SNC-300 non-addressable smoke/heat detector

Installation Instructions

www.numens.net 1 32-0032-r02_2015-05

Cautions

ELECTRICAL HAZARD: Disconnect power from equipment prior to making

any internal adjustments. Service should only be performed by qualified

personnel.

FRAGILE: Inspect the equipment prior to installation. Do not install the

equipment if damage is apparent. Do not attempt to disassemble this

equipment. If damaged, return to the supplier.

ELECTROSTATIC HAZARD: This is sensitive electronic equipment. Apply

safe ant-static practices when handling this equipment.

CIRCUIT LIMITATIONS: The maximum number of detectors connected to

a single detection zone is limited by the control and indicating equipment,

and may be limited by local regulations.

Introduction

SNC-300 non-addressable photoelectric smoke/heat detectors are

state-of-the-art detectors suitable for connection to 2-wire or 4-

wire non-addressable fire detection control and indicating

equipment, or to addressable fire detection control and indicating

equipment that can accept non-addressable type detectors

1

.

These instructions provide trained installation personnel with

details to install and commission SNC-300 smoke/heat detectors

for optimum performance.

Preparation

Before commencing installation, ensure all equipment (base and

detector) and tools to mount and connect the equipment are

available, such as drills, mounting screws, cables and ladders.

SNC-300 smoke/heat detectors can be installed with the following

bases and accessories.

Description Part number Datasheet

5-terminal 102 mm low profile base CN3023 31-0035

5-terminal 102 mm low profile base

a

CN3021 31-0035

9-terminal 102 mm low profile base CN3043 31-0037

9-terminal 102 mm low profile base

a

CN3041 31-0037

Detector monitor module 620-001 31-0027

Remote indicator

b

681-001 31-0034

a

UL-approved.

b

Requires 9-terminal base.

Installation

Base

The base can be mounted directly onto an electrical junction box

such as an octagonal (75 mm, 90 mm or 100 mm), a round

(75 mm), or a square (100 mm) box without using any type of

mechanical adapter.

1. Feed the conductors through the middle of the base for

termination to the base contacts.

2. Mount the base on the junction box or directly onto a flat

surface.

3. Mount the base to the surface using fixing screws that are

suitable to securely fix the base to the surface.

Wiring

Base terminals accept (0.4 ~ 2.5) mm

2

conductors.

1. Strip the conductor insulation to expose 5 mm of the

conductor.

2. Connect the conductors to the base terminals.

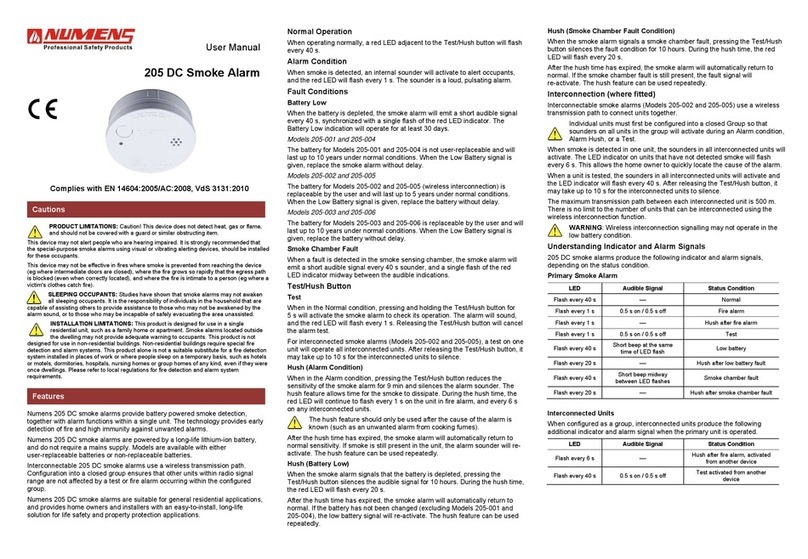

a. See Fig. 1 for detectors using 2-wire bases.

