SEC-03M User Manual

________________________________________________________________________________________________________________

___________________________________________________________________________

version 1.8 page 2

Table of Contents

About this Manual ................................................................................................................... 4

1.Safety Regulations .............................................................................................................. 5

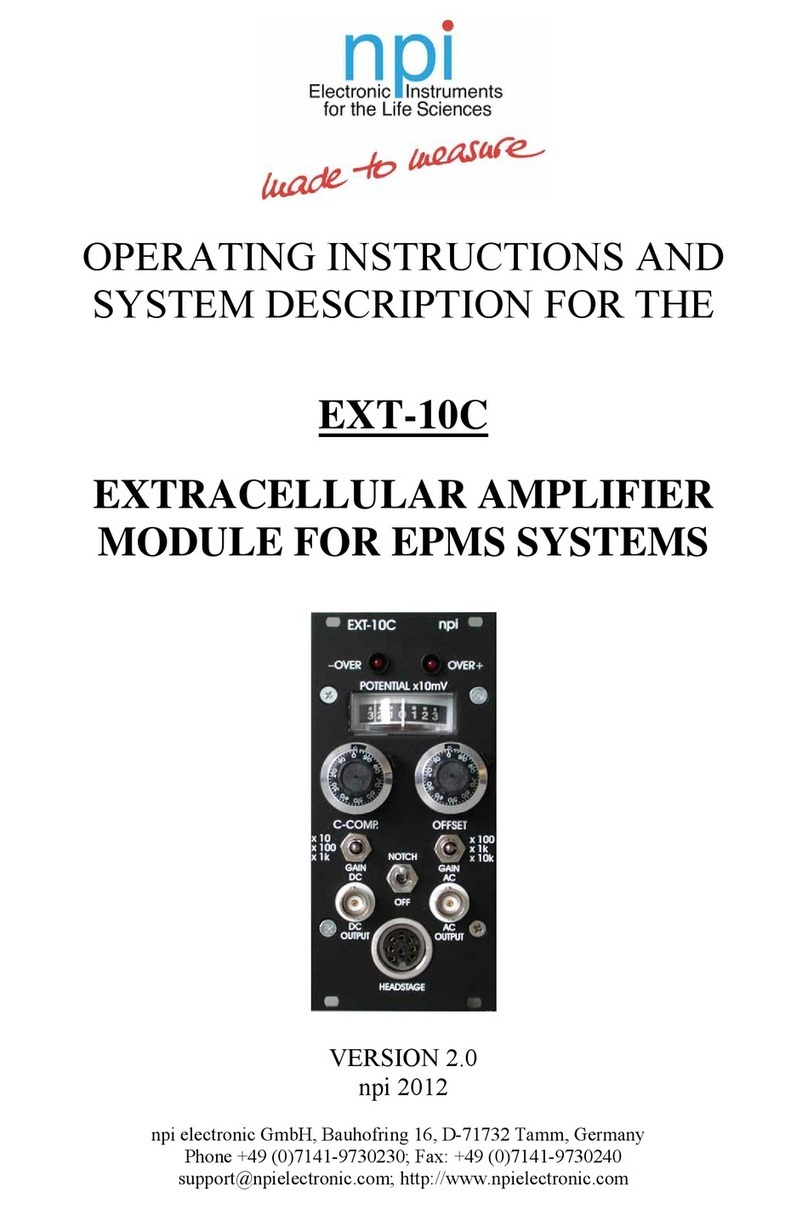

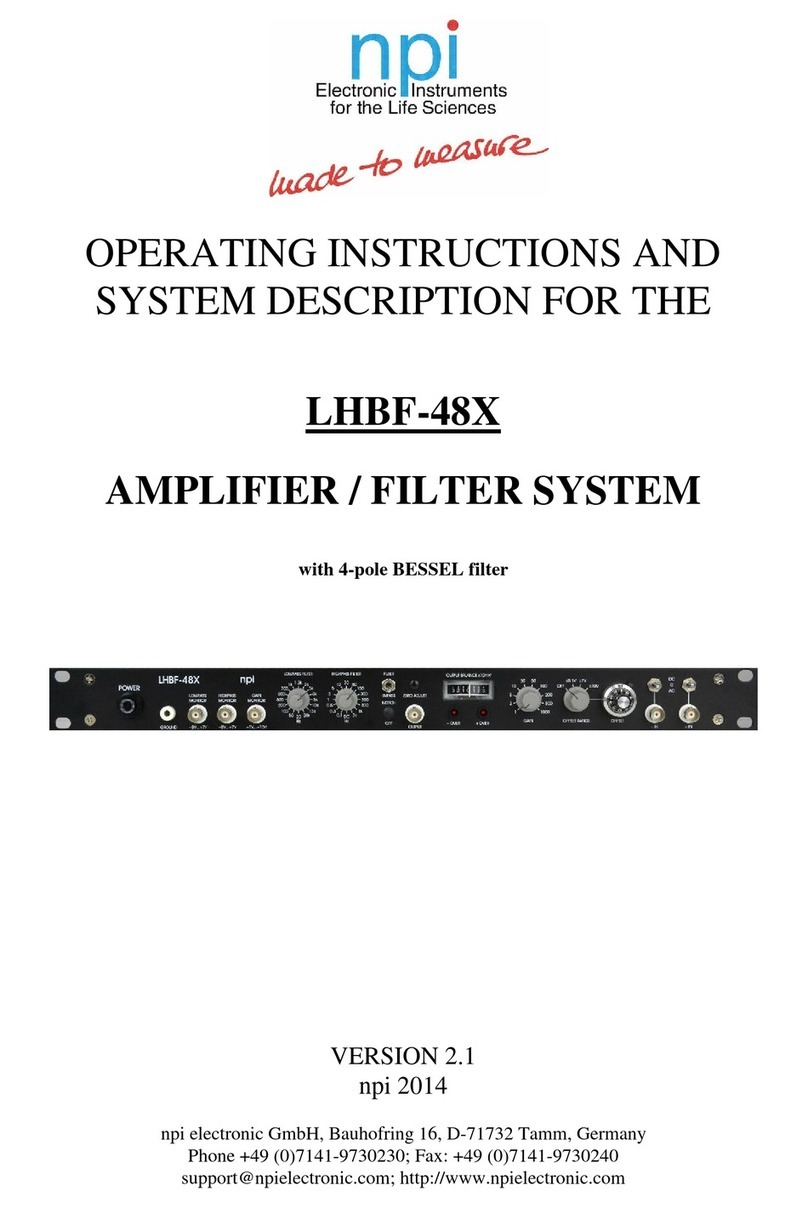

2.EPMS-07 Modular Plug-In System .................................................................................... 6

2.1.General System Description / Operation..................................................................... 6

2.2.EPMS-07 Housing....................................................................................................... 6

2.3.EPMS-E-07 Housing ................................................................................................... 6

2.4.PWR-03D .................................................................................................................... 6

2.5.System Grounding ....................................................................................................... 7

EPMS-07 ..................................................................................................................... 7

EPMS-E-07.................................................................................................................. 7

2.6.Technical Data............................................................................................................. 7

EPMS-07 ..................................................................................................................... 7

EPMS-E-07.................................................................................................................. 7

