NOVOTEST UD2301 User manual

ULTRASONIC FLAW DETECTOR

NOVOTEST UD2301

Operating Manual

2014

Development and manufacturing of non-

destructive testing units and system

Ultrasonic Flaw Detector NOVOTEST UD2301

1

CONTENTS

1. List of Abbreviations used.………………………………………….2

2. Introduction.………………………………………………………….2

3. Operating Conditions.……………………………………………….3

4. Specifications.…………………………………………………….….4

5. Operating principle.………………………………….…………..….5

6. Operation of the device.…………………………………………….7

7. Basic settings of flaw detector.…………………………………...22

8. Device memory.………………………………………………...….29

9. Calibration of the flaw detector.……………………...………..….30

10. Maintenance.…………………………………………………….....35

11. Precautions and trouble shouting.……………………...….…….35

12. Manufacturer’s guarantee and service maintenance.……….....35

Development and manufacturing of non-

destructive testing units and system

Ultrasonic Flaw Detector NOVOTEST UD2301

2

1. List of Abbreviations used

The manual has the following abbreviations and symbols:

AFS –automatic signaling of defects;

TVG –time varied gain;

NDT –nondestructive testing;

CB –calibration block;

US –ultrasonic.

2. Introduction

2.1. Appointment of flaw detector

Flaw detector is designed for testing of products for the presence of

defects such as discontinuity and homogeneity of materials, semi-

finished products and welds for measuring depth and coordinates of

defects, measure the thickness and sound velocity in the material.

Flaw detector implements shadow, echo and mirror-shadow testing

methods. Flaw detector allows user to create, record and stored in

nonvolatile memory temporary implementation of pulsed ultrasonic

signals to subsequent transmitting to the PC for analysis and

presentation in the form of a document. Integrated liquid crystal

display (LCD) provides a mapping of ultrasonic signals in the form of

A-scan, as well as images of cross sections of testing objects in the

form of B-scans.

Flaw detector can be used in mechanical engineering, aerospace,

metallurgy, mounting hardware, power equipment, as well as for the

testing of transportation facilities.

2.2. Testing

For proper ultrasonic testing user must have testing methods for

similar products and special requirements for ultrasonic testing.

These requirements include: the definition of the task of testing,

selection of suitable control techniques (testing schemes), the

Development and manufacturing of non-

destructive testing units and system

Ultrasonic Flaw Detector NOVOTEST UD2301

3

selection of transducers, an assessment of the known conditions of

control in such materials, the selection of the minimum size of the

reflector for this type of product, reject level and so on.

2.3. Velocity of ultrasonic vibrations

Accuracy of measurement of thickness and position of defects

depends on the correct setting of the ultrasonic velocity in the

material. Velocity of ultrasound is dependent on the physical

characteristics of the material and its temperature.

3. Operating Conditions

The device is designed to operate in the following environmental

conditions:

- The temperature from -15 to +50 °C;

- Relative humidity to 95% at a maximum temperature of +35 °C.

The location of the flaw detector must be protected from direct

exposure to dust, moisture and corrosive environments. The field

strength of radio noise at the location of the flaw detector should not

exceed the value of the infringing operation, i.e. creator of the flaw

detector at the amplifier input voltage greater than half the maximum

sensitivity. At high field strength of radio interference must be taken

measures to shielding placements of flaw detector from the external

electromagnetic field.

Operating position of the flaw detector may be any convenient for

the user. To avoid moisture condensation inside the flaw detector

when moving it from a cold to a warm place, it is necessary to

sustain flaw detector for at least 4 hours before turning on in the

premises.

