nox-crete PFCS 3615 FN User manual

2

6393250

Spare Parts

Piezas de repuesto

Pièces de Rechange

Ersatzteile

3

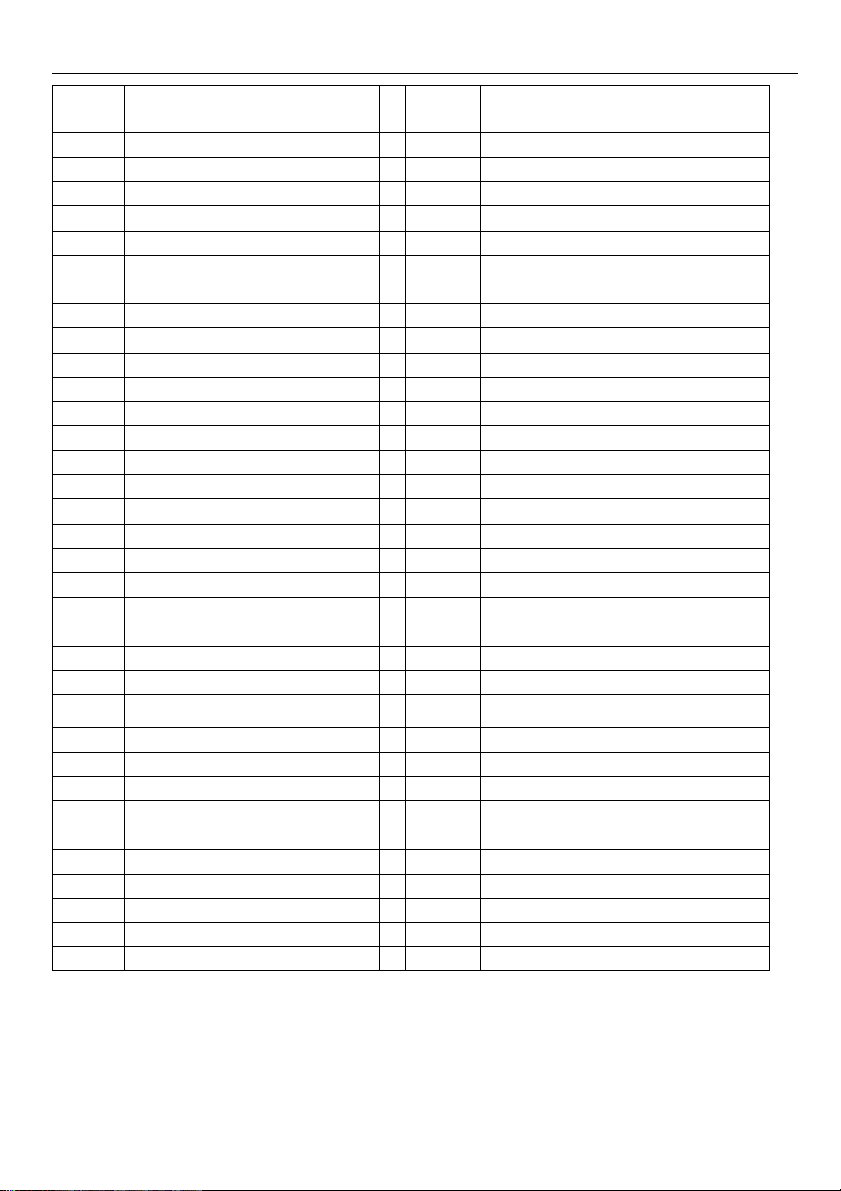

Ref

Part #

!

Ref

Part #

A

Air pump, brass

23

Filter housing R.25 in., brass

B

Piston rod assembly

24

100 mesh filter

C

Transport cart

25

Gasket D23 x D18 x 2 mm

D

Air compressor fill valve

26

Screw M3 x 12 mm

E

Carrying strap

27

Hex. Nut M3

F

Pressure regulator, brass with

pressure gauge

28

Trigger

G

Spiral hose with couplings

29

Valve body, brass

H

Trigger valve

30

Valve pin assembly

I

Service Kit

31

Screw seat

1

Piston rod with handle

32

Brass spray wand

2

Bumper spring

33

Buckle

3

Screw D3.5 x 16 mm

34

Wand extension ( 24 in. 61 cm)

4

Cylinder cap

35

200 mesh anti-siphon filter *

5

Piston 38 mm

36

Cap nut, brass

6

Piston cup washer 38 mm

37

80005 Spray tip

7

Safety valve 6 bar with gasket

38

800067 Spray tip

8

Gasket D14 x D9.7 x 2 mm

39

8001LP Spray tip

9

Funnel cover

40

8002LP Spray tip

10

Cylinder tube with gasket and

valve disk

41

8003LP Spray tip

11

O-ring D47 x 5.33 mm

42

8004LP Spray tip

12

Foot valve disk

43

8005LP Spray tip

13

Pressure gauge 6 bar w/ gasket

44

Holding rod

14

Pump holder with screw

45

Assembly kit for transport trolley

15

Spare parts container with lid

46

Holding rod attachment

16

O-ring D10 x 3 mm

47

Hubcap

17

Coupling M10 (spiral hose),

with gasket

48

Wheel

18

Cap nut, brass

49

Axle for transport trolley

50

Stand

20

Spiral hose 2.5 m (PUR)

51

Protective cup

21

.25 in. adapter

52

Gasket D17 x D13 x 2 mm

22

Gasket D15 x D11 x 2 mm

53

Stainless Steel Tank

4

5

6

7

USA

IRL

AUS

GB

NZ

CDN

IND

Welcome

Congratulations for purchasing your new Perfect Form and Concrete Sprayer. Your

satisfaction with NOX-CRETE products and services is very important to us. If you are not

satisfied or have questions and concerns not covered in these instructions, please contact

Nox-Crete at:

Nox-Crete Products Group

(800) 669-2738| 1444 S 20th St. | Omaha, NE | 68108 | customerservice@nox-crete.com

Read these instructions before using the sprayer.

Keep the use instructions in a safe and convenient place.

Usage

This sprayer is designed for NOX-CRETE products and other construction chemicals that

can be applied with a sprayer.

Read Nox-Crete’s sprayer usage instructions before each application. This sprayer is

designed only for use in exterior applications.

Improper use may result in personal injury.

Not suitable for

• Flammable liquids with a flashpoint below 100°F (38°C)

• Hydrogen peroxide or other strong oxidizers

• Corrosive substances (acids and bases)

• Products containing ammonia

• Products containing acetone

• Extremely viscous liquids

• Use with food

Under no circumstances should you use

• External pressure sources without the optional NOX-CRETE compressed air valve

• With flammable liquids

• For storing hazardous substances

• As an eyewash

Safety

Read sprayer instruction manual thoroughly prior to use.

Keep sprayer out of reach of children.

Never spray on people, animals, electrical devices and lines, into the wind, or into

bodies of water.

Repairs and modifications to the sprayer tank can result in serious injury.

Do not bypass or disable the sprayer safety valve.

8

USA

IRL

AUS

GB

NZ

CDN

IND

Contact between the sprayer and hydrogen peroxide or other oxidizing agents may

result in increased pressure similar to an explosion. Never place strong oxidizing

agents in the sprayer.

Remove and replace damaged and nonfunctioning parts.

Avoid ignition sources when spraying combustible liquids.

Do not allow the sprayer to remain under pressure and/or be exposed directly to

sunlight for extended periods of time. Make certain the sprayer is not heated beyond

the maximum operating temperature (→Table 1 below).

Never blow through the sprayer tip or valves with your mouth.

Use only Nox-Crete replacement and accessory parts.

Wear suitable protective equipment when working with hazardous substances.

When hand pumping or filling sprayer tank with compressed air, always observe the

pressure gauge to ensure the maximum spraying pressure is not exceeded.

(→Table 1 below).

Before filling, after use and before maintenance work, allow the residual pressure in

the tank to dissipate completely (→Section “After Use,“ Section 1).

Technical data

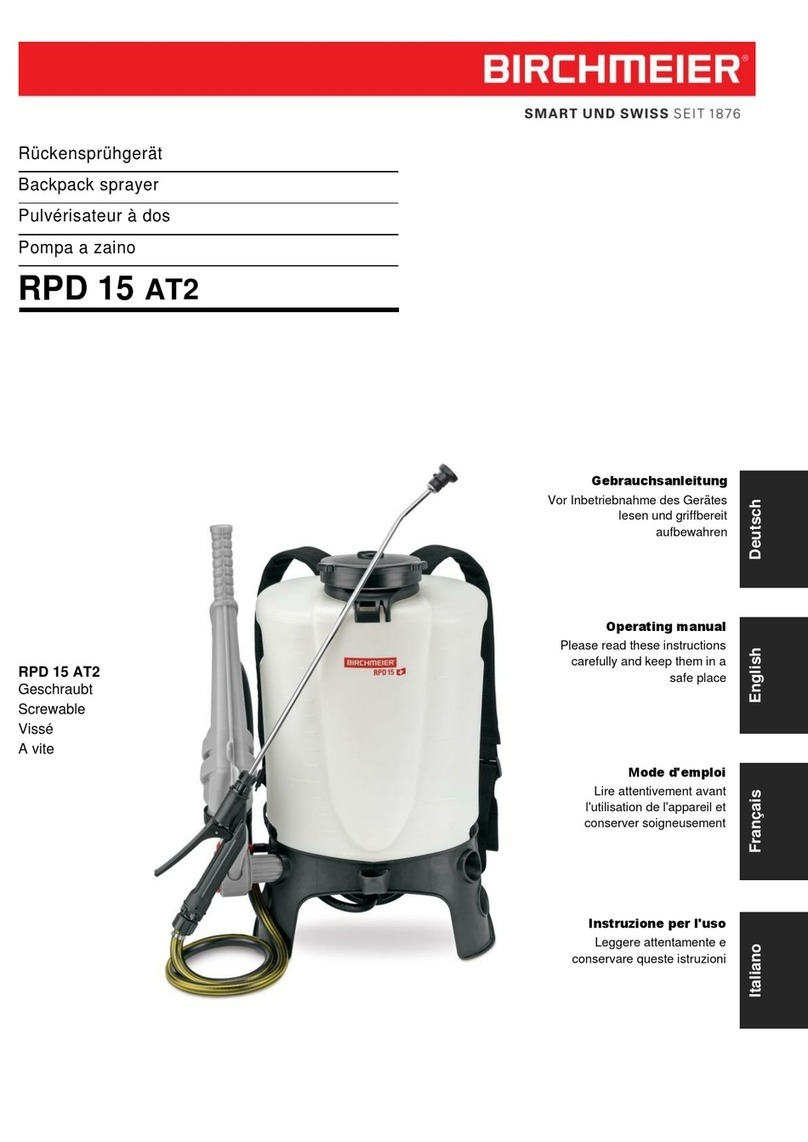

TABLE 1

Device Name

PERFECT Form and Concrete Sprayer

Type

Pressurized Tank

Max. usable volume

2.7 gal (10.2 l)

Total volume

3.4 gal (12.9 l)

Max. spraying pressure

87 psi (6 bar)

Max. operating temperature

122 °F (50°C)

Weight when empty

10.4 lb (4.7 kg)

Material of tank

Stainless steel

Where device is carried

Shoulder or backpack

Technical residual quantity

0.008 gal (0.03 l)

