nox-crete Excel 130 User manual

Excel 130 Concrete Form Sprayer

REV 04/2020

NOX-CRETE PRODUCTS GROUP

USER GUIDE AND PARTS LIST

DO NOT USE WITH FLAMMABLE MATERIALS

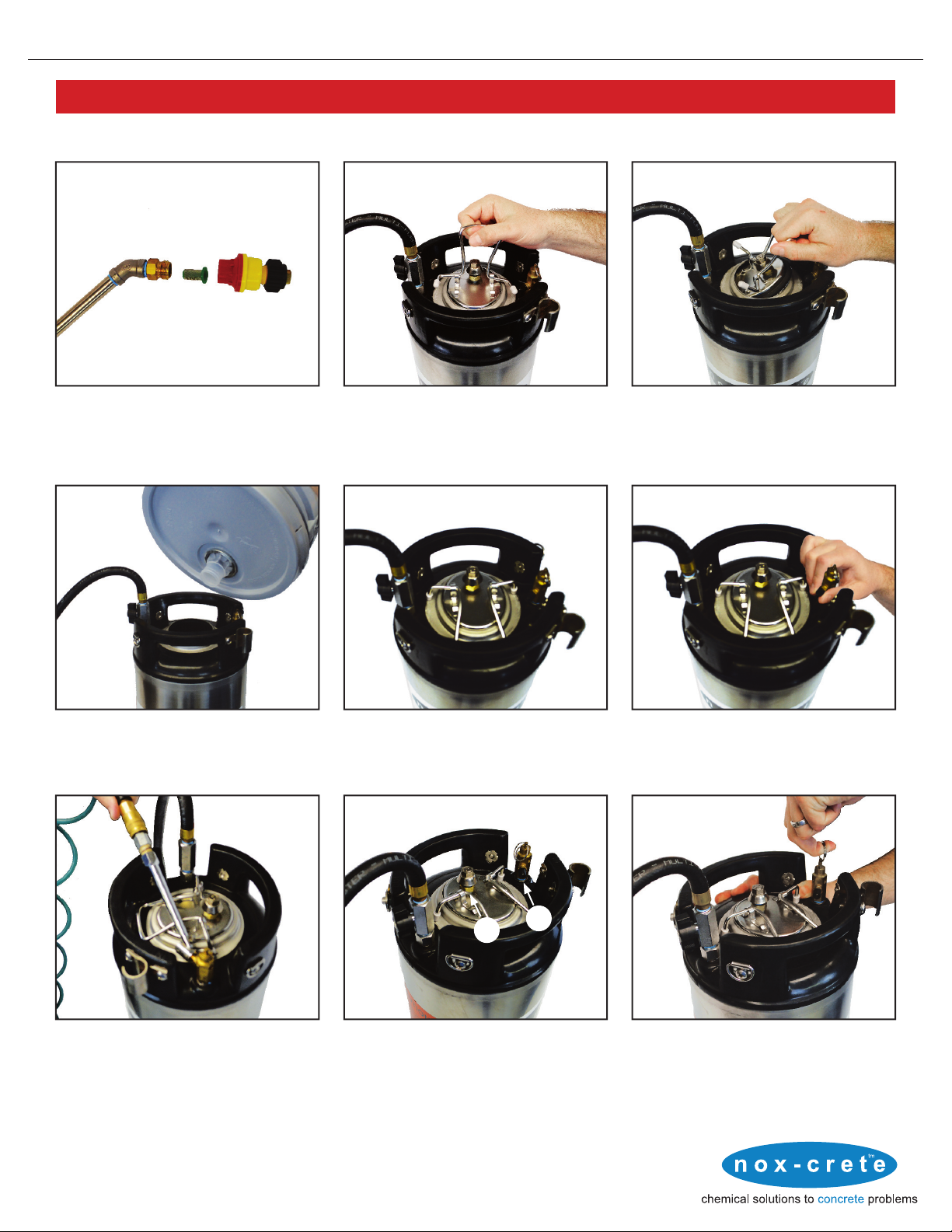

1. Attach CF Valve to brass 11/16”

male fitting.

