page

4

ADDRESSING AND COMMUNICATIONS

Each XP95 evice respon s to interrogation an comman

from central control equipment. It communicates to the

panel information on status, comman bits, type, location,

an other information that allows an alarm to be raise

even when the evice is not itself being interrogate .

Message error checking is also provi e . The evices are

compatible with Series 90, Discovery®an XPlorer systems

an control equipment to ai maintenance, extension an

upgra e of existing systems.

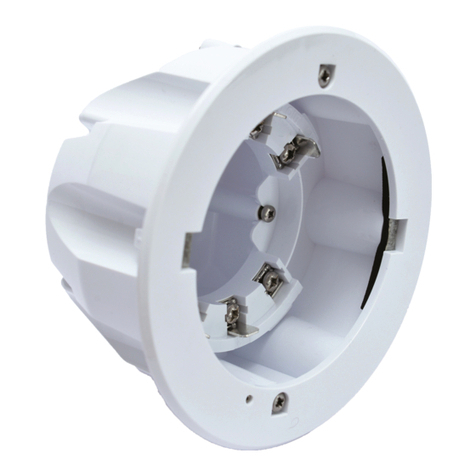

A unique, patente XPERT car provi es simple, user

frien ly an accurate i entification of etector location

whereby a co e car , inserte in the base, is rea by

any etector once it is plugge in. All the electronic

components are in the etector but the location information

is hel in the base. The a ress car simplifies an spee s

up installation an commissioning. A ressing errors

uring maintenance an service are eliminate .

The XP95 manual call point continues to use DIL switch

a ressing, but its interrupt feature also provi es automatic

reporting of its location in the interrupt mo e.

The XP95 etectors provi e an alarm facility that automatically

puts an alarm flag on the ata stream an reports its a ress

when the pre-set EN54 threshol s are excee e . The

evices provi e great flexibility in system esign with the

control equipment etermining the characteristics of the

system. A large an growing range of compatible control

equipment is available from many sources - etails are

inclu e in Apollo publication PP1010, which is available

on request.

APPLICATION OF XP95 DETECTORS

The choice of etector from the XP95 range follows the

well establishe principles of system esign. That is, the

optimum etector type will epen on the type of fire risk

an fire loa , an the type of environment in which the

etector is site .

For general use, smoke etectors are recommen e since

these give the highest level of protection. Smoke etectors

from the XP95 range may be ionisation, optical or

multisensor types. It is generally accepte that ionisation

types have a high sensitivity to flaming fires whereas

optical etectors have high sensitivity to smoul ering fires.

As a result of this, ionisation types are wi ely use for

property protection, an optical types for life protection.

These general principles still apply to XP95 etectors

although the availability of a multisensor in the range

offers more choice to the system esigner.

The multisensor is basically an optical smoke etector an

will therefore respon well to the smoke from smoul ering

fires. The etector also senses air temperature. This

temperature sensitivity allows the multisensor to give a

response to fast burning (flaming) fires, which is similar to

that of an ionisation etector. The multisensor can

therefore be use as an alternative to an ionisation etector

Where the environment is smoky or irty un er normal

con itions, a heat etector may be more appropriate. It

must be recognise , however, that any heat etector will

respon only when the fire is well establishe an

generating a high heat output.

Unless otherwise specifie , evices escribe in this gui e

are suitable for in oor use only.