9

USA

IRL

AUS

GB

NZ

CDN

IND

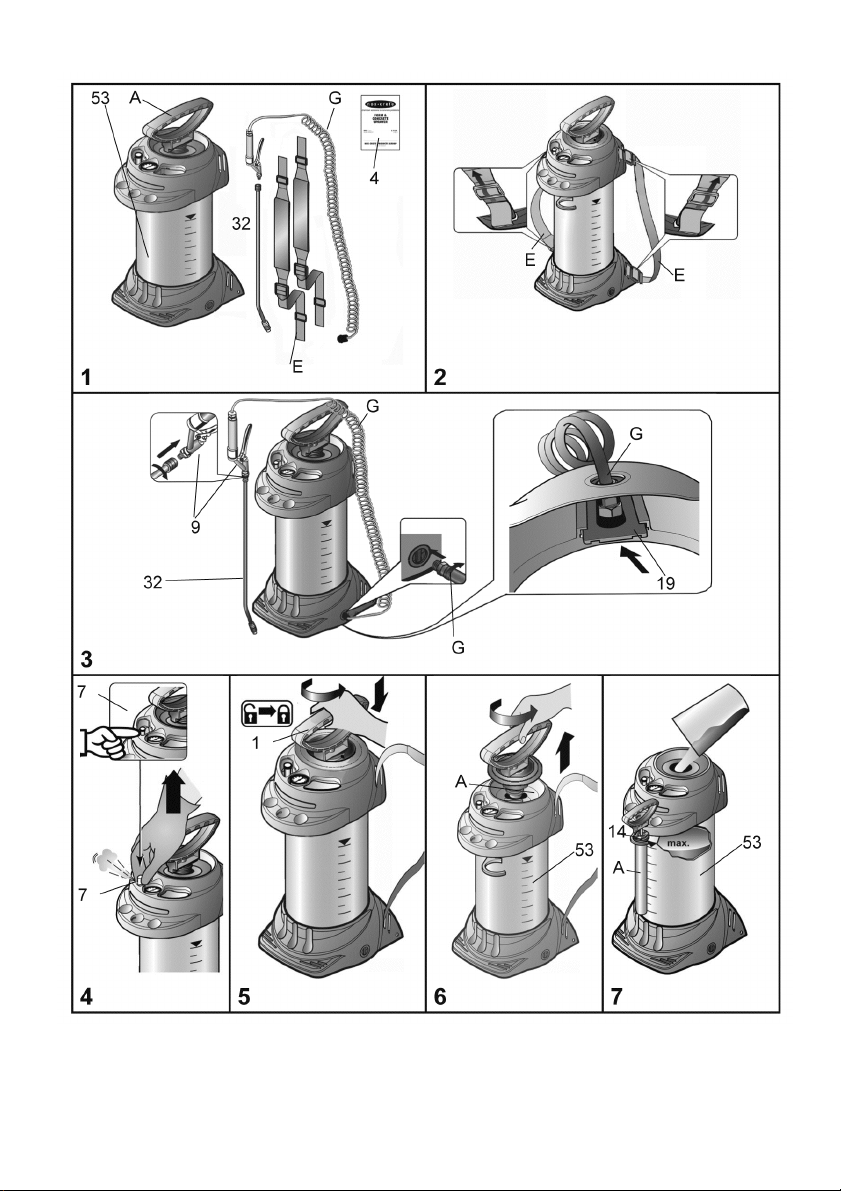

Refer to the illustrations on pages 4-6 for the following instructions.

Assembly

1. Fasten the carrying strap(s) [E] on the tank [53]. (Fig. 2)

2. Screw the hose [G] tightly into the tank outlet port. (Fig. 3).

Note the location of the spigot in order to be able to insert the lock.

3. Insert the lock [19]. (Fig. 3)

►The lock closes and the hose is secured from unscrewing out of the tank.

4. Screw the spray wand [32] onto the trigger valve [H]. (Fig. 3)

Checks

Visual inspection: Are the tank [53], pump [A], hose [G] with trigger valve [H], pressure

gauge [F] and spray wand [32] undamaged? (Figs. 1, 10, 11)

Pay special attention to the connections between the tank – hose and the hose –

trigger valve and to the condition of the pump threading and hose.

No leaks: Pump up the empty device to 30 PSI (2.1 bar).

►The pressure must not decrease more than 7 PSI (.5 bar) within 30 minutes.

Function: Pull the red button on the safety valve [7]. (Fig. 4).

►The pressure must dissipate.

Activate the trigger valve [H] (Fig. 13).

►The trigger valve must open and close.

Sprayer Preparations

Observe the instructions in the section entitled “Safety”.

1. Pull up the red button on the safety valve [7] until all excess pressure is released from

the tank. (Fig. 4).

2. Press the pump handle [1] down and turn it counterclockwise.

3. The pump handle is locked in place. (Fig. 5).

4. Unscrew the pump [A] from the tank [53]. (Fig. 6).

To ensure the pump remains clean during storage, we recommend you attach the

pump to the pump holder [14]. (Fig. 7)

5. Pour the liquid to be sprayed into the tank. (Fig. 7)

6. Screw the pump [A] into the tank [53]. (Fig. 8)

7. Swivel in the pump holder [14]. (Fig. 8)

Pressurizing with manual Pump

1. Press the pump handle [1] down and turn it clockwise.

►The pump handle is unlocked. (Fig. 9).

2. Manually pump until the required pressure is generated. (→Table 2) in the tank [53]

(Fig. 10).

The maximum pressure should not exceed 90 PSI (red line on the pressure gauge

[13], Fig. 10). If the maximum pressure is exceeded, the safety valve will engage

and release the excess pressure.

10

USA

IRL

AUS

GB

NZ

CDN

IND

3. Press the pump handle [1] down and turn it counterclockwise.

►The pump handle is locked in place. (Fig. 5).

Pressurizing with an air compressor / external pressure source

1. Connect the compressed-air hose to the compressed-air filling valve [D]. (Fig. 11).

►Pressurize to the desired pressure - maximum pressure 87 PSI (6 bar).

Ensure that the pressure of your air compressor is regulated to a maximum of 87 PSI

(6 bar).