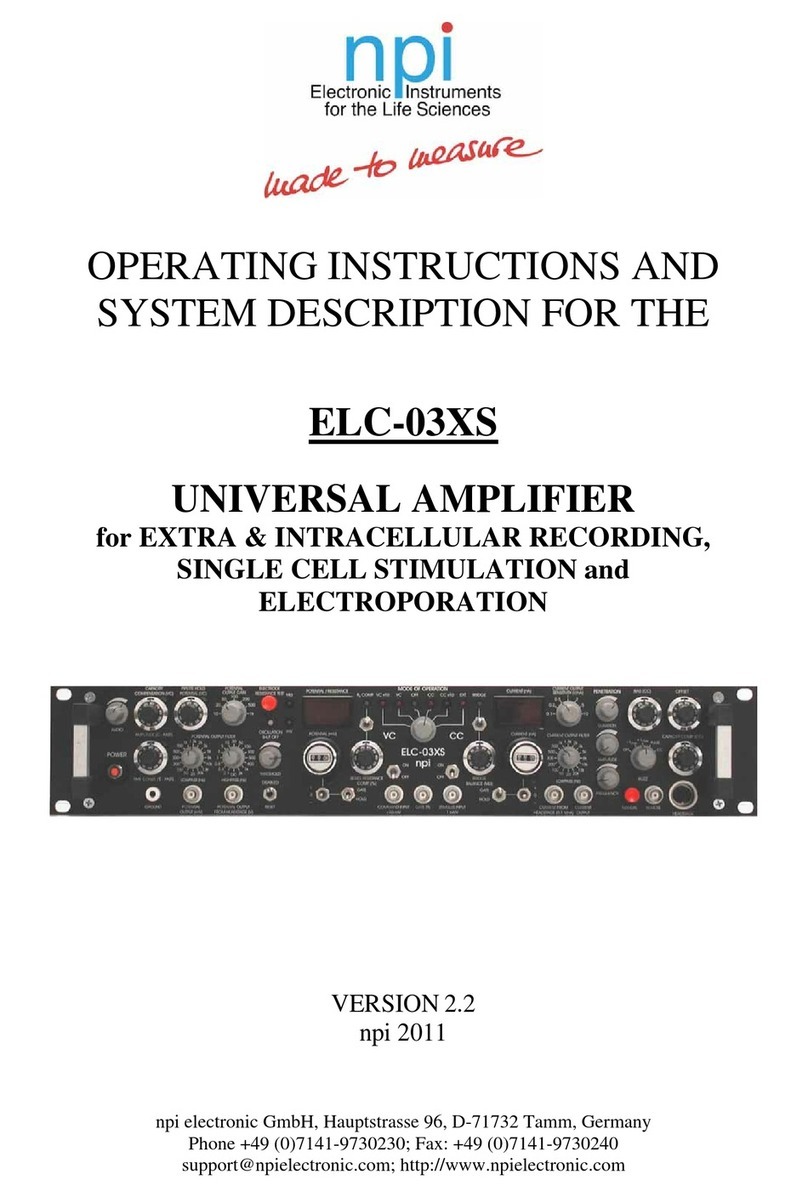

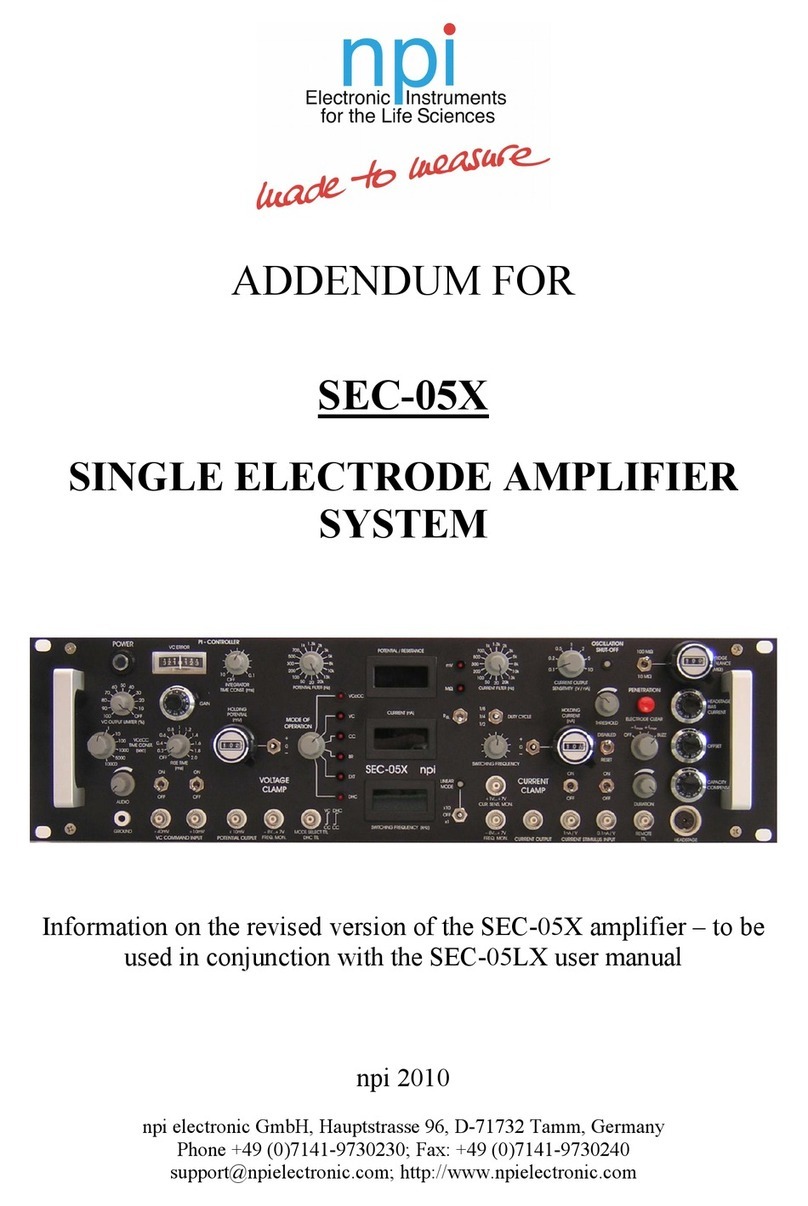

3.Introduction......................................................................................................................... 8

3.1.Why a Single Electrode Clamp?.................................................................................. 8

3.2.Principle of Operation ................................................................................................. 10

Major Advantages of the npi SEC System .................................................................. 12

3.3.Advantages of the Modular SEC-03M System ........................................................... 12