Development and manufacturing of non-

destructive testing units and system

Ultrasonic Flaw Detector NOVOTEST UD2301

4

4. Specifications

Operating Frequency Range

from 1 to 10,0 MHz

The range of measured time intervals

(duration of scanning)

from 6 to 1000 µs

Velocity range

1000 - 9999 m / s

The error of measurement of time

intervals

not exceed ± 0,025 µs

Maximum permissible error of

measurement of the amplitudes of the

signals at the receiver input in the

range from 0 to 110 dB

not exceed ± 0,5 dB;

Testing gain range

125 dB

Averaging over the quantity of starts

from 1 to 16

Digitally reconfigurable bandpass filter with tunable center

frequency of the filter from 1 Hz to 10 MHz

The range of variation of temporal

sensitivity adjustment (TVG)

40 dB

Number of control points TVG

15

The duration of the excitation pulse to

the load

from 0,0 to 0,5 µs

The amplitude of the excitation pulse to

the 50 Ohm load, not less

100, 200, 300

Operating frequency range of the

receiver on the level -3 dB

from 1 to 10 MHz

Deviation of the amplitudes of input

signals in the range from 10 to 100% of

the screen height not more than

1 dB

Scanning

from 1 to 1000 µs

Delay of scanning

from 0 to 2000 µs

Range of measurement of time

intervals

from 0 to 1000 µs

Setting a delay in the prism of the

from 0 to 15 µs

Development and manufacturing of non-

destructive testing units and system

Ultrasonic Flaw Detector NOVOTEST UD2301

5

probe

Automatic signaling of defects (AFS)

dual-gate

Setting range of AFS gates

from 0 to 2000 µs

Adjusting thresholds of AFS gates

from 0 to 100 %

высоты экрана

Detection of signals

positive half-wave, radio

mode

Dimensions (WxHxD)

80х162х38 mm;

Weight, not more

250 g (without batteries)

Mean time between failures

not less than - 3000

hours

Ultrasound probes used - ultrasonic piezoelectric transducers for

pulse flaw detectors.

The dimensions of the operating area of the screen is 48 x 74 mm.;

Electrical power is supplied from the following sources:

- AC power from 100 to 250 V, a frequency of (50 ± 1) MHz;

- AA batteries 1,5 V (3 pcs.).

5. Operating principle

Operating principle of flaw detector is based on the ultrasonic

contact NDT method, which uses the properties of ultrasonic

vibrations to reflect from the borders between materials with different

acoustic impedance. The ultrasonic transducer emits ultrasonic

impulse into the tested object. Reflected from the defects or the

product surface the echo signals are received by the ultrasonic

transducer. The resulting electrical signals are subject to

amplification, digitization, processing and output to the display.

Displays echoes received by the flaw detector is performing as

scanning of type A (A-scan) as well as images of cross sections of

tested objects in form of B-scan.

Development and manufacturing of non-

destructive testing units and system

Ultrasonic Flaw Detector NOVOTEST UD2301

6

5.1. Electronic unit of flaw detector

Flaw detector makes the formation of electrical pulses to excite the

piezoelectric transducer, gain derived from the piezoelectric

transducer signals, processing and visualization of the formation and

representation measurements in digital form, saving data in non-

volatile memory and transfer it to PC.

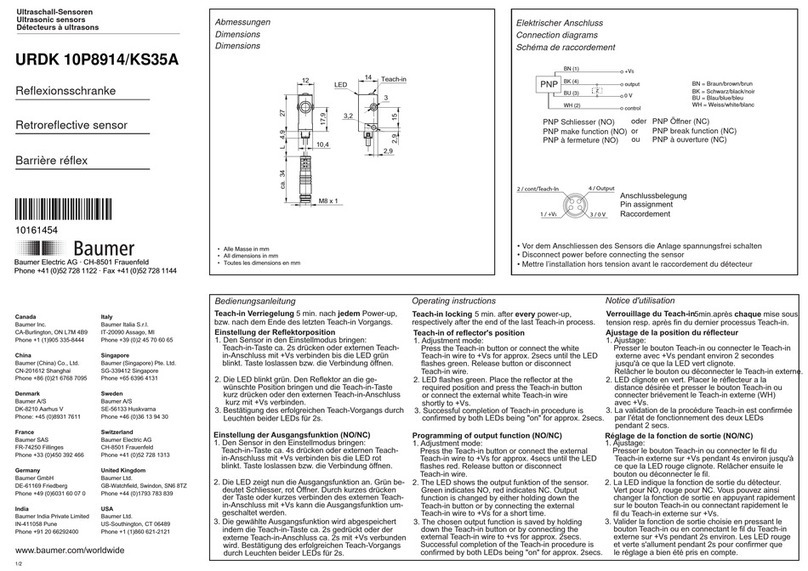

The appearance of the electronic unit is shown on picture 6.1.