2. Lift handle to begin removal of lid. 3. Push lid towards inside of tank and

turn it sideways so it can easily be

removed.

4. Fill sprayer with desired product. 5. Place the lid back on the sprayer

by reversing the order of step 3.

6. Remove cap to air compressor fill

valve.

Materials with a flash point below 120°F (49°C)

7. Use an air compressor to fully

charge the sprayer. (Note**Green CF-

Valve requires 40 psi to open,Yellow

and Red CF-Valve requires 60 psi to

open, sprayer holds up to 130 PSI).

8. Sprayer features 2 safety pressure

relief valves.

A. 130 PSI Lid Relief Valve

Assembly

B. 125 PSI Fill Relief Valve

9. Pull up on Fill Relief Valve to

release air pressure from the tank

before removing the lid to refill.

NOX-CRETE QUICK START GUIDE Excel 130 Concrete Form Sprayer

AB

NOX-CRETE QUICK START GUIDE Excel 130 Concrete Form Sprayer

10. Lock shutoff to prevent trigger

from being compressed when not

spraying.

11. Shutoff lock released allowing

trigger to be compressed to dispense

product.

12. Ball valve turned on to allow

product into hose and wand

assembly.

13. Ball valve turned off to prevent

product from entering hose and wand

assembly.

DO NOT USE WITH FLAMMABLE MATERIALS

Materials with a flash point below 120°F (49°C)