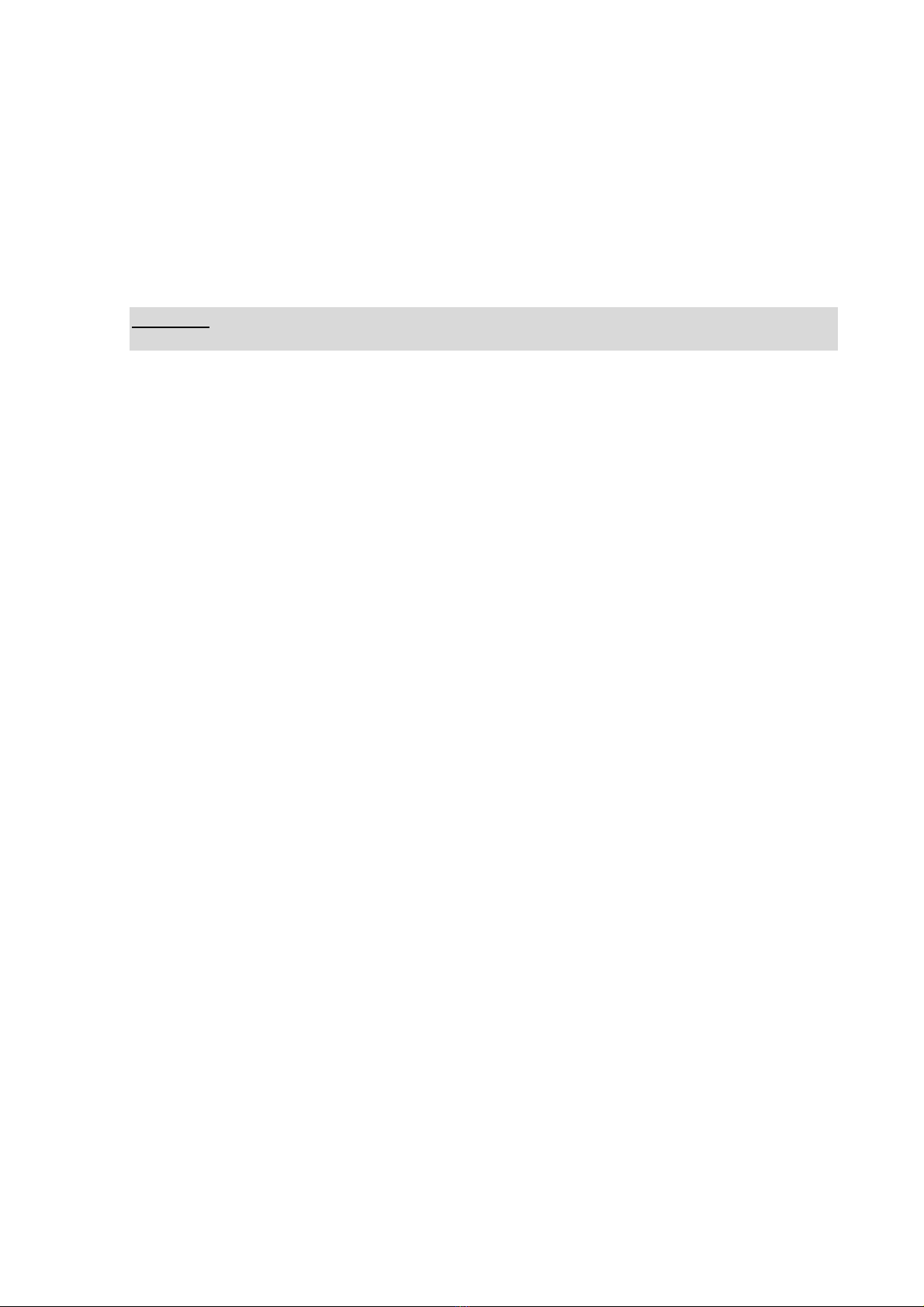

4.SEC-03M System ............................................................................................................... 13

4.1.SEC-03M Components................................................................................................ 13

4.2.Description of the Front Panel..................................................................................... 14

5.Headstages .......................................................................................................................... 19

5.1.Standard and low-noise (SEC-HSP) headstages ......................................................... 19

5.2.Low-noise headstage (SEC-HSP)................................................................................ 21

6.Setting up the SEC-03M System ........................................................................................ 22

7.Passive Cell Model ............................................................................................................. 23

7.1.Cell Model Description ............................................................................................... 23

7.2.Connections and Operation ......................................................................................... 24

7.3.Connections and Operation ......................................................................................... 25

8.Test and Tuning Procedures ............................................................................................... 27

8.1.Headstage Bias Current Adjustment............................................................................ 27

8.2.Electrode Selection...................................................................................................... 28

8.3.Offset Compensation ................................................................................................... 28

8.4.Bridge Balance (in BR mode) ..................................................................................... 29

8.5.Switching Frequency and Capacitance Compensation (in switched modes) .............. 31

Criteria for the selection of the switching frequency .................................................. 31

8.6.Capacity Compensation - Tuning Procedure............................................................... 33

First part: basic setting................................................................................................. 33

Second part: fine tuning............................................................................................... 38

8.7.Testing Operation Modes ............................................................................................ 39

Current Clamp (in BR- or discontinuous CC mode) ................................................... 39

Voltage Clamp............................................................................................................. 39

9.Sample Experiments ........................................................................................................... 41

9.1.Sample Experiment using a Sharp Microelectrode ..................................................... 41

9.2.Sample Experiment using a Suction Electrode............................................................ 44

10.Tuning VC Performance.............................................................................................. 46

General Considerations................................................................................................ 46

Tuning Procedure ........................................................................................................ 47

11.Trouble Shooting ......................................................................................................... 48

12.Appendix ..................................................................................................................... 49