TABLE OF CONTENTS

NITESTAR NS-50 and NS-60 . . . . . . . . . . . . . . . . . . . . . . . .2

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . .2

Automatic Error Correction (AEC) . . . . . . . . . . . . . . . .3

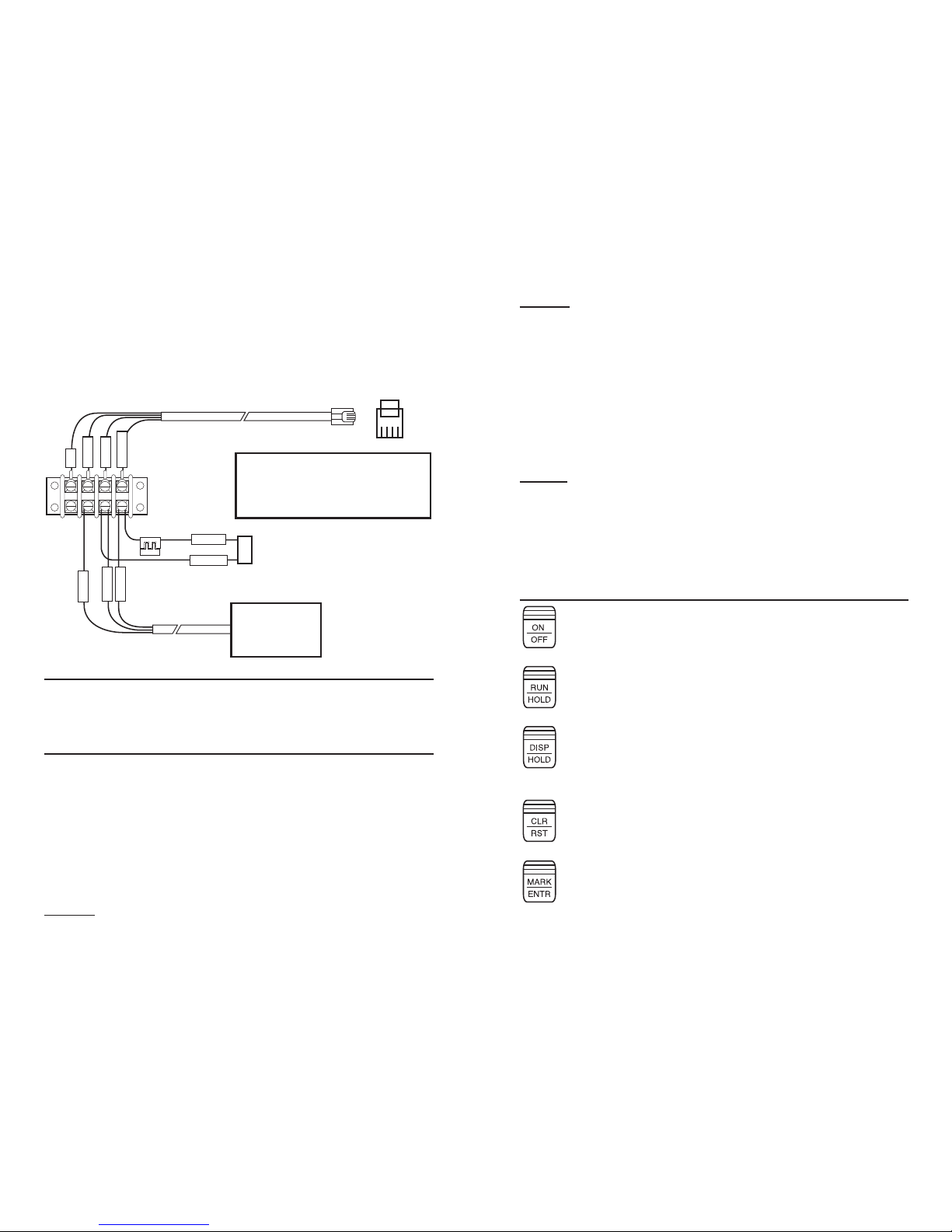

INSTALLATION

Mounting The Nitestar . . . . . . . . . . . . . . . . . . . . . . . .3

Mounting The Terminal Block . . . . . . . . . . . . . . . . . . .3

Wiring The Nitestar . . . . . . . . . . . . . . . . . . . . . . . . . .4

KEY DESCRIPTIONS

On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Run/Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Disp/Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Clear/Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Mark/Enter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Calibrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Pre Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Up/Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Brightness (Backlight) . . . . . . . . . . . . . . . . . . . . . . . .6

Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Speed Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Periodic Distance Interval . . . . . . . . . . . . . . . . . . . . . .7

Program Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Memory View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

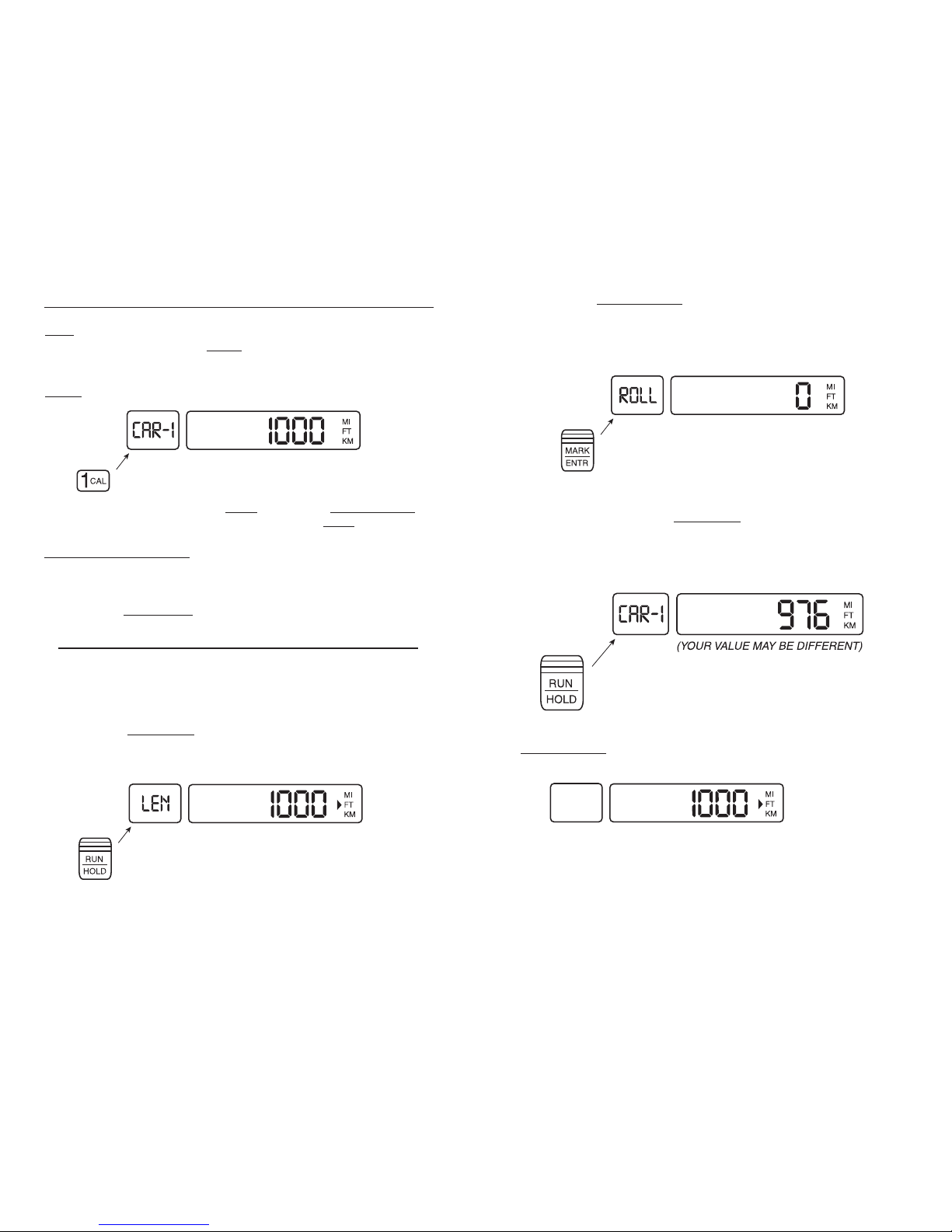

CALIBRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Pre-Calibration Procedures . . . . . . . . . . . . . . . . . . . . .7

Instrument Calibration . . . . . . . . . . . . . . . . . . . . . . . .8

Calibration Summary (Automatic) . . . . . . . . . . . . . . .10

Calibration Summary (Manual) . . . . . . . . . . . . . . . . .10

MEMORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Storing Events to Memory . . . . . . . . . . . . . . . . . . . .11

Recalling Events from Memory . . . . . . . . . . . . . . . . .13

Memory Store Summary . . . . . . . . . . . . . . . . . . . . . .14

Store Memory Locations . . . . . . . . . . . . . . . . . . . . . .14

Printing Memory . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Changing Memory Output Format . . . . . . . . . . . . . . .16

Plain Language Events . . . . . . . . . . . . . . . . . . . . . . .16

Memory Recall Summary . . . . . . . . . . . . . . . . . . . . .17

SURVEY DATA MANAGEMENT SOFTWARE . . . . . . . . . . . . .18

GPS System Overview . . . . . . . . . . . . . . . . . . . . . . .18

GPS Receiver Overview . . . . . . . . . . . . . . . . . . . . . .18

GPS Specifications . . . . . . . . . . . . . . . . . . . . . . . . . .19

PERIODIC DISTANCE INTERVAL (PDI)

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

TTL PDI Connection . . . . . . . . . . . . . . . . . . . . . . . . .19

TTL PDI Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

12V PDI Connection . . . . . . . . . . . . . . . . . . . . . . . . .20

Setting PDI Distance . . . . . . . . . . . . . . . . . . . . . . . .20

Setting PDI Duration (Time) . . . . . . . . . . . . . . . . . . .21

Setting PDI Duration (Distance) . . . . . . . . . . . . . . . .21

Inside Front Cover

Setting the Type of PDI . . . . . . . . . . . . . . . . . . . . . .22

Low Going High (PDI Output) . . . . . . . . . . . . . . . . . .22

High Going Low (PDI Output) . . . . . . . . . . . . . . . . . .23

Flip Flop (PDI Output) . . . . . . . . . . . . . . . . . . . . . . . .23

Advanced PDI Uses . . . . . . . . . . . . . . . . . . . . . . . . .24

Set Count Increment . . . . . . . . . . . . . . . . . . . . . . . .24

Set Count Pre-Distance . . . . . . . . . . . . . . . . . . . . . .25

Summary PDI Keys . . . . . . . . . . . . . . . . . . . . . . . . . .25

PDI Count Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

EMERGENCY 9-1-1 PROGRAM . . . . . . . . . . . . . . . . . . . . .26

Set Count Increment . . . . . . . . . . . . . . . . . . . . . . . .26

Set Count Pre-Distance . . . . . . . . . . . . . . . . . . . . . .27

AUXILLARY PROGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . .27

Self Test (PRM 1) . . . . . . . . . . . . . . . . . . . . . . . . . .28

Speed Trap (PRM 6) . . . . . . . . . . . . . . . . . . . . . . . . .28

Begin / End (PRM 15) NS-60 Only . . . . . . . . . . . . . . .29

Calculation Programs . . . . . . . . . . . . . . . . . . . . . . . .29

Area Calculation (PRM 10) . . . . . . . . . . . . . . . . . . . .30

Volume Calculation (PRM 11) . . . . . . . . . . . . . . . . . .30

Cost Calculation (PRM 12) . . . . . . . . . . . . . . . . . . . .30

Tonnage Calculation (PRM 13) . . . . . . . . . . . . . . . . .31

Tonnage Cost (PRM 14) . . . . . . . . . . . . . . . . . . . . . .31

Time Speed Delay Use (PRM 30) . . . . . . . . . . . . . . . .32

Time Speed Delay Limits . . . . . . . . . . . . . . . . . . . . . .33

Printer Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

SERIAL I/O

Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Serial Connector Diagram . . . . . . . . . . . . . . . . . . . . .34

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Baud Rate Setting . . . . . . . . . . . . . . . . . . . . . . . . . .34

DPU-414 PRINTER OPERATING INSTRUCTIONS . . . . . . . . . .35

Operating The Printer . . . . . . . . . . . . . . . . . . . . . . . .35

Functions That Use The Printer . . . . . . . . . . . . . . . . .35

Charging The Printer . . . . . . . . . . . . . . . . . . . . . . . .35

Opening The Paper Holder . . . . . . . . . . . . . . . . . . . . .36

Loading The Paper . . . . . . . . . . . . . . . . . . . . . . . . . .36

General Specifications (DPU-414) . . . . . . . . . . . . . . .37

TROUBLESHOOTING

Determining The Problem . . . . . . . . . . . . . . . . . . . . . . . . .37

Instrument is Operational But Won’t Count . . . . . . . . . . . .38

WARRANTY

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

HYPERTERMINAL STEP-BY-STEP GUIDE . . . . . . . . . . 40 – 44

SPECIFICATIONS

Nitestar Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . .45

CALIBRATION LOG WORKSHEET . . . . . . . . . . . . . . . . . . . 46

NITESTAR RETURN FORM . . . . . . . . . . . . . . . . . . . . . . . . 47

1