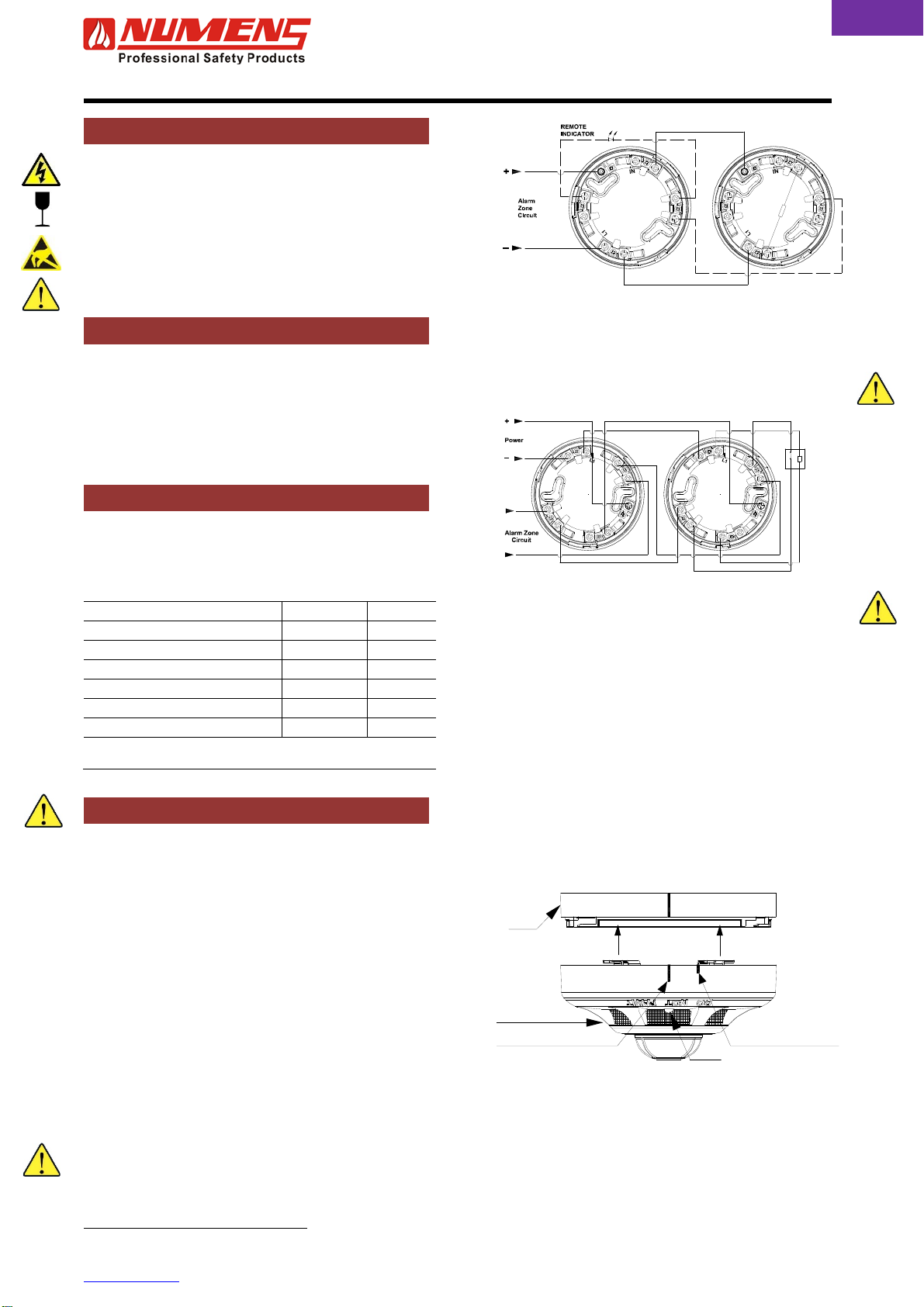

b. See Fig. 2 for detectors using 4-wire bases.

WARNING: Take care to ensure the insulation does not get

clamped by the terminal contact.

1

May be used with the 620-001 detector monitor module.

Fig. 1: 2-wire base wiring connections

Note 1: 9-terminal base required if a remote indicator is installed.

Note 2: If a remote indicator is not installed, the polarity of the zone circuit

wiring may be reversed.

WARNING: Do not short-circuit terminals 2 and 5.

Fig. 2: 4-wire base wiring connections

WARNING: Do not short-circuit terminals 2 and 5.

3. After all the bases are installed and wired, fit the end-of-line

resistor.

Note: The value of the end-of-line resistor depends on the control and

indicating equipment to which the detectors are installed.

4. Check the wiring for continuity, short circuits and earth faults.

Output Relay (where fitted)

The output relay is factory-adjusted with normally-open contacts

that close on alarm. No setting adjustment is required.

Detector

WARNING: Do not install the detector head until the area is

thoroughly cleaned of construction debris, dust, etc.

