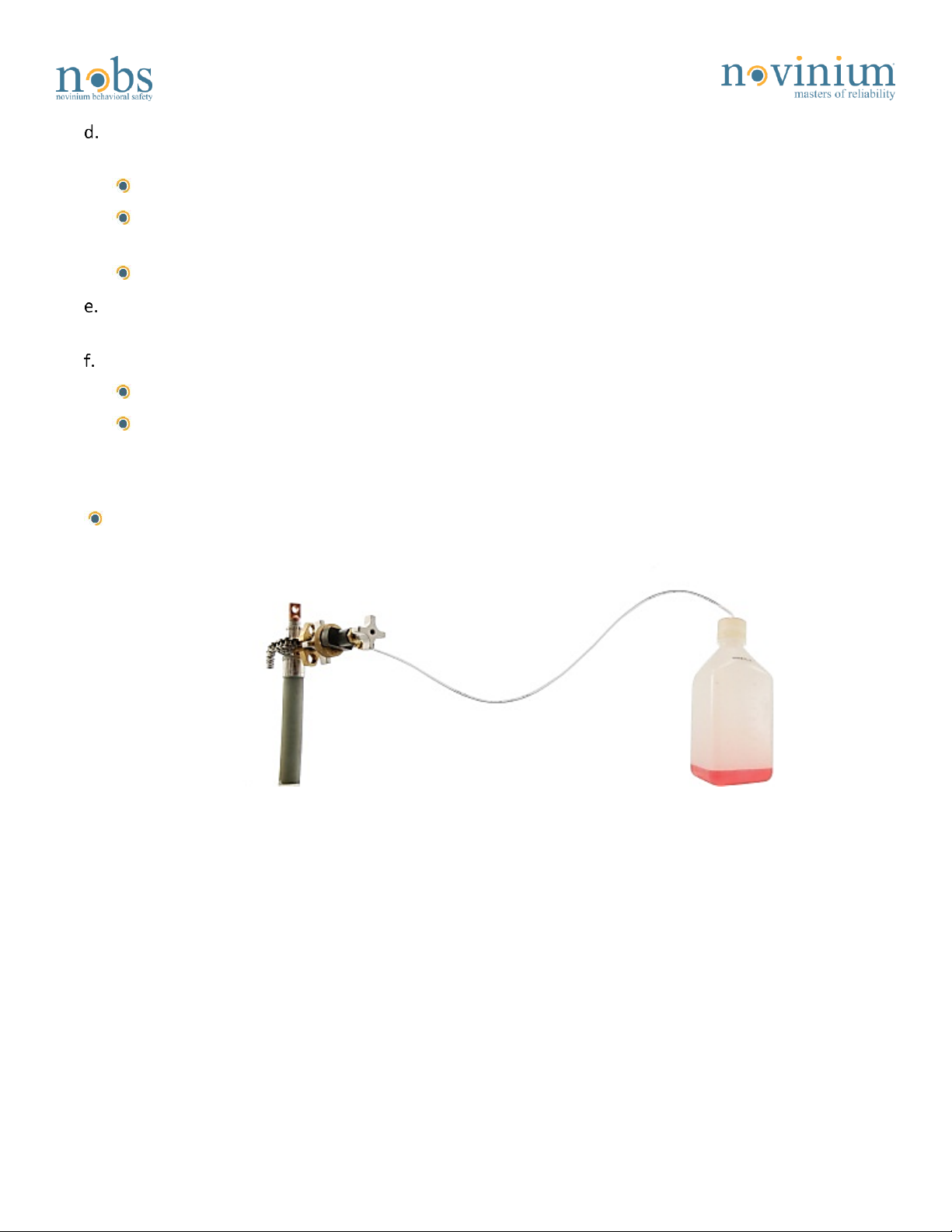

Fluid Arrival ............................................................................................................................................................................. 8

1. Flush the cable. ........................................................................................................................................................... 8

2. Reduce pressure to the tailored injection pressure (TIP). .......................................................................................... 8

3. Pin the outlet. ............................................................................................................................................................. 8

URD Cables and Pressurization ............................................................................................................................................... 9

1. Flow rate signals the end of injection. ........................................................................................................................ 9

2. Pin the inlet. .............................................................................................................................................................. 10

Recording Tank Levels........................................................................................................................................................... 11

1. Record the injection end time and feed tank level................................................................................................... 11

2. Remove the injection equipment. ............................................................................................................................ 11

3. Attach Craft Tags....................................................................................................................................................... 11

Resuming Component Installation........................................................................................................................................ 11