Spraying

Observe the instructions in the section entitled “Safety”.

Operate the sprayer only while it is vertical or suspended upright and nearly vertical.

Avoid allowing drops of spray to drift onto areas not being treated.

Review the product to be sprayed health and safety warnings.

1. Carry the sprayer in your hand or place it on your back. (Fig. 12)

►To prevent dripping, purge the sprayer by holding the spray wand in the air

before spraying and open the trigger valve until no liquid mixed with air is

released.

2. Begin spraying.

Table 2

Spray Tip Recommendation Guide

Products

Recommended Spray Tip

Cures and Sealers

8003LP, 8004LP or 8005LP

Water Repellant Sealers

8003LP, 8004LP or 8005LP

Form Release Agents

Chembeton & Pro Release

8003LP

All other release agents

80005, 800067 or 8001LP

Liquid Floor Hardeners

8004LP or 8005LP

Tilt-Up Cures and Bondbreakers

8003LP, 8004LP or 8005LP

►

3. If the spraying pressure decreases more than 10 PSI (.7 bar) from the optimum level,

increase the pressure by hand pumping or with compressed air.

If liquid mixed with air emerges from the nozzle, the tank is empty.

After Usage

Observe the instructions in the section entitled “Safety”.

1. Pull up the red button on the safety valve [7] until all excess pressure is released from

the tank. (Fig. 4).

2. Lock the pump handle in place [1]. (Fig. 5).

3. Unscrew the pump [A] from the tank [53]. (Fig. 6).

11

USA

IRL

AUS

GB

NZ

CDN

IND

Collect and dispose of the residual liquid according to all applicable laws,

requirements and regulations. Review the liquid manufacturer’s health, safety and

disposal warnings!

4. Rinse out the sprayer with the appropriate solvent or water.

5. Wipe off all solvent or water residue.

6. To store the sprayer, separate the tank and pump and store in a dry place protected

from sunlight and freezing temperatures.

Care and maintenance

Observe the instructions in the section entitled “Safety”.

After using the device 50 times or at least once a year:

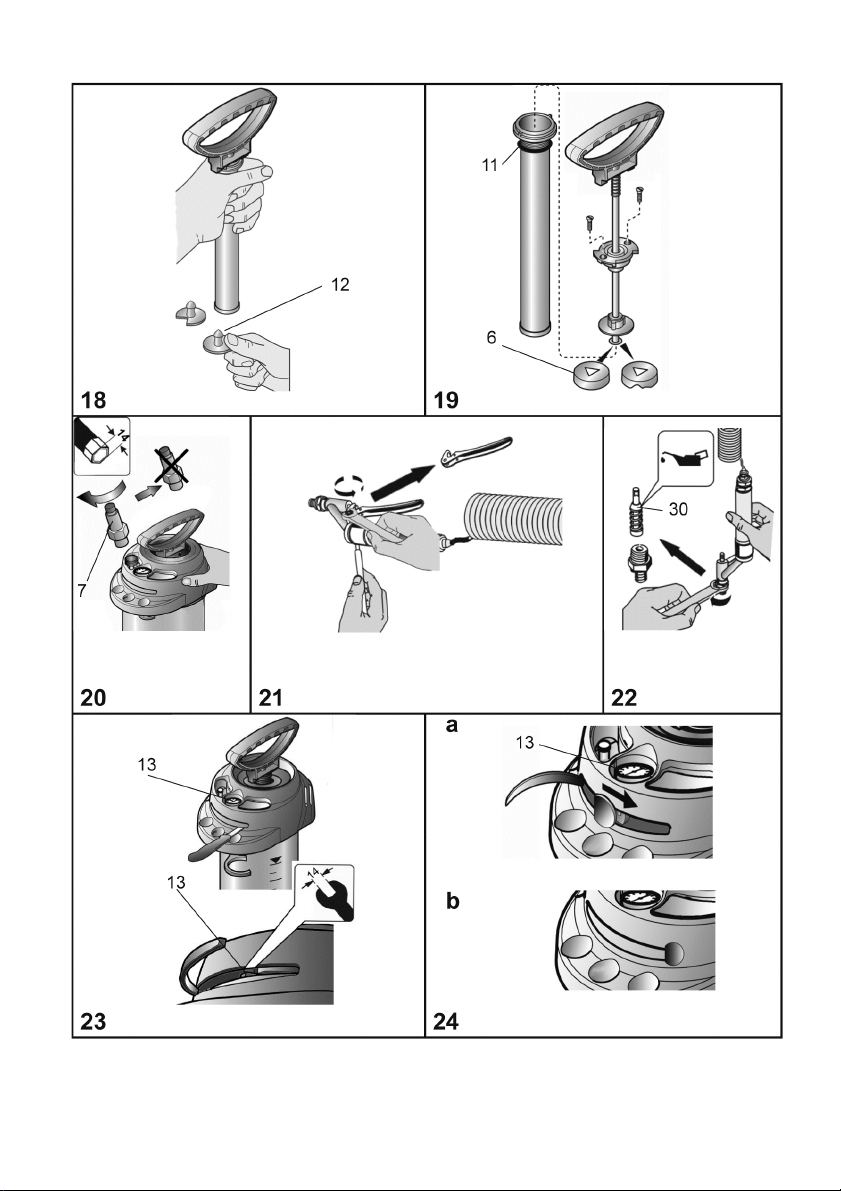

• Disassemble the sprayer [A] and grease the piston cup washer [6]. (Fig. 14 -15).

• Clean the spray tip [37-43] with the appropriate cleaning solvent or water. If required use a

needle. (Fig. 16).

• Remove the 200 mesh anti-siphon filter [35] from the end of the wand and the 100 mesh

filter location inside the trigger valve filter house [24] and clean thoroughly with the

appropriate solvent or water. (Fig. 17).

• Grease the seals [6] and [11 and 30]. (Fig. 19 and 22)

• Visually check the sprayer before each use for signs of leakage. Replace all worn parts.

Replace the tank if any holes are observed.

Troubleshooting

Use only NOX-CRETE spare and accessory parts (you will find some in the spare

parts container (page 2 and 3).

Problem

Cause

Remedy

No pressure builds up in

the device

The pump is not screwed on

tightly.

Screw the pump on tightly

O-ring [11] on the pump is

faulty.

Replace the O-ring. (Fig. 19).

Foot valve disk [12] defective.

Replace the foot valve.

(Fig. 18).

Piston washer [6] is defective.

Replace piston washer.

Liquid flows out of the

pump.

Foot valve disk [12] defective.

Clean or replace the foot valve

disk. (Fig. 18).

The sprayer does not

spray even though

pressure is present.

Filters [24 and 35]and / or

spray tip [37-43] blocked.

Pressure regulator [F] is set too

low.

Clean the filters or / and spray

tip. (Fig. 16 +17)

Turn pressure regulator dial

clockwise to increase pressure.

12

USA

IRL

AUS

GB

NZ

CDN

IND

Problem

Cause

Remedy

Safety valves blows off

too early.

Safety valve [7] is defective.

Replace safety valve. (Fig. 20).

The trigger valve does

not close.

Liquid emerges without

the lever being activated.

Seal [30] on the pressure bolt

not greased.

Defective valve pin assembly or

seal [30].

Grease the seal of the pressure

bolt. (Fig. 22).

Replace the valve pin assembly

or seal. (Fig. 22).

Pressure gauge is not

indicating any tank

pressure.

Pressure gauge [16] defective.

Replace pressure gauge. (Fig.

23 & 24)

Warranty

We guarantee that from the time it is first purchased for a period of the legally valid required

warranty period (maximum 3 years) this sprayer will not exhibit any material or processing

errors. If defects are discovered during the warranty period, Nox-Crete, Inc. or the distributor

in your area will repair the sprayer without charging for the labor or material or (at the

discretion of Nox-Crete, Inc.) replace the sprayer itself or its defective parts.

If such defects are discovered, please contact us immediately. We require a copy of the

invoice or cash register receipt for purchase of the device.

The warranty does not include wearing parts (seals, O-rings, diaphragm, etc.) or defects

which have occurred due to improper use or unforeseeable circumstances.

CE Declaration of Conformity

Products of series PERFECT (3615) meet the requirements of Pressure Equipment

Directive 97/23/EC and bear the CE marking.

Table of contents

Other nox-crete Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

Toro

Toro 41177 Multi-Pro 1250 Operator's manual

Parkside

Parkside PFS 280 A1 Operation manual

Anest Iwata

Anest Iwata WIDER2L-10G2P instruction manual

Campbell Hausfeld

Campbell Hausfeld AL1860 - METAL Operating instructions and replacement parts list

Hozelock

Hozelock 4507 manual

Anest Iwata

Anest Iwata OCX-128 instruction manual