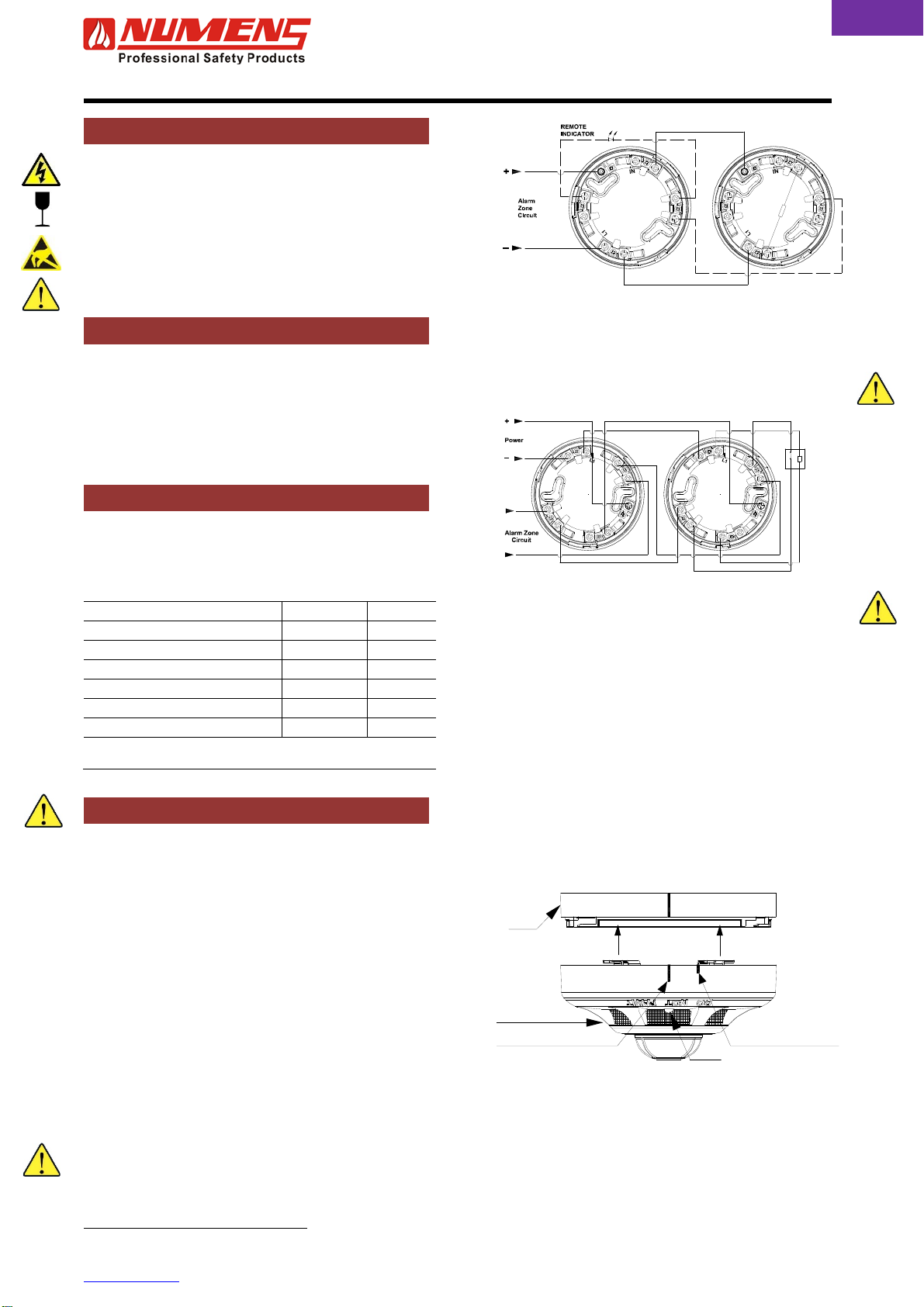

1. Align the detector alignment mark with the short alignment

mark in the base, as shown in Fig. 3.

2. Mate the detector head onto the base and rotate it clockwise

to secure it. The long alignment marks should be aligned.

Fig. 3: Fitting the detector to the base

5

L2

4

_

3

R

2

L1

1

6

OUT

4

_R

3

2

L1

1

6

OUT

5

L2

End-of-line

device

1

6

OUT

5

L2

4

3

R

_

L1

IN

2

1

6

OUT

5

L2

4

3

_

R

L1

IN

2

Optional

Power

Supervision

Relay

Detector head

LED

Short AlignmentMark

Long AlignmentMark

Base