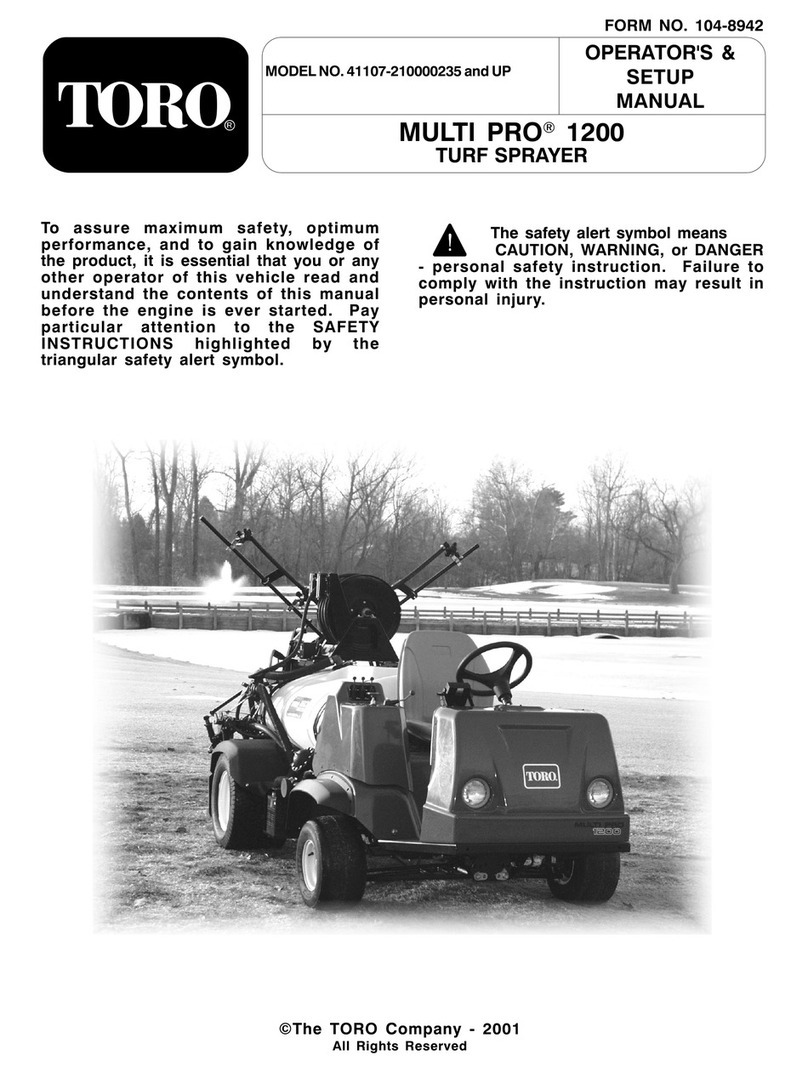

Introduction

Readthismanualcarefullytolearnhowtooperateand

maintainyourproductproperly.Theinformationinthis

manualcanhelpyouandothersavoidinjuryandproduct

damage.AlthoughTorodesignsandproducessafe

products,youareresponsibleforoperatingtheproduct

properlyandsafely.YoumaycontactTorodirectlyat

www.Toro.comforproductandaccessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Note:Ifyouareinstallingthiskit(theProControlXP

SpraySystemKit)alongwithoneormoreotherkits,

suchastheEductorKit(model41612),theElectric

HoseReelKit(model41613),ortheTankRinseKit

(41614),werecommendthatyouassemblethekitsinto

themanifoldvalveassemblyatthesametime.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

illustratesthelocationofthemodelandserialnumbers

ontheproduct.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Figure1

1.Safetyalertsymbol.

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

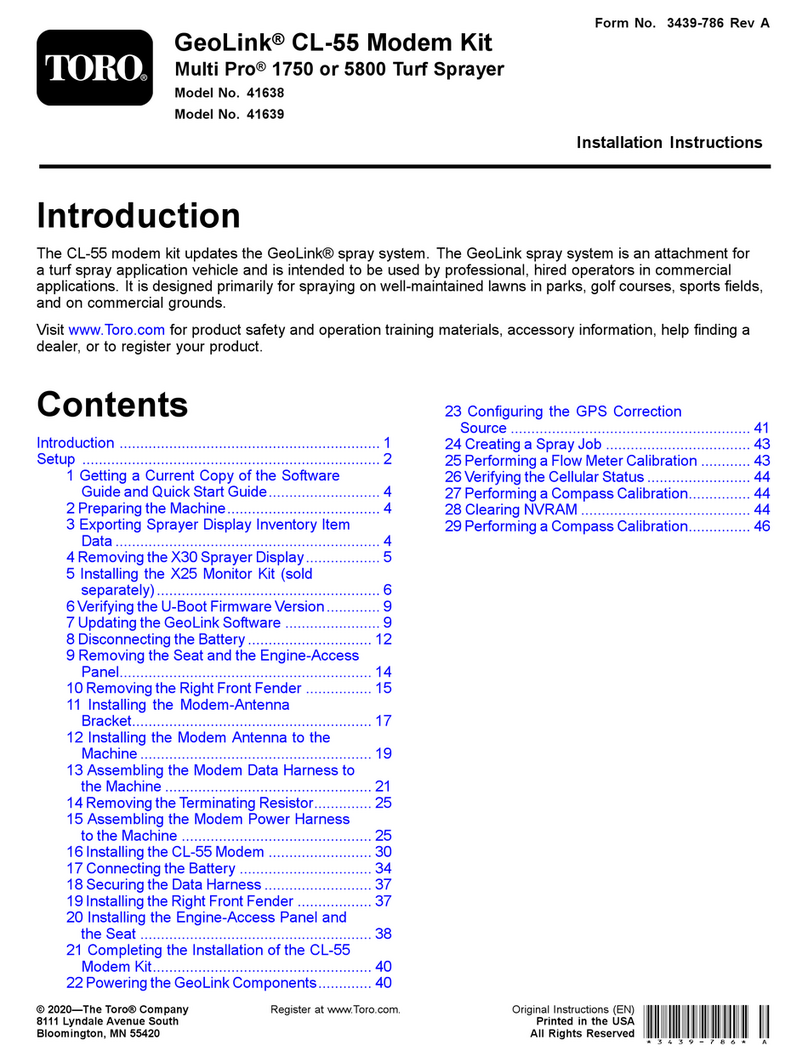

Contents

Introduction.................................................................2

Safety...........................................................................3

Setup...........................................................................4

1InstallingtheConsoleComputer........................4

2InstallingtheFlowmeter....................................5

ProductOverview........................................................7

Controls...............................................................7

Operation.....................................................................9

InitiallyProgrammingtheConsole

Computer.........................................................9

DisplayingData..................................................11

Self-TestingtheConsoleComputer.....................11

ActivatingtheDataLock....................................11

ChangingtheDataLock.....................................11

EnteringtheModeSequencewiththeData

LockActivated...............................................11

SettingthePowerDownDelayTime...................12

UsingtheConsoleComputerAlarm...................12

SettingUptheSystem.........................................12

InitiallyField-testingtheSystem..........................13

Maintenance...............................................................14

RecommendedMaintenanceSchedule(s)................14

CleaningtheFlowmeter......................................14

ProgrammingtheConsoleComputer..................14

CalibratingtheFlowmeter..................................16

TestingtheFlowmeterCable...............................16

Troubleshooting.........................................................17

©2011—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved