08/2022 Rev. 1.1

i

CONTENTS

Contents ...............................................................................................................................................i

Safety ..................................................................................................................................................ii

Electr omagnetic Compatibility (EMC) ......................................................................................................iii

Techni cal Spe cifications ........................................................................................................................ iv

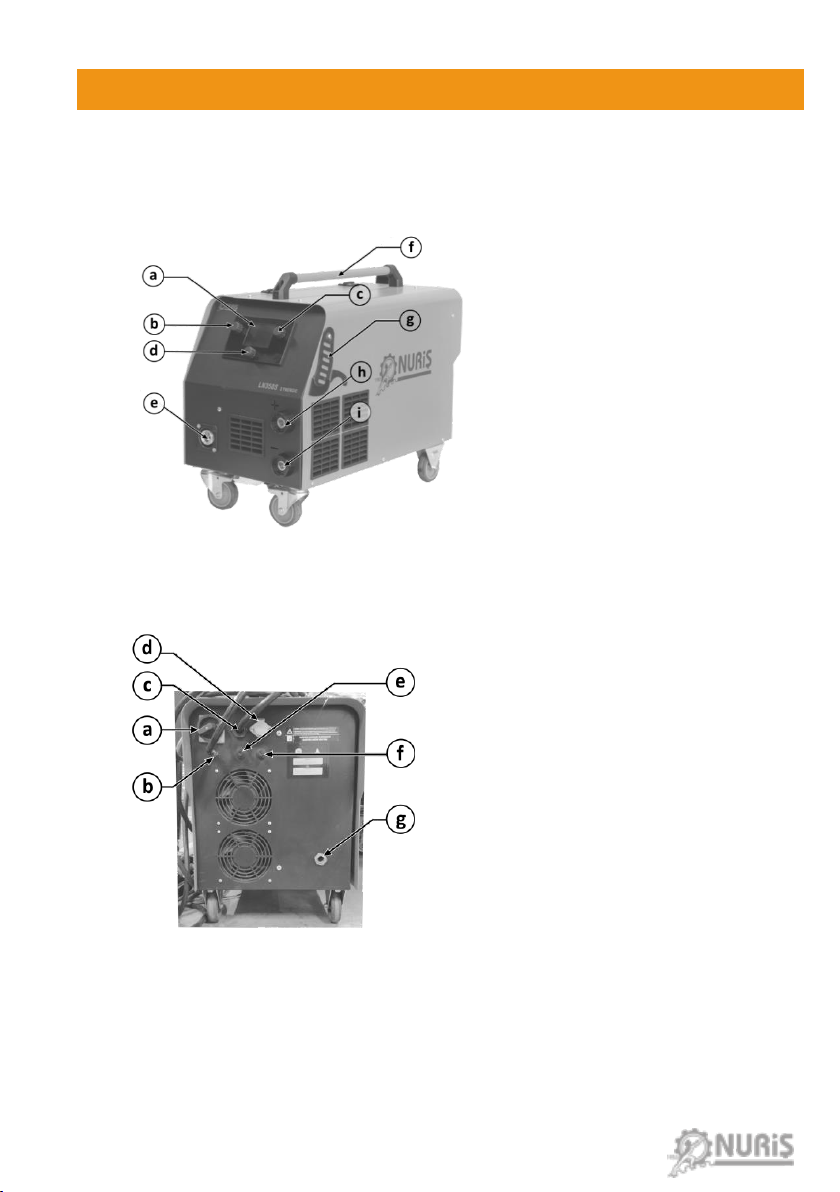

1.Intr oduction....................................................................................................................................... 1

2.Conne ction Guide ............................................................................................................................... 2

