OM0255 Page 4 of 103

July/2019

LabGard® ES HD Energy Saver Class II, Laminar Flow Biosafety Cabinet

Models NU-581-400E/500E/600E Operation & Maintenance Manual

TABLE OF CONTENTS

Section No. 1.............................................................................. General Information

Section No. 2.............................................................................. Models & Features

Section No. 3.............................................................................. Warranty Disclaimer

Section No. 4.............................................................................. Shipments

Section No. 5.............................................................................. Installation Instructions

5.1..................................................................................... Location

5.2..................................................................................... Set-up Instructions

5.3..................................................................................... Testing Methods and Equipment

Section No. 6.............................................................................. Operating the NU-581E

6.1..................................................................................... Biosafety Cabinet Control

6.2..................................................................................... Operating Guidelines

6.3..................................................................................... Operating Sequence

6.4..................................................................................... Ergonomics

6.5..................................................................................... Cleaning Procedures

Section No. 7.............................................................................. General Maintenance

7.1..................................................................................... Decontamination

7.2..................................................................................... Fluorescent Lamp Bulb Replacement

7.3..................................................................................... Primary HEPA Prefilter Replacement

7.4..................................................................................... Secondary HEPA Filter/Motor Replacement

7.5..................................................................................... Sliding Window Replacement & Manual Adjustment

7.6..................................................................................... Airflow Control System Setup & Calibration

7.7..................................................................................... HEPA Filter Leak Tests

7.8..................................................................................... Airflow Smoke Pattern Test

7.9..................................................................................... Cleanliness Classification Test for Pharmacy Application

7.10................................................................................... Main Control Board Description & Replacement

7.11................................................................................... Digital Airflow Sensor Description & Replacement

Section No. 8..................................................................................... Error Messages, Troubleshooting, Option-Diagnostics &

Airflow Sensor Performance Verification

Section No. 9.............................................................................. Remote Contacts

Section No. 10............................................................................ Optional Equipment

10.1................................................................................... Ultraviolet Light

Section No. 11............................................................................ Electrical/Environmental Requirements

Section No. 12............................................................................ Disposal and Recycle

Insert.......................................................................................... Replacement Parts

MANUAL DRAWINGS

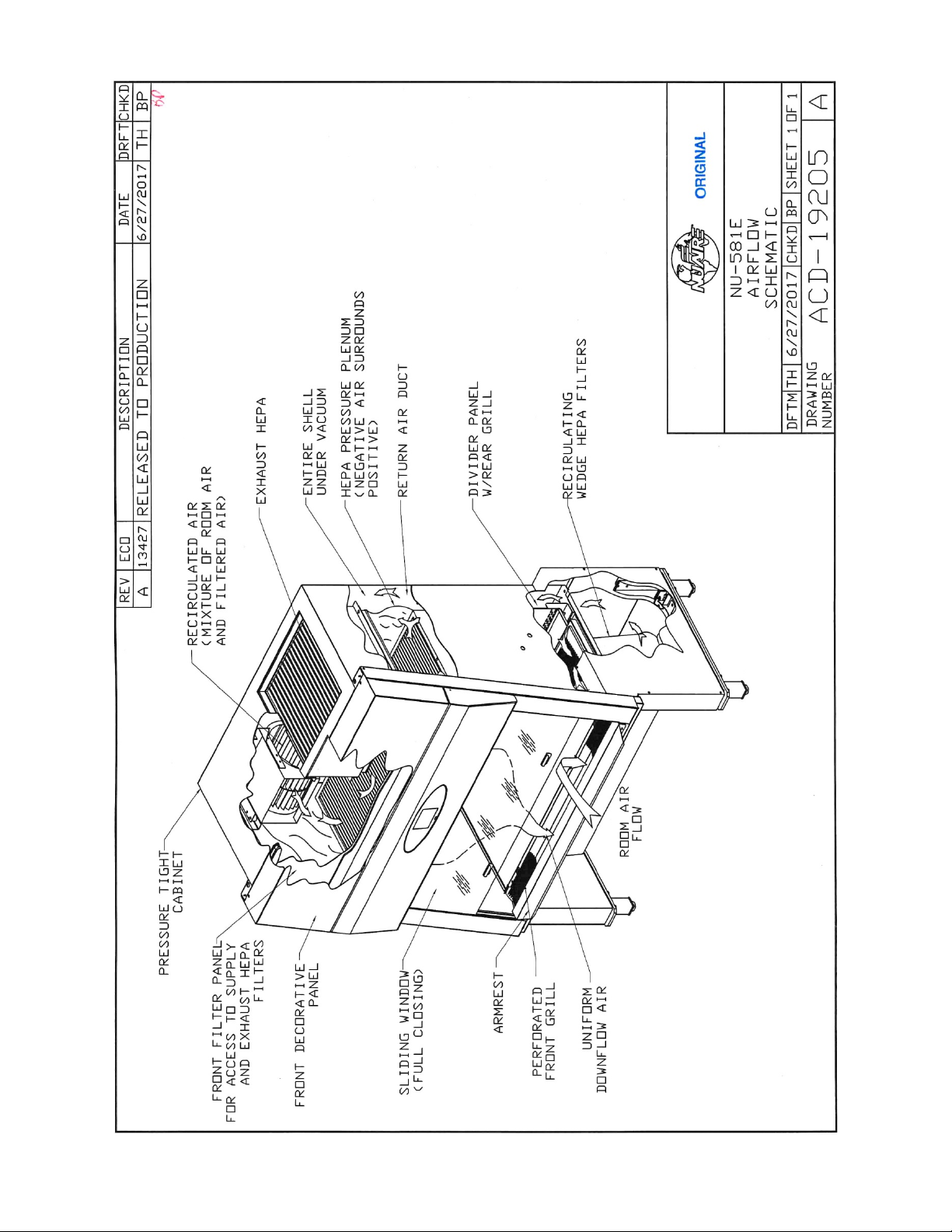

ACD-19205................................................................................. NU-581E Airflow Schematic

