407 reflective beam line-type smoke detector

Installation and Service Manual

232-0061-r04_2020-10

© 2019, 2020 Ambest Electronics (Ningbo) Co Ltd. All rights reserved.

All specifications and other information shown were current at the date of publication and subject to change without notice.

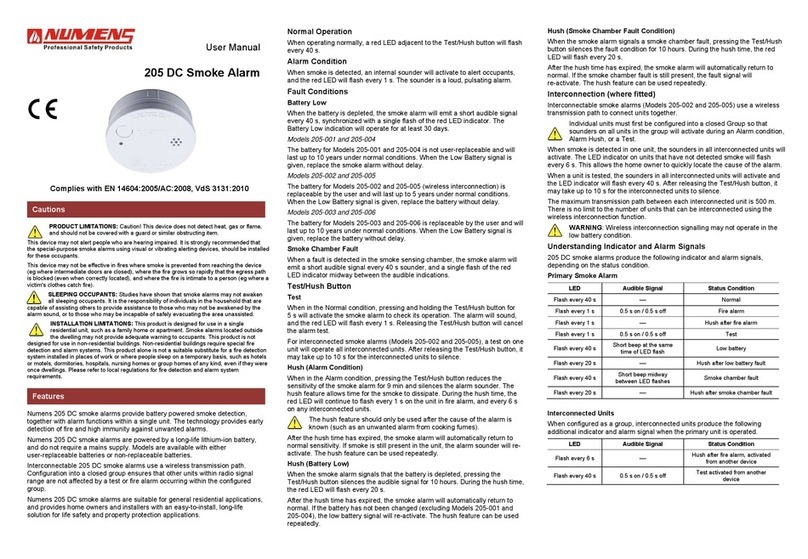

Detector Body

Smoke

Mounting

Bracket

Infrared

Beam

Reflector

<100m

Fig. 2 – Operating principle

1.3.2. Automatic Light Compensation

Dust in the environment may obscure the lens and contaminate the reflector. In this event, the detector will

automatically compensate the received signal to ensure normal operation. When the compensation limit is

exceeded, the detector will release a Fault signal.

1.3.3. Transceiver Self-diagnosis

The detector checks the transmitter, receiver and amplifier circuits. In the event that these components fail,

the detector will release a Fault signal.

1.3.4. Fault Conditions

The detector monitors the correct operation of the internal detection circuitry and the optical pathway.

If a failure of the internal detection circuitry is detected, then the device will release a fault signal to the

control and indicating equipment. The fault signal will cause the yellow Fault LED and the Fault relay to

operate.

If the optical path is interrupted for more than 10 s by an opaque object the yellow Fault LED and Fault relay

will operate. If the optical path is not restored, within a further 30 s the red Fire Alarm LED and the Alarm

relay will operate. The yellow Fault LED and Fault relay will turn off. When the optical path is restored, the

fault signal will cancel automatically. If the detector has released an Alarm signal, then the detector must be

reset to clear the Alarm signal.

1.4. Connection to Control and Indicating Equipment

There are two options available to connect 407 line-type smoke detectors to CIE.

1.4.1. Direct Connection Option

When connecting to non-addressable CIE, the 407 detectors can be connected directly to detection zone

transmission path. The specific connection wiring will be introduced in the installation section.

1.4.2. Indirect Connection Option

When connecting to addressable CIE or non-addressable CIE, the 407 detector can be connected to a single

input module (Part number 621-007). The 621-007 input module provides a switchable DC 24 V supply to the

407 detector, and transfers Alarm signal from the 407 detector to the CIE.

The switchable DC 24 V supply voltage falls to 0 V when the CIE enters the Reset Condition, providing a

simultaneous reset to the 407 line-type smoke detector.