3

• Locate the power unit away from the general living area in an

accessible location for changing the soil bag and periodically

cleaning the secondary filter.

• When planning, remember the power unit is equipped with

an inlet to service a garage, basement, utility room, etc.,

wherever it is located.

• Locate the power unit within six feet of a grounded electrical

outlet. The power unit requires a 120vAC power source.

• Do not locate the power unit close to a source of extreme

heat (i.e., water heater) or in an area with a high ambient

temperature (i.e., attic, furnace room).

• If the power unit is located in a closet or a small utility room,

make sure the area is well-ventilated (i.e., with door louvers).

• Exhausting the power unit to the outside is recommended for

optimal performance but is not required. The exhaust should

not be vented into a wall, a ceiling or a concealed space in

the house. If the exhaust line is vented outside the home,

Model 393 Wall Cap or a roof vent are recommended.

WARNING: Power unit must not be mounted in a high

ambient temperature area such as attic, furnace room, etc.

TUBING AND WALL INLET LOCATIONS

1. Locate inlets on interior walls, choosing central locations

which allow several rooms to be cleaned from a single inlet

using a 30 foot long hose.

2. The tubing installation should consist of a main trunk line

running from the farthest wall inlet to the power unit

location, with branch lines running to each additional inlet.

Keep all tubing lines as straight as possible and use as few

fittings as possible. Beginning at the area farthest from the

power unit, choose a tentative inlet location. Measure 30

feet from the proposed inlet location to the farthest corner of

the rooms to be cleaned by that inlet to determine if inlet

location is proper.

3. If working from blueprints (or building plans drawn at

1⁄4" = 1 ft. scale), use a 71⁄2" chain as your guide to

determine inlet locations.

4. Move tentative inlet location if necessary. Use the same

procedure to determine each additional inlet location,

always working toward the power unit.

5. Be sure tubing will not interfere with electrical, plumbing or

other mechanical installations.

6. Locate inlets within six feet of an electrical receptacle to

allow use of optional current-carrying hose.

7. Be sure inlets will not be blocked by doors or furniture.

LOCATING THE POWER UNIT

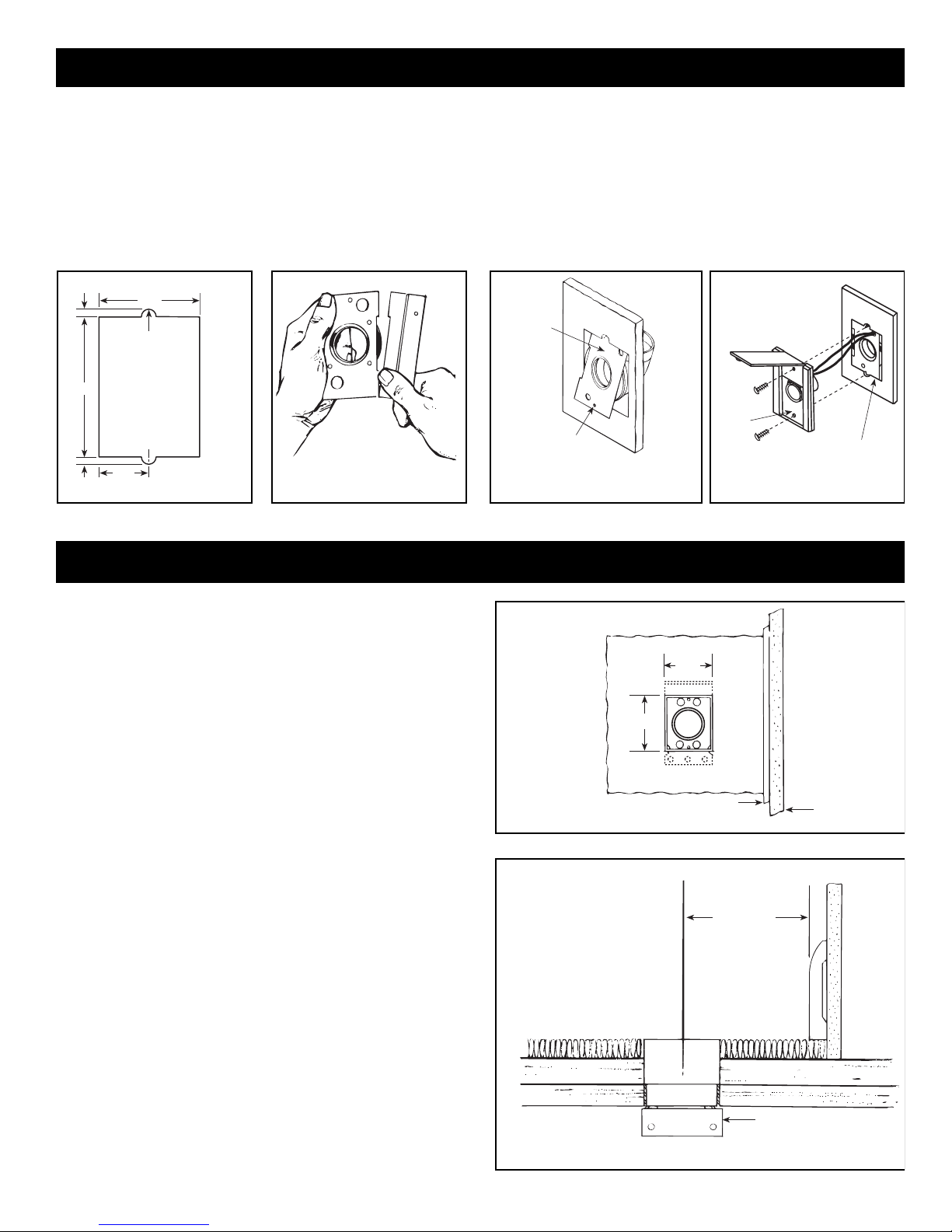

Built-In Appliances. You will often

find a hollow space behind built-in

kitchen appliances. If this space lines

up with an obstruction-free interior wall

above or a closet, this might be a key

to your installation. See Figure 5.

You may also want to consider

running exposed tubing through

cabinets or cupboards.

Cold-Air Return. A cold-air

return often provides a straight

run from basement to other levels

of the house. See Figure 6.

The ductwork is easily cut for

access. Seal around the tube

when completing the installation.

FIGURE 5

FIGURE 6

LOCATING ACCESS KEYS IN

EXISTING CONSTRUCTION

Let's say, for example, you have a two-story house and you want

to locate the power unit in the basement. If you can't find interior

walls on both the first and second floors which line up and are free

from obstacles. How do you get from the basement to the attic?

Unless your home is a ranch-style house where a single trunk

line can run directly through the attic or basement, you should first

investigate your house to find the key to running your tubing from

level to level. Look for an accessible area free from obstructions

that will accommodate the 2" tubing.

If you understand how your existing home is constructed, it can

be relatively easy to find access routes to run the tubing. Refer

again to the illustration on page 2 as you consider your home

construction.

Some of the keys you might find in your home are illustrated here.

FIGURE 4

Stacked Closets or Laundry

Chute. Many homes will have

an upstairs closet located

directly above a downstairs

closet. It is easy to run the

tubing from one floor level to

another inside these stacked

closets. In these installations

the tubing is often left exposed

inside the closets. See Figure

4. A laundry chute could also

provide access from basement

to upper floors.

TUBING