Operation of flaw detector makes by keyboard. Visualization of

signals and display of measurement results, the state of flaw

detector and other information is shown on the LCD.

Connecting the probe is carried out by the coaxial cable through the

connectors LEMO, which are located on top side of the devices

body.

The device is powered by a three batteries type AA, or the included

in set external charger connected to the mini-USB connector located

on the bottom of the electronic unit of the flaw detector.

5.2. Probes

Flaw detector is designed to operate with the contact, dual element

and separated ultrasonic transducers with an operating frequency in

the range from 1 to 10.0 MHz.

The device uses a generator of bipolar sounding pulses with

adjustable duration, which provides compatibility with both probes:

have integrated terminating inductance and without them, allowing

operation operate with most types of probes on the market.

Depending on the type of probe it is used two types of cables and,

correspondingly, two ways to connect the probe:

- Ultrasonic transducers (type S) are connected via single cable

LEMO-LEMO to the left LEMO connector;

- Dual element transducers (type D) are connected by a double

cable 2LEMO-2LEMO. Right connector is used to connect the

Development and manufacturing of non-

destructive testing units and system

Ultrasonic Flaw Detector NOVOTEST UD2301

7

receiver of the piezoelectric element, the left - transmitter of the

piezoelectric element.

6. Operation of the device

The basis of flaw detector operation is founded on the ability of

ultrasonic vibrations spread into tested object and reflect from

internal defects and object sides. The received signal is amplified

and then converted into digital form processed by the

microprocessor and the graphics and digitally displayed on the

display.

Visualization of signals, display of measurement results, state of the

flaw detector and other information are shown on the LCD. Exterior

of the flaw detector is shown on picture 6.1.

Picture 6.1 Exterior of the flaw detector

Development and manufacturing of non-

destructive testing units and system

Ultrasonic Flaw Detector NOVOTEST UD2301

8

6.1. Controls

Controls of the flaw detector presents as a keyboard.

The keyboard has 10 keys:

- switching on/off –press and hold for at least 3 seconds to

turn on or off the device.

-"freezing” of the screen.

-screen rotation 90°.

- menu options.

- cancel the action and return to the previous menu.

- cursor movement, decrease the selected parameter.

- cursor movement.

- cursor movement, increase the selected parameter.

- cursor movement.

- enter.

To change the value of the selected parameter use the buttons

or to select the parameter, by key (decrease

Development and manufacturing of non-

destructive testing units and system

Ultrasonic Flaw Detector NOVOTEST UD2301

9

the value of the selected parameter) or (increasing the value

of the selected parameter) to set the required value.

To change the discreteness of the selected parameter value

changes, as well as to confirm the selected action use key .

Selected discreteness displays as one of the icons near

the variable parameter.

6.2. Preparing to work with the device

Read this instruction manual and follow its instructions.

Flaw detector must be protected from direct exposure to dust,

moisture, corrosive environments, and must be sufficiently lit by light

sources.

The field strength of the external interference at the location of the

flaw detector must not exceed values that violate its performance. At

high field strength of external interference must be taken to shielding

placements of the flaw detector, as well as its power supply and

connected cables.

When operating from AC power to the flaw detector must be

supplied mains with voltage from 100 to 250 V and with frequency of

(50 ± 1) Hz.

If in the power supply network arise switching noise in power supply

network of the flaw detector must enable network filter.

To avoid moisture condensation inside the body, when moving from

a cold environment to a warm, device must be hold in the warmth for

4 hours to dry completely.