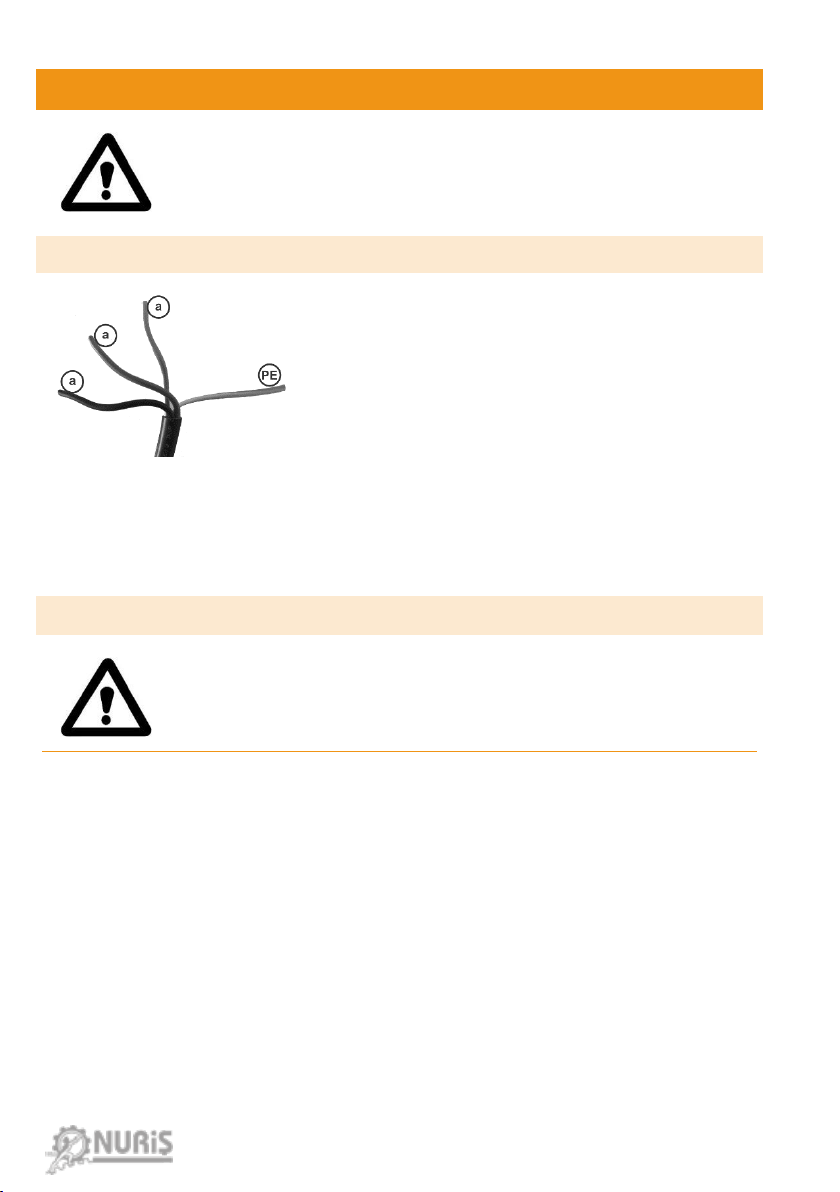

2.1. Pow er Connection....................................................................................................................... 2

2.2. Conne ction of the Welding Wir e ................................................................................................... 2

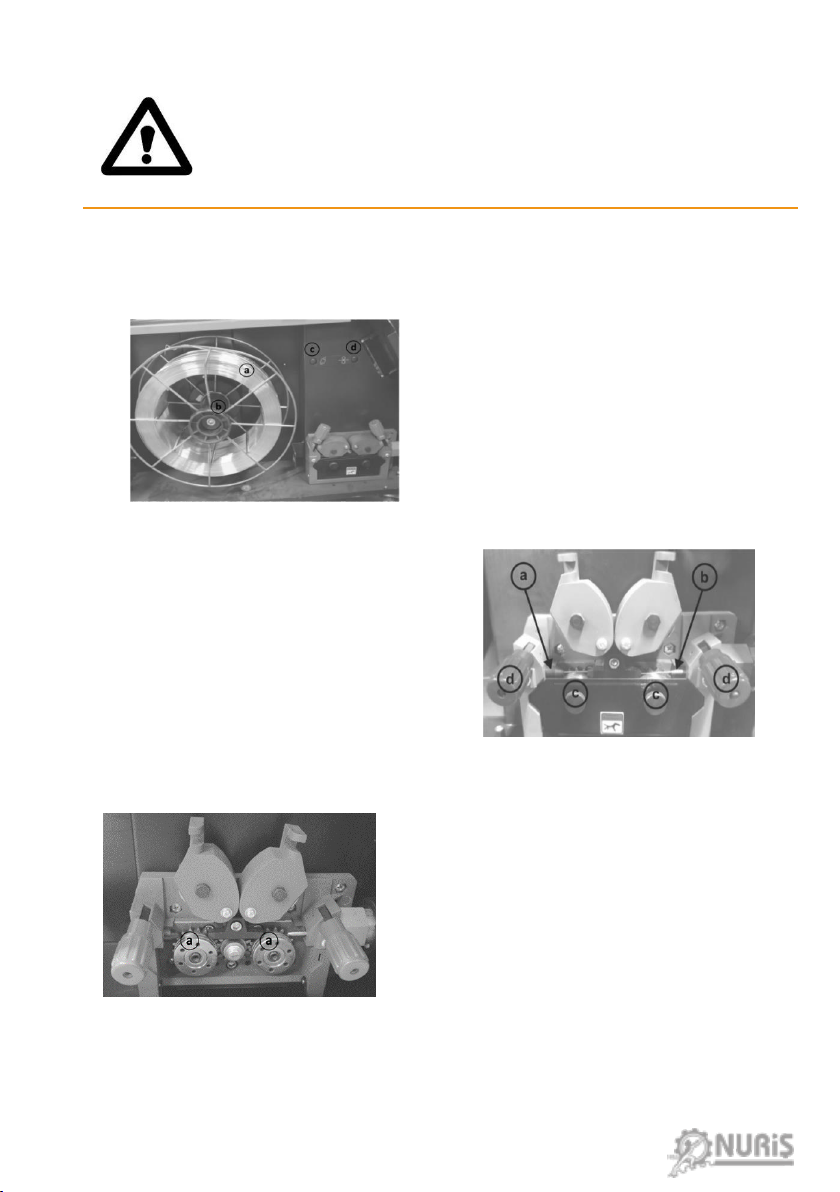

2.2.1 Placing the Wir e Spool .......................................................................................................... 2