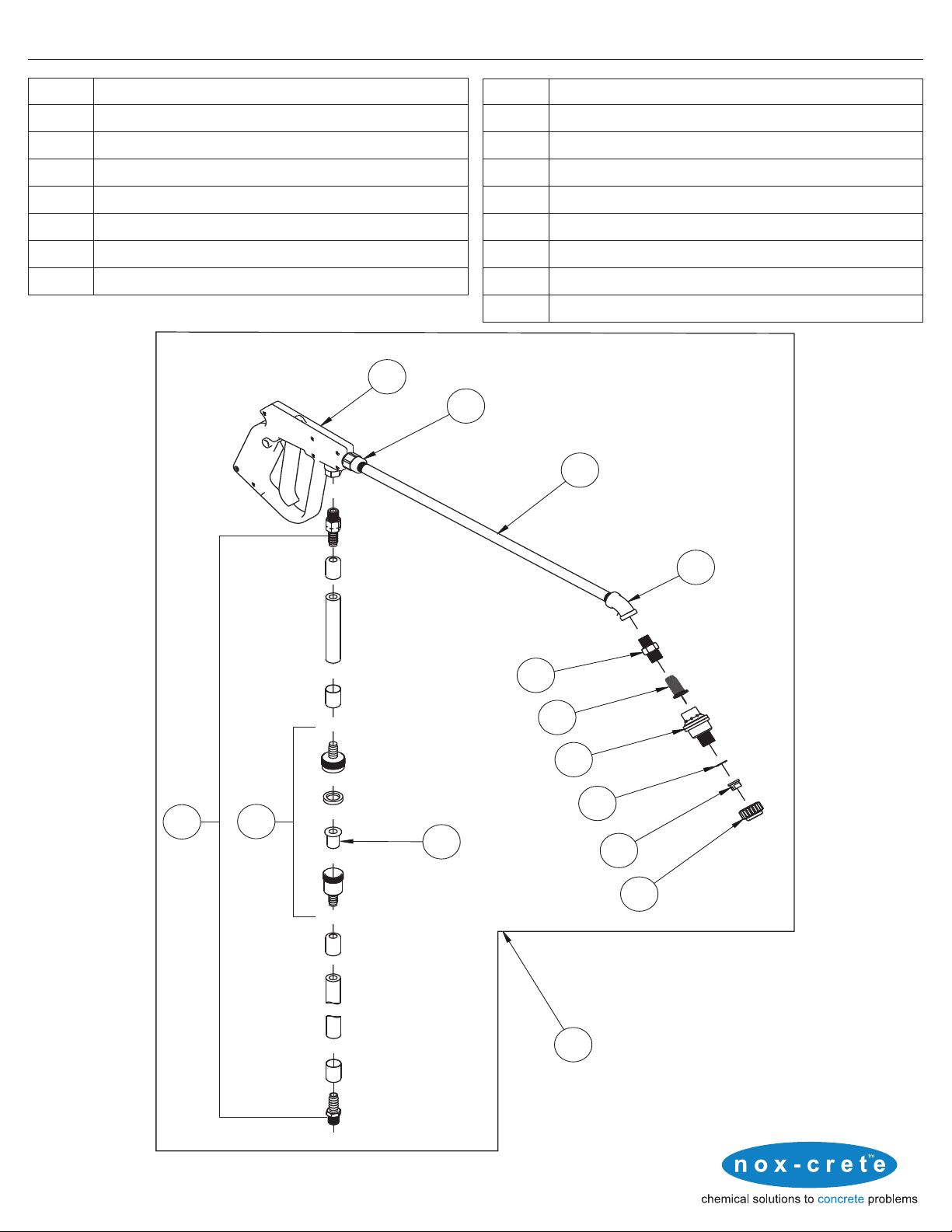

Part # Product Description

438 LARGE STAINLESS T-NUT

443 LARGE STAINLESS BOLT

446 SHOULDER STRAP 1-1/2” BLACK

447 STAINLESS STEEL D -RING

451 TANK CONVERSION FITTING

452 VITON LID SEAL

453 INLET/OUTLET SEAL

8475 BOLT

8476 NYLON SPACER

8504 WASHER

SCHEMATICS & PARTS LIST Excel 130 Concrete Form Sprayer

Part # Product Description

8121 BALL VALVE

8448 STAINLESS STEEL WAND HOLDER

8462-R 5 GALLON TANK LID W/ RV HOLE

8522 125 PSI FILL RELIEF VALVE

8530 TANK LID, 130 PSI LID RELIEF

VALVE ASSEMBLY, VITON SEAL

8531 130 PSI LID RELIEF VALVE

450

451

8121

443

446

447

438

443

447

438

443

8448

453

453

438

8530

452

8522

8462-R

8531

TIP HOLDER PARTS

(NOT PICTURED)

455

8449

456

8465

8441

463

8464

8305

898

867

800067

8442

8436/7

552

Part # Product Description

455 HOSE INLINE FILTER COMPLETE

456 IN-LINE FILTER REPLACEMENT

463 SHUT-OFF/WAND ADAPTER

552 GREEN 100 MESH WAND STRAINER

876 NYLON TIP GASKET

898 MALE NOZZLE BODY ADAPTER

8305 45 DEGREE STEEL ELBOW

SCHEMATICS & PARTS LIST Excel 130 Concrete Form Sprayer

Part # Product Description

8437 RED/YELLOW 60 PSI CF VALVE

8436 GREEN/BLUE 40 PSI CF VALVE

8441 PISTOL GRIP SHUT-OFF WITH VITON

8442 PLASTIC RETAINER CAP

8449 COMPLETE HOSE/WAND ASSEMBLY

8464 18” STAINLESS STEEL WAND

8465 EXCEL 130 HOSE ASSEMBLY

800067 SPRAY TIP

1. If the sprayer is filled with both product and

compressed air but will not spray:

A. Ensure sprayer is lled with more than 40 psi if equipped

with green CF valve or 60 psi if equipped with red/yellow

CF valve.

B. Air may be caught between the shut-off and spray tip.

1. Remove the CF valve on the end of the wand.

2. Open the shut-off valve by pulling trigger and allowing

air to escape until liquid ows out.

3. Replace the CF valve to begin normal spray operation.

4. Use a rag to catch any excess product. (g. 1A)

C. Filters may be plugged. Check the lters and clean of any

debris.

1. Relieve pressure in the sprayer.

2. Unscrew inline lter housing and then remove bronze

lter. (g. 2A)

3. Unscrew CF valve and remove plastic lter in brass

housing. (g. 3A)

4. Clean lter with solvents and/or compressed air.

5. Put all lters back in place.

D. Tip may be plugged. Check tip and clean of any debris.

1. Remove black plastic cap from CF valve.

2. Clean tip with compressed air and/or solvent.

3. Replace tip and reattach black plastic cap to CF valve.

2. If spray continues to come out of tip when

shut-off valve has been released:

More than likely there is air caught between the shutoff and

the tip.

