4

nuaire.co.uk 029 2085 8400 05. 03. 19. Document Number 671919

Installation and Maintenance High Performance Extract Fan

5.0 Maintenance

5.1 General

IMPORTANT

Before cleaning, always ensure that you have isolated your

cooker hood from the electrical power supply.

On/Off Button

Decrease Speed Button

Increase Speed Button

Digital Display

Light Button

Figure 12. Control Panel

Clean the external parts of your cooker hood with lukewarm mild liquid

detergent and a new damp cloth. Never use metal pads, chemical,

abrasive material or a stiff brush. Never insert pointed objects into the

motor’s protective grid.

5.2 Carbon Filters (Recirculation Mode)

If the appliance is being used in recirculation mode then it is necessary

to replace the carbon filters at least once a year for general cooking

applications. Heavier use of the cooker hood will require higher

frequency carbon filter replacement. Telephone 02920 858 400

aftersales@nuaire.co.uk

Speed 1: Used for light cooking (small amount of steam).

Speed 2: Used for general cooking.

Speed 3: Used for heavy cooking (large amount of steam).

5.3.1 Quick Timer

Press & hold the - and + buttons for 1 second. The digital display will

begin flashing. After five minutes the motor & light will automatically

turn off and a buzzer will sound for one second.

5.3.2 Booster Function

The cooker hood has a booster function, to activate the booster,

increase the speed to setting 4. The hood will increase speed for 5

minutes, before slowing down again.

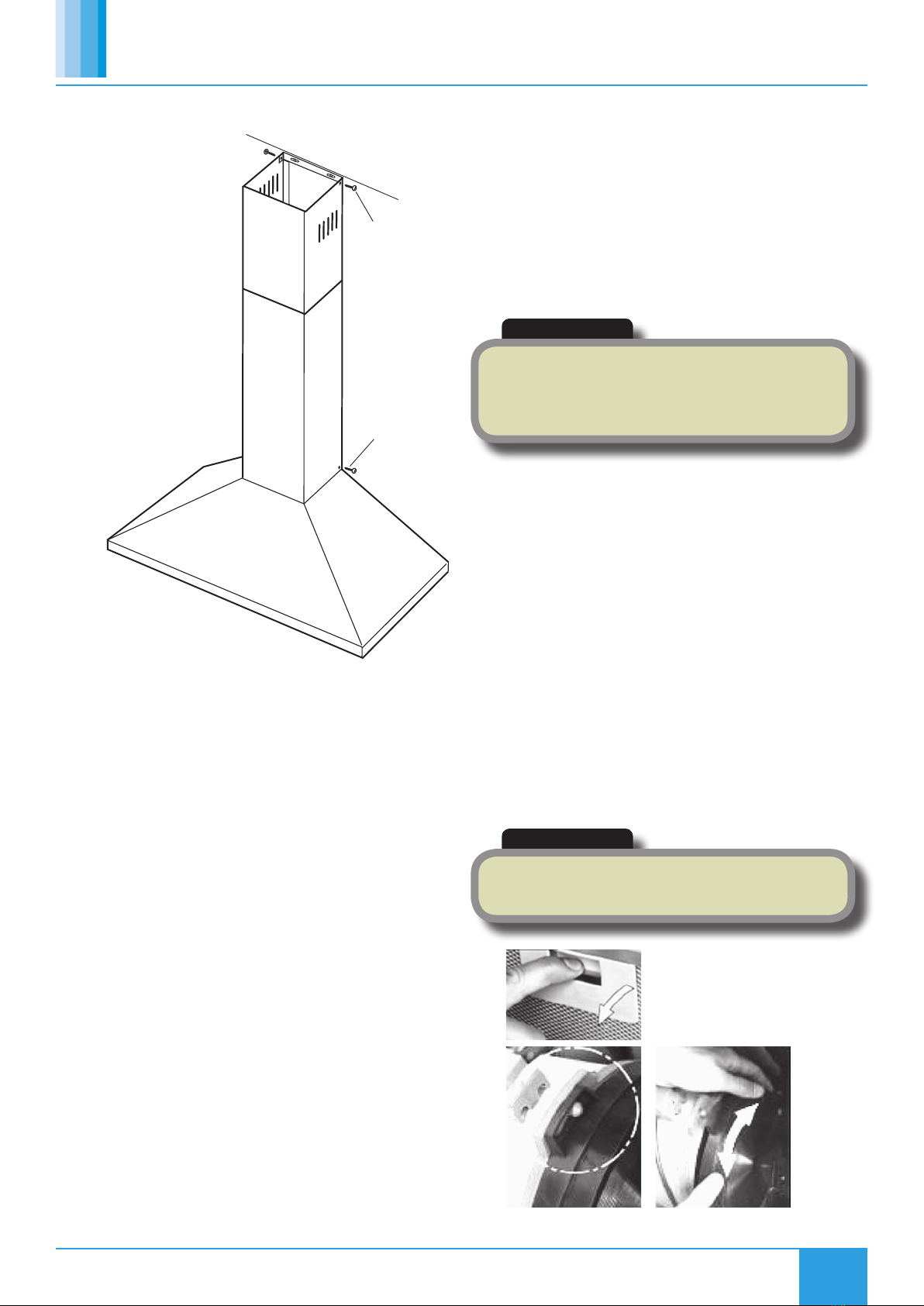

Figure 13. Removing metal grease filters

•Remove the grease filters.

•Hook the carbon filter over the pins that are located at the end of

the motor (Figure 9). Turn the carbon filter clockwise, until you feel

it click into place.

•Repeat this process for the second carbon filter. You need to place

a carbon filter at either end of the motor.

•Refit the grease filters.

4.0 Operation

5.3 Grease Filters

Grease filters collect grease and dust which has a direct effect on the

efficiency of the cooker hood. If not cleaned, the (potential flammable)

grease residue will saturate on the filter. Clean the filter every month

to prevent any risk of fire.

Remove the grease filters by pulling down on the handle and pulling

them away from the cooker hood. Soak the grease filter in hot water

and washing up liquid for about an hour. Rinse them off thoroughly

with hot water. Repeat the process if required. Refit the grease filters

once they have dried.

It is important to let the grease filters dry thoroughly before refitting

them in the cooker hood.

5.4 Lights

Prior to touching the light bulbs ensure they are cool. Find the bulb

that requires replacement, you will find it located in the light fixture

which is inside the exposed section of the canopy.

Disconnect the light wiring point and remove the bulb holders and

wiring from the hood. Important: It is not possible to replace the bulbs

individually, it will be necessary to obtain the bulbs, bulb holders and

wiring as a complete part (LED light: MAX 1.5W).

Fit the replacement bulbs, bulb holders and wiring in the same manner

as the originals and reconnect the light wiring point.

6.0 Warranty

The 2 year warranty starts from the day of delivery and includes parts

only.

This warranty is void if the equipment is modified without

authorisation, is incorrectly applied, misused, disassembled, or not

installed, commissioned and maintained in accordance with the details

contained in this manual and general good practice.

The product warranty applies to the UK mainland and in accordance

with Clause 14 of our Conditions of Sale. Customers purchasing from

outside of the UK should contact Nuaire International Sales office for

further details.

7.0 After Sales

For technical assistance or further product information, including spare

parts and replacement components, please contact the After Sales

Department.