At air temperatures below 10°C after switching on flaw detector must

be warmed for at least 15 minutes.

Development and manufacturing of non-

destructive testing units and system

Ultrasonic Flaw Detector NOVOTEST UD2301

10

Controls and indicator of the flaw detector located on the front panel,

as shown in Picture 6.1.

Operating connectors are located at the top and bottom sides of the

devices body.

WARNING! To prevent damage of connectors and cables - follow

the instructions below!

Used in the device connectors consist of two parts: the instrument

socket and the cable plug (Pic. 6.2.).

Picture 6.2. Connector used in the device

A method of connecting and disconnecting the plug and socket

shown on Picture 6.2.1. When connecting user must ensured that

the points of red color (if any) are plotted on the plug and the socket

are jumped together.

CAUTION: When disconnecting the plug from the socket, hold its

body in the dotted area. Do not pull the cable!!

Picture 6.2.1 Manipulations with LEMO connectors

Development and manufacturing of non-

destructive testing units and system

Ultrasonic Flaw Detector NOVOTEST UD2301

11

6.3. Turning on the flaw detector

If operation will be carried out by an external power supply, it is

necessary to connect the power supply unit of the flaw detector to

the power connector, located on the down side of the devices body.

Operation of the device is possible during battery charging.

Before switching on flaw detector connect transducer. Connect the

power adapter supplied with flaw detector to the corresponding

connector. If you connect the battery and power supply, the flaw

detector is powered from the power supply, if the power supply is

disconnected, flaw detector automatically goes to battery supply.

To enable (disable) flaw detector press and hold it for at least

3 seconds to short beep.

When you turn on the device screen of main menu is displayed.

Picture 6.3. Main menu of the flaw detector.

Development and manufacturing of non-

destructive testing units and system

Ultrasonic Flaw Detector NOVOTEST UD2301

12

The main menu of flaw detector is consists of four sections:

- Measurements;

- Archive;

- Setup;

- Information.

6.4. Connecting the transducer to the flaw detector

Combined probe is connected to the left connector on the top panel

of flaw detector and set in parameter group "Probe" parameter

"DUAL" to "OFF".

Dual element transducers connect as follows: emitting plate of dual

probe connect to the left connector, and the receiving plate connect

to the right connector on top side of body of the flaw detector by

inserting the cable connectors until its click. Set the parameter group

"Probe" parameter "DUAL" to "ON".

6.5. The main modes of operation of the flaw detector

"Measurement" mode - goes to the measurement;

"Archive" mode - displays all stored measurement results and

settings;

"Settings" mode - in this mode you can set the following settings:

Time, Date, Language, Brightness, Palette, Sound, Auto off, Clear

SD;

"Information" mode - display information about the manufacturer.

To select the required mode, move cursor by keys to select mode,

and confirm selection by pressing the Enter button.

6.5.1"Measurement" mode

"Measurement" mode is the main mode (Pic. 6.5.1), designed for

ultrasonic testing.

Development and manufacturing of non-

destructive testing units and system

Ultrasonic Flaw Detector NOVOTEST UD2301

13

Picture 6.5.1 "Measurement" mode

All parameters for configuring the measuring part of flaw detector

divided into groups, depending on the selected group user gets

access to the various parameters.

Group

Parameters

Main

GAIN

VELOCI

TY

SCALE

RANGE

DELAY

F.FILT

FILTER

REJECT

Puls/recv

GAIN

RANGE

DELAY

RECTIF

Y

POWER

F.FILTE

R

FILTER

REJECT

Gates

GAIN

GATE

START

WIDTH

LEVEL

PARAM.

1

PARAM.

1

PARAM.

1

Functions

GAIN

DSG

TVG

REJECT

PEAK

B-SCAN

AVG

Probe

DUAL

DELAY

ANGLE

X.VAL

FREQ

PULSE

TVG

GAIN

RANGE

DELAY

TVG

CLEAR

POINT

POS.