1. Place a rag over the tip and hold the tip skyward.

2. Open the shutoff valve for a few seconds to push any

air out of the system.

3. If spray continues to come out, you may need to

replace the CF valve.

3. If sprayer will not pressurize when filled with air:

Clean the lid seal to make sure it tightly seals to the stain

less steel top.

TROUBLESHOOTING GUIDE Excel 130 Concrete Form Sprayer

REMOVE AIR TRAPPED IN WAND

REMOVE FILTER TO CHECK FOR DEBRIS

REMOVE FILTER TO CHECK FOR DEBRIS

(g. 1A)

(g. 2A)

(g. 3A)

Use Instructions

• For product and air ll intructions, refer to the Excel 130

Quick Start Guide.

• For specic product information, refer to the Product Data

Sheet.

• Spray tips may vary depending on product. Refer to

Spray Tip Recommendation Guide.

• Use the 40 PSI valve in temparatures above 50°F (10°C).

• Use the 60 PSI valve in temparatures below 50°F (10°C).

Maintenance Instructions

• Empty contents of sprayer at the end of each day and

leave clean with the appropriate cleaning solutions. Leave

lid loose on clean sprayer to allow tank to air dry.

• If liquid lter becomes plugged, remove lter and wash

out with solvent.

Notice to Users

• This sprayer is designed for Nox-Crete products only.

• This sprayer is designed only for use in exterior

applications.

• Improper use or failure to follow instructions can result in

explosive failure with potentially serious injuries. For safe

use of product, you must read and follow all instructions

before use

• Do not leave pressurized sprayer unattended in the hot

sun. Heat can cause pressure buildup.

• Do not store chemicals in sprayer. Empty and clean

sprayer after each use.

• Always wear goggles, rubber gloves, rubber boots, and

protective clothing when spraying. If air concentrations

exceed the OSHA established TLV for chemical being

sprayed, suitable respiratory protection is required.

• Never user any tool to remove lid if there is pressure in the

sprayer.

• Do not attempt to modify or repair this sprayer except

with original manufacturer’s parts.

• Routinely inspect sprayer before each use for signs of

wear or damage.

• Replace worn or damaged parts before use.

• When lling tank with compressed air, always observe the

pressure gauge to ensure the maximum spraying pressure

is not exceeded.

• When pressurizing the sprayer, hold the sprayer off to the

side. Do not stand with your head or body directly over

the sprayer.

• DO NOT PRESSURIZE OVER 130 PSI.

Warranty

NOTICE-READ CAREFULLY

CONDITIONS OF SALE

NOX-CRETE offers this product for sale subject to, and Buyer and all users are deemed to have accept-

ed, the following conditions of sale and limited warranty which may only be varied by written agreement

of a duly authorized corporate ofcer of NOX-CRETE. No other representative of or for NOX-CRETE is

authorized to grant any warranty or to waive limitation of liability set forth below.

WARRANTY LIMITATION

NOX-CRETE warrants this product to be free of manufacturing defects. If the product when purchased

was defective and was within use period indicated on container or carton, when used, NOX-CRETE will

replace the defective product with new product without charge to the purchaser.

NOX-CRETE makes NO OTHER WARRANTY, either express or implied, concerning this product. There

is NO WARRANTY OF MERCHANTABILITY. In no case shall NOX-CRETE be liable for special, indirect or

consequential damages resulting from the use or handling of the product, and no claim of any kind shall

be greater in amount than the purchase price of the product in respect of which damages are claimed.

INHERENT RISKS

NOX-CRETE MAKES NO WARRANTY WITH RESPECT TO THE PERFORMANCE OF THE PRODUCT

AFTER IT IS APPLIED BY THE PURCHASER, AND PURCHASER ASSUMES ALL RISKS ASSOCIATED

WITH THE USE OR APPLICATION OF THE PRODUCT.

Excel 130 Concrete Form Sprayer

DO NOT USE WITH FLAMMABLE MATERIALS

Materials with a flash point below 120°F (49°C)

Contact Us

800-669-2738

402-341-2080

Table of contents

Other nox-crete Paint Sprayer manuals