4

CONTENT

Page

CONTENT................................................................................................................................................................ 4

1. INTRODUCTION............................................................................................................................................. 5

1.1. USE AND FUNCTION .................................................................................................................................... 5

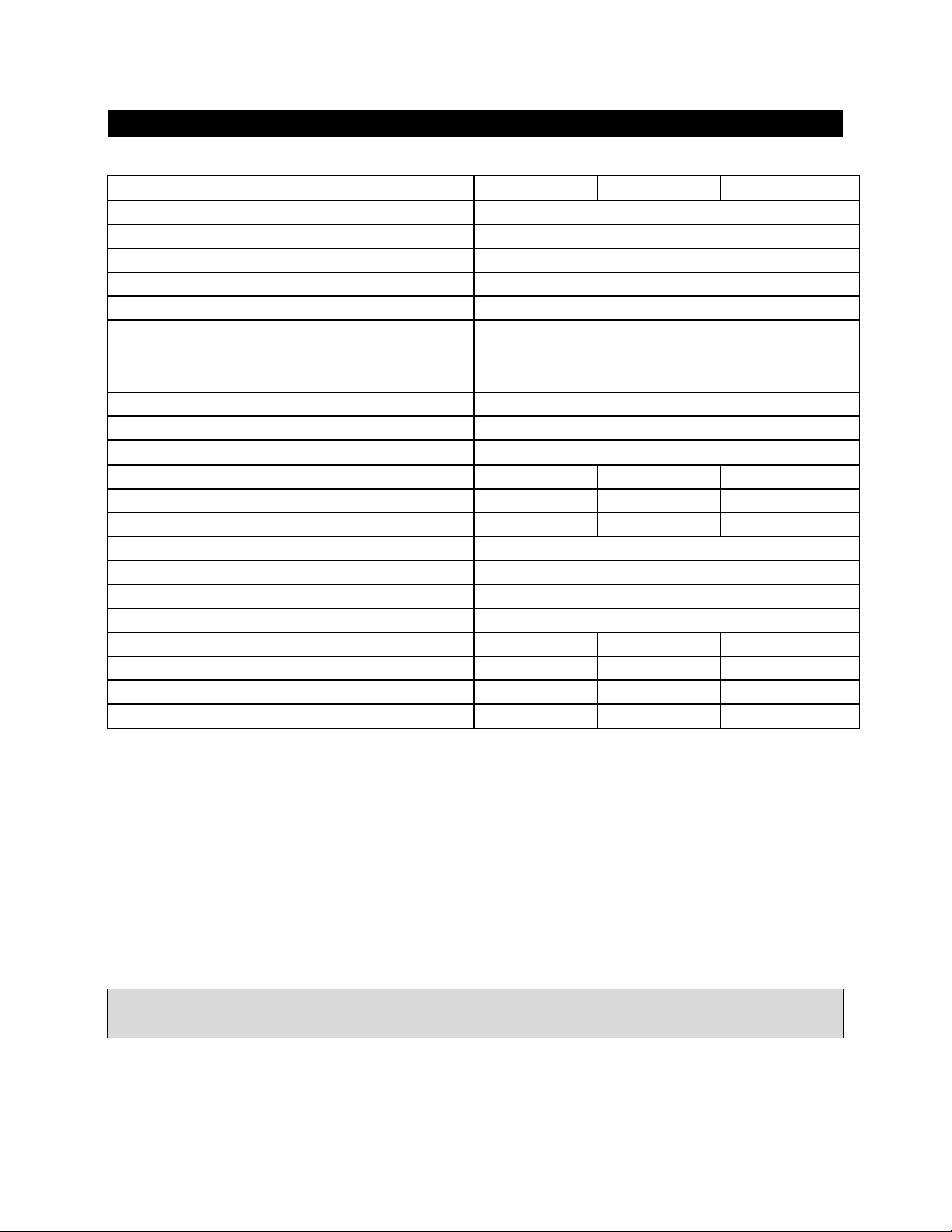

2. TECHNICAL SPECIFICATIONS.......................................................................................................................... 6

2.1. TECHNICAL SPECIFICATIONS TABLE............................................................................................................. 6

2.2. OPTIONAL ACCESSORIES ............................................................................................................................. 6

3. PRECAUTIONS AND LIMITATIONS ON USE .................................................................................................... 7