+dВ

DGS

GAIN

DGS

POINT

POS.

dВ

A LEVEL

mm2

AFS

START

WIDTH

GATE

MEAS.

MODE

CONTR.

SEARC

H

ALLARM

Development and manufacturing of non-

destructive testing units and system

Ultrasonic Flaw Detector NOVOTEST UD2301

14

Block 1

PARAM.

1

PARAM.

2

PARAM.

3

Block 2

PARAM.

1

PARAM.

2

PARAM.

3

Block 3

PARAM.

1

PARAM.

2

PARAM.

3

Description of parameters of flaw detector

Groups

Parameters

Description

Main

GAIN

Setting of gain of received path from 0

to 126 dB, in steps of 0.5, 5 dB.

VELOCITY

Display the set velocity of ultrasonic

vibrations in the tested material.

Adjustment range from 1000 to 9999 m

/ s.

Accuracy of the measurement the

depth, coordinates of defects and

thickness are depends on the accuracy

of the velocity settings.

SCALE

Selection of the display unit parameter

settings. Has two meanings:

microseconds (µs) and mm.

RANGE

The duration of scanning - depth

sounding along the beam.

Adjustment range from 1 to 1000 µs.

Flaw detector processed only signals

that are under scanning.

DELAY

The "Delay" specifies the time delay

relative to the start of scanning of the

probe pulse.

Setting range from 0 to 1000 µs.

F.FILT

Selecting the central operating

frequency of receiver path (selection of

frequency range receiver path). It can

take values from 1 MHz to 10 MHz.

Development and manufacturing of non-

destructive testing units and system

Ultrasonic Flaw Detector NOVOTEST UD2301

15

FILTER

Turn on / off frequency filter.

REJECT

Parameter allows to set the minimum

level of the signals displayed on the

screen.

Puls/recv

GAIN

Setting of gain of received path from 0

to 126 dB, in steps of 0.5, 5 dB.

RANGE

The duration of scanning - depth

sounding along the beam.

Adjustment range from 1 to 1000 µs.

Flaw detector processed only signals

that are under scanning.

DELAY

The "Delay" specifies the time delay

relative to the start of scanning of the

probe pulse.

Setting range from 0 to 1000 µs.

RECTIFY

Selecting the type of visualization of the

signal. Can take two values: the POS

HW and RADIO.

POWER

Setting the level of the generator

excitation. It can take values 100V, 150

V, 200 V.

F.FILT

Selecting the central operating

frequency of receiver path (selection of

frequency range receiver path). It can

take values from 1 MHz to 10 MHz.

FILTER

Turn on / off frequency filter.

REJECT

Parameter allows to set the minimum

level of the signals displayed on the

screen.

Gates

GAIN

Setting of gain of received path from 0

to 115 dB at 0.1, 1 dB.

GATE

Selecting gate. Takes the values: A or

Development and manufacturing of non-

destructive testing units and system

Ultrasonic Flaw Detector NOVOTEST UD2301

16

B.

START

Coordinate of the beginning of the

selected gate. It can take values from 0

to the maximum value of scanning.

WIDTH

The width of the selected control gate

along the beam. It can take values from

0 to the maximum value of scanning.

The total value of the start and the width

of the gate can not exceed the value of

the maximum scanning.

LEVEL

The threshold level of the selected

control gate. Is given in % of the screen

height, can take values from 0 to 100%

of the screen height.

PARAM.1

Allows to select the measured value in

the first block. **

PARAM.1

Allows to select the measured value in

the first block. **

PARAM.1

Allows to select the measured value in

the first block. **

Functions

GAIN

Setting of gain of received path from 0

to 115 dB at 0.1, 1 dB.

DGS

Turn on / off DGS

TVG

Turn on / off TVG

REJECT

Parameter allows to set the minimum

level of the signals displayed on the

screen.

PEAK

Turn on / off fixing the maximum

amplitude of the echo.

B-Scan

Turn on / off display of a scanning-type

B-scan.

AVG.

Number of echoes which are averaged

Development and manufacturing of non-

destructive testing units and system

Ultrasonic Flaw Detector NOVOTEST UD2301

17

result.

Probe

DUAL

Set the type of the connected ultrasonic

transducer. Has two meanings: the

combined and separate (dual).

DELAY

Setting a delay in the prism of

transducer.

ANGLE

The angle of entry of the ultrasonic

vibrations to the connected transducer.

X.VAL

Allows to specify an arrow of transducer

(set from 0 to 90 mm).

FREQ

Setting the operating frequency of the

ultrasonic transducer. Has a range from

1 MHz to 10 MHz.

PULSE

Setting the duration of the transducer

pulse.

TVG

GAIN

Setting of gain of received path from 0

to 126 dB, in steps of 0.5, 5 dB.

RANGE

The duration of scanning - depth

sounding along the beam.

Adjustment range from 1 to 1000 µs.

Flaw detector processed only signals

that are under scanning.

DELAY

The "Delay" specifies the time delay

relative to the start of scanning of the

probe pulse.

Setting range from 0 to 1000 µs.

TVG

Turn on / off TVG.

CLEAR

Allows to reset the TVG.

POINT

Select point TVG and display the total

number of points. The maximum

number of points TVG - 15.

POS.

Displays coordinates of the position of

Development and manufacturing of non-

destructive testing units and system

Ultrasonic Flaw Detector NOVOTEST UD2301

18

the current point of TVG. The distance

between two neighboring points is not

less than 3 microseconds.

+dВ

Gain of the current point TVG. The total

value of all the points of the TVG not

more 40 dB, accuracy of setting 0.1 dB.

DGS

GAIN

Setting of gain of received path from 0

to 126 dB, in steps of 0.5, 5 dB.

DGS

Turn on / off DGS.

POINT

Select Point TVG and display the total

number of points. The maximum

number of points TVG - 15.

POS.

Displays coordinates of the position of

the current point of TVG. The distance

between two neighboring points is not

less than 3 microseconds.

dВ

Gain of the current point DGS. The total

value of all the points of the DGS not

more 40 dB, accuracy of setting 0.1 dB.

А LEVEL

Allows to set the level / amplitude of the

reference signal.

mm2

Allows to set the value of the equivalent

area of the reflector.

AFS

START

Coordinate of the beginning of the

selected gate. It can take values from 0

to the maximum value of scanning.

WIDTH

The width of the selected control gate

along the beam. It can take values from

0 to the maximum value of scanning.

The total value of the start and the width

of the gate can not exceed the value of

the maximum scanning.

Development and manufacturing of non-

destructive testing units and system

Ultrasonic Flaw Detector NOVOTEST UD2301

19

GATE

Selecting gate. Takes the values: A or

B.

MEAS.

A method for determining the time of

arrival of the signal in the tested gate:

"by the peak" - on the state of the

maximum signal in the control gate;

"by the flank" - on the first crossing of

the signal with the threshold in the

control gate.

MODE

Determines the mode of operation of

the gate:

MORE - echo level is crossed gate;

LESS - echo signal is below the gate.

CONTR.

Setting the control area. The maximum

value of 20 dB, but can not exceed the

value of the search gate.

SEARCH

Setting the level of the search area. The

maximum value is 20 dB.

ALARM

Turn on / off sound.

