Version 2.0NS022219 6

65

* solid state relay output type factory is set to ,

the relay contact output type factory set to .

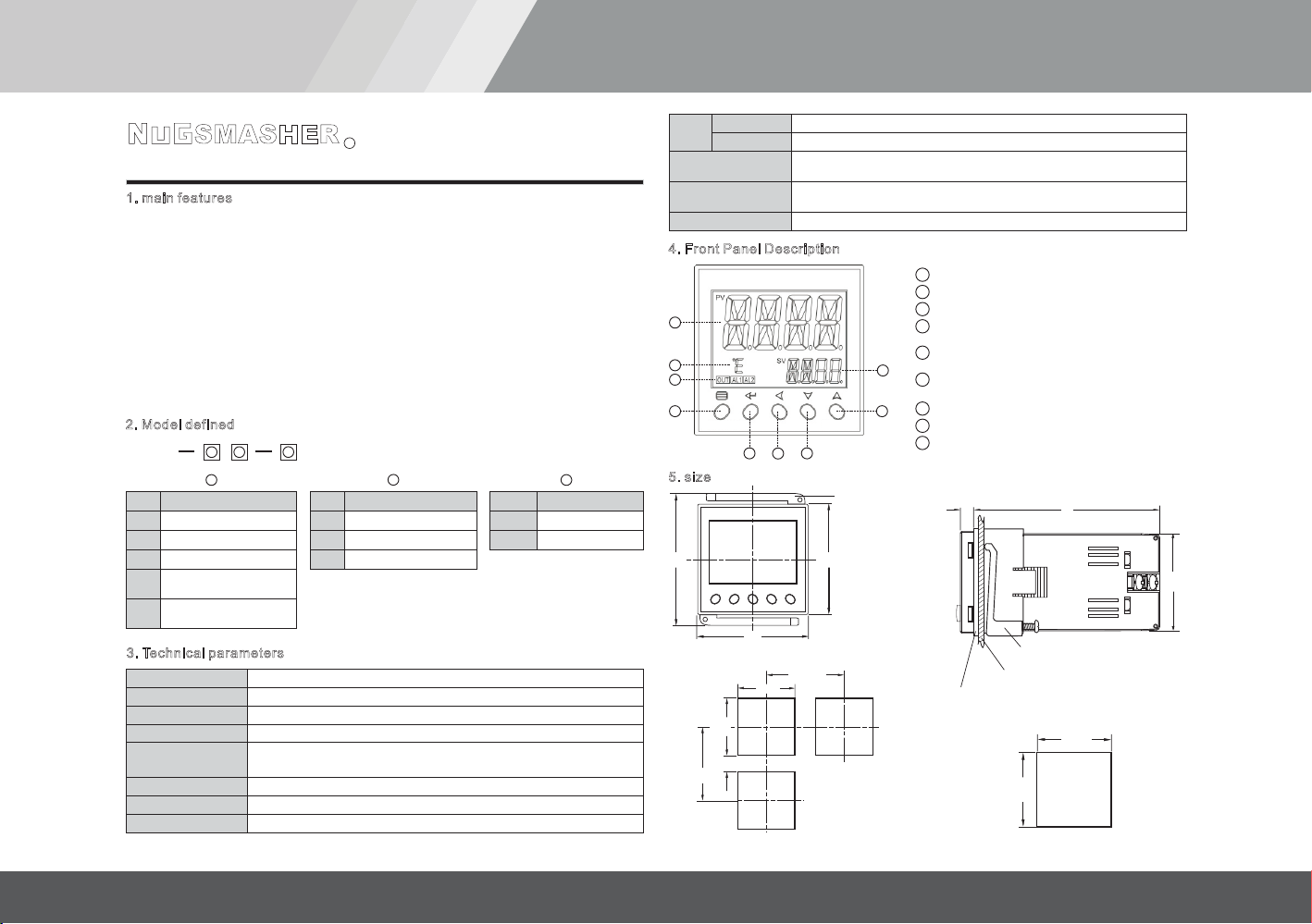

8. default settings.