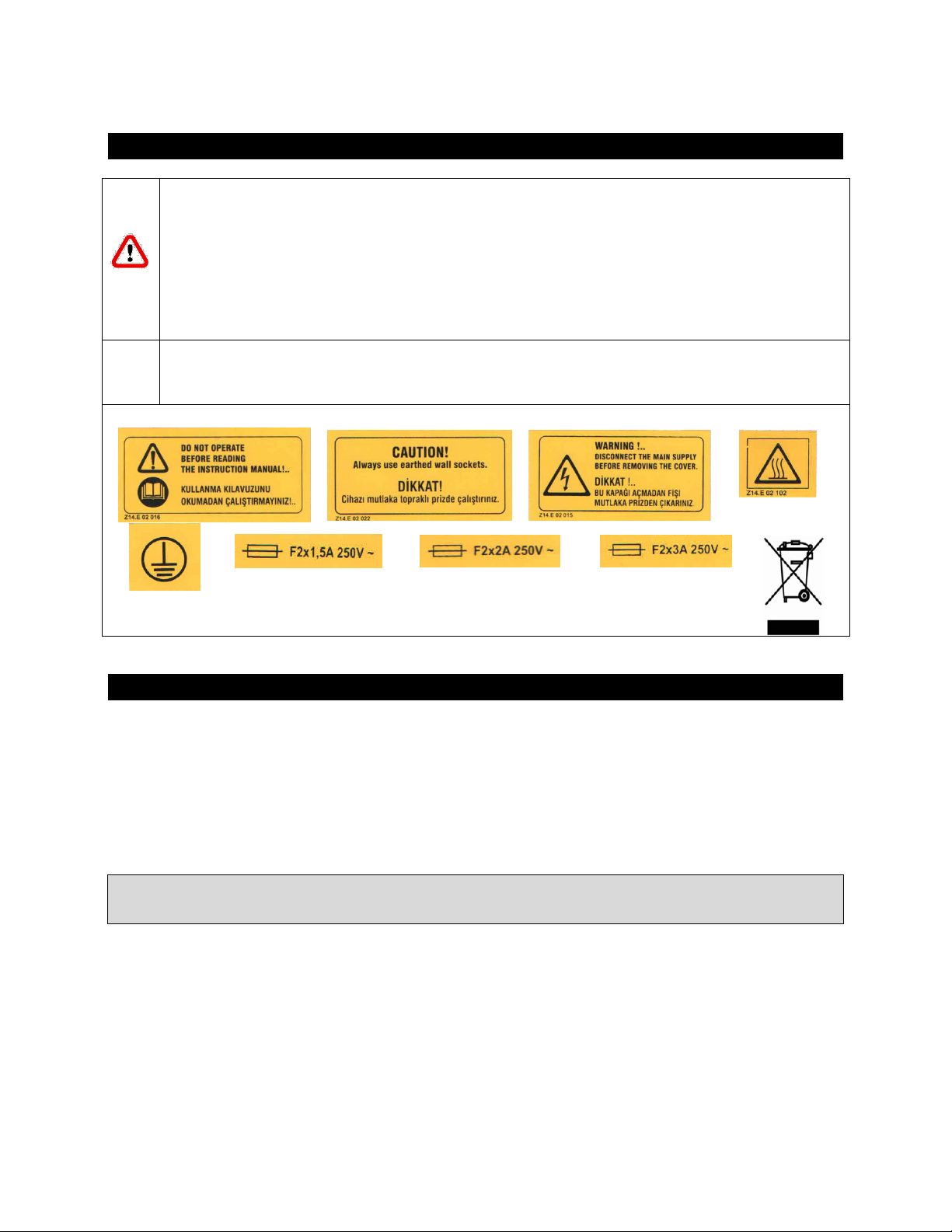

4. SYMBOLS AND LABELS .................................................................................................................................. 8

5. INSTALLATION............................................................................................................................................... 8

5.1. ENVIRONMENTAL CONDITIONS .................................................................................................................. 8

5.2. HANDLING AND TRANSPORTATION ............................................................................................................ 8

5.3. UNPACKING................................................................................................................................................. 9

5.4. MAINS SUPPLY ............................................................................................................................................ 9

5.5. POSITIONING............................................................................................................................................... 9