Block 1

PARAM.1

Allows to select the measured values in

the first of three blocks. **

PARAM.2

Allows to select the measured values in

the first of three blocks. **

PARAM.3

Allows to select the measured values in

the first of three blocks. **

Block 2

PARAM.1

Allows to select the measured values in

the second of three blocks. **

PARAM.2

Allows to select the measured values in

the second of three blocks. **

PARAM.3

Allows to select the measured values in

the second of three blocks. **

Block 3

PARAM.1

Allows to select the measured values in

Table of contents

Other NOVOTEST Security Sensor manuals

Popular Security Sensor manuals by other brands

Orno

Orno OR-CR-207 manual

Honeywell Home

Honeywell Home Resideo PROSIXPIR installation instructions

Skana

Skana 9202554 instruction manual

Schwaiger

Schwaiger Secure4You HGA300 532 instructions

Honeywell

Honeywell EC-FX-NH3 Instruction and installation manual

Powerfix Profi

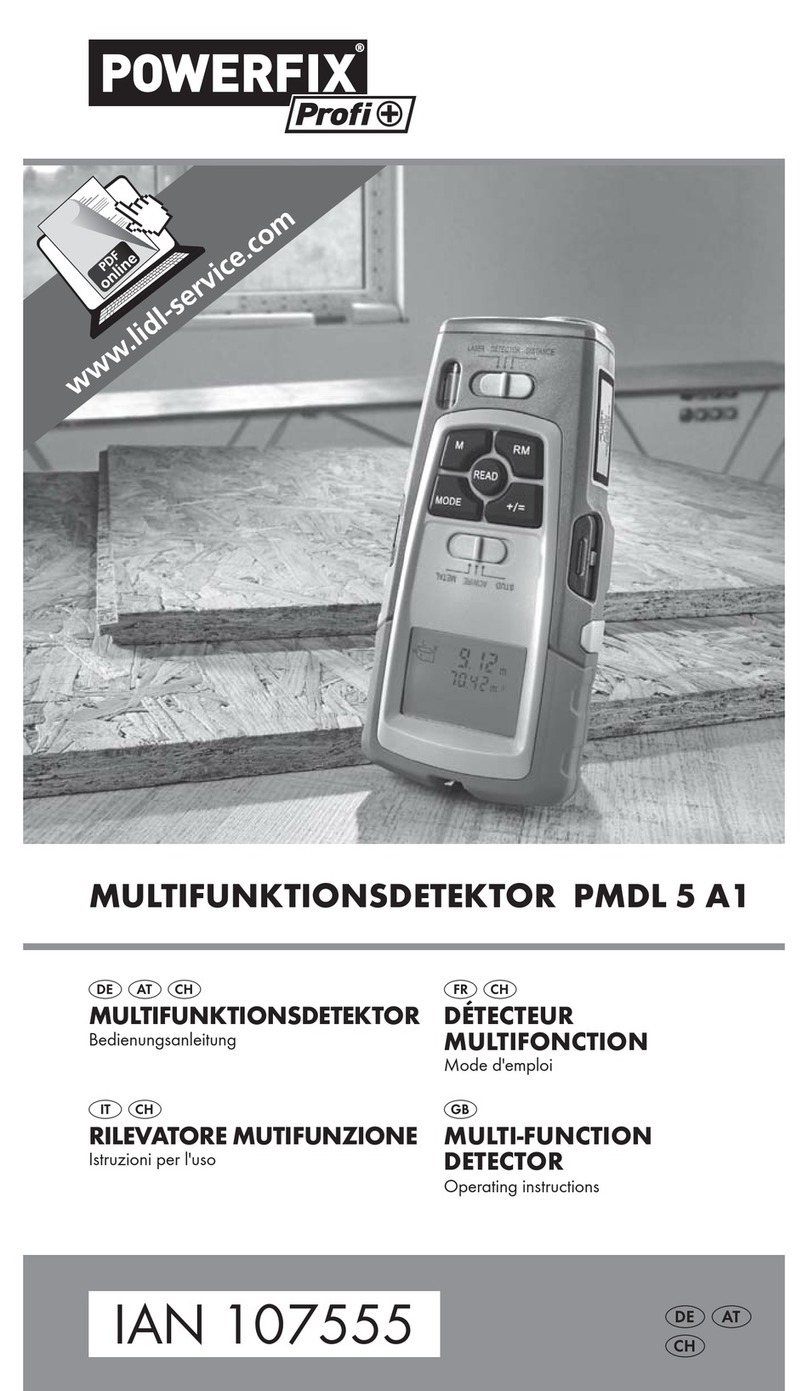

Powerfix Profi PMDL 5 A1 operating instructions