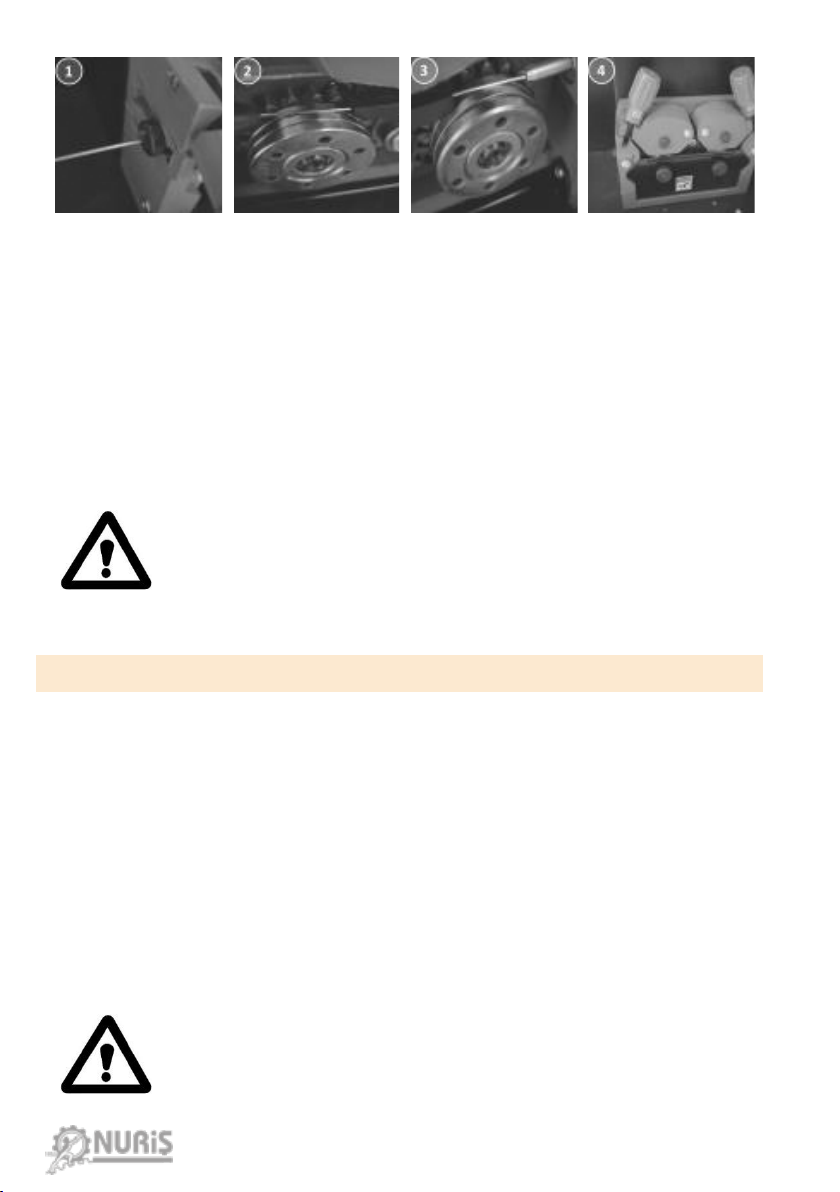

2.2.2 Wir e Feeding System............................................................................................................. 3

2.3. Gas connection........................................................................................................................... 4

3.Stor age and Installation....................................................................................................................... 5

3.1. Stor age and Oper ation Environment.............................................................................................. 5

3.2. Tr anspor tation ........................................................................................................................... 5

3.3. Installation ................................................................................................................................ 5

4.Oper ation.......................................................................................................................................... 6

4.1. Sele cting Syner gic Pr ograms......................................................................................................... 6

4.2. Symbols and Meanings ................................................................................................................. 8

4.3. Settings..................................................................................................................................... 9

4.4. Pr ogr ams..................................................................................................................................11

5. Maintenance and Trouble Shooting......................................................................................................11

5.1. Per ıodic Maintenance.................................................................................................................12

5.1.1. Daily Maintenance ..............................................................................................................12

5.1.2. Quar ter ly Maintenance........................................................................................................12

5.1.3. Semi-Annually Maintenance .................................................................................................12

5.2. Non-Per iodic Maintenance ..........................................................................................................12

5.3. Possible Pr oblems and Error s.......................................................................................................13

5.3.1. Err or Messages and Meanings ...............................................................................................15

6. Tr anspor tation .................................................................................................................................16

7. Manufactur er Company......................................................................................................................16

8. Ser vice............................................................................................................................................16