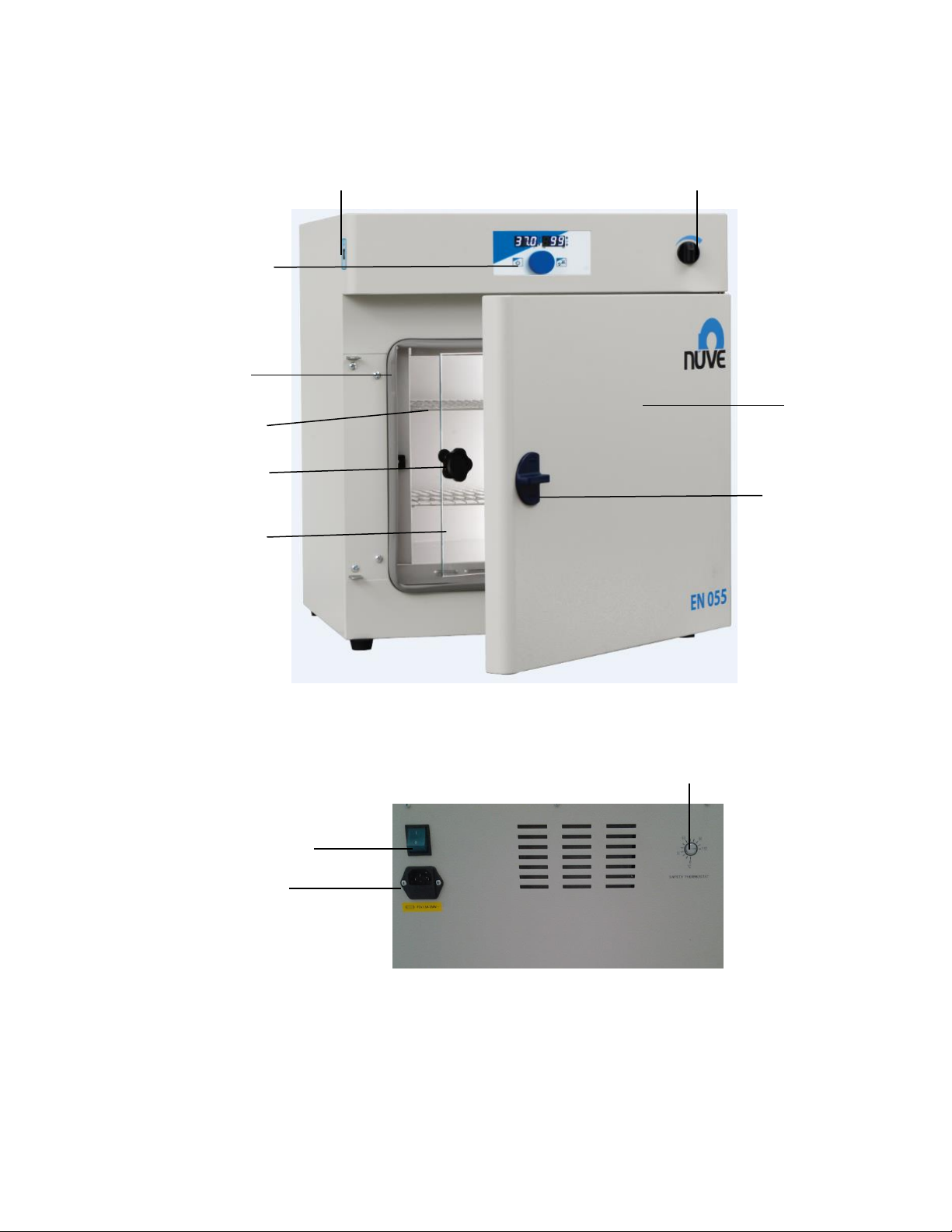

5.6. GENERAL PRESENTATION.......................................................................................................................... 10

5.7. CONTROL PANEL ....................................................................................................................................... 11

5.7.1. Explanations and Functions for Display and Control Panel .................................................................. 11

5.8. PRIOR TO OPERATION ............................................................................................................................... 12

6. OPERATING PRINCIPLES ...............................................................................................................................13

6.1. PREPARATION OF USER SETTINGS............................................................................................................. 13

6.1.1. oP Operator Menu Parameters ............................................................................................................ 13

6.2. PROGRAMMING SUMMARY ..................................................................................................................... 14

6.3. COMPLETION OF THE OPERATION ............................................................................................................ 17

7. PERIODIC MAINTENANCE AND CLEANING....................................................................................................17

7.1. PERIODIC MAINTENANCE.......................................................................................................................... 17

7.2. CLEANING.................................................................................................................................................. 17

8. DISPOSAL MANAGEMENT CONCEPT ............................................................................................................18

9. TROUBLESHOOTING.....................................................................................................................................18

9.1. ERROR CODES EXPLANATIONS .................................................................................................................. 18

9.2. FUSE REPLACEMENT ................................................................................................................................. 19

10. ELECTRICAL CIRCUIT DIAGRAM................................................................................................................20

10.1. EN 032 ELECTRICAL CIRCUIT DIAGRAM ..................................................................................................... 20

10.2. EN 055 AND EN 120 ELECTRICAL CIRCUIT DIAGRAM ................................................................................. 21