Control

mode

onoF: on-off control. For situation not requiring high precision.

FPId: advanced artificial intelligence ”FUZZY PID“ control.

onoF

FPId

onr: Reverse acting. Increase in measured variable causes a

decrease in the output, such as heating control.

ond: Direct acting. Increase in measured variable causes an

increase in the output, such as refrigerating control.

Selection of

heating

refrigeration

CntL

orEv onr

ond

Proportional

band

1~32000

Proportional band in PID and APID control. Instead of percentage

of the measurement range, the unit is the same as PV.

Generally, optimal P, I, D and CP can obtained by auto tuning. They

can also be manually inputted if you already know the correct

values.

P

CP Control cycle CP reflect the instrument operator to adjust the speed, the size of

the CP that affect the control accuracy.

With SSR, SCR output control cycle preferable to shorter, usually

0.5-3.0 Seconds. The relay switch output is generally in 15-40 sec.

When the output relay switches , the CP will be limited to

3 seconds, And self-tuning At will automatically set the CP as the

appropriate value, taking into account the control accuracy And

mechanical switch life.

When the control mode CntL = onoF, the action of the CP as an

output disconnect or power-on output ON Delay time.

0.2~

300.0

Int Input Signal Input spec:

K、E、J、N、Pt(Pt100)

dp Decimal

point

0 (no decimal), 0.0 (one decimal place).

InF

dU

SvL

SvH

-999~

+3200

SC Input Shift

Adjustment

Sc is used to shift input to compensate the error caused by

transducer, input signal, or auto cold junction compensation of

thermocouple.

PV after compensation=PV before compensation + Sc It is generally

set to 0. The incorrect setting will cause measurement inaccurate.

-199.9~

+400.0

PV

input filter

The value of InF will determine the ability of filtering noise.

When a large value is set, the measurement input is stabilized but

the response speed is slow. Generally, it can be set to 1 to 3.

If great interference exists, then you can increase parameter “InF”

gradually to make momentary fluctuation of measured value less

than 2 to 5.

When the instrument is being metrological verified, “InF” s can be

set to 0 or 1 to shorten the response time.

Temperature

unit selection

°C:

°F:fahenheit equals

celsius equals

Low limit

of SV

Minimum value that SV is allowed to be.

Upper limit

of SV

Maximum value that SV is allowed to be.

0~40

°C

°F

HYS Control

hysteresis

0~200.0

HYS is used for on-off control to avoid frequent on-off action of relay.

For a reverse acting (heating) system, when PV > SV, output turns

off; when PV<SV-HYS, output turns on.

For a direct acting (cooling) system, when PV<SV, output turns off;

when PV>SV+HYS, output turns on.

Differential

time

No derivative effect when d=0 0~3200

seconds

d

0

0.0

Integration

time

No integral effect when I=0 1~9999

seconds

I

*

Parameter code factory setting Parameter code Parameter code

factory setting factory setting

9. Wiring diagram.

+

ABB

-

1 2

109876

11

12

13

345

AL1

-

+

OUT

COM

N/O

AL2

N/O

N/OCOM N/C

POWE R

COM

10. Note

( )

( )

( )

1 Can not normally display measured values in the display window alternating show:

"orAL" character, indicating that the input of the measurement signal abnormalities or Out of

range; check Int parameter settings, and then the input sensor signals are the same category,

if it is determined the same, check the input sensing Signal not pick the wrong line, if it is

determined to not pick the wrong line, check whether the sensor problem, replace another

sensor to try.

2

heat dissipation, instrument internal temperature rise due to thermal radiation will lead to a

result of the measurement accuracy and service life of the affected. In this Case, to be taken

to a forced cooling fan or other measures to reduce the ambient temperature.

3 the extension or connection then the thermocouple leads should be used with the

thermocouple type to match the compensation conductor; extend or connect the

thermoelectric Resistance of the lead, you should use the minimal resistance of the wire and

cable away from power lines and load connection, in order to avoid signal interference.

The instrument used by the local environmental temperature and humidity can not

exceed the scope of the provisions, the instrument around should allow sufficient space for

R

SMASHER