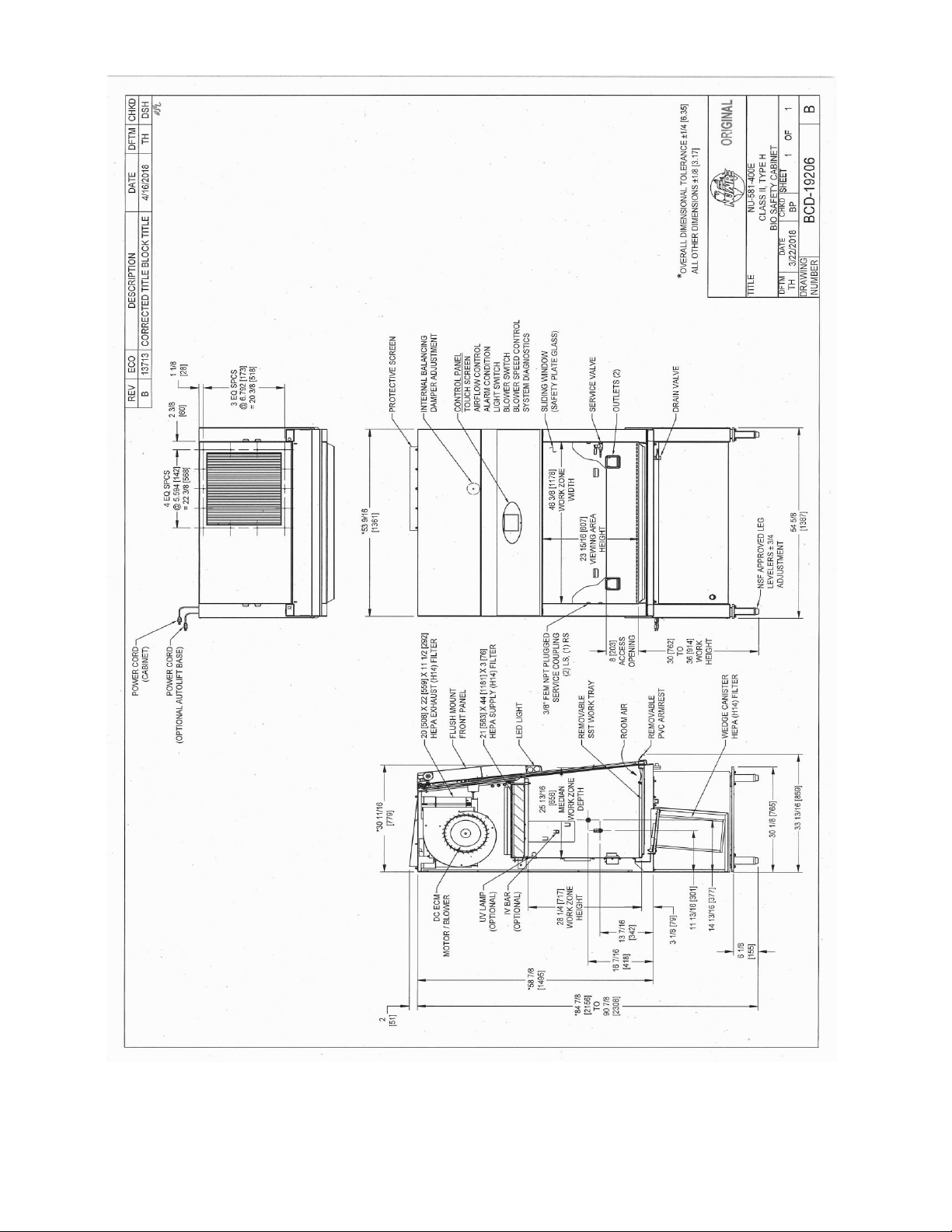

BCD-19206 ................................................................................. NU-581-400E Specification Drawing

BCD-19207 ................................................................................. NU-581-500E Specification Drawing

BCD-19208 ................................................................................. NU-581-600E Specification Drawing

BCD-19209 ................................................................................. NU-581E Security Drain Valve Installation

BCD-16509 ................................................................................. Auto Decontamination Setup

ASSEMBLY DRAWINGS

BCD-11817 ................................................................................. Control Center & Front Decorative Panel Assembly

BCD-11686 ................................................................................. Sliding Window Assembly & Adjustment

BCD-13923 ................................................................................. NU-581 Manual Base Adjustment

BCD-19210 ................................................................................. NU-581 Window Assembly Hinge Operation

BCD-12281 ................................................................................. Auto Window Switch/Cable Adjustment and Maintenance

BCD-12282 ................................................................................. Auto Window Cable and Window Assembly

ELECTRICAL SCHEMATICS

BCD-19211 ................................................................................. NU-581-400E/500E/